Bracket capable of quickly bonding and curing with window glass

A kind of window glass, fast technology, applied in door/window accessories, wing fan control mechanism, construction and other directions, can solve the problems of small contact area between PU glue and air, long curing time of PU glue, etc., to reduce the production accuracy and installation difficulty, improve curing efficiency, and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

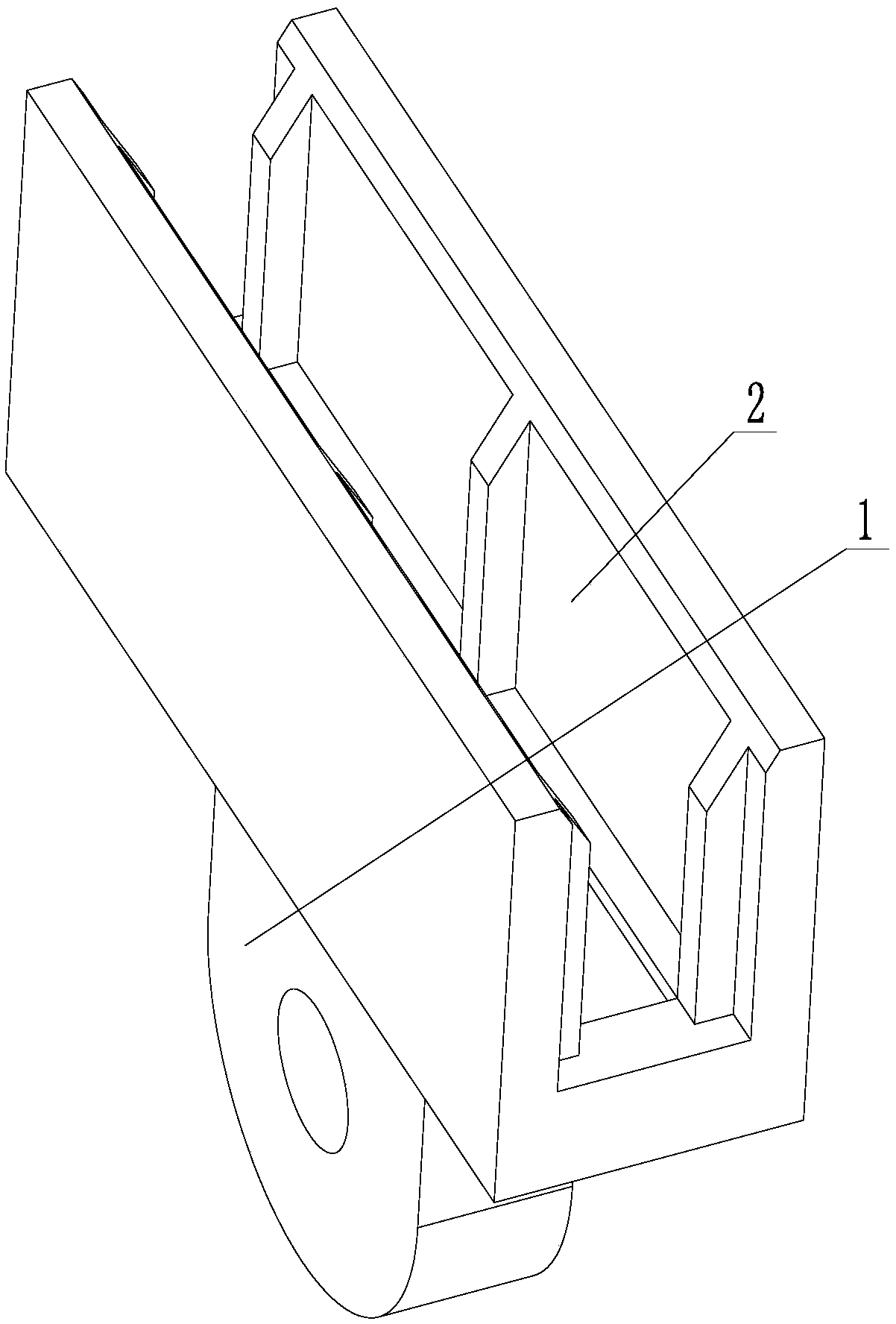

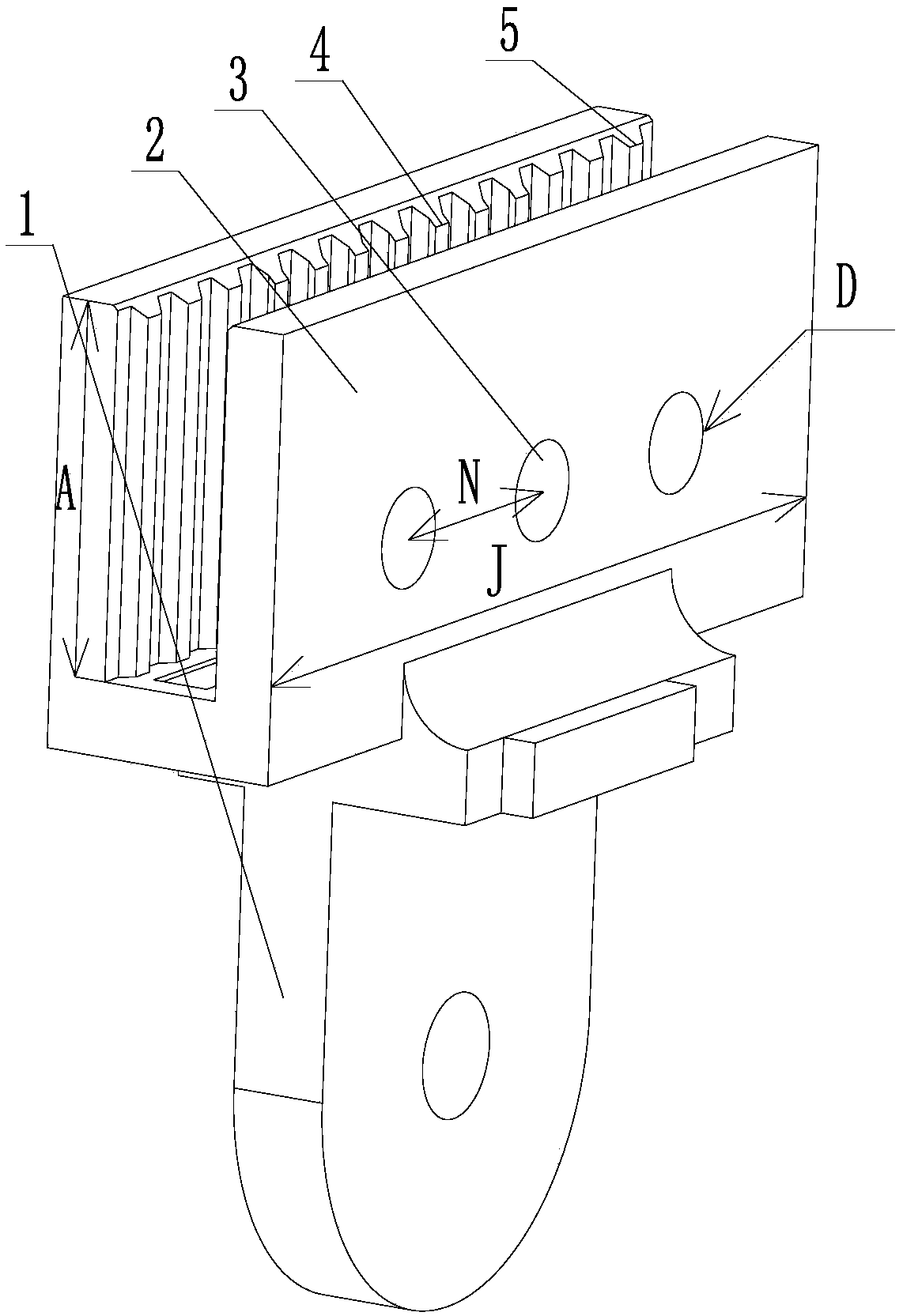

