Absorption oil-gas recycling system and absorption oil-gas recycling process

A recycling and adsorption technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high environmental requirements, high power consumption, high cost, and achieve significant energy saving and environmental protection, easy to reuse, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

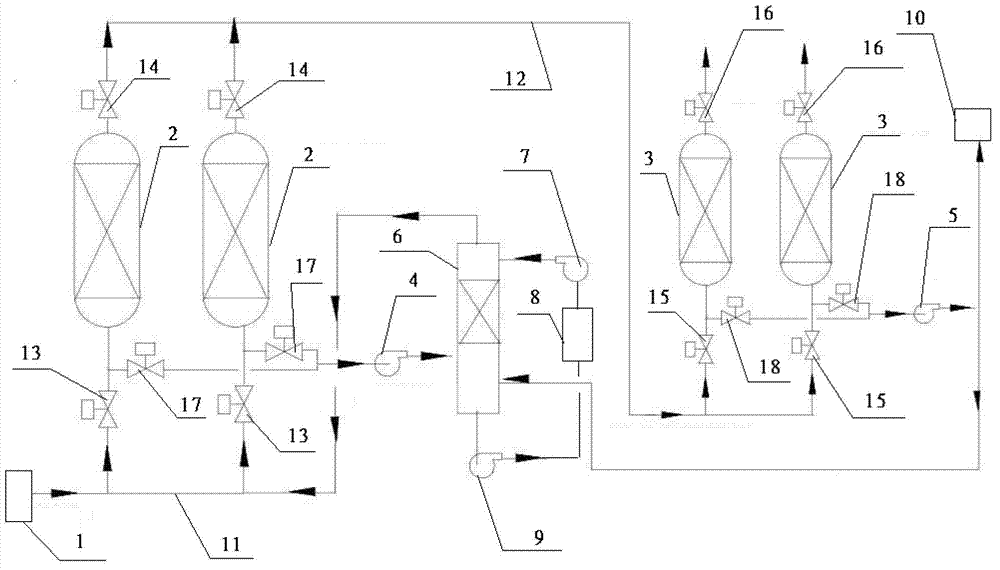

[0047] Such as figure 1 As shown, the adsorption oil and gas recovery treatment system of the present invention includes a control system (not shown in the figure) and an oil and gas input system 1 controlled by the control system, an adsorption device, a desorption device, an absorption device and a storage device connected to each other; The adsorption device is connected with the oil and gas input system 1; wherein:

[0048] The absorption device includes an absorption tower 6 and an absorbent supply device connected to the absorption tower 6, and the absorbent supply device includes an absorbent delivery pump 7 and an absorbent storage tank 8 connected to each other;

[0049] The desorption device is a secondary desorption device, including a first-stage desorption vacuum pump 4 and a second-stage desorption vacuum pump 5 connected to the absorption tower 6;

[0050] The storage device includes a liquid storage device and a gas storage device 10, the liquid storage device...

Embodiment 2

[0083] Such as figure 1 As shown, the setting and distribution of an adsorption oil gas recovery treatment system are the same as in Embodiment 1.

[0084] Applying the adsorption type oil gas recovery treatment system of the present invention to carry out crude oil gas recovery treatment process is the same as embodiment 1, except the following steps:

[0085] In step (2), the concentration of the effluent is measured to reach 30g / m by analyzing the online concentration analyzer 3 , alternately replace the first-stage adsorption tower 2 and / or the second-stage adsorption tower 3 for adsorption; the specific surface of the adsorbent activated carbon is 240,000m 2 / kg;

[0086] In step (3), the vacuum degree during the desorption of the first-stage desorption vacuum pump 4 and the second-stage desorption vacuum pump 5 is 90kpa;

[0087] In step (4), the absorbent is gasoline, and the flow rate of gasoline circulated through the absorbent delivery pump 7 is 80m 3 / h.

[008...

Embodiment 3

[0090] Such as figure 1 As shown, the setting and distribution of an adsorption oil gas recovery treatment system are the same as in Embodiment 1.

[0091] Applying the adsorption type oil gas recovery treatment system of the present invention to carry out crude oil gas recovery treatment process is the same as embodiment 1, except the following steps:

[0092] In step (2), the concentration of the effluent is measured to reach 25g / m by analyzing the online concentration analyzer 3 , alternately replace the first-stage adsorption tower 2 and / or the second-stage adsorption tower 3 for adsorption; the specific surface of the adsorbent activated carbon is 200,000m 2 / kg;

[0093] In step (3), the vacuum degree during desorption of the first-stage desorption vacuum pump 4 and the second-stage desorption vacuum pump 5 is 85kpa;

[0094] In step (4), the absorbent is diesel oil, and the flow rate of the diesel oil to be circulated through the absorbent delivery pump 7 is 50m 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com