Method for forming amphoteric ion structure on surface of separation membrane and separation membrane

A zwitterion and surface structure technology, applied in the field of separation membranes, can solve the problems of destroying the separation skin structure, damaging the rejection rate of separation membranes such as RO membranes and NF membranes, and water flux, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Configure an aqueous solution of positively charged substances, which contains 0.03g / mL of hyperbranched polyethyleneimine, 0.0025g / mL of EDC (1-ethyl-(3-dimethylaminopropyl) carbodiethylene amine hydrochloride) and 0.004 g / mL of NHS (N-hydroxysuccinimide).

[0041] (2) Configure an aqueous solution of negatively charged substances, which contains 0.03g / mL of acrylic acid and 0.0003g / mL of p-benzoquinone, wherein p-benzoquinone is used as a polymerization inhibitor of acrylic acid to prevent acrylic acid from occurring in the reaction process. polyreaction.

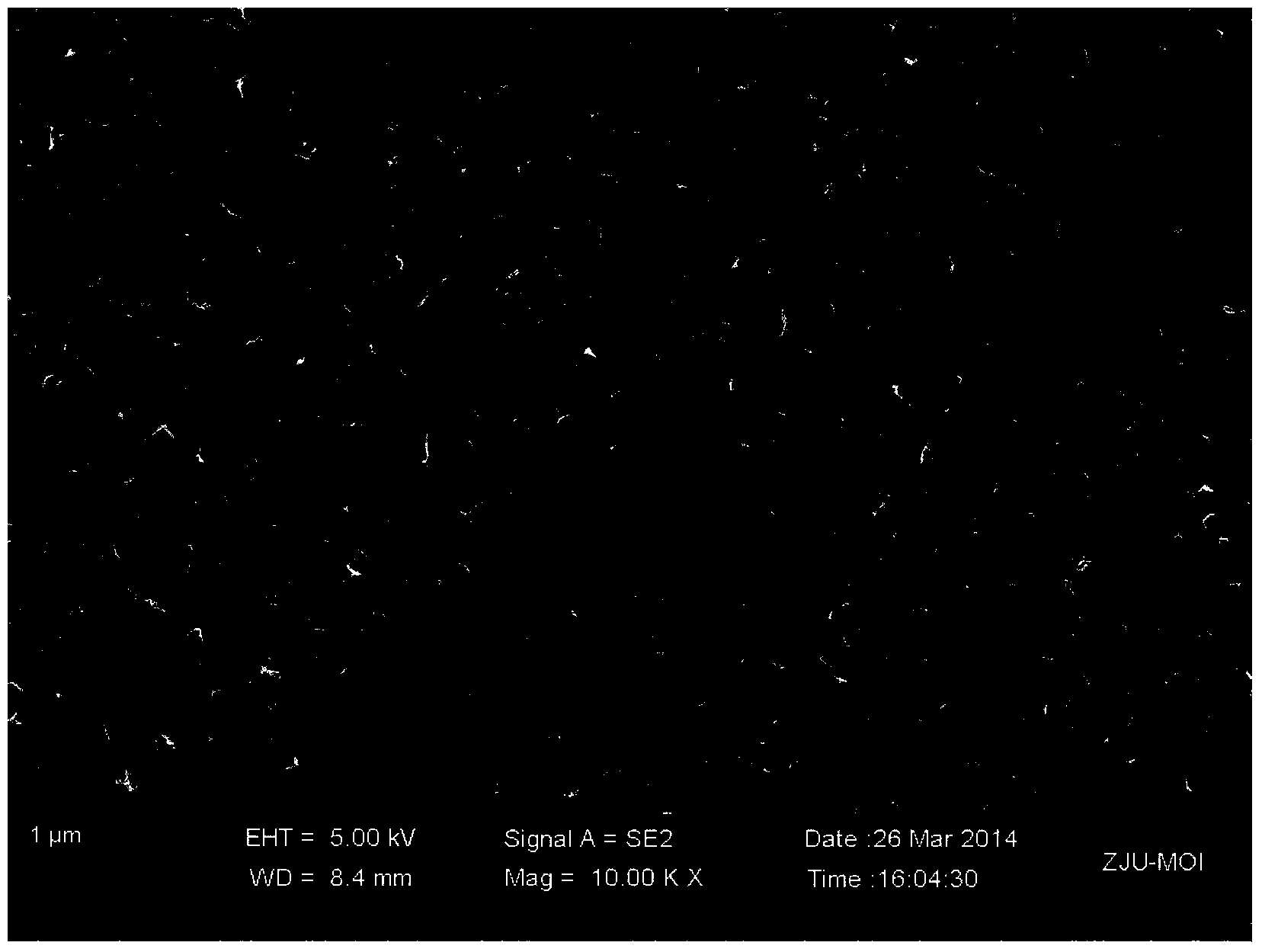

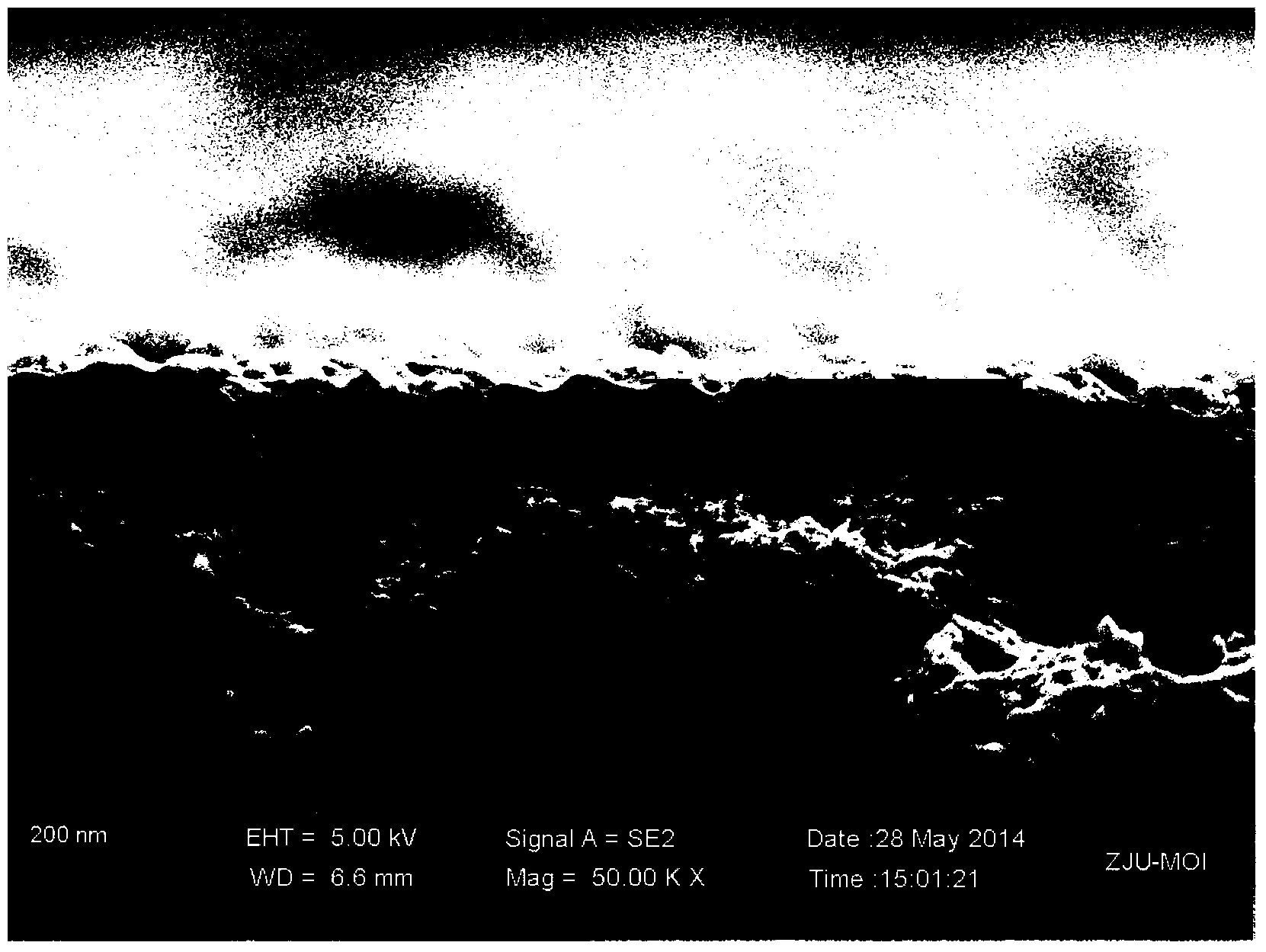

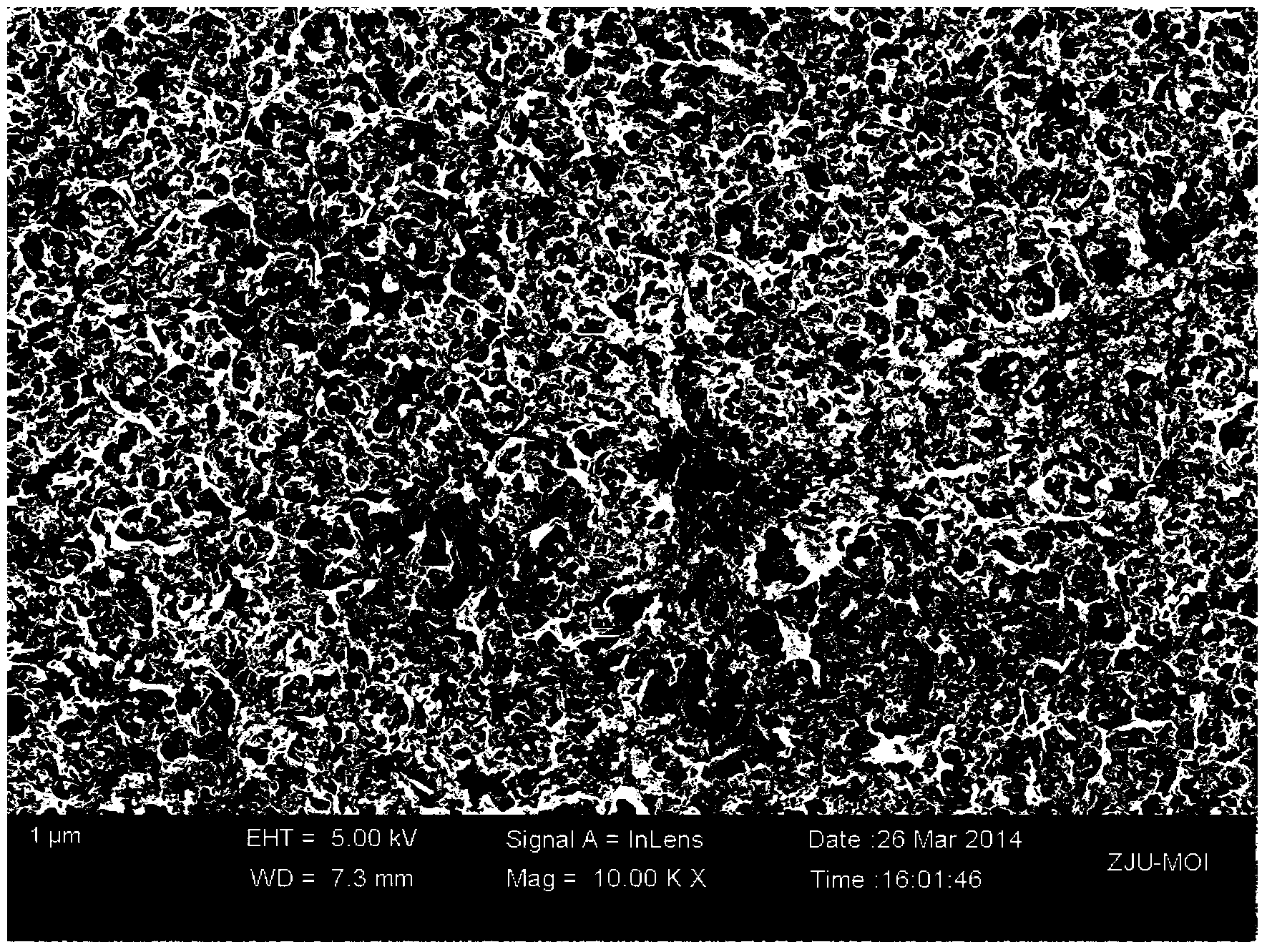

