Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

A water-based polyurethane, two-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor dispersion stability of matting powder, increase the complexity of construction process, uneven dispersion of matting powder, etc., and achieve matting Remarkable effect, stable and uniform dispersion effect, good cross-linking and curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

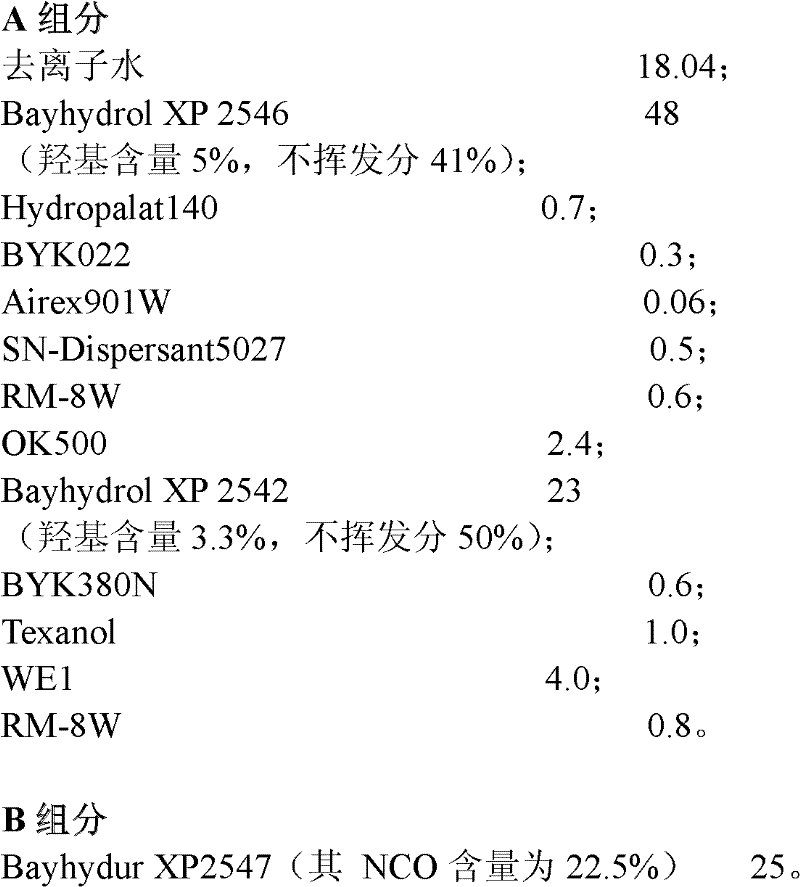

[0031] Two-component water-based polyurethane wear-resistant matte varnish consists of A and B components.

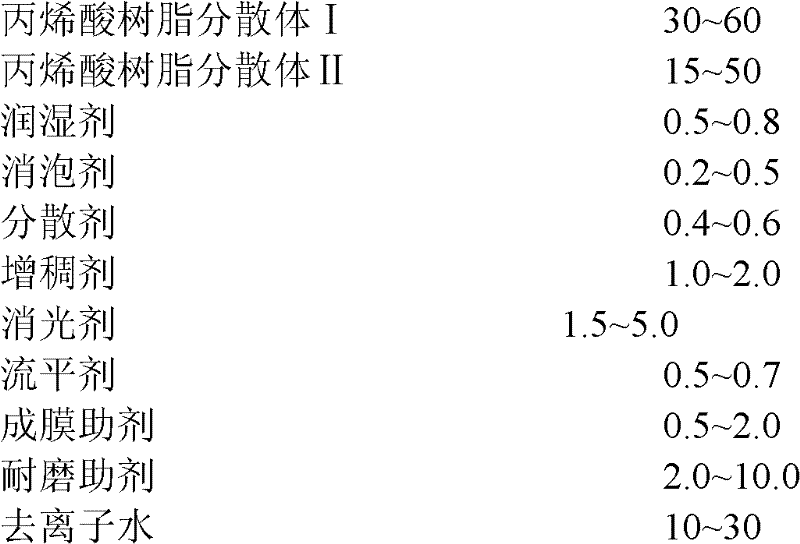

[0032] The components A and B are composed in parts by weight as follows:

[0033]

[0034] The manufacturing method is as follows: the two-component water-based polyurethane wear-resistant matte varnish is prepared from component A and component B. The preparation process of component A is as follows: First, add deionized water into the dispersing tank, start the dispersing machine, adjust the speed to 800 rpm, and put in Bayhydrol XP 2546, wetting agent, defoamer, dispersant, thickener, Matting agent, adjust the speed at 1500 rpm, fully disperse for 20-30 minutes; adjust the speed at 300-500 rpm, then add Bayhydrol XP 2542, leveling agent, film-forming aid, wear-resistant additive, thickener, continue Disperse for 10-15 minutes. After the dispersion is completed, the material is discharged. A component is prepared. B component is Bayer's water-based polyurethan...

Embodiment 2

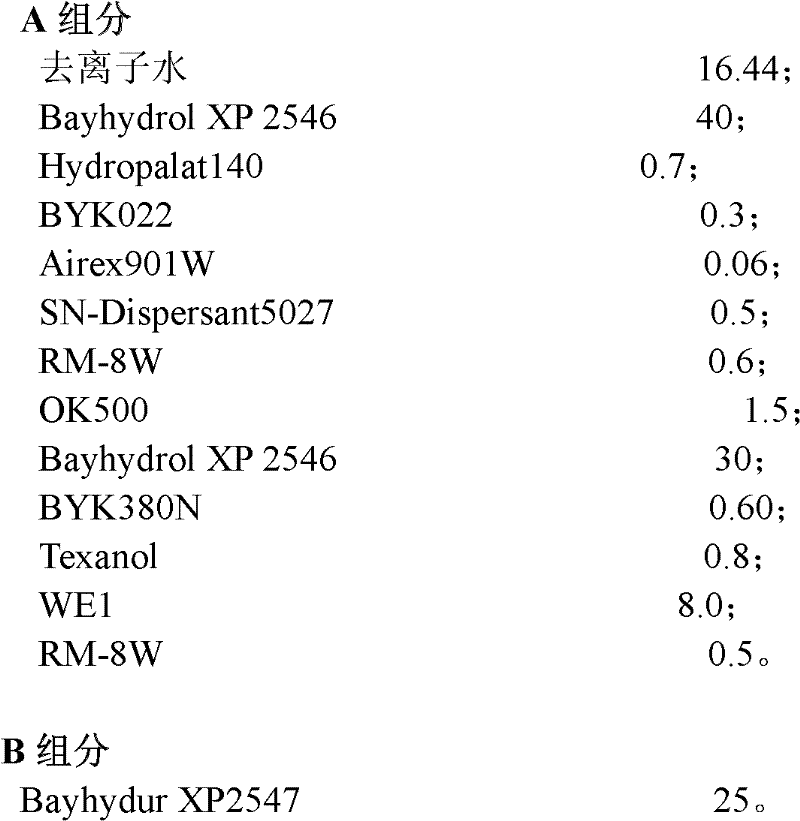

[0038] Two-component water-based polyurethane wear-resistant matte varnish consists of A and B components.

[0039]The components A and B are composed in parts by weight as follows:

[0040]

[0041] The manufacturing method and film-making method are the same as in Example 1.

[0042] The test results are shown in Table 1.

Embodiment 3

[0044] Two-component water-based polyurethane wear-resistant matte varnish consists of A and B components.

[0045] The components A and B are composed in parts by weight as follows:

[0046]

[0047]

[0048] The manufacturing method and film-making method are the same as in Example 1.

[0049] The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com