ITO film loaded silica optical fiber and preparation method thereof

A silica fiber and thin film technology, applied in the directions of cladding fiber, optical waveguide light guide, etc., can solve the problems of records, no fiber preparation method, etc., and achieve the effect of smooth and dense surface, perfect thin film crystallization, and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

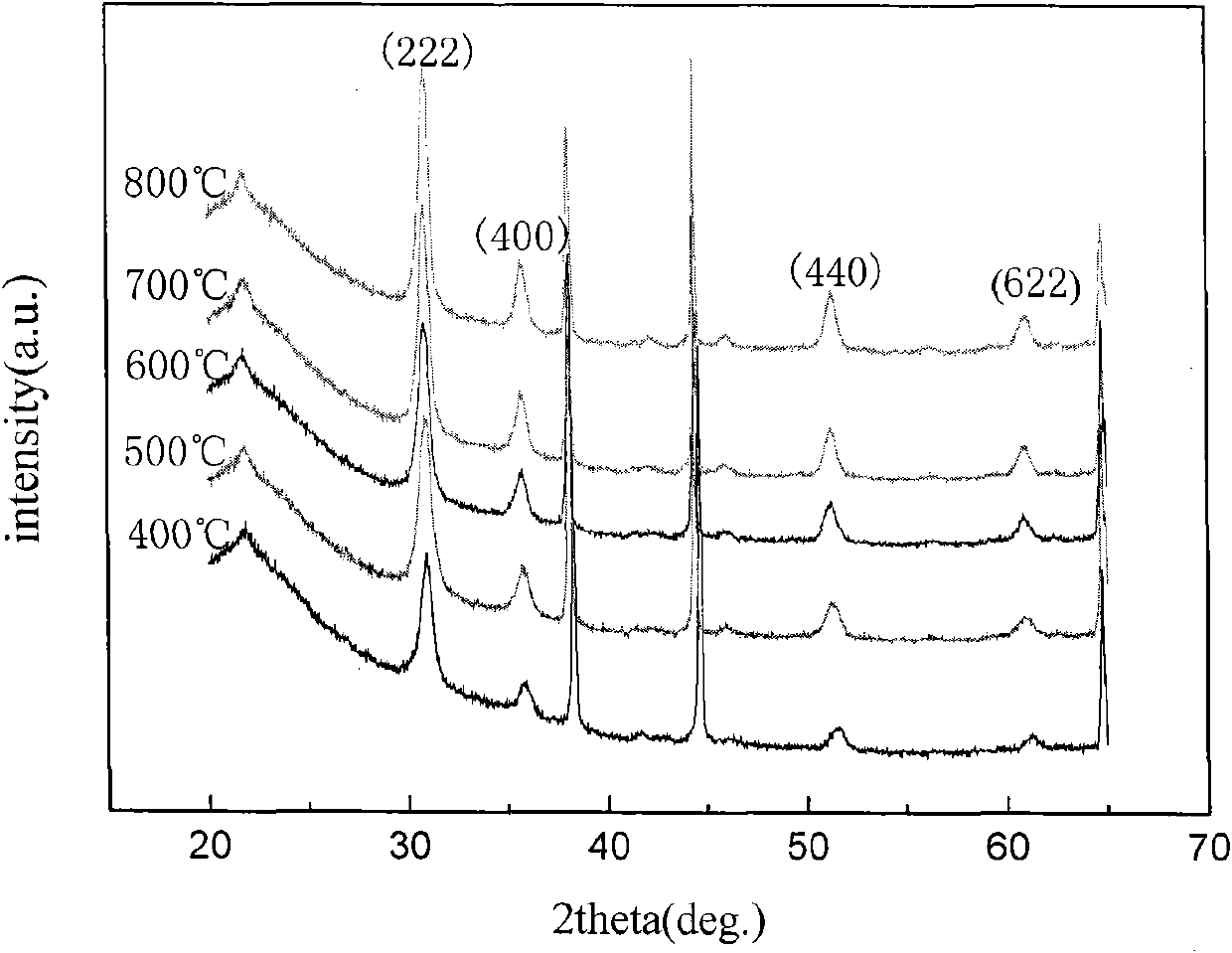

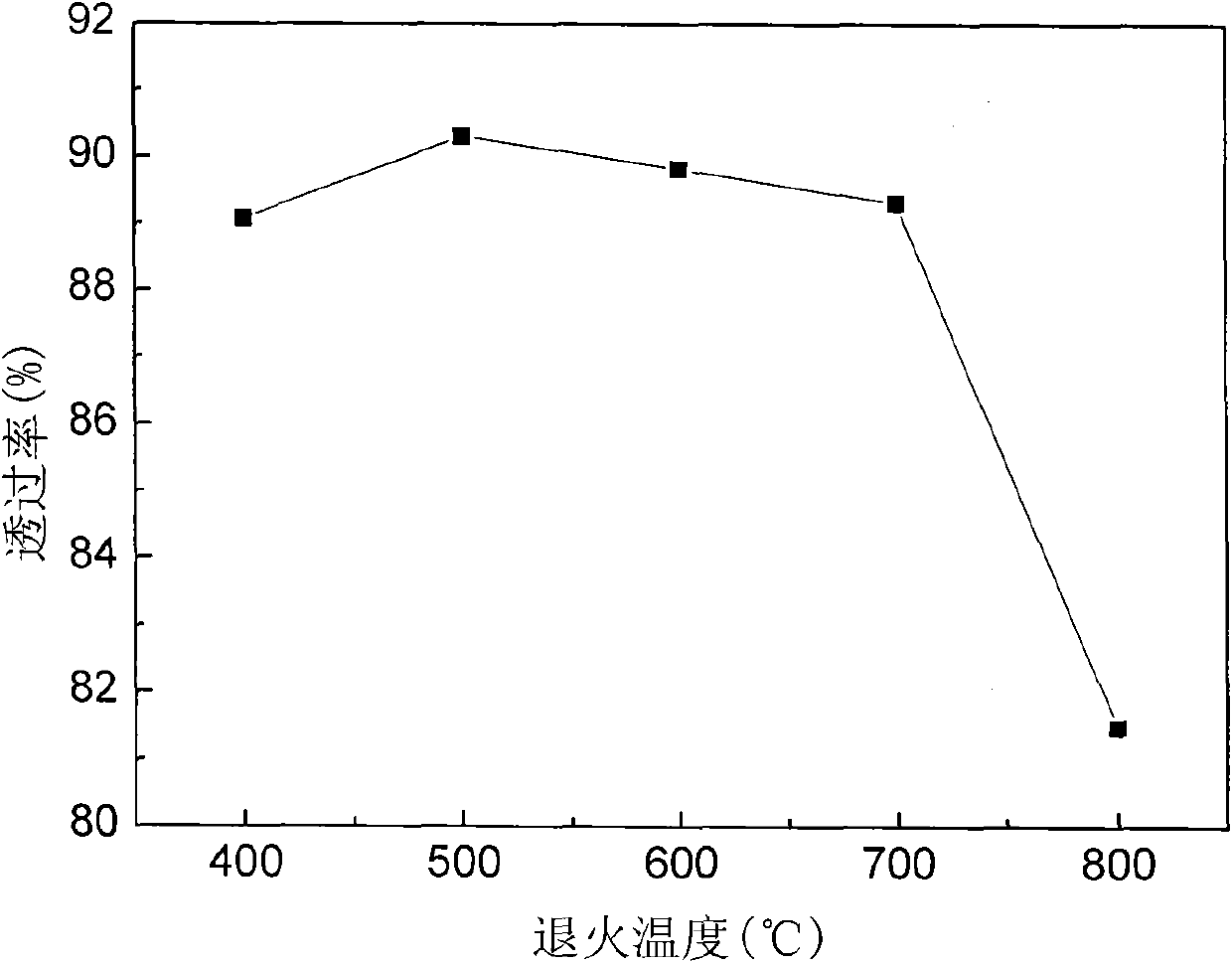

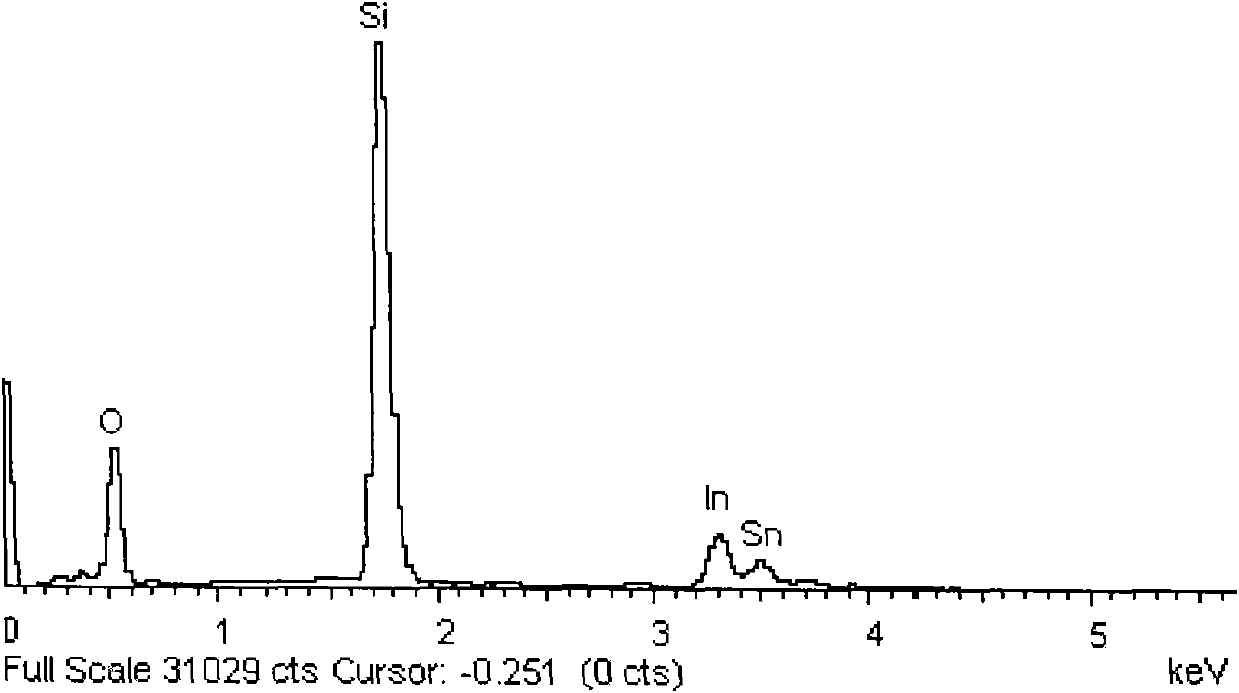

Method used

Image

Examples

specific Embodiment 1

[0027] The preparation method of the silica optical fiber of loading ITO thin film, comprises the following steps:

[0028] (1) Pre-treatment of the fiber surface in sequence:

[0029] After the coating layer was removed from the quartz optical fiber, it was placed in deionized water for ultrasonic treatment for 10 minutes; degreasing with 40% NaOH solution for 15 minutes; to analyze the surface roughening of pure HF solution for 20 minutes; finally placed in 15% NH 3 Activation treatment in a mixed solution of water and sodium dodecylbenzenesulfonate for 8 minutes;

