Wolframium (W) doped diamond-like coating and preparation method thereof

A diamond coating and diamond layer technology, applied in metal material coating process, coating, metal layered products, etc., can solve problems such as inability to completely eliminate, poor surface roughness, etc., and achieve good oxidation resistance and chemical stability. , Good anti-oxidation performance, wear-resistant and anti-friction performance, high coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 provides a kind of method for preparing tungsten-doped diamond-like coating on the surface of high-speed steel. It should be noted that the tungsten-doped diamond-like coating prepared by the method of the present invention can be used on any black or non-ferrous metal material surface carried out above, not limited to this example.

[0031] Example 1

[0032] (1) Substrate pretreatment: use high-speed steel substrate with hardness HRC=60 after quenching at 1170°C and tempering at 550°C (material: W 18 Cr 4 V) As a substrate, its surface is degreased and polished, then immersed in acetone for ultrasonic cleaning, and then dehydrated with alcohol.

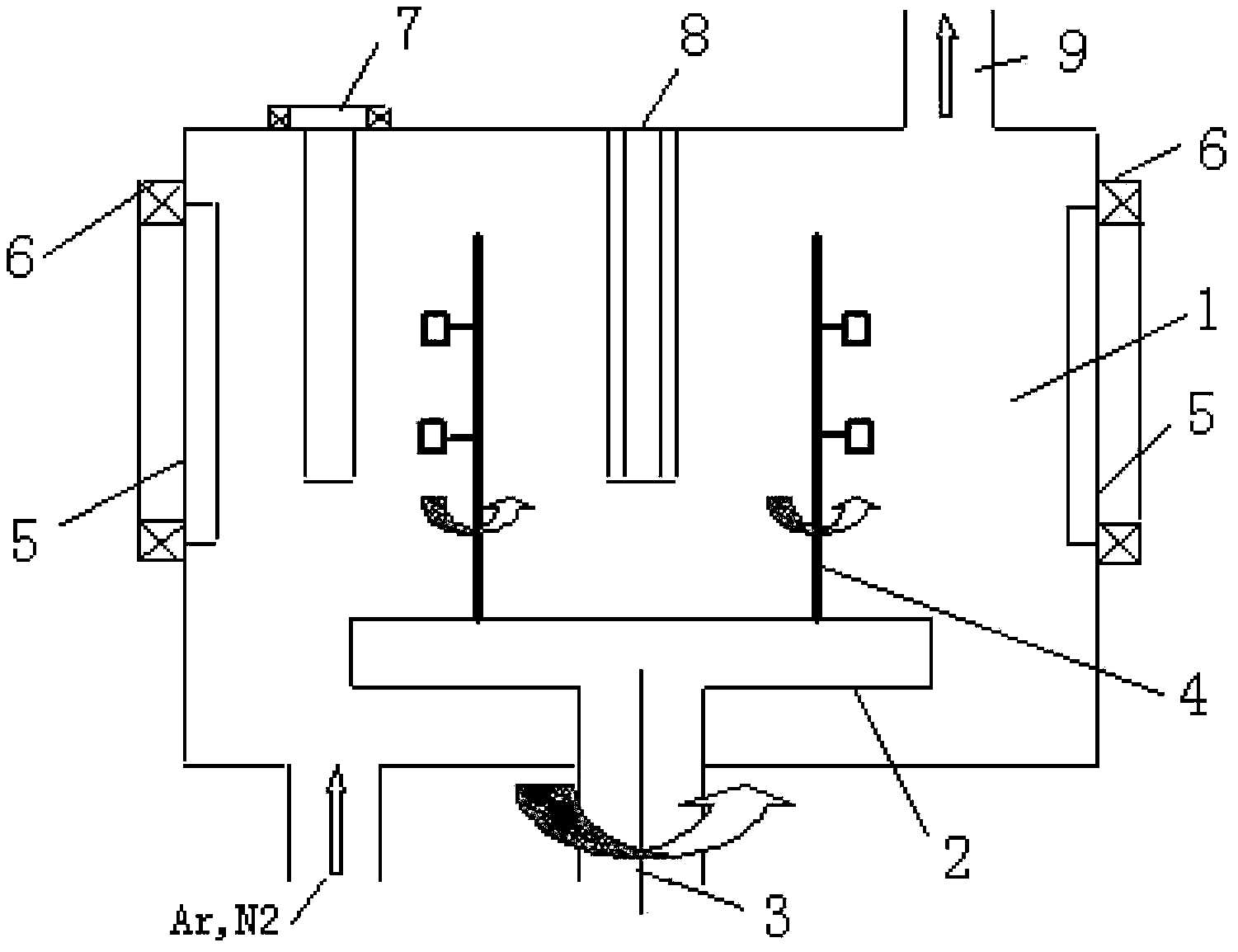

[0033] (2) Put the pretreated substrate on the turret rod in the vacuum chamber of the arc and magnetron sputtering composite coating equipment. Such as figure 1 As shown, the arc and magnetron sputtering composite coating equipment at least includes a vacuum chamber 1, a turret 2, a bias voltage 3, a turret ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com