A preparation method of uniformly doped one-dimensional dilute magnetic semiconductor material

A dilute magnetic semiconductor and uniform doping technology, which is applied in semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, zinc oxide/zinc hydroxide, etc., can solve the problem that the nanostructure morphology is not easy to control , to achieve high sample purity and crystallinity, low manufacturing and production costs, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

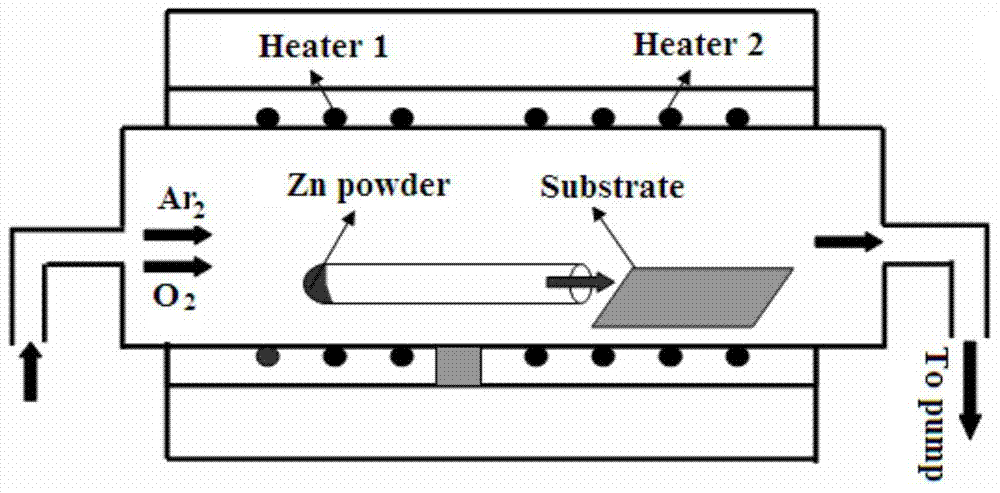

[0028] (1) Take zinc powder with a purity of 99.99% and manganese dioxide powder with a purity of 99.9% in a molar ratio of 19:1 with an electronic balance, and use an agate mortar to mix the two evenly and put them into a quartz tube. bottom, such as figure 1 As shown, the quartz tube is placed on a horizontal long quartz glass plate, and finally the quartz plate is sent to a suitable position in the horizontal tube furnace, and the tube furnace is sealed with a stainless steel flange;

[0029] (2) Use a mechanical pump to evacuate the tube furnace, and start heating the quartz tube after 30 minutes at a heating rate of 10° C. / min. During the heating process, argon was passed as a protective gas, and the fluid flow rate was set at 100 Sccm.

[0030] (3) When the temperature of the zinc powder is raised to 520° C., oxygen is introduced, and the flow rate is set to 30 Sccm. When the zinc powder and manganese dioxide powder reach 800°C, keep the constant temperature for 60 min...

Embodiment 2

[0034] (1) Use an electronic balance to weigh zinc powder with a purity of 99.99% and manganese chloride powder with a purity of 99.9% in a molar ratio of 9:1, and put them into the bottom of quartz tubes with different lengths, and then place two quartz tubes The tube is placed on a horizontal long quartz plate, the silicon substrate is placed horizontally at the quartz tube mouth, and finally the quartz plate is sent to a suitable position in the tube furnace, and the tube furnace is sealed with a stainless steel flange.

[0035] (2) Use a mechanical pump to evacuate the tube furnace. Manganese chloride powder and zinc powder are heated to 800°C and 550°C after 80 minutes, and then oxygen is introduced to keep the manganese chloride at a constant temperature. After the zinc powder reaches 650°C Keep the constant temperature for 30 minutes. During the heating process, argon was passed as a protective gas, and the flow rate was set at 100 Sccm.

[0036] (3) After the reaction...

Embodiment 3

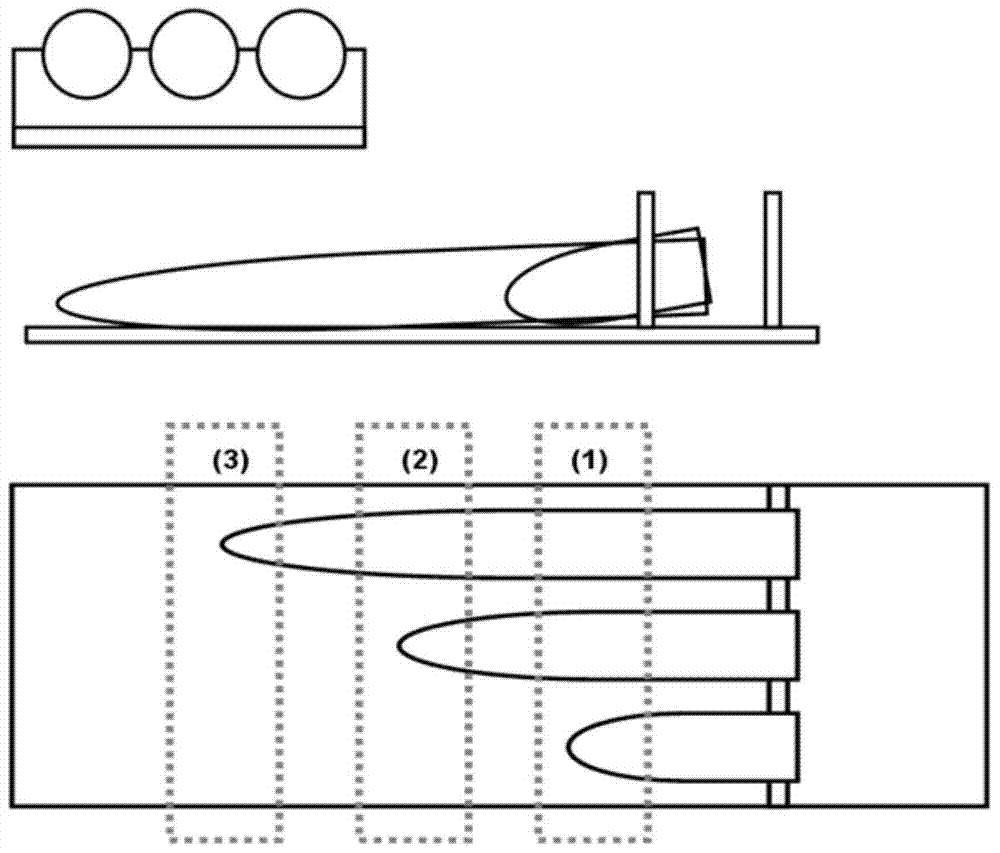

[0039] (1) Use an electronic balance to weigh zinc powder with a purity of 99.99% and manganese chloride powder with a purity of 99.9% at a molar ratio of 9:1, and put them into the bottom of quartz tubes with different lengths. Then place the two quartz tubes on a long horizontal quartz plate as figure 2 As shown, place the silicon substrate horizontally at the mouth of the quartz tube. Finally, the quartz plate is sent to a suitable position in the tube furnace, and the tube furnace is sealed with a stainless steel flange.

[0040] (2) Use a mechanical pump to evacuate the tube furnace, manganese chloride powder and zinc powder are heated to 800°C and 550°C respectively after 80 minutes, and then oxygen is introduced to keep the manganese chloride at a constant temperature, and the zinc powder reaches 650°C After that, keep the constant temperature for 30 minutes. During the heating process, argon was passed as a protective gas, and the flow rate was set at 100 Sccm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com