Sealed self-aligning roller bearing for high-speed rail and repair method thereof

A technology of self-aligning roller bearing and repair method, applied in the field of bearings, can solve the problems of high maintenance cost, low bearing capacity, high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention are described with reference to the accompanying drawings.

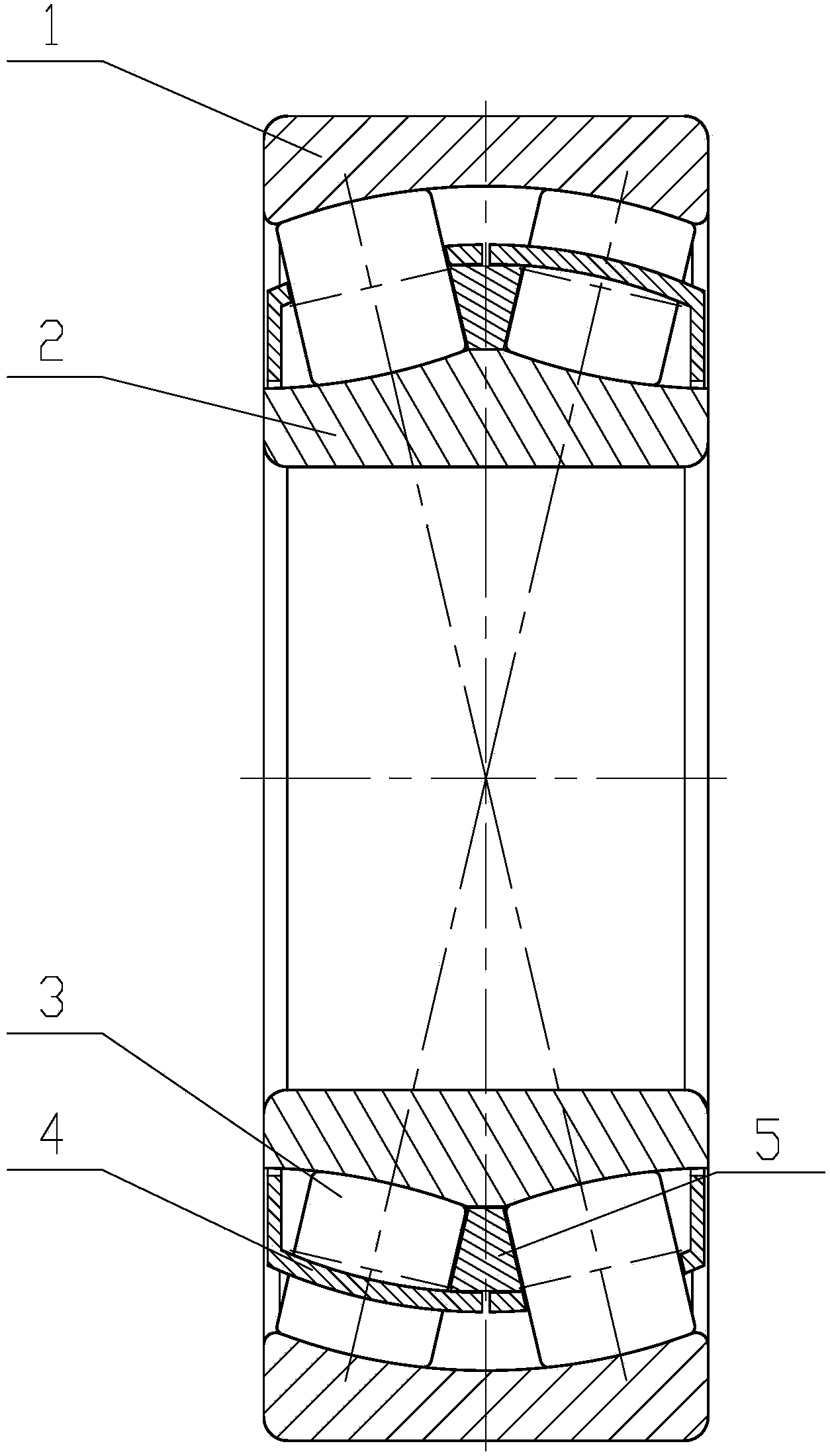

[0033] as attached Figure 5 Shown: the parts of the bearing of the present invention include an outer ring 1, an inner ring 2, a roller 3, a nylon cage 4, and a sealed housing 6.

