Method for forming display part of push-type switch and push-type switch with the display part

A display and switch technology, applied in the direction of electric switches, legends, electrical components, etc., can solve the problems of image deformation, pressing operation can not be sure to open-close connection, easy to generate burrs, etc., to achieve excellent atmospheric corrosion resistance, image Excellent visibility and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

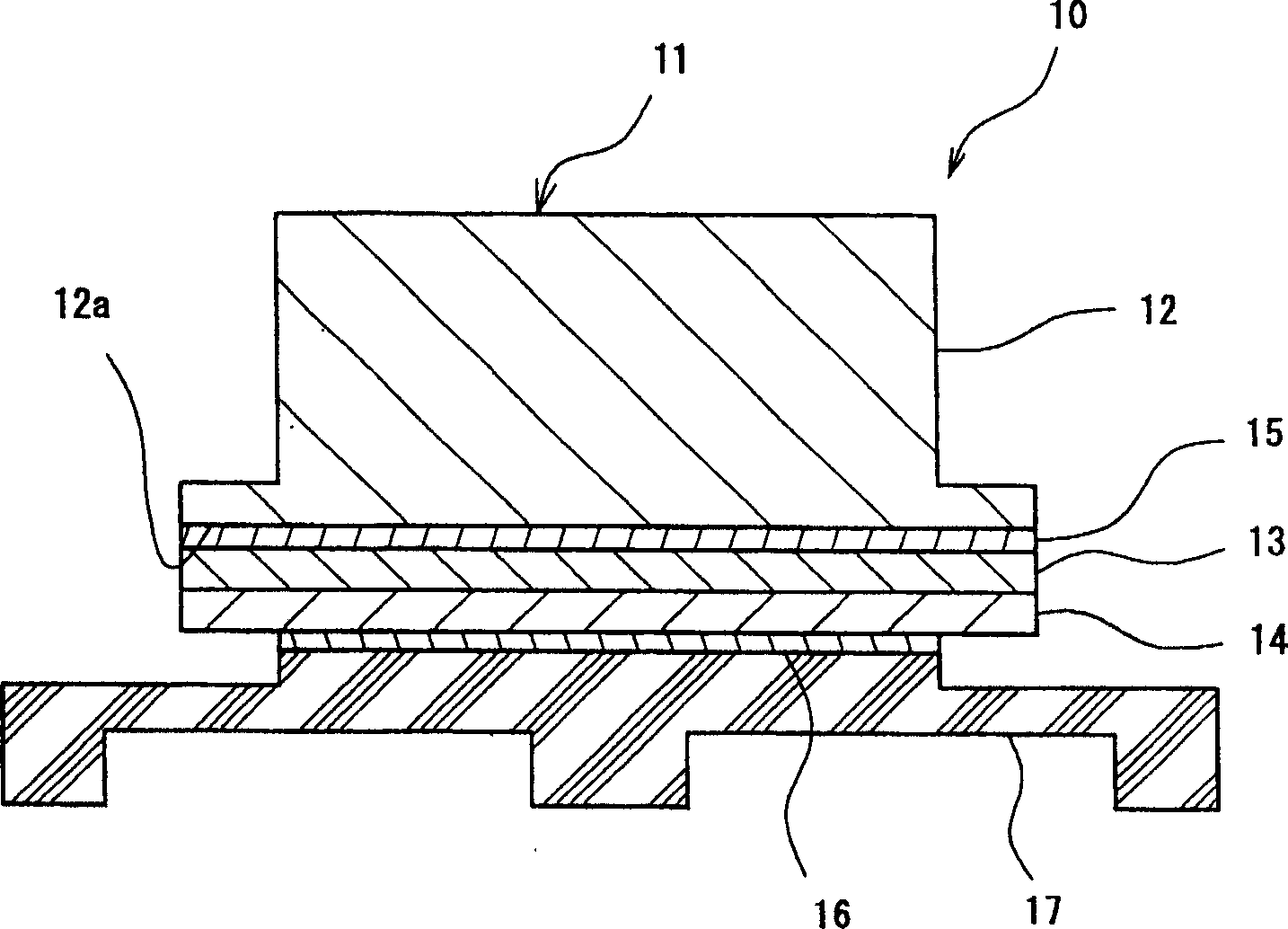

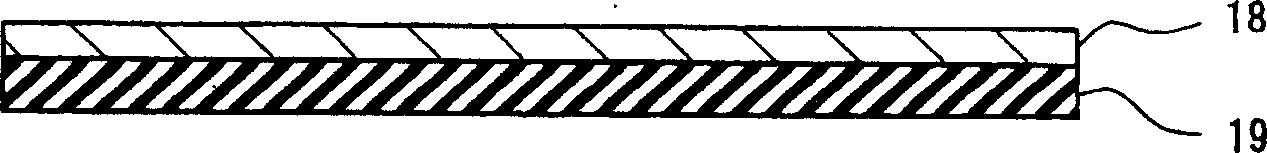

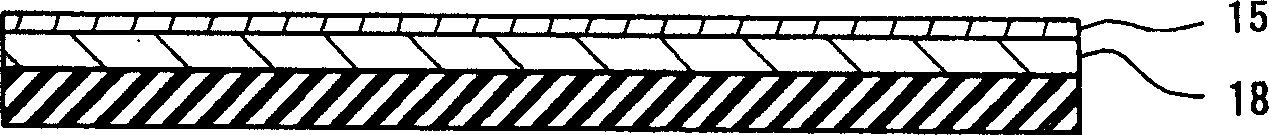

[0127] Embodiment 1: ( figure 1 ,figure 2)

[0128] Color design data created using a computer is printed on a predetermined substrate 19 with a predetermined color printer, and the colored layer 18 is formed on the substrate 19 . On this substrate 19, a sample provided with a predetermined receiving layer (not shown in the figure) was prepared. On the inner surface 12a of the key top body 12 made of polycarbonate resin molded by an injection molding machine, or on the colored layer 18, the hot-melt adhesive 15 with a specified light transmission property of 5 μm is uniformly coated with a layer thickness of 5 μm by screen printing, And let it dry and solidify. Then, in order to transfer the colored layer 18 to the inner surface 12a of the key top body, the positions of the key top body 12 and the substrate 19 are aligned, and the key top body 12 and the substrate 19 are squeezed with a pressure of 0.3Mpa. After 2 seconds, add After performing thermal transfer at a predete...

Embodiment 2

[0132] Embodiment 2: ( image 3 ,Figure 4)

