Preparation method of calcium doped lead titanate ceramic fiber

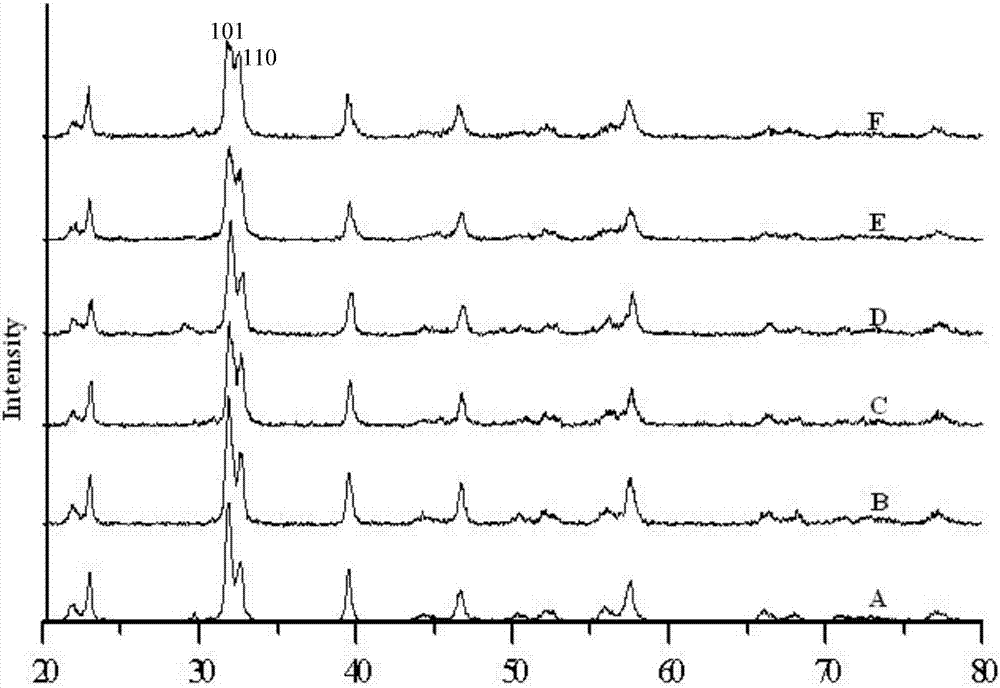

A ceramic fiber, lead titanate technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of lead titanate ceramic difficulties, large coercive field, sample fragmentation and other problems, achieve high uniformity, reduce Calcination temperature, easy modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0037] A method for preparing calcium-doped lead titanate ceramic fibers, the innovation of which is that a sol-gel method is adopted, and the specific steps are as follows:

[0038] (1) Preparation of stable sol:

[0039]a. Mix tetrabutyl titanate with chelating agent triethanolamine, and heat to reflux, then add solvent absolute ethanol to fully stir to form a clear sol;

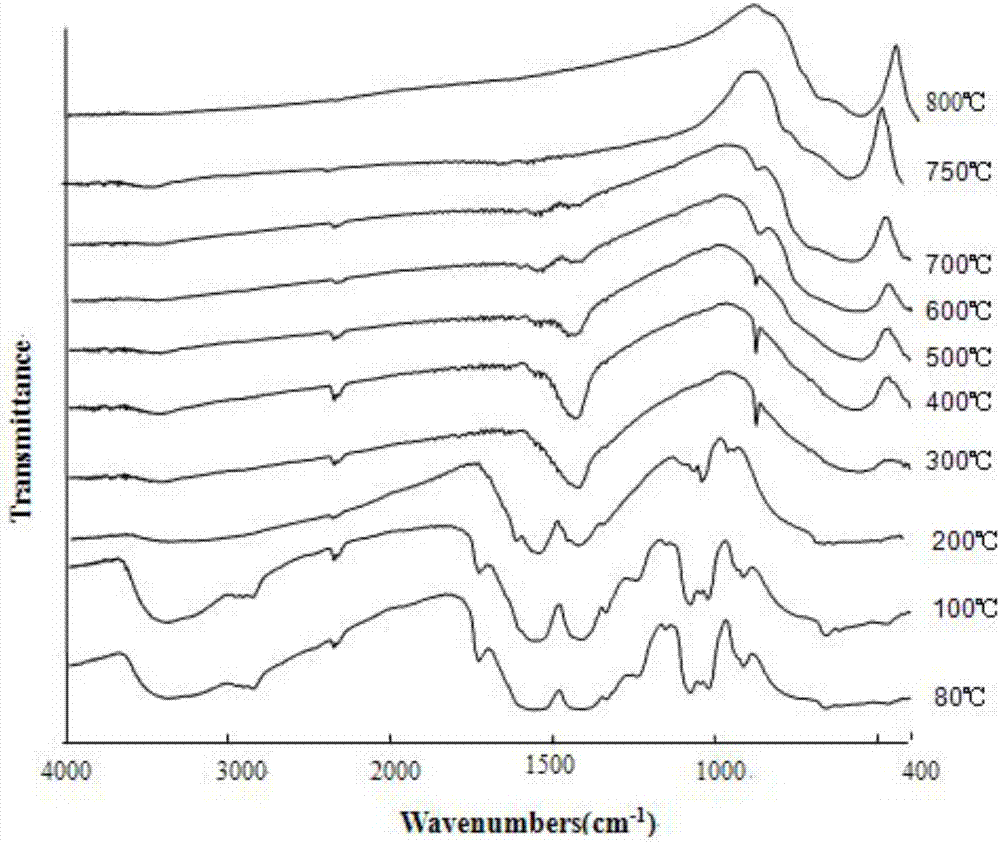

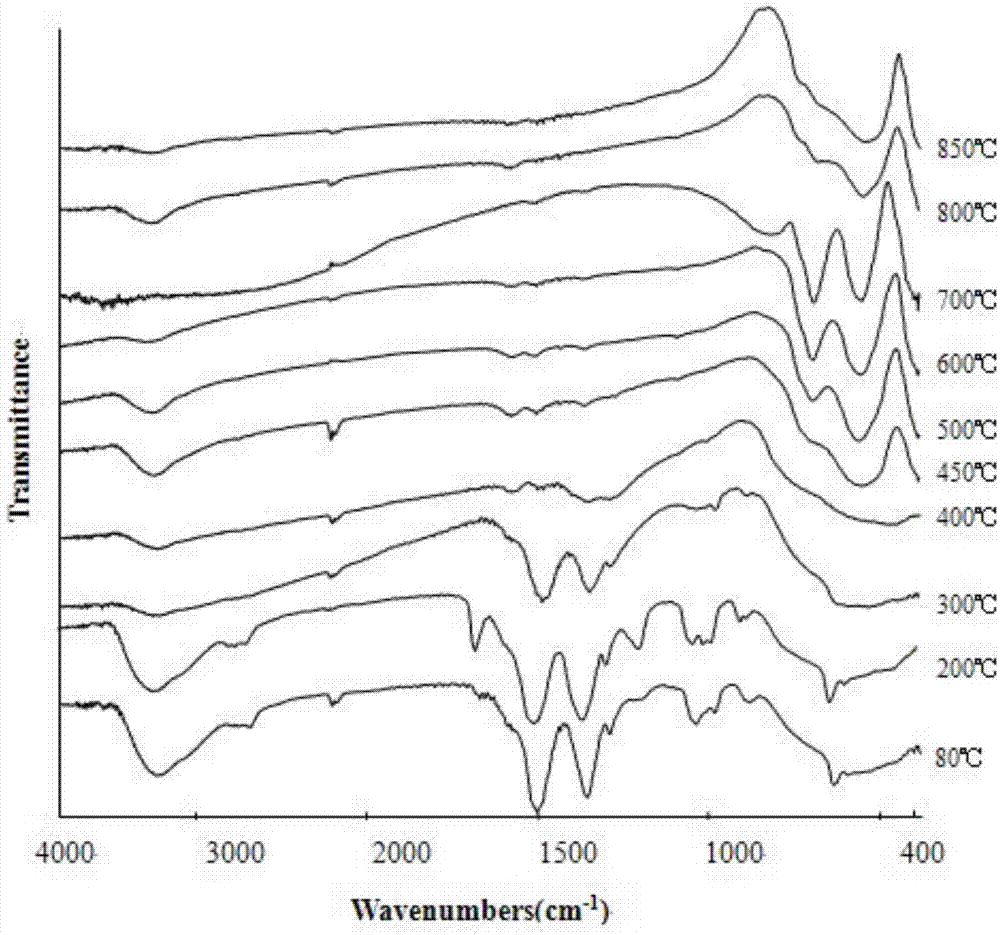

[0040] b. Add the catalysts glacial acetic acid, calcium acetate, and lead acetate trihydrate in sequence to the clear sol, the concentration is controlled at 1mol / L, and reflux and stir in a water bath at 80°C for 1 hour to obtain stable Pb 1-x Ca x TiO 3 (x=0-30%) pale yellow stable sol;

[0041] The molar ratio of calcium acetate to lead acetate trihydrate, glacia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com