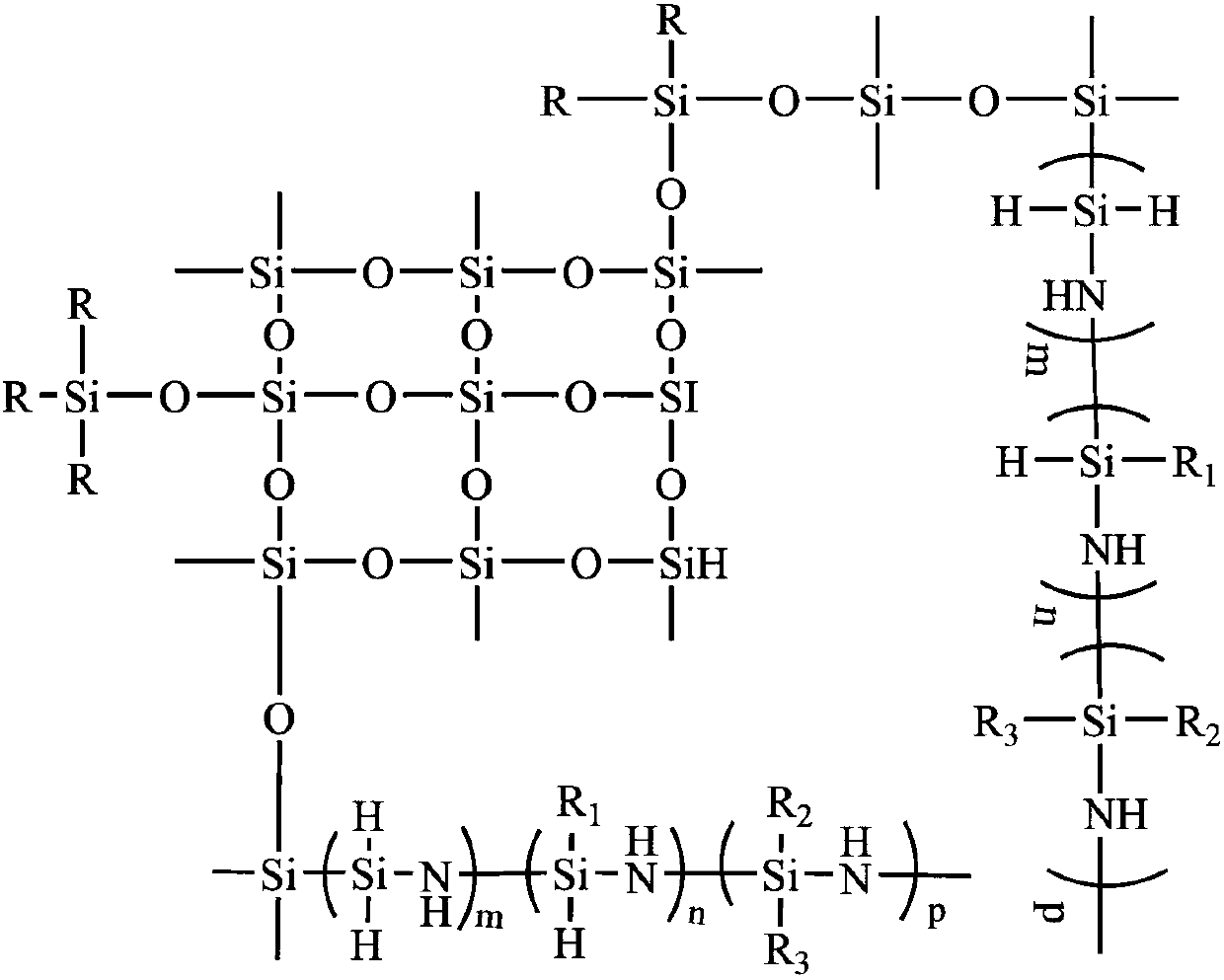

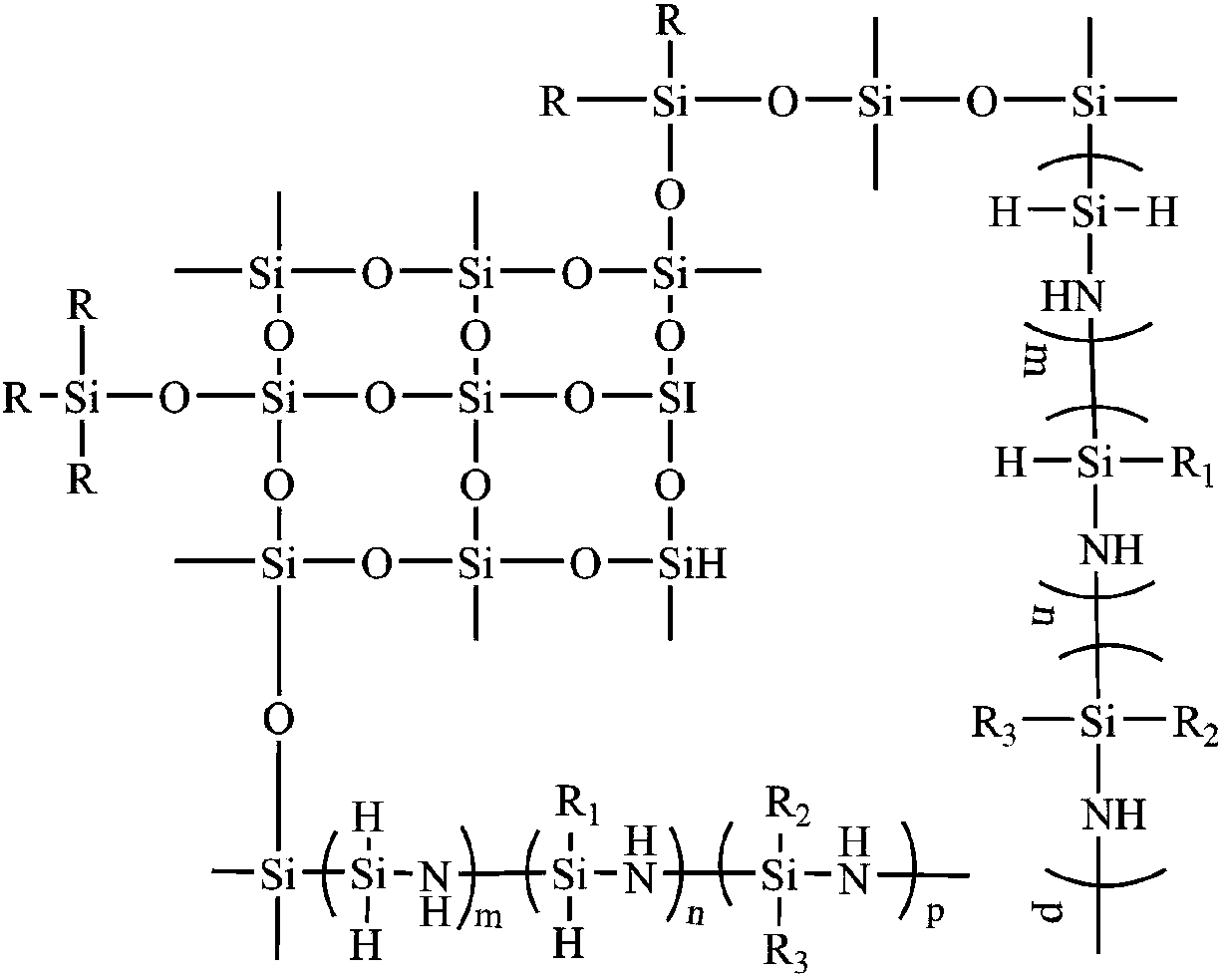

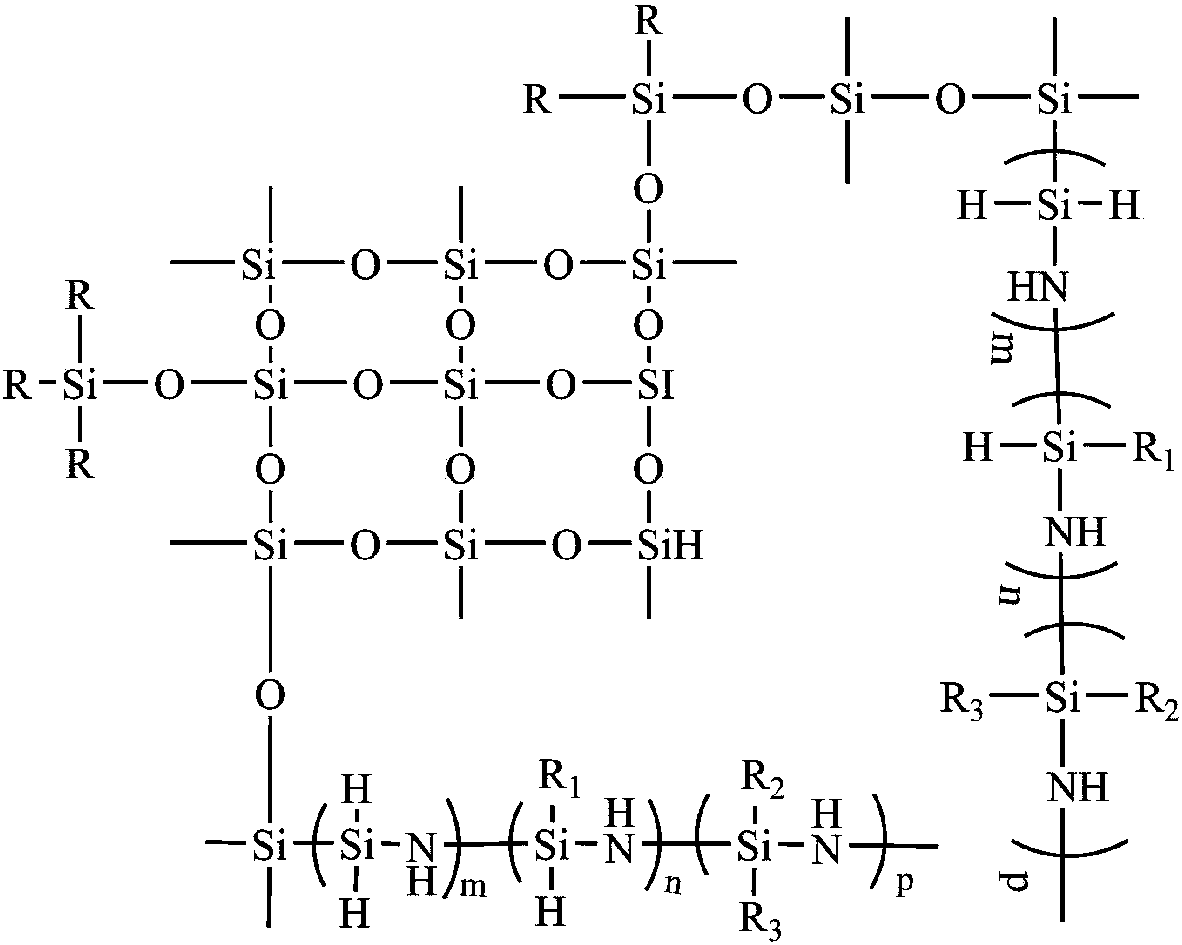

Super-hard organic silicone hydrophobic glass resin and preparation method thereof

A technology of hydrophobic glass and silicone, which is applied in the direction of coating, etc., can solve the problems of inability to obtain a wide range of popularization and application, and the high price of polysilazane, and achieve no cracking and pulverization, high light transmittance, and film formation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of superhard organosilicon hydrophobic glass resin of the present invention, preparation method is as follows:

[0021] a) Synthesis of active silicone resin: 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 1.0%), 10 parts of vinyl MQ silicone resin (vinyl content 2.2%), 5-10 parts Parts polyhydroxypolysiloxane (viscosity 30mm 2 / s), 2 parts of amino-terminated silicone oil (viscosity 100mm 2 / s), 300 parts of xylene were added to the reactor, stirred evenly and heated to 50°C, then 0.5 parts of chloroplatinic acid solution with a platinum concentration of 1500ppm, 06 parts of