High-entropy alloy spherical powder for molten additive manufacturing of powder bed and preparing method and application thereof

A high-entropy alloy and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as the inability to meet the fine-grained requirements, reduce the mechanical properties of the product, and poor powder sphericity, and achieve the suppression of the formation of satellite balls and hollow powder, easy Obtain the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

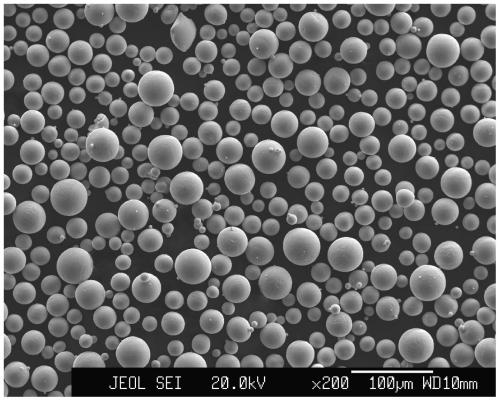

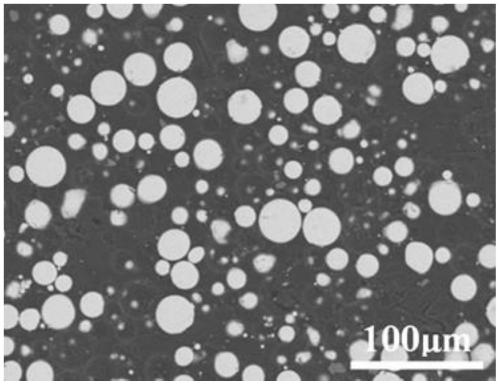

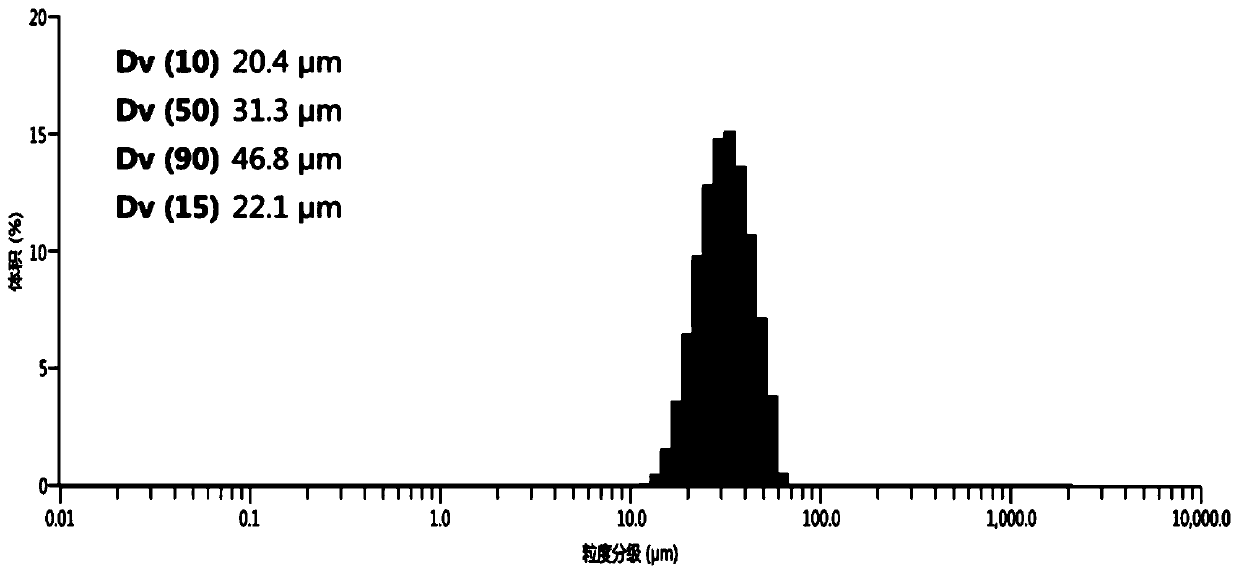

[0051] Embodiment 1: the preparation method of AlFeNiCuTiV high-entropy alloy powder for powder bed fusion additive manufacturing

[0052] (1) Prepare high-entropy alloy wires: Al, Fe, Ni, Ti, V single metal wires are wound and twisted, and the pure Cu tube is used to wrap the wound metal wires tightly, and then drawn to make AlFeNiCuTiV high-entropy alloy wires material; the surface of the high-entropy alloy wire is cleaned to remove oil and scale; the diameters of Al, Fe, Ni, Ti, and V metal wires are: 3mm, 2.5mm, 2.5mm, 3.25mm, and 2.75mm; The outer diameter of the Cu tube is 8.25mm, and the inner diameter is 6.25mm; the purity of Al, Fe, Ni, Ti, V elemental metals and pure Cu tube is 99.9%, and the diameter of the produced high-entropy alloy wire is 3mm.

[0053] (2) Preparation before atomization: Vacuumize the atomization tank first, turn off the vacuum pump after the vacuum degree is less than 10Pa, and then pass in inert gas to atmospheric pressure; send the high-entro...

Embodiment 2

[0057] Example 2: AlFeNiCuTiV for powder bed fusion additive manufacturing 0.5 Preparation method of high entropy alloy powder

[0058] (1) Prepare high-entropy alloy wires: Al, Fe, Ni, Ti, V single metal wires are wound and stranded, covered with pure Cu tubes to wrap them tightly, and then drawn to make AlFeNiCuTiV 0.5 High-entropy alloy wire; the surface of the high-entropy alloy wire is cleaned to remove oil stains and scales; the diameters of Al, Fe, Ni, Ti, V elemental metal wires are: 2.4mm, 2mm, 2mm, 2.6mm, 1.8mm; the outer diameter of the Cu tube is 6.4mm, the inner diameter is 4.8mm; the purity of Al, Fe, Ni, Ti, V elemental metals and pure Cu tubes are all 99.9%, and the diameter of the produced high-entropy alloy wire is 2mm.

[0059] (2) Preparation before atomization: Vacuumize the atomization tank first, turn off the vacuum pump after the vacuum degree is less than 10Pa, and then pass in inert gas to atmospheric pressure; send the high-entropy alloy wire into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com