Paint used for coiled metal material

A technology for metal coils and coatings, applied in the field of back paint, top coat, and primer for metal coils, it can solve the problems of heavy smoke, chemical resistance, water resistance, stain resistance, corrosion resistance and friction resistance, High energy consumption and other issues, to achieve excellent flexibility and hardness, excellent chemical resistance, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

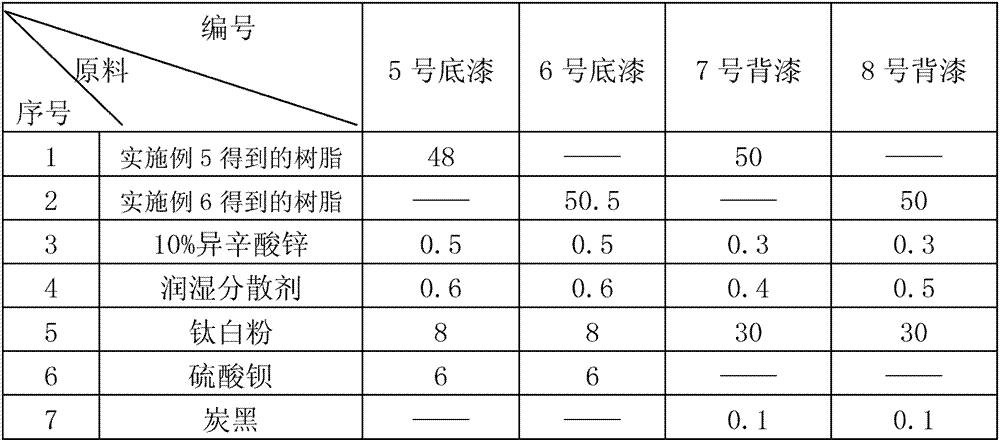

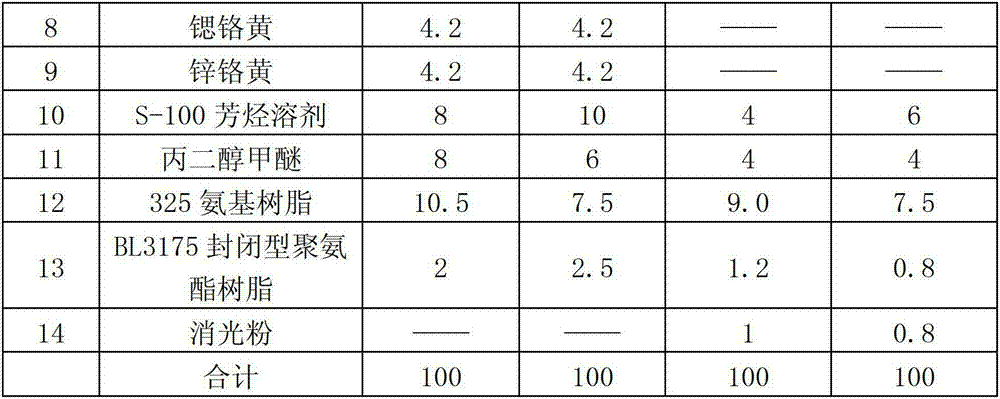

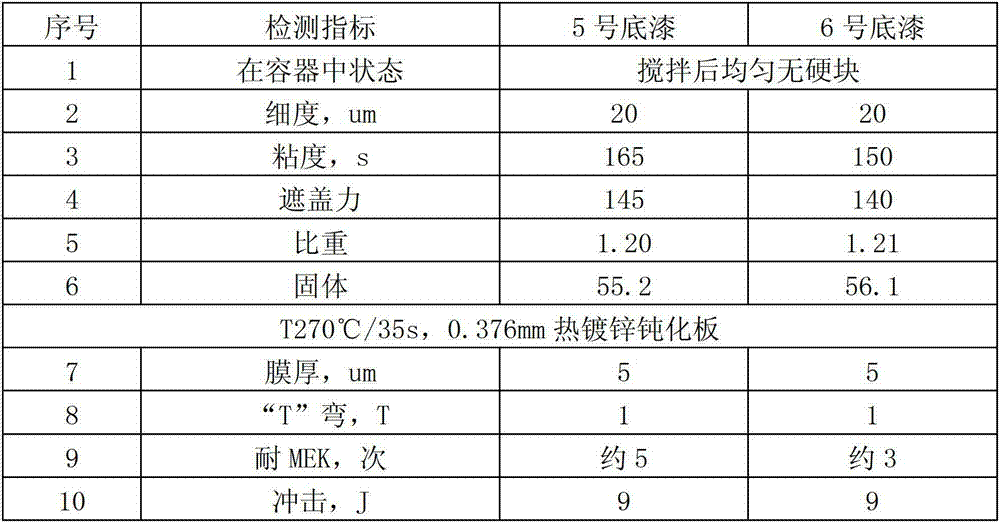

[0029] Embodiment 1-4 is the preparation method of saturated polyester resin.

[0030] Embodiment 5-6 is the preparation method of epoxy modified saturated polyester resin.

Embodiment 1

[0032]Add 127g of xylene into a four-necked flask equipped with a vertical condenser, a mechanical stirrer, a thermometer and a constant pressure dropping funnel. Add 370g of styrene, 88.5g of allyl alcohol, and 10.3g of premixed monomers of di-tert-butyl peroxide into the constant pressure dropping funnel, heat the xylene to 135°C while stirring, and first add about 95g of premixed monomers body, react until the reflux slows down, then start to add the premixed monomer dropwise, finish adding in 2-3 hours, close the constant pressure dropping funnel, the maximum reaction temperature is 145°C, and after 1 hour of heat preservation reaction, take a sample and measure When the conversion rate of the monomer reaches more than 98%, cool down to no reflux, replace the oil-water separator, and add 69.2g of adipic acid, raise the temperature to 180-200°C, keep warm for esterification until the acid value is less than 8mgKOH / g, vacuum remove and flow out until there is no effluent, co...

Embodiment 2

[0041] Add 100g xylene into a four-necked flask equipped with a vertical condenser, a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 379g styrene, 60.5g allyl alcohol, 60.5g hydroxyethyl acrylate, and 10.5g over Add the premixed monomer of di-tert-butyl oxide into the constant pressure dropping funnel, heat the xylene to 135°C under stirring, first add about 100g of the above premixed monomer, react until the reflux slows down, and start adding the premixed After the monomer is added dropwise in 2-3 hours, the constant pressure dropping funnel is closed, the maximum reaction temperature is 145°C, and after 1 hour of heat preservation reaction, the conversion rate of the monomer is measured to be above 98% by sampling, and the temperature is lowered to no reflux. Install an oil-water separator, add 50.8g of adipic acid, heat up to 180-200°C, keep warm for esterification until the acid value is less than 8mgKOH / g, remove the effluent in a vacuum un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com