Printing decoration metallic plate capable of panel beating and manufacturing method thereof

A manufacturing method and technology of metal plates, applied in the direction of metal layered products, chemical instruments and methods, printing, etc., can solve the problems of high product cost, high cost, environmental pollution, etc., to improve product grades, improve corrosion resistance, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

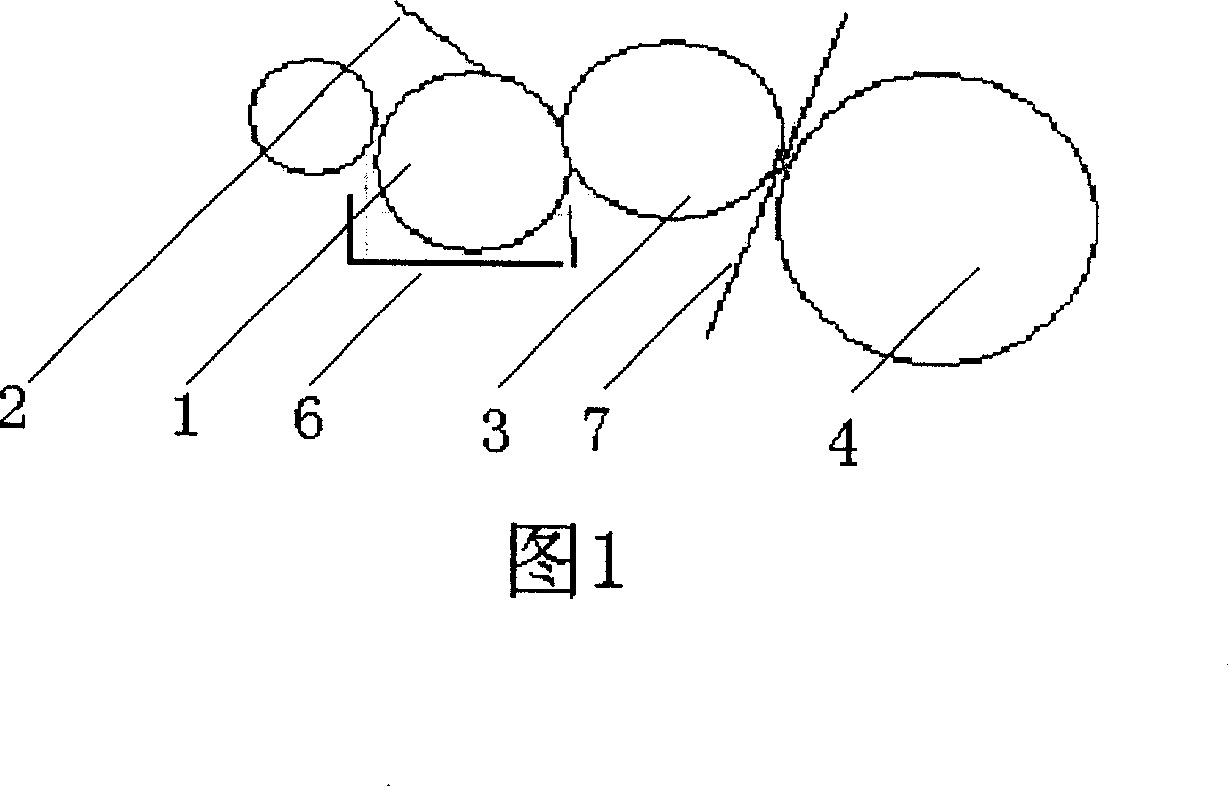

[0044] In this embodiment, the printing process is as follows, a gravure roll 1, the gravure roll 1 is immersed in the printing ink storage tank 6 to continuously coat the ink, the gravure roll 1 after the ink is dipped Use the scraper 2 to scrape off excess ink, and the ink pattern on the gravure roller 1 is transferred to the surface of the printing rubber roller 3, and the printing rubber roller 3 prints the ink pattern on its surface on the steel plate 7, and the other side of the steel plate is set A support roller 4.

Embodiment 2

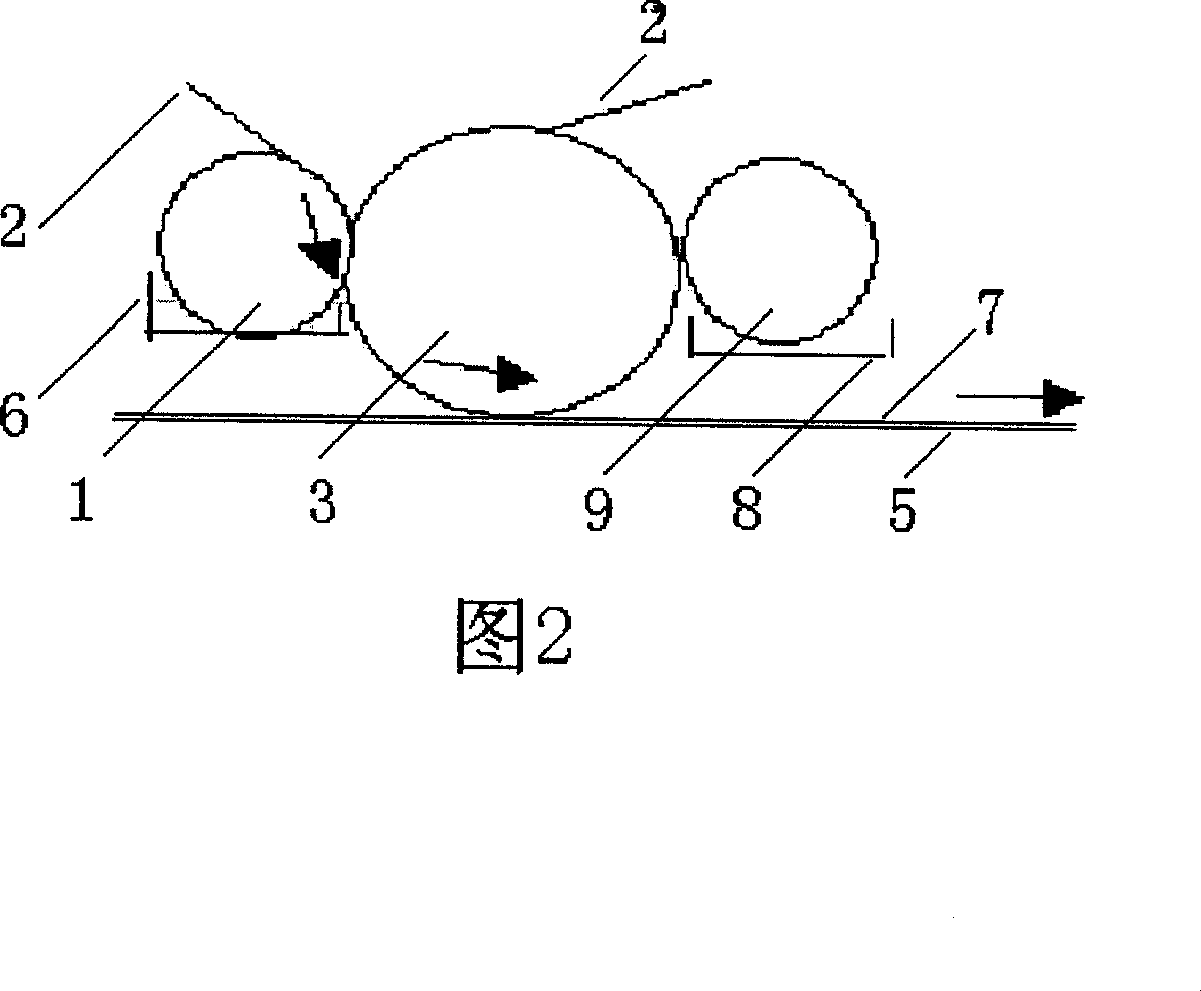

[0046] In this embodiment, the printing process is as follows, a gravure roll 1, the gravure roll 1 is immersed in the printing ink storage tank 6 to continuously coat the ink, the gravure roll 1 after the ink is dipped Use the scraper 2 to scrape off the excess ink, the ink pattern on the gravure roller 1 is transferred to the surface of the printing rubber roller 3, and the printing rubber roller 3 prints the ink pattern on its surface on the steel plate 7, and the support of the steel plate 7 is on the plane On the support transmission belt 5, on the other side of the printing rubber roller 3, a cleaning roller 9 is arranged, and the cleaning roller 9 is immersed in the washing tank 8 and is continuously cleaned. Another doctor blade 2 is arranged on the printing rubber roller 3 .

[0047] In the steel plate printing process of the present invention, if the ink printing lines are not clear, a cleaning roller can be added at the position of the printing rubber roller.

[00...

experiment example 1

[0052] Pilot projects

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com