KH560 were added, and the reaction continued at 50°C for 5 hours; b) polysilicon Azane-modified copolymerization: add 1 part of chloroplatinic acid solution with a platinum concentration of 1500 ppm, 10 parts of hydrogen-containing polymethylhydrogen siloxane to the reactor and heat to 80 ° C, slowly drop into the reactor through the feeding port...

Embodiment 2

[0026] A kind of superhard organosilicon hydrophobic glass resin of the present invention, preparation method is as follows:

[0027] a) Synthesis of active silicone resin: 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 1.5%), 10 parts of vinyl MQ silicone resin (vinyl content 1.5%), 8 parts more Hydroxypolysiloxane (viscosity 100mm 2 / s), 5 parts of amino silicone oil (viscosity 100mm 2 / s), 200 parts of petroleum ether (90~120°C) were added to the reactor, stirred evenly and heated to 60°C, then 1.5 parts of platinum complex solution with a platinum concentration of 1500ppm, 0.9 parts of KH550 were added, and the reaction was continued at 60°C for 3 Hours; b) polysilazane modified copolymerization: add 0.5 parts of platinum complex solution with platinum concentration of 1500ppm to the reactor, 10 parts of hydrogen-containing polymethylhydrogen siloxane and heat to 75 ° C, through the feeding port to Slowly add 10 parts of alkyl...

Embodiment 3

[0029] A kind of superhard organosilicon hydrophobic glass resin of the present invention, preparation method is as follows:

[0030] a) Synthesis of active silicone resin: 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 0.8%), 7 parts of vinyl MQ silicone resin (vinyl content 2.5%), 8 parts Hydroxypolysiloxane (viscosity 100mm 2 / s), 4 parts of amino silicone oil (viscosity 200mm 2 / s), 250 parts of diluent were added into the reactor, stirred evenly and heated to 50°C, then 1.5 parts of platinum complex solution with a platinum concentration of 1500ppm, 1 part of methyltriethoxysilane coupling agent were added, at 55°C Continue to react for 3 hours; b) polysilazane modified copolymerization: add 0.8 parts of platinum complex solution with platinum concentration of 1500ppm to the reactor, 10 parts of hydrogen-containing polymethylhydrogen siloxane and heat to 65 ° C, pass Slowly add 15 parts of polysilazane dropwise from the feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com