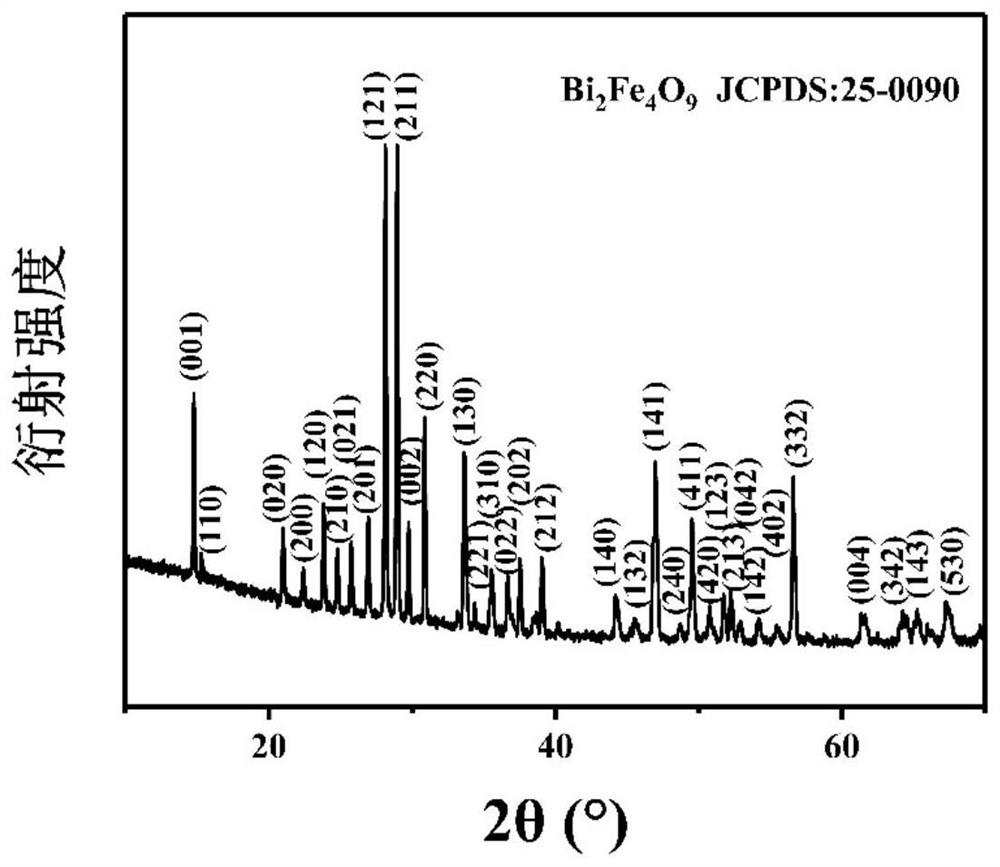

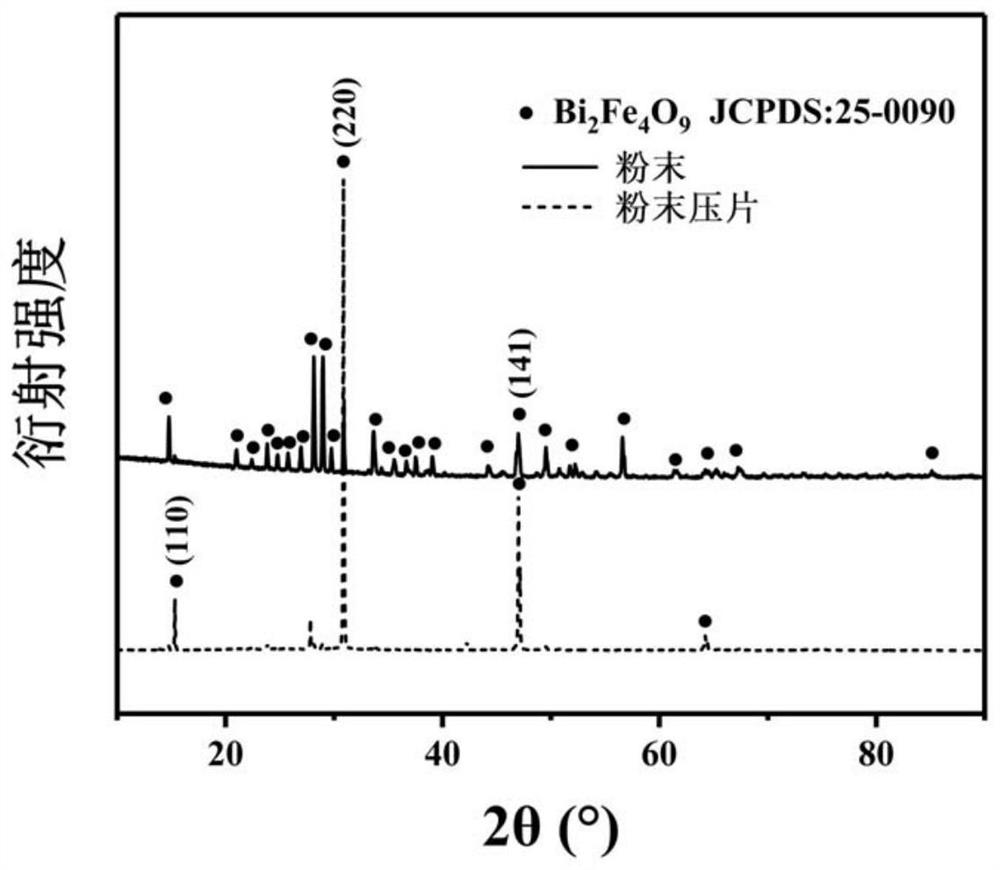

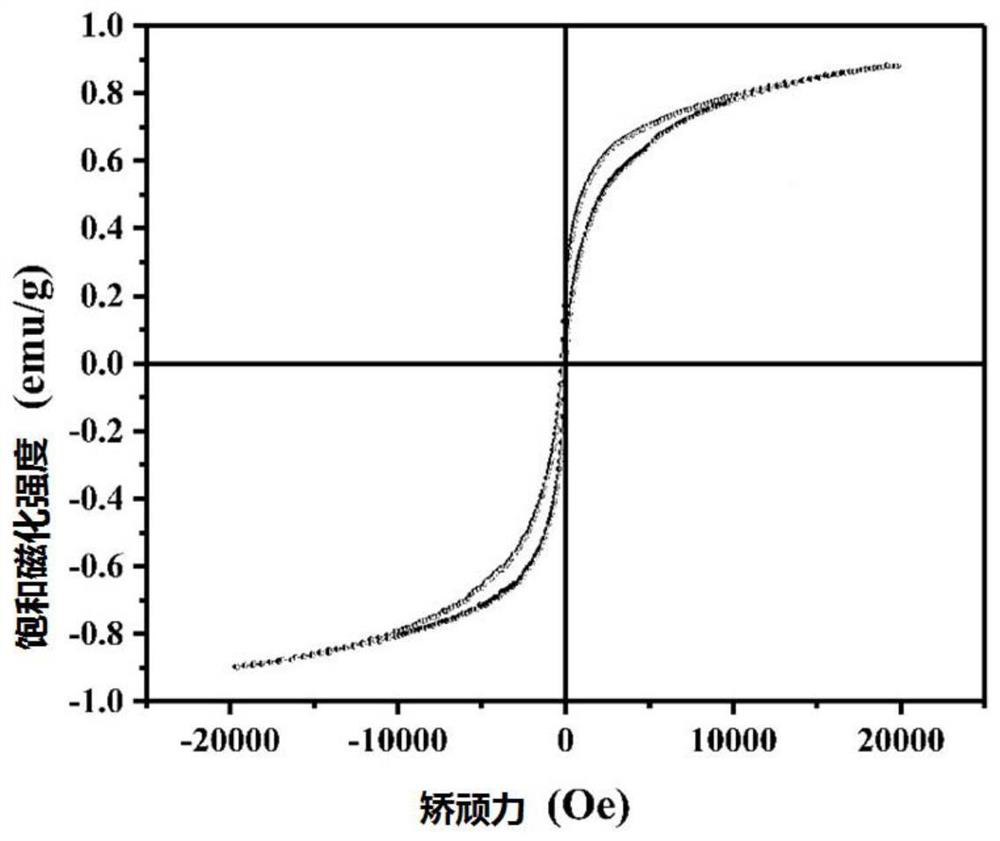

A micron-scale regular square bar bi 2 fe 4 o 9 Preparation method, product and application of multiferroic material

A bi2fe4o9, multi-ferrous material technology, applied in the field of material science, can solve the problems of difficult synthesis of pure phase, incomplete reaction, poor repeatability, etc., and achieve the effect of green synthesis process, low equipment requirements, and regular morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Add 1 mmol of Bi(NO) to 40 mL of deionized water under stirring 3 ) 3 ·5H 2 O, continue to stir for 30min, then add 1.5mmol of Fe(NO 3 ) 3 ·9H 2 O, continue to stir for 30min to obtain Bi 3+ with Fe 3+ The molar ratio of the mixed solution is 1:1.5;

[0038] (2) adding 16g of NaOH to the above-mentioned mixed solution, making the NaOH concentration in the mixed solution 10mol / L, and continuing to stir for 2h to obtain a precursor suspension, which was transferred to a 50mL reactor liner;