[0133] Color design data created with a computer is printed on a predetermined substrate 29 using a predetermined color printer, and a colored layer 28 is formed on the substrate 29 provided with a predetermined receiving layer (not shown). On the surface 22a of the key top body 22 made of polycarbonate resin formed by an injection molding machine, a predetermined coloring auxiliary layer 24 was applied to a thickness of 5 μm according to a sample. Then, the hot-melt adhesive 25 having predetermined translucency is uniformly applied on the colored layer 28 or the surface 22a of the key top body 22 by screen printing, and dried and cured. In order to transfer the colored layer 28 on the key top body 22 side, align the positions of the key top body 22 and the substrate 29, press the key top body 22 and the substrate 29 with a pressure of 0.3Mpa, and add a specified temperature after 2 seconds. After thermal transfer, the substrate 29 ...

Embodiment 5

[0140] Embodiment 5: ( Figure 10 )

[0141] The color design data created using a computer is printed with a printer on a substrate 58 made of a PET film or acrylic film with a thickness of 100 μm provided with a predetermined image bearing layer, and a colored layer 59 is formed on the substrate 58 . A hot-melt adhesive 53 with predetermined translucency is uniformly applied on the colored layer 59 by screen printing, and dried and solidified to a layer thickness of 5 µm. Moreover, cooperate with the prescribed light-transmitting film 53 with a thickness of 50 μm, transfer the colored layer 59 to the light-transmitting film 53 for position alignment, press the substrate 58 and the light-transmitting film 53 with a pressure of 0.3 Mpa, and pass through 2 seconds After thermal transfer at 200° C., the substrate 58 was peeled off, and the display layer 55 was formed on the surface of the light-transmitting film 53 . For each sample, a predetermined coloring auxiliary layer 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com