Phase change energy storage microcapsule of composite shell and its making method

A technology of phase change energy storage and microcapsules, which is applied in the field of preparation of phase change energy storage microcapsules, phase change energy storage microcapsules and its preparation, and can solve the problems of microcapsules which are difficult to seal, crush resistance, poor mechanical and impact resistance, Poor sealing performance and other problems, to achieve the effect of improved sealing performance, good dispersion, low degree of supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

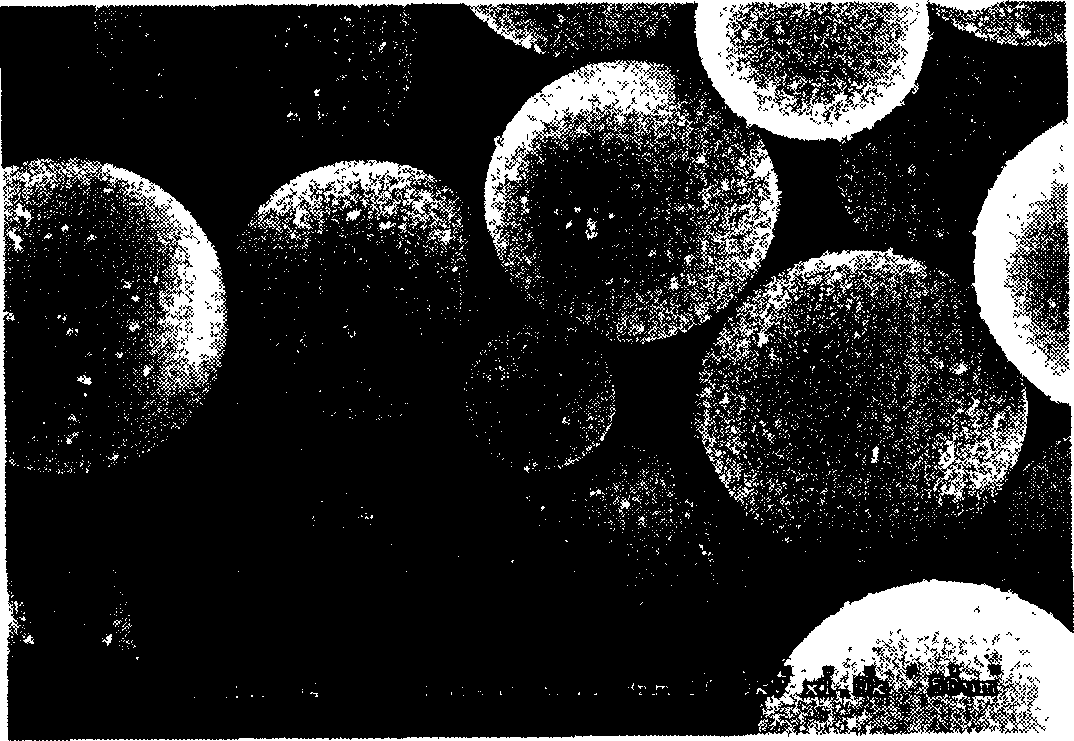

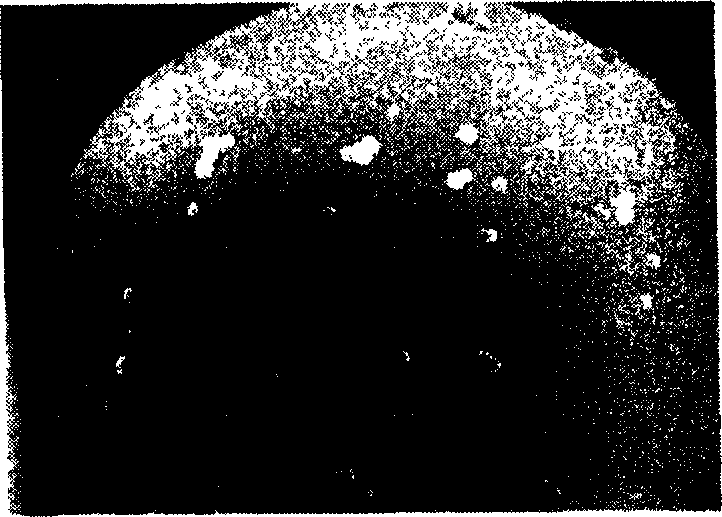

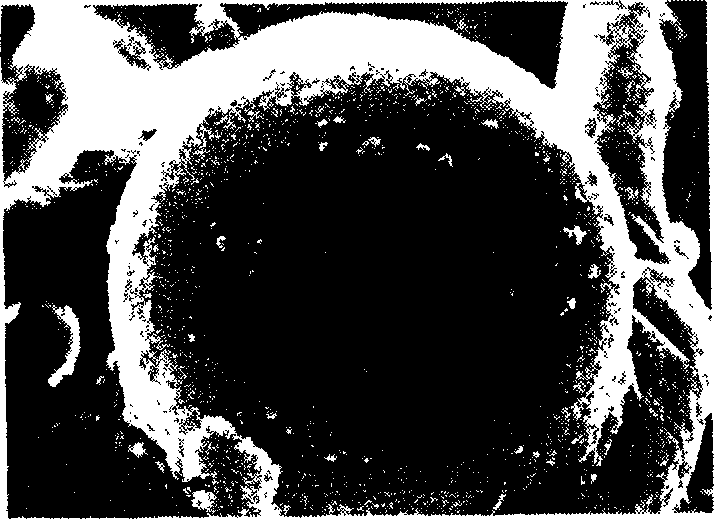

Image

Examples

Embodiment 1

[0022] (1) Preparation of melamine resin prepolymer A: Take 3.05g melamine, 10ml deionized water and 4.0g formaldehyde solution and stir evenly, adjust the pH value to 8.0 with 20% sodium hydroxide, and control the temperature at 70-75 °C, react for 30 minutes. Prepolymer A of melamine resin was prepared.

[0023] (2) Preparation of PEG200 modified melamine resin prepolymer B: Take 0.1527g PEG200, 10ml deionized water and 0.5g acetic acid and stir evenly, add 0.1916g melamine, the pH value of the reaction solution is 4.6-4.8, and the temperature is controlled At 90±2°C, react for 1 hour and drop to 80°C, adjust the pH value to 7.0 with 20% sodium hydroxide, add 3.0587g melamine and 4.25g, 37% formaldehyde solution, adjust the pH of the reaction solution with triethanolamine When the value reaches 8.0, the temperature is controlled at 75-80° C. to continue the reaction for 30 minutes to obtain PEG200-modified melamine resin prepolymer B.

[0024] (3) Preparation and character...

Embodiment 2

[0025] Example 2, microcapsules are prepared and characterized according to the method of Example 1, the difference is that the quality of the two resin prepolymers is different from that of Example 1, the quality of A increases by 1.1290g, and the quality of B decreases 1.1290g, the measurement results are shown in Table 1.

Embodiment 3

[0026] Example 3, microcapsules were prepared and characterized according to the method of Example 1, the difference being that in the resin prepolymer B, benzomelamine and melamine were mixed in a mass ratio of 1:19 instead of the dense one in Example 1. amine. The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com