Liquid crystal microcapsule and preparation method thereof

A technology of microcapsules and liquid crystals, applied in the field of liquid crystal microcapsules and its preparation, can solve the problems of strong toxicity of raw materials and unfavorable large-scale production, etc., and achieve the effects of improving compatibility, long storage time of liquid crystals, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to one aspect of the present invention, a kind of preparation method of liquid crystal microcapsule is provided, comprises the steps:

[0037] a) adding an emulsifier to water to obtain a dispersion, using the dispersion as the water phase;

[0038] b) uniformly mixing the liquid crystal, monoolefin monomer, polyolefin crosslinking agent and initiator to obtain a mixture, which is used as the oil phase;

[0039] c) mixing the water phase and the oil phase to obtain an oil-in-water emulsion through emulsification;

[0040] d) forming liquid crystal microcapsules with a core-shell structure by emulsion polymerization of the emulsion; and

[0041] e) centrifuging and spray drying the liquid crystal microcapsules to obtain a dry powder of the liquid crystal microcapsules.

[0042]Wherein, the amount of the olefinic monomer is 20-80 parts by weight based on 100 parts by weight of the liquid crystal; the amount of the polyolefin crosslinking agent is 5-80 parts by...

Embodiment 1

[0062] In this example, sodium salt hydrolyzate of alternating copolymer of styrene and maleic anhydride (purchased from Sartomer) was used as an emulsifier.

[0063] 10g of aqueous solution of 10wt% styrene-maleic anhydride alternating copolymer sodium salt was added to 77g of water, and the pH value was adjusted to 4.5 with hydrochloric acid, and this solution was used as the water phase;

[0064] Mix 10g of liquid crystal, 2g of styrene, 1g of divinylbenzene, and 0.06g of azobisisobutyronitrile as an initiator, heat up to 60°C, stir to make them evenly mixed, and use it as an oil phase;

[0065] Mix the above-mentioned water phase and oil phase, heat up to 70°C, and use a high-speed mixer to shear and emulsify for 2 minutes at a speed of 12,000 rpm to obtain an oil-in-water emulsion;

