Method for modifying polyethersulfone forward osmosis membrane through ZIF-8 in-situ growth and obtained membrane

A ZIF-8, in-situ growth technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of failure, ZIF-8 does not grow stably, powder is easy to fall off, etc., to prevent Effects of Membrane Defect Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

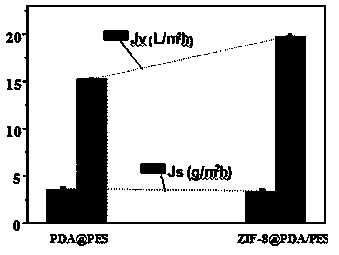

[0055] Prepare a modified polyethersulfone forward osmosis membrane 1 according to the following steps:

[0056] (1) Pretreatment of polyethersulfone basement membrane

[0057] Weigh 10g of sodium bisulfite powder and dissolve it in 1000mL of deionized water to prepare a sodium bisulfite solution with a mass volume ratio of 1%. Soak a circular polyethersulfone basement membrane with a diameter of 8cm in the sodium bisulfite solution Sterilized and stored, after soaking for 24 hours, take out the polyethersulfone basement membrane and place it in ultrapure water for later use. The polyethersulfone basement membrane soaked in ultrapure water for 24 hours can be used for modification synthesis.

[0058] (2) Dopamine (PDA) modified polyethersulfone membrane

[0059] Dopamine modification: Weigh 2 g of dopamine hydrochloride and place it in 1000 mL of prepared Tris buffer solution to prepare a dopamine hydrochloride solution, which is sealed for use. Soak the polyethersulfone ba...

Embodiment 2

[0063] Prepare a modified polyethersulfone forward osmosis membrane 2 according to the following steps:

[0064] (1) Pretreatment of polyethersulfone basement membrane

[0065] Weigh 10g of sodium bisulfite powder and dissolve it in 1000mL of deionized water to prepare a sodium bisulfite solution with a mass volume ratio of 1%. Soak a circular polyethersulfone basement membrane with a diameter of 8cm in the sodium bisulfite solution Sterilized and stored, after soaking for 24 hours, take out the polyethersulfone basement membrane and place it in ultrapure water for later use. The polyethersulfone basement membrane soaked in ultrapure water for 24 hours can be used for modification synthesis.

[0066] (2) Dopamine (PDA) modified polyethersulfone membrane

[0067] Dopamine modification: Weigh 2g of dopamine hydrochloride and place it in (1000mL) prepared Tris buffer solution to prepare a dopamine hydrochloride solution and seal it for use. Soak the polyethersulfone basement m...

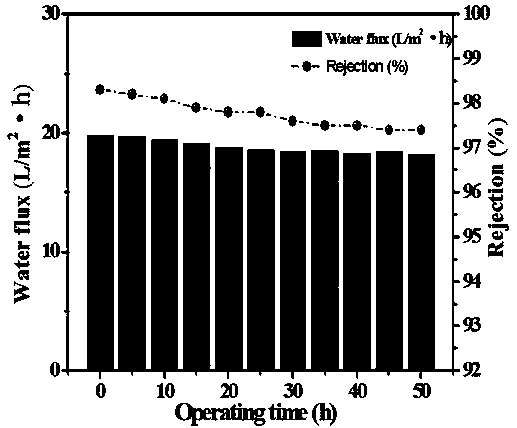

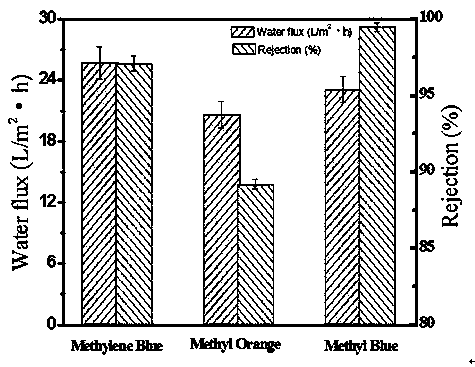

Embodiment 3

[0081] Prepare a modified polyethersulfone forward osmosis membrane 1 according to the following steps:

[0082] (1) Pretreatment of polyethersulfone basement membrane

[0083] Weigh 10g of sodium bisulfite powder and dissolve it in 1000mL of deionized water to prepare a sodium bisulfite solution with a mass volume ratio of 1%. Soak a circular polyethersulfone basement membrane with a diameter of 8cm in the sodium bisulfite solution Sterilized and stored, after soaking for 24 hours, take out the polyethersulfone basement membrane and place it in ultrapure water for later use. The polyethersulfone basement membrane soaked in ultrapure water for 24 hours can be used for modification synthesis.

[0084] (2) Dopamine (PDA) modified polyethersulfone membrane

[0085] Dopamine modification: Weigh 2 g of dopamine hydrochloride and place it in 1000 mL of prepared Tris buffer solution to prepare a dopamine hydrochloride solution, which is sealed for use. Soak the polyethersulfone ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com