[0030] (2) Pour the mixed solution of indium nitrate and acetylacetone into a three-necked flask, and heat it in a water bath at 65°C for 2 hours; then mix it with tin chloride dissolved in absolute ethanol, continue to heat and reflux for 1 hour, take out the solution, and Place it in the air for 24 hours to obtain a uniform and transparent light yellow sol; the molar ratio of indium nitrate: acetylacetone: abs...

specific Embodiment 2

[0032] The preparation method of the silica optical fiber of loading ITO thin film, comprises the following steps:

[0033] (1) Pre-treatment of the fiber surface in sequence:

[0034] After the coating layer was removed from the silica optical fiber, it was placed in deionized water for ultrasonic treatment for 30 minutes; degreasing with 40% NaOH solution for 16 minutes; to analyze the surface roughening of pure HF solution for 15 minutes; finally placed in 10% NH 3 Activation treatment in a mixed solution of water and sodium dodecylbenzenesulfonate for 9 minutes;

[0035] (2) Pour the mixed solution of indium nitrate and acetylacetone into a three-necked flask, and heat it in a water bath at 63°C for 2 hours; then mix it with tin chloride dissolved in absolute ethanol, continue to heat and reflux for 1 hour, take out the solution, and Place it in the air for 24 hours to obtain a uniform and transparent light yellow sol; the molar ratio of indium nitrate: acetylacetone: abs...

specific Embodiment 3

[0037] The preparation method of the silica optical fiber of loading ITO thin film, comprises the following steps:

[0038] (1) Pre-treatment of the fiber surface in sequence:

[0039] After the coating layer was removed from the quartz optical fiber, it was placed in deionized water for ultrasonic treatment for 20 minutes; degreasing with 40% NaOH solution for 20 minutes; to analyze the surface roughening of pure HF solution for 16 minutes; finally placed in 13% NH 3 Activation treatment in a mixed solution of water and sodium dodecylbenzenesulfonate for 10 minutes;

[0040] (2) Pour the mixed solution of indium nitrate and acetylacetone into a three-necked flask, and heat it in a water bath at 64°C for 2 hours; then mix it with tin chloride dissolved in absolute ethanol, continue to heat and reflux for 1 hour, take out the solution, and Place it in the air for 24 hours to obtain a uniform and transparent light yellow sol; the molar ratio of indium nitrate: acetylacetone: ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com