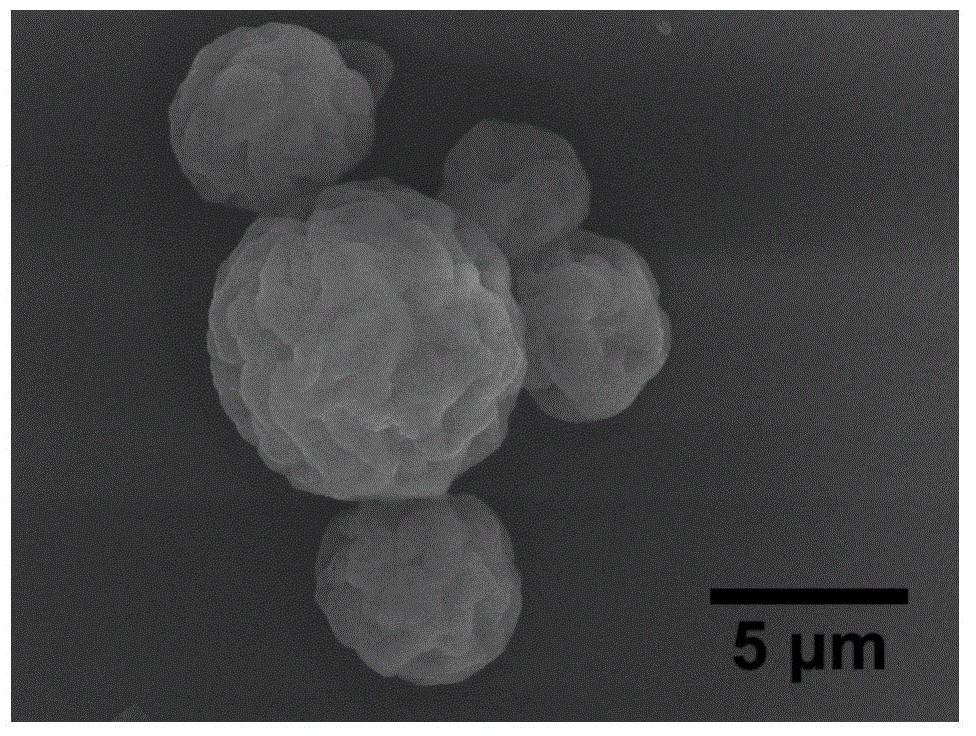

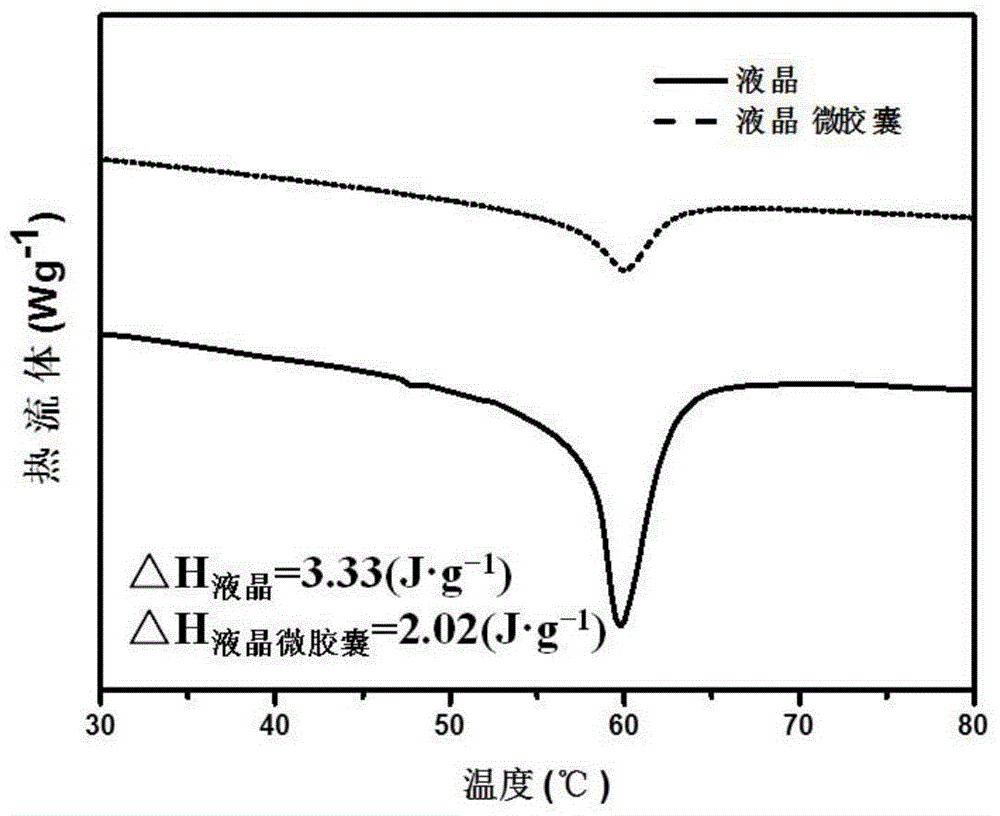

[0066] The above-mentioned oil-in-water emulsion was transferred to a preheated reaction kettle, and an inert gas-nitrogen was introduced, mechanically stirred at 200 rpm, and emulsion polyme...

Embodiment 2

[0071] In this example, sodium di-isooctyl sulfonate (purchased from Alfa Aesar) was used as an emulsifier.

[0072] Add 0.4 g of sodium dioctyl sulfonate to 82 g of water, and this solution is used as the water phase;

[0073] Mix 10g of liquid crystal, 2g of styrene, 1g of divinylbenzene, and 0.06g of azobisisovaleric acid as an initiator, and stir to make them evenly mixed as an oil phase;

[0074] Use a microporous membrane with an average pore size of 100nm for membrane emulsification to obtain an oil-in-water emulsion;

[0075] The above-mentioned oil-in-water emulsion was transferred to a preheated reaction kettle, and an inert gas-nitrogen was introduced, mechanically stirred at 200 rpm, and emulsion polymerization was carried out at 70°C for about 8 hours.

[0076] As the polymerization reaction proceeds, the monomers polymerize inside the liquid crystal, and migrate to the interface between the liquid crystal and water under the action of phase separation, thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com