[0042] (3) Under normal temperature and pressure, the polyamide reverse osmosis membrane was immersed in the solution of positively charged substances for 4 hours, and the amino group on the hyperbranched polyethyleneimine and the polyamide RO membrane (polyamide reverse osmosis membrane) were catalyzed by EDC / NHS. ) reacted with the carboxyl groups on the surface, so that a large amount of positively charged ...

Embodiment 2

[0047] (1) Prepare an aqueous solution of a positively charged substance, which contains 0.05 g / mL of tetraethylenepentamine, 0.0025 g / mL of EDC and 0.004 g / mL of NHS.

[0048] (2) Configure an aqueous solution of negatively charged substances, which contains 0.03g / mL of acrylic acid and 0.0003g / mL of p-benzoquinone, wherein p-benzoquinone is used as a polymerization inhibitor of acrylic acid to prevent acrylic acid from occurring in the reaction process. polyreaction.

[0049] (3) Under normal temperature and pressure, the polyamide reverse osmosis membrane is immersed in the solution of positively charged substances for 4 hours, and the amino group on the tetraethylenepentamine reacts with the carboxyl group on the surface of the polyamide RO membrane under the catalysis of EDC / NHS, so that A large amount of positively charged tetraethylenepentamine was grafted on the surface of polyamide RO membrane.

[0050] (4) Rinse the polyamide RO membrane grafted with tetraethylenepe...

Embodiment 3

[0053] (1) Prepare an aqueous solution of a positively charged substance, which contains 0.005g / mL of 4-amino-3-hydrazino-5-mercapto-1,2,4-triazole, 0.0025g / mL of EDC and 0.004g / mL of NHS.

[0054] (2) Configure an aqueous solution of negatively charged substances, which contains 0.03g / mL of acrylic acid and 0.0003g / mL of p-benzoquinone, wherein p-benzoquinone is used as a polymerization inhibitor of acrylic acid to prevent acrylic acid from occurring in the reaction process. polyreaction.

[0055] (3) Immerse the polyamide reverse osmosis membrane in the solution of positively charged substances for 5 hours at normal temperature and pressure, and 4-amino-3-hydrazino-5-mercapto-1,2,4-tri The amino group on the azole reacts with the carboxyl group on the surface of the polyamide RO membrane, so that a large number of positively charged 4-amino-3-hydrazino-5-mercapto-1,2,4- Triazole.

[0056] (4) Rinse the polyamide RO membrane grafted with 4-amino-3-hydrazino-5-mercapto-1,2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com