Light guide plate with light diffusion function

A technology of light guide plate and light diffusion, which is applied in the directions of light guide, optics, optical components, etc., can solve the problems of insufficient fixation of light guide plate and diffuser plate and high cost, and achieve the effect of uniform and soft light emission, low cost and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

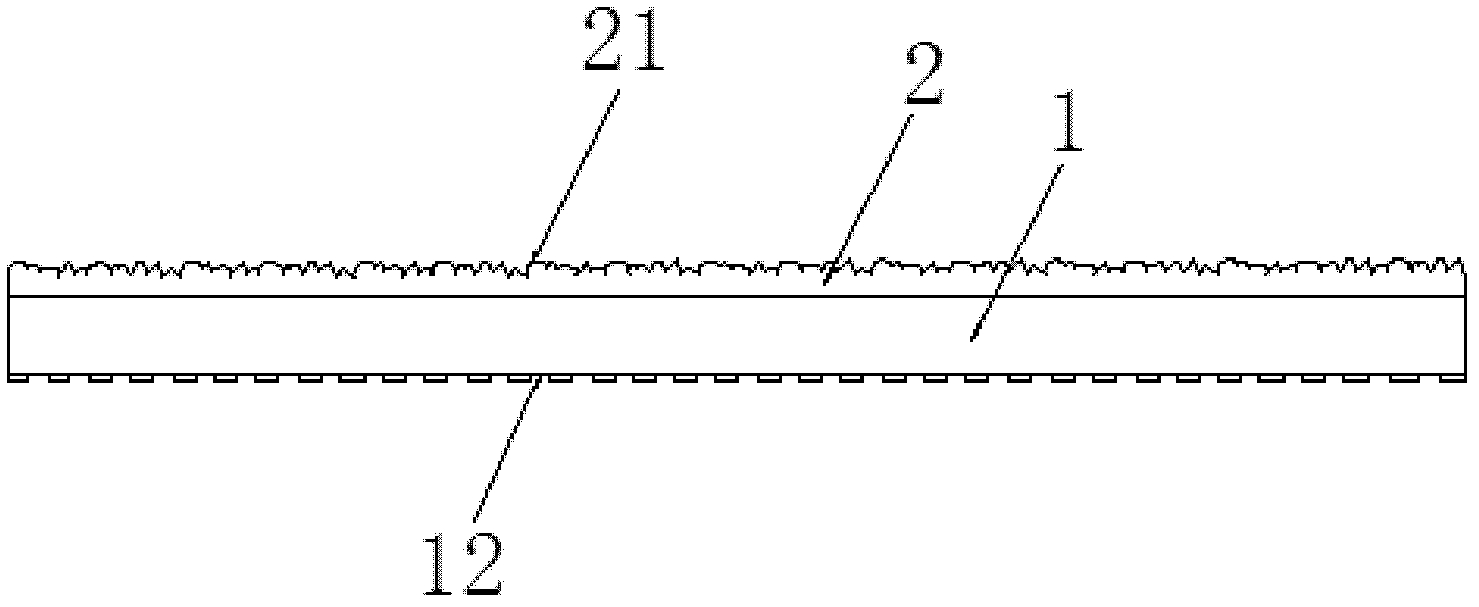

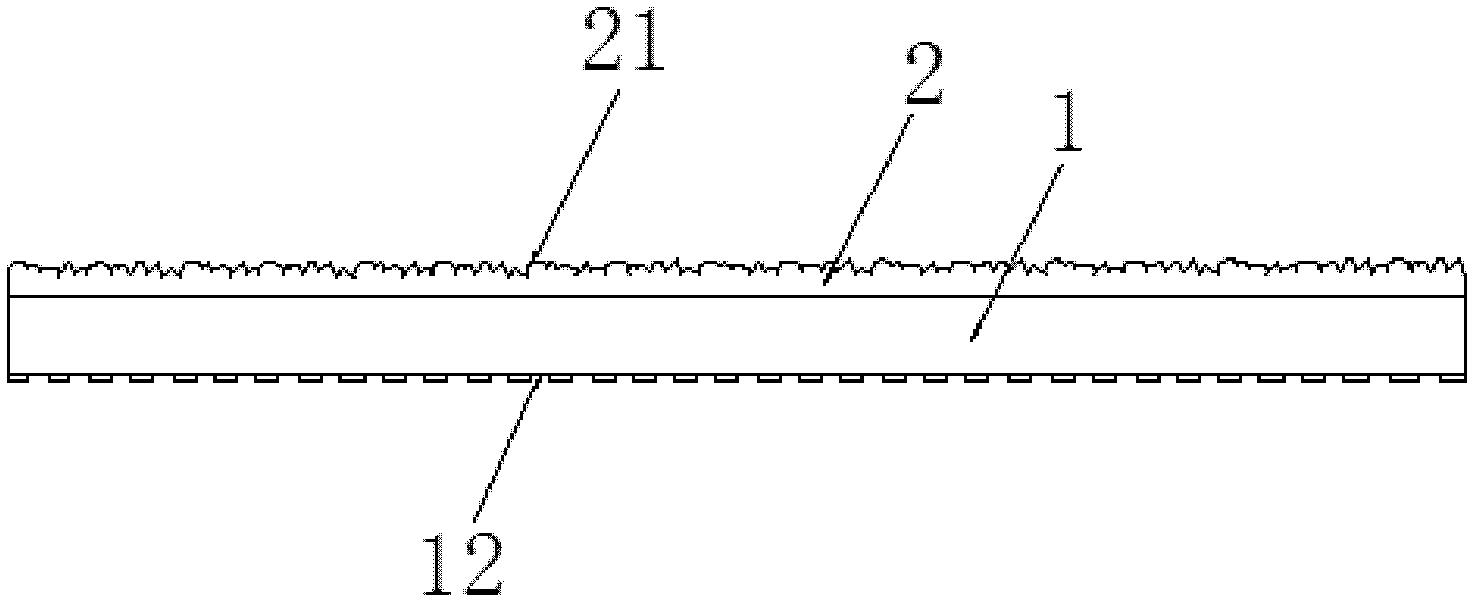

[0015] Embodiment: A light guide plate with light diffusion function, provided with a transparent substrate 1 and a diffusion film 2, the transparent substrate 1 has two opposite surfaces and are respectively a front and a back 12, and the back 12 of the transparent substrate has A number of light guide points, the diffusion film 2 has two opposite surfaces and are respectively an outer surface 21 and a veneer, the veneer of the diffusion film is adhered to the front of the transparent substrate, and the outer surface of the diffusion film 21 is an uneven rough surface.

[0016] The present invention is to form a light guide point on the back of the transparent substrate, which is the prior art. It can make the transparent substrate have a light guide function, and can convert the line light source into a surface light source, and stick a diffusion film on the front of the transparent substrate. The outer surface of the film is uneven and rough, so it has the function of light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com