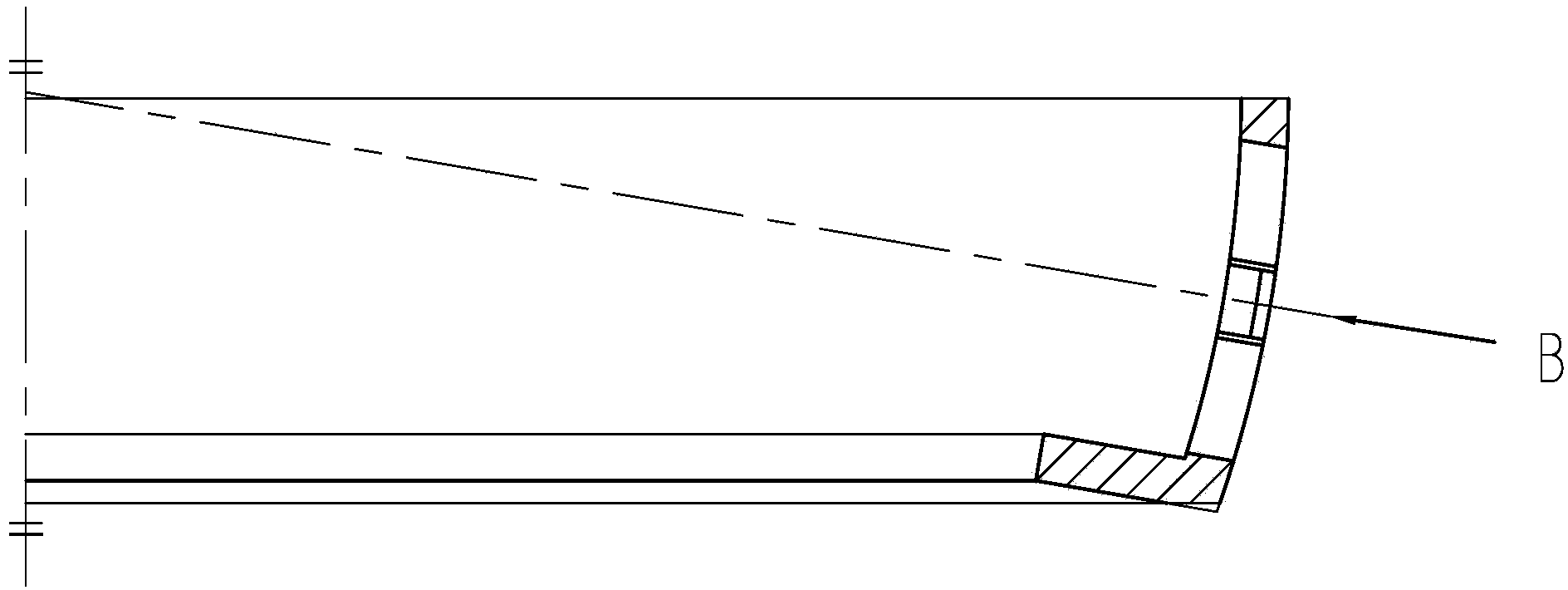

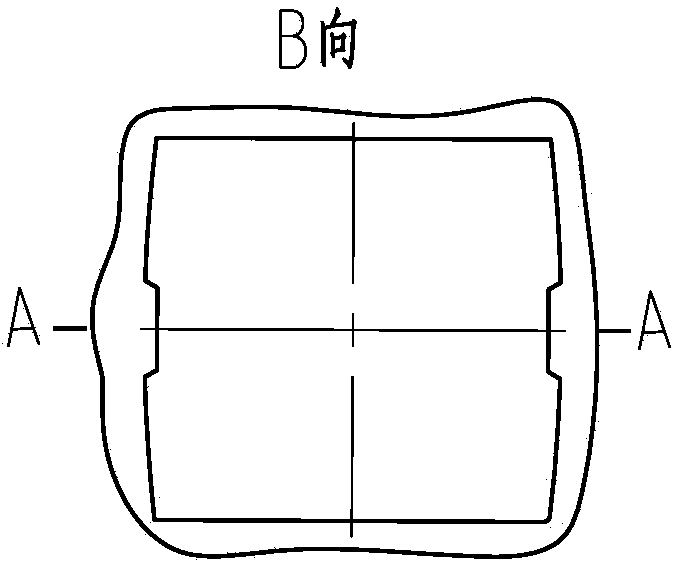

[0034] as attached Figures 5 to 6 As shown: the axial section of the nylon cage 4 is a " / " profile, that is, the inner and outer tapered surfaces are shown as a flat line L on the section, parallel to each other. Both end faces of the cage are annular planes M perpendicular to the axial direction. The outer diameter of the large end and the inner diameter of the small end of the cage near both sides are cylindrical surfaces N parallel to the axial direction. The cage is made of glass fiber reinforced nylon 66 and adopts integral injection molding. The glass fiber reinforced nylon 66 is an engineering plastic material. Please refer to the relevant technical standards for engineering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com