Back light system

A technology of backlight system and light source, which is applied in the field of backlight system, can solve the problems of high cost, single function, cumbersome color filter manufacturing process, etc., and achieve the effect of low cost and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

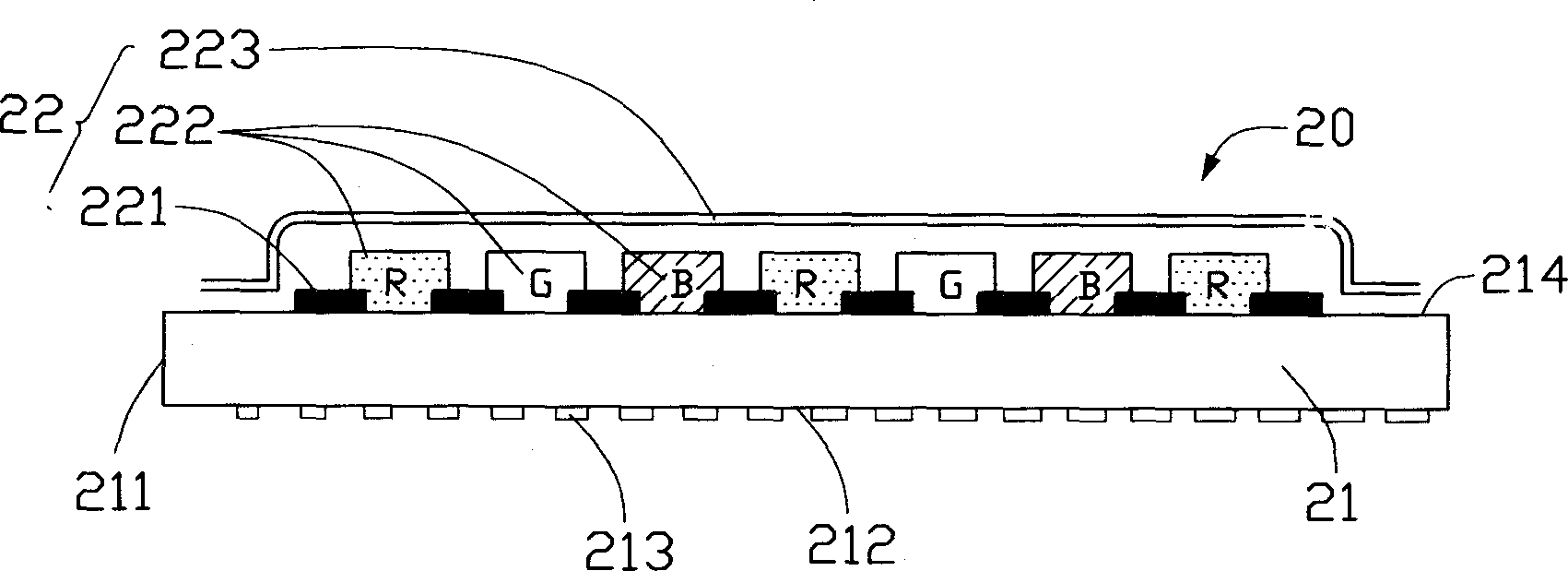

[0015] Please refer to image 3 As shown, the light guide plate 20 used in the backlight system of the present invention is made of transparent materials such as acrylic, glass or polycarbonate. The light guide plate 20 includes a light guide base 21 and a filter unit 22, wherein the light guide The substrate 21 is in the shape of a flat plate, which has a light incident surface 211, a bottom surface 212 connected to the light incident surface 211, and a light exit surface 214 opposite to the bottom surface 212, wherein the bottom surface 212 has a plurality of scattering units, and the scattering units are convex Point 213 , the size of the bumps 213 increases along the direction away from the light incident surface 211 and the arrangement gradually changes from sparse to dense. In addition, the light guide base 21 can also be designed as a wedge or a triangle as required. The filter unit 22 is composed of a light-shielding layer 221 for light-shielding, red (R), green (G), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com