Cu-doped-ZnO nano columnar crystal film with room-temperature ferromagnetism and preparing method of Cu-doped-ZnO nano columnar crystal film

A room temperature ferromagnetic, columnar crystal technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, to achieve the effect of easy mass preparation, low cost of consumables, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Zn 1-x Cu x The preparation method of the O target is not limited, for example, it can be prepared by a solid phase reaction method. In one example, Zn 1- x Cu x The preparation method of the O target includes: mixing CuO powder and ZnO powder, grinding, pressing and forming operations, and then firing ZnO by solid state reaction method. 1-x Cu x O (x=0.01~0.1) target. In a more preferred example, Zn 1-x Cu x The preparation method of O target material comprises: (a) according to Zn 1-x Cu x O (x=0.01~0.1) Set the atomic ratio to weigh CuO powder with a purity of ≥99.99% and ZnO powder with a purity of ≥99.99%, mix these powders together, and put them into a grinding jar; (b) adopt the improved The horizontal ball mill (authorized announcement number: CN203235523U) fully grinds the CuO and ZnO powders loaded into the grinding tank; (c) presses the ground CuO and ZnO mixed powder according to the size of the target material; (d) The pressed Zn 1-x Cu x The O...

Embodiment 1

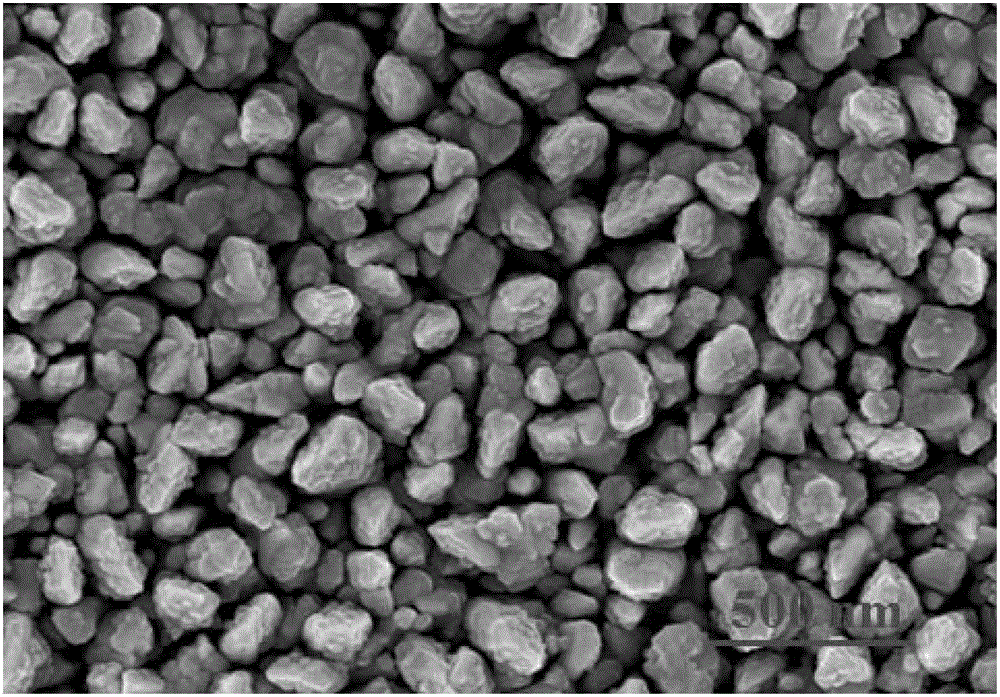

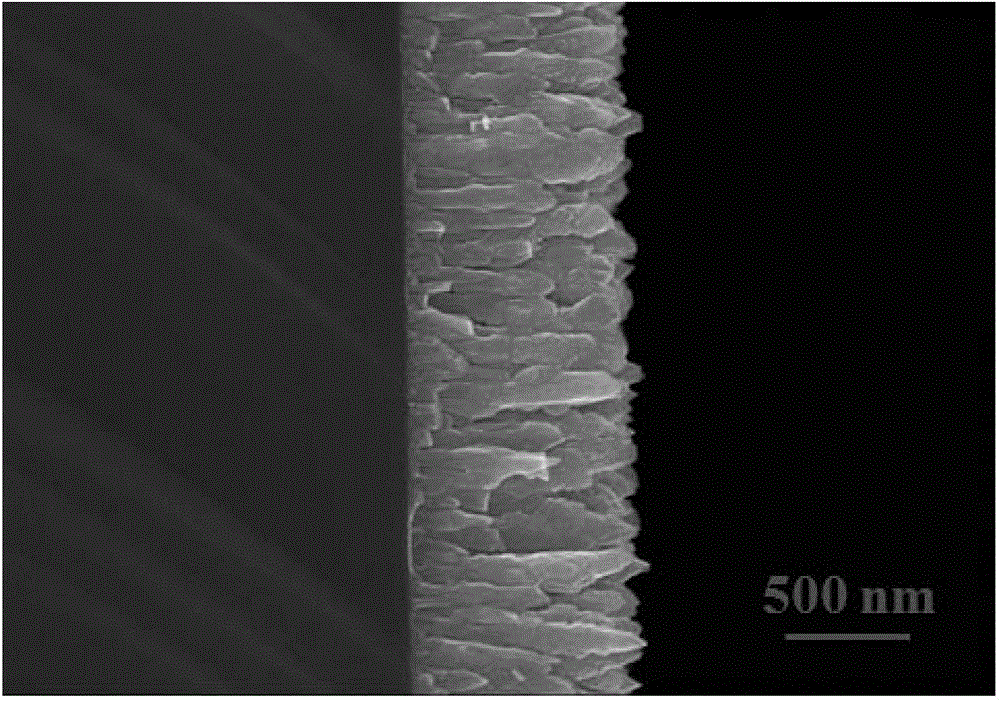

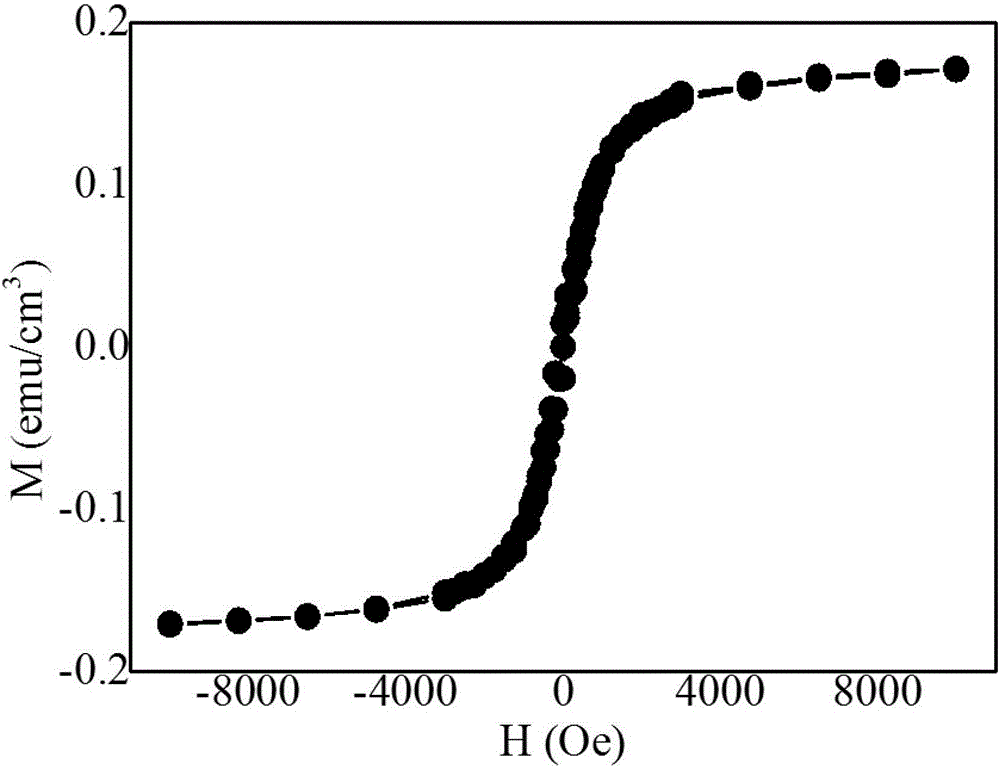

[0036] Example 1Zn 0.97 Cu 0.03 Preparation of O Nanocolumnar Thin Films

[0037] (1) The preparation of ceramic targets for thin film deposition, including: (a) using an electronic balance, according to Zn 0.97 Cu 0.03 The atomic ratio in the molecular formula of O weighs 1.500g of CuO powder with a purity of ≥99.99%, weighs 49.618g of ZnO powder with a purity of ≥99.99%, and mixes these powders together; (b) put these powders into an agate grinding jar, And put agate balls in it; (c) use an improved horizontal ball mill (authorized announcement number: CN203235523U) to fully grind the CuO and ZnO powders loaded into the grinding tank, and the grinding time is ≥ 48h; (d) take out the grinding The final powder is separated from the agate ball; (e) the ground CuO and ZnO mixed powder is pressed into a disc shape according to the size of the target; (f) the pressed ZnO 0.97 Cu 0.03 O the green body is put into the sintering furnace; (g) fully sintered under the condition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com