[0039] (3) The above-mentioned reaction kettle liner containing the precursor solution was sealed in the reaction kettle, and after 12 hours of reaction at 180 ° C, it was naturally cooled to room temperature in the air, the reaction product was taken out, filtered, and washed with deionized water and absolute ethanol respectively. , drying to obtain micron-scale regular square Bi 2 Fe 4 O 9 Multiferroic material.

Embodiment 2

[0041] (1) Add 1 mmol of Bi(NO) to 40 mL of deionized water under stirring 3 ) 3 ·5H 2 O, continue to stir for 30min, then add 2mmol of Fe(NO 3 ) 3 ·9H 2 O, continue to stir for 30min to obtain Bi 3+ with Fe 3+ The molar ratio of the mixed solution is 1:2;

[0042] (2) 14.4g of NaOH was added to the above mixed solution, so that the NaOH concentration in the mixed solution was 9mol / L, and the stirring was continued for 2h to obtain a precursor suspension, which was transferred to the 50mL reactor liner;

[0043] (3) The above-mentioned reaction kettle liner containing the precursor solution was sealed in the reaction kettle, and after 12 hours of reaction at 180 ° C, it was naturally cooled to room temperature in the air, the reaction product was taken out, filtered, and washed with deionized water and absolute ethanol respectively. , drying to obtain micron-scale regular square Bi 2 Fe 4 O 9 Multiferroic material.

Embodiment 3

[0045] (1) Add 1 mmol of Bi(NO) to 40 mL of deionized water under stirring 3 ) 3 ·5H 2 O, continue to stir for 30min, then add 2mmol of Fe(NO 3 ) 3 ·9H 2 O, continue to stir for 30min to obtain Bi 3+ with Fe 3+ The molar ratio of the mixed solution is 1:2;

[0046] (2) adding 16g of NaOH to the above-mentioned mixed solution, making the NaOH concentration in the mixed solution 10mol / L, and continuing to stir for 2h to obtain a precursor suspension, which was transferred to a 50mL reactor liner;

[0047] (3) The above-mentioned reaction kettle liner containing the precursor solution was sealed in the reaction kettle, and after 12 hours of reaction at 180 ° C, it was naturally cooled to room temperature in the air, the reaction product was taken out, filtered, and washed with deionized water and absolute ethanol respectively. , drying to obtain micron-scale regular square Bi 2 Fe 4 O 9 Multiferroic material.

[0048] Micron-scale regular square bar Bi 2 Fe 4 O 9 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com