Hydrogen oxygen combustion-supporting device for improving combustion efficiencies of kiln in blown glass factory and boiler in power plant

A boiler combustion, hydrogen-oxygen technology, applied in glass furnace equipment, combustion methods, combustion equipment and other directions, can solve the problems of high cost, low heating efficiency, insufficient fuel combustion, etc., to promote cracking, improve combustion efficiency, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

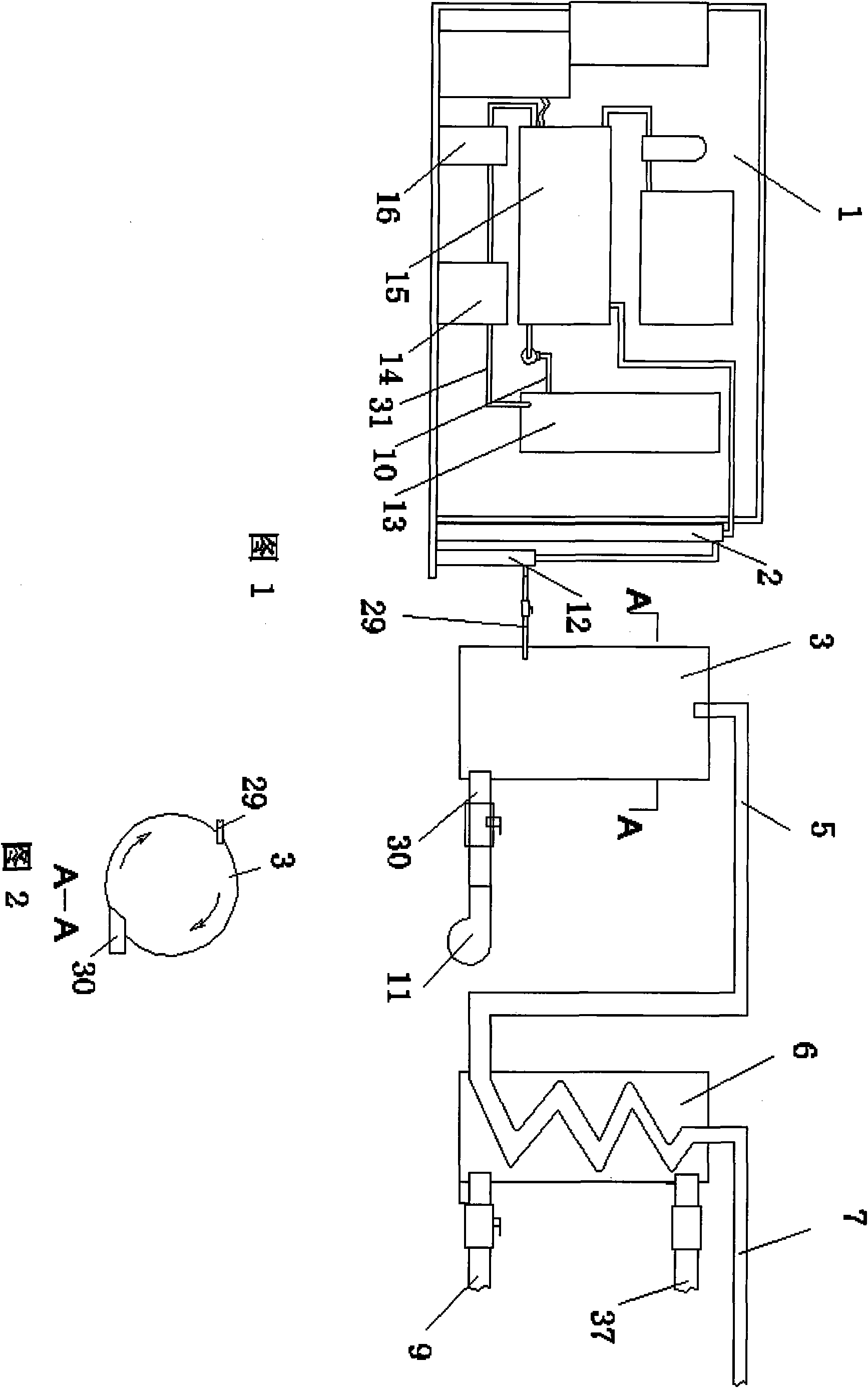

