Waterborne radiation curing coating decorative plate and preparation method thereof

A radiation-cured and decorative board technology, applied in antifouling/underwater coatings, fireproof coatings, polyester coatings, etc., can solve the problems of shortened construction period, difficult construction, long period, etc., and achieve good energy saving and simple manufacturing process , smooth and dense surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Decorative panel 1 of water-based radiation curing paint walnut pattern

[0040] The decorative board 1 includes a cement fiber board and a penetration-strengthening primer, a sealing coat, a first layer of adhesive primer, a white primer, a second layer of adhesive primer, a transfer film, and a third layer of adhesive primer that are sequentially coated on the surface of the cement fiber board. Primer, topcoat.

[0041] Among them, the penetration-enhanced primer, the sealing coat, the first layer of adhesive primer, the white primer, the second layer of adhesive primer, the third layer of adhesive primer, and the topcoat, sequentially include water-based radiation-curable coatings X1, X2, X3, X4, X3, X3, X6.

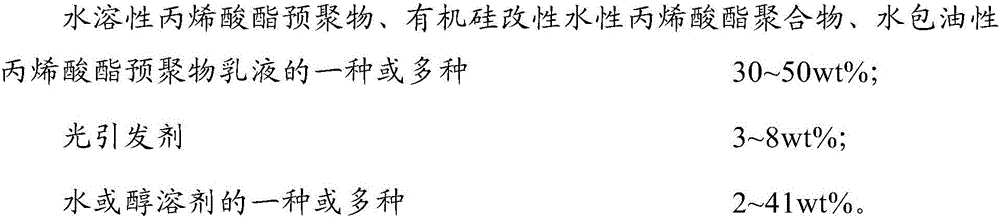

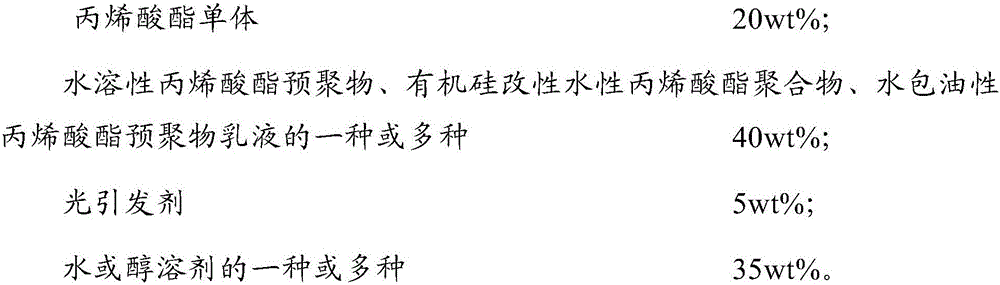

[0042] Waterborne Radiation Curing Coating X1 includes the following components and contents:

[0043] Water-soluble epoxy acrylate 1wt%, DPGDA15wt%, water-based urethane acrylate 25wt%, water-based amino acrylate 10wt%, bis(2,4,6-trimethylbenzoyl)-...

Embodiment 2

[0055] Embodiment 2 water-based radiation curing paint light blue decorative board 2

[0056] The decorative board 2 includes a cement fiber board and a penetration-strengthening primer, a sealer coat, a white sealer coat, a first layer of adhesive primer, a white sealer coat, a second layer of adhesive primer, a color paint layer, and a surface that are sequentially coated on the surface of the cement fiber board. paint layer.

[0057] Among them, the penetration-enhanced primer, sealer coat, white sealer coat, the first layer of adhesive primer, the second layer of adhesive primer, color paint, and top coat respectively include: water-based radiation-curable coating X1, X2, X3, X4, X4 , X7, X6.

[0058] Waterborne Radiation Curing Coating X1 includes the following components and contents:

[0059] Water-soluble epoxy acrylate 1wt%, DPGDA15wt%, water-based urethane acrylate 25wt%, water-based amino acrylate 10wt%, bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide 8wt%, etha...

Embodiment 3

[0073] Embodiment 3 water-based radiation curing paint light yellow decorative board 3

[0074] The decorative board 3 includes a cement fiber board and a penetration-strengthening primer, a sealer coat, a first layer of primer, a white primer, a second layer of primer, color paint, and a top coat that are sequentially coated on the surface of the cement fiber board.

[0075] Among them, the penetration-enhanced primer, sealer coat, white primer, the first layer of adhesive primer, the second layer of adhesive primer, color paint, and top coat respectively include: water-based radiation-curable coatings X1, X2, X8, X3, X3 , X5, X9.

[0076] Waterborne Radiation Curing Coating X1 includes the following components and contents:

[0077] Water-soluble epoxy acrylate 1wt%, DPGDA15wt%, water-based urethane acrylate 25wt%, water-based amino acrylate 10wt%, bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide 8wt%, ethanol 21wt%, purified water 20wt%.

[0078] Waterborne Radiation Cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com