Edible fungus inoculation working system

A working system and technology of edible fungus, applied in application, horticulture, botanical equipment and methods, etc., can solve the problems of large damage to human body, inconvenient operation, and low service life of equipment, so as to improve the yield of inoculation and reduce production cost , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the specific embodiments and accompanying drawings.

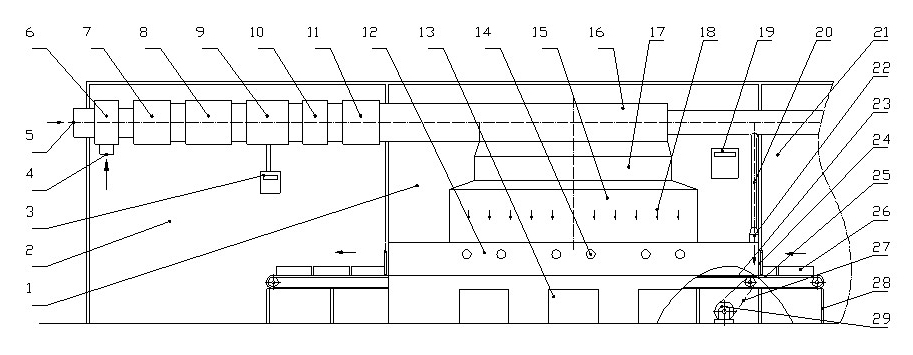

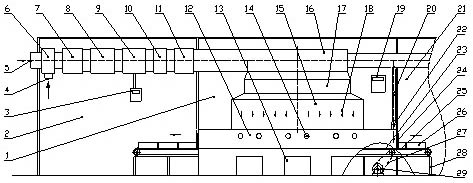

[0015] The edible fungus inoculation working system of the present invention is composed of a fungus bag transmission system, an air filtration disinfection circulation system and the like.

[0016] Reference attached figure 1 , the bacteria bag transmission system includes a conveyor belt (25) driven by a conveyor belt motor (29) and a chain drive (27) supported on a conveyor belt bracket (28). The left and right partition walls of the inoculation room (1) are respectively equipped with loose-leaf dampers (24). The bacteria bag flow box (26) placed above the conveyor belt enters the inoculation room from the cooling room (21) through the right damper door, and then is sent to the buffer room (2) through the left damper door. Below the transmission belt in the inoculation chamber is provided with a windshield (23) that runs through the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com