Ultrathin bamboo-wood fiber board with bio-based non-formaldehyde adhesive and manufacturing method thereof

A technology of bamboo and wood fiber and a manufacturing method, which is applied to the field of ultra-thin bamboo and wood fiber board and its manufacturing, can solve the problems of high formaldehyde emission, low mechanical properties, poor water resistance, etc., and achieves smooth and compact surface, good mechanical properties, and uniform material in all directions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

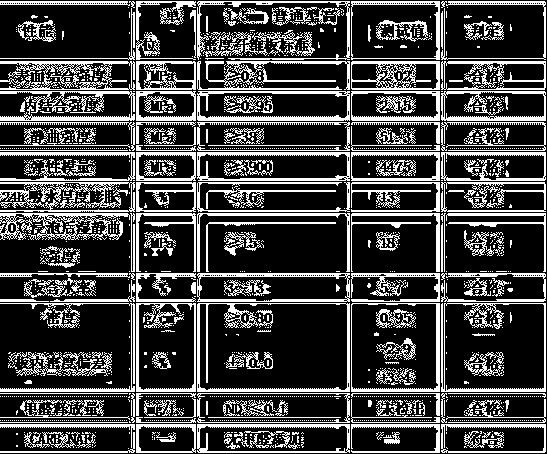

Image

Examples

Embodiment

[0035] A kind of 1.5mm ultra-thin bamboo fiber board manufacture method, the steps are as follows:

[0036] 1) Peeling: The wood is conveyed into the peeling machine for peeling treatment, and the bark content is required to be less than 5%; the bamboo is directly sent to the chips without peeling.

[0037] 2) Chipping: Bamboo wood is made into bamboo chips by a chipping mechanism, and bamboo chips, bamboo shreds, and bamboo chips account for 40% of the total mass; pine wood is made into pine chips by a chipping mechanism, and pine chips account for 30% of the total mass; 1. Miscellaneous wood chips are made into eucalyptus chips by chippers, eucalyptus chips account for 20% of the total mass, and miscellaneous wood chips account for 10% of the total mass;

[0038] 3) Cooking and grinding: Bamboo chips and wood chips are softened by cooking. The cooking time is 2.5min, the temperature is 175°C, and the pressure is 0.8MPa. The softened wood chips are ground into bamboo and wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com