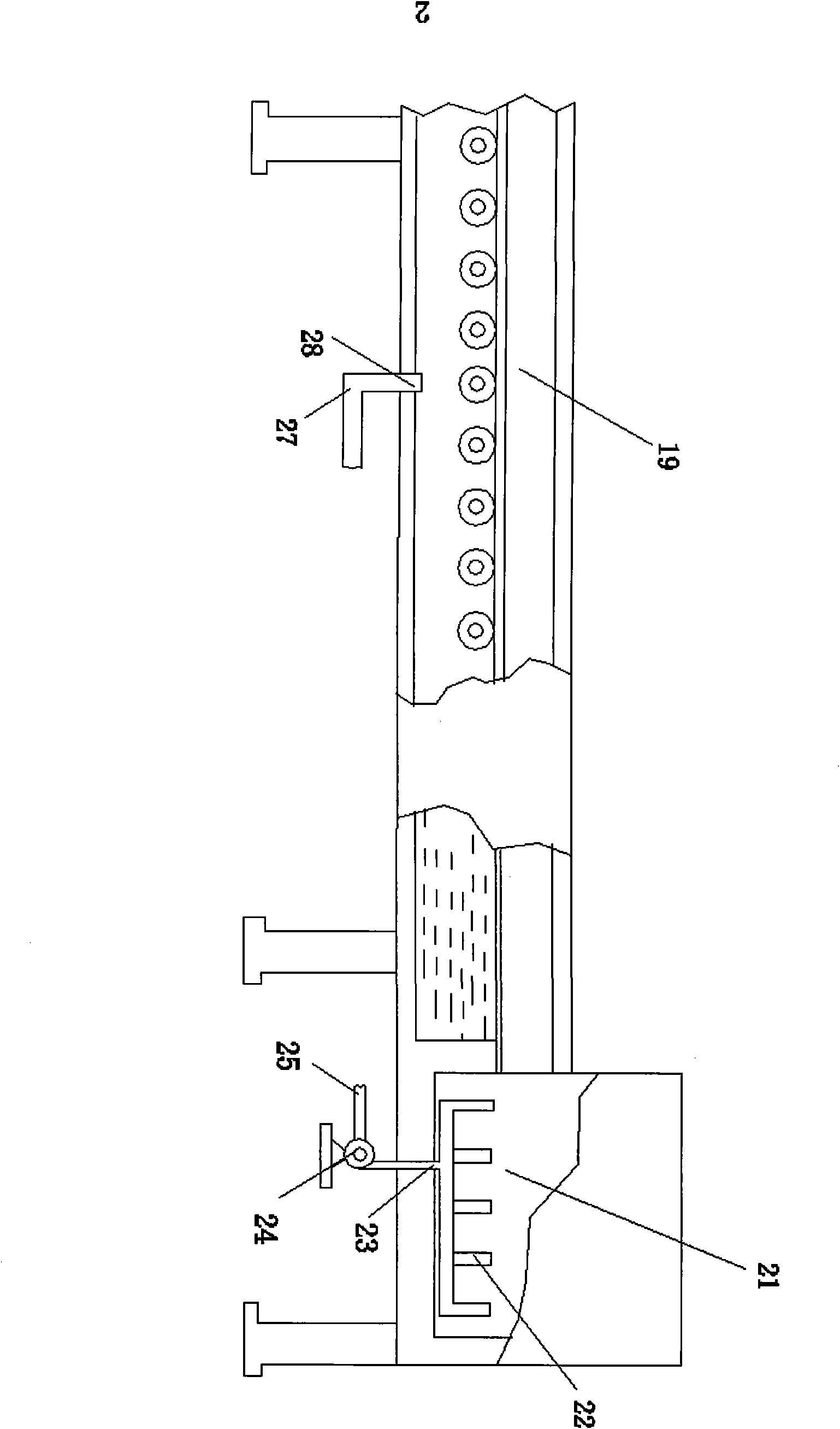

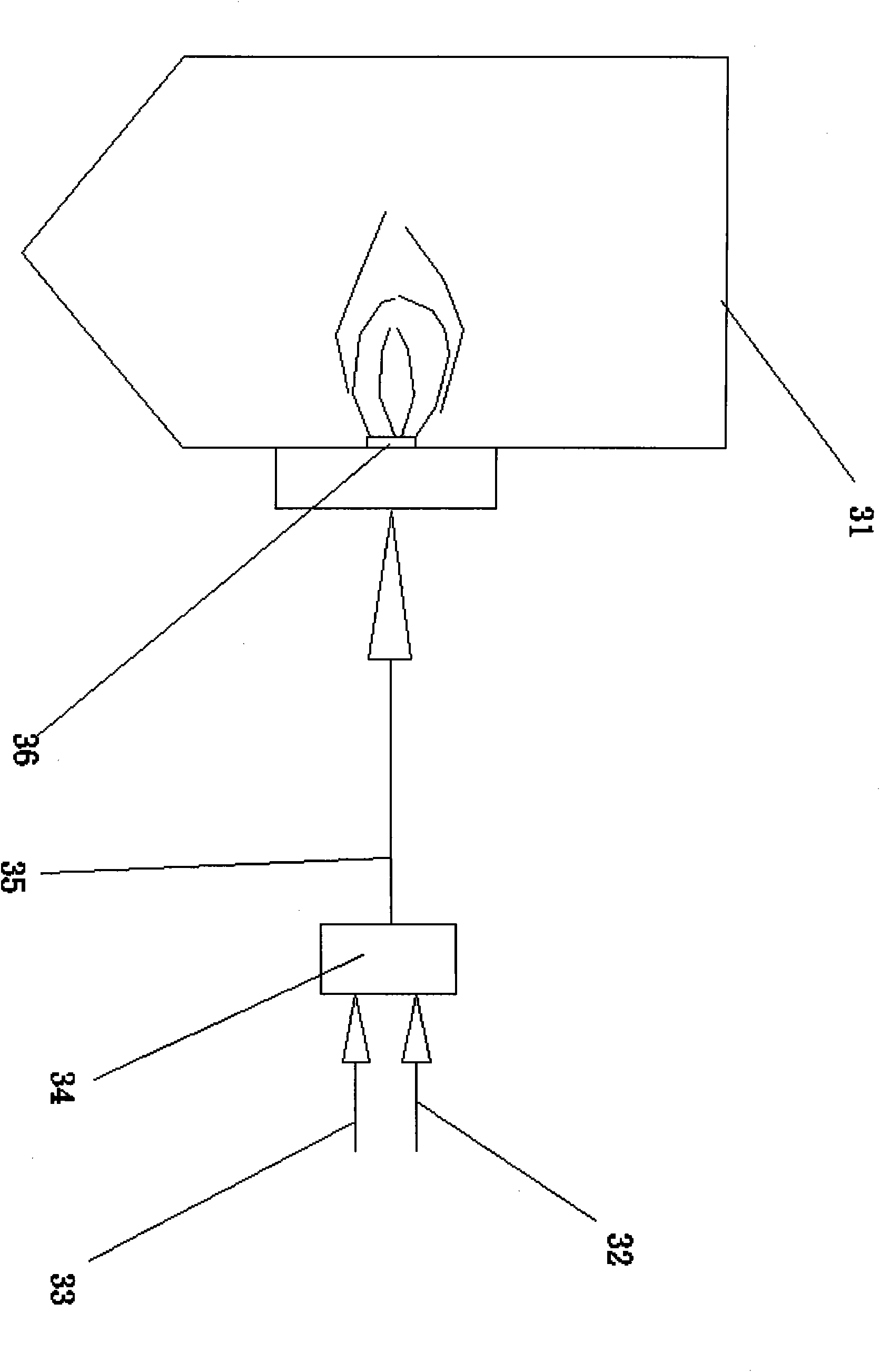

[0017] refer to Figure 1 to Figure 4 It can be seen that the present invention comprises: oxyhydrogen machine 1, oxyhydrogen mixing tank 3, heating tank 6, mixing blower 11, described oxyhydrogen machine 1 is provided with an ultrasonic activator 14 for activating water and a magnetization activation device 16, the The activation device is arranged in the circulating water path of the electrolytic cell 15, the water outlet pipe 10 of the electrolytic cell circulating water is connected with the water inlet pipe of the radiator 13, the water outlet pipe 31 of the radiator is connected with the water inlet pipe of the ultrasonic activator 14, and the ultrasonic activator The outlet pipe of the magnetic activator is connected to the water inlet pipe of the magnetic activation device 16, and the outlet pipe of the magnetic activator is connected to the electrolytic cell 15. The ultrasonic activator is arranged in a closed shell container, and the circulating water enters from one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com