Rear suspension point swinging device for suspended edge roller

The technology of a swing device and an edger, which is applied in the field of glass machinery, can solve the problems that the requirements of ultra-thin glass production cannot be fully met, the processing and appearance, the running accuracy cannot be achieved, and the operation of the floor-type edger is inflexible. Achieve the effect of high operation and adjustment accuracy, low friction coefficient and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

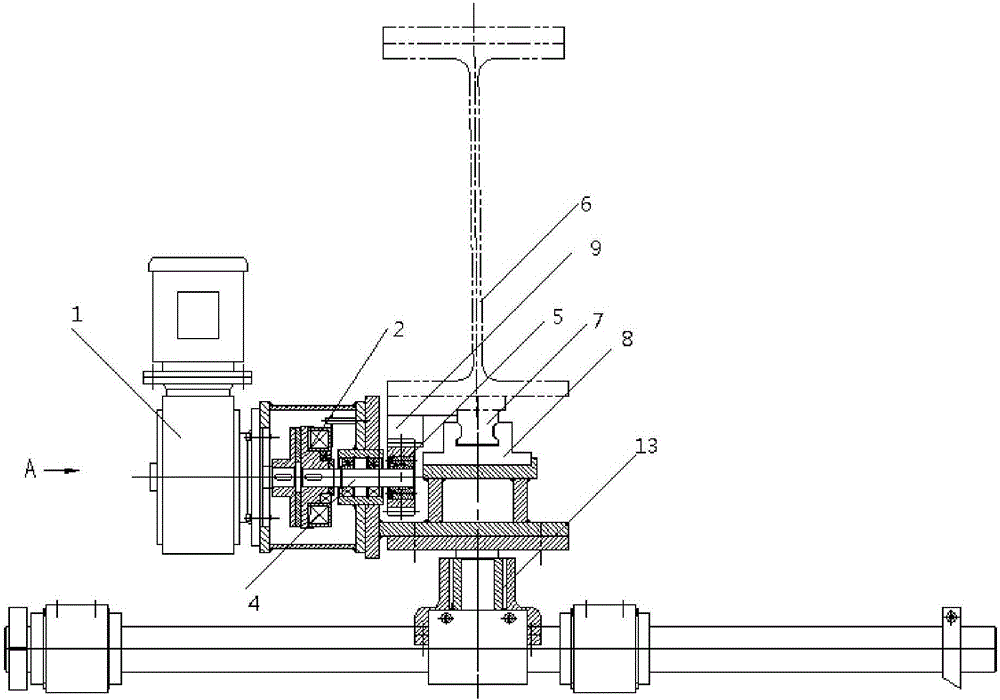

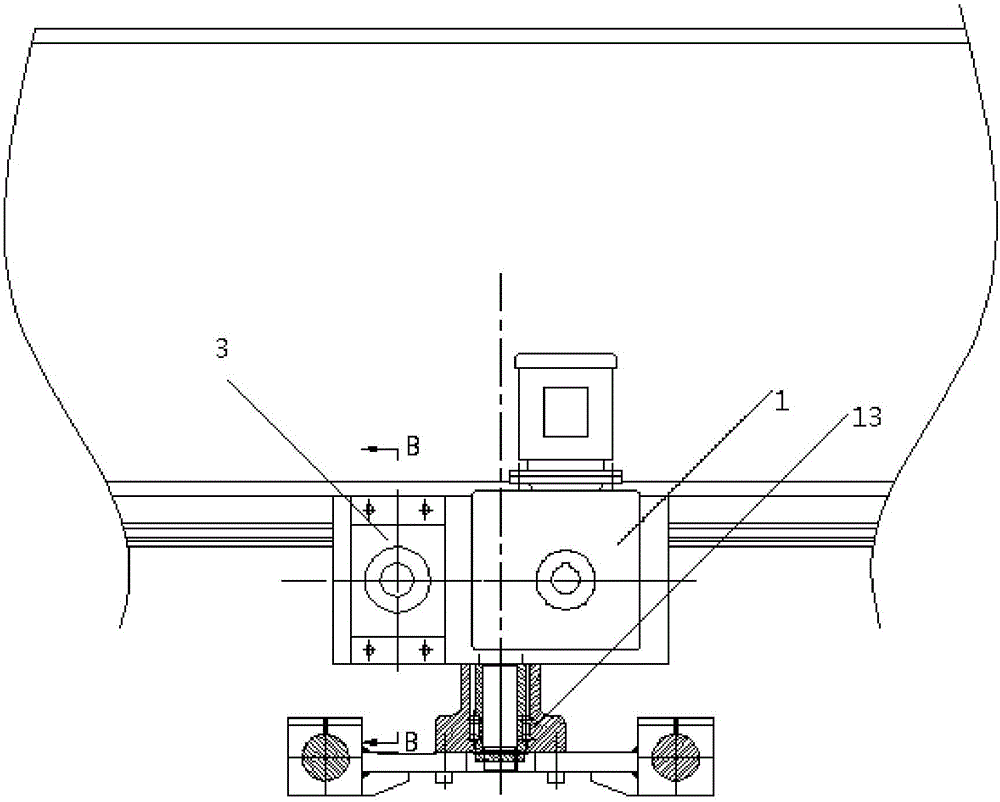

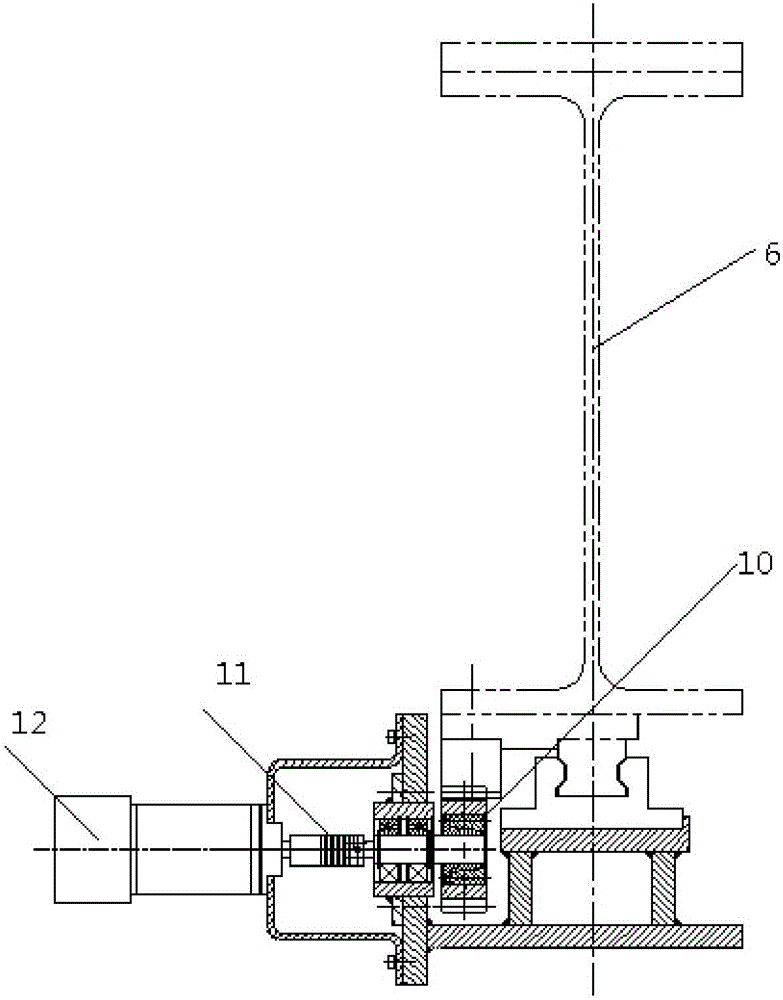

[0016] Referring to the accompanying drawings, a new type of rear suspension point swing device for hanging edge pulling machine includes a motor reducer 1, an electromagnetic clutch 2, and a position detector 3. The electromagnetic clutch 2 is installed on the driving shaft 4, and the other end of the driving shaft 4 is installed with a The driving gear 5 and the bottom of the rear suspension point device 6 are slidably installed on the frame 8 of the edge pulling machine through the linear guide rail pair 7, and a rack 9 is installed on one side of the rear suspension point device 6 to cooperate with the driving gear 5; the position detector 3 includes There is a driven detection gear 10, an elastic coupling 11, and a rotary encoder 12. The rack 9 of the rear suspension point device 6 cooperates with the driven detection gear 10. The rear suspension point device 6 is installed on the pull side through a rotating hub bearing 13. Machine rack 8.

[0017] The detection device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com