Combined type antiskid glue cushion

An anti-slip rubber pad and combined technology, applied in the field of rubber pads, can solve the problems of rubber pads such as limitations of stiffness, single material, single function, and single decorative color, and achieve simple manufacturing process, scientific and reasonable structure, and good decorative effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

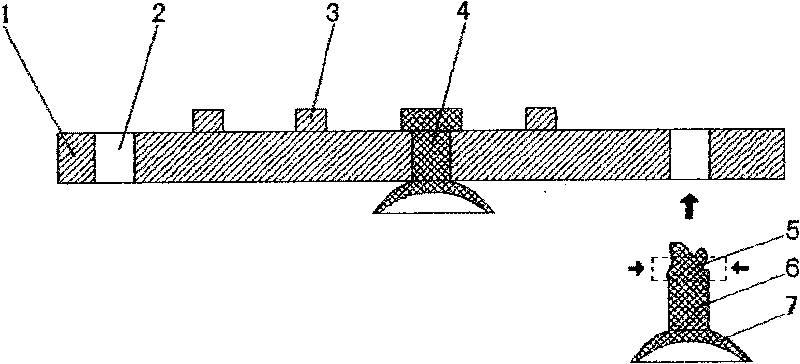

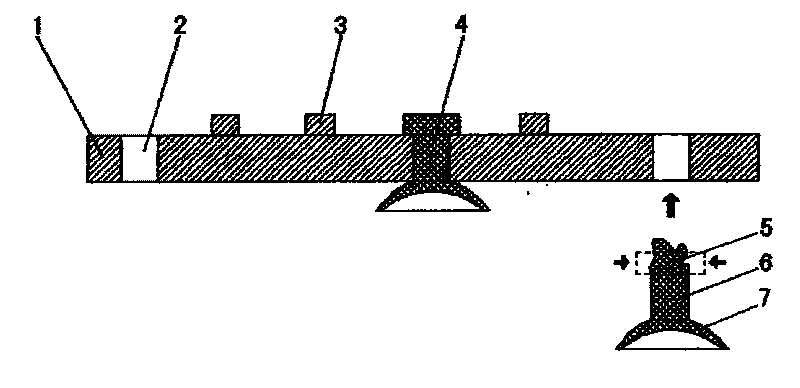

[0017] combine figure 1 , the specific embodiments of the present invention are described as follows:

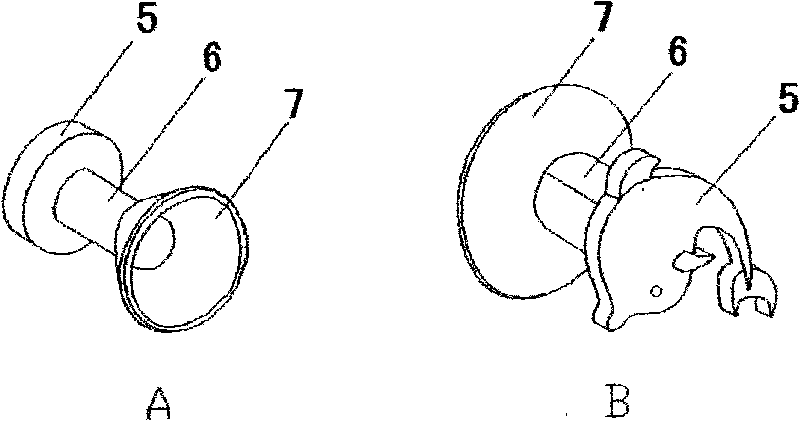

[0018] A combined anti-slip rubber pad, which is assembled from a base pad 1 and rubber parts 4, is characterized in that a through hole 2 is arranged on the base pad 1, and the through hole 2 is a mounting hole for the rubber part 4, and the rubber part 4 is a molded part, its upper end is a functional end 5, its lower end is a suction cup 7, and the middle of the upper end and the lower end is a connecting part 5, and the shape of the connecting part 6 matches the through hole 2 on the base pad 1, so The rubber part 4 is clamped on the base pad 1 through the connecting part 5 .

[0019] Protrusions 3 can be arranged on the surface of the base pad 1 in cooperation with the rubber parts, and the protrusions 3 can perform functions such as decoration and massage.

[0020] The glue parts 4 are elastic bodies, and the colors can be the same or different.

[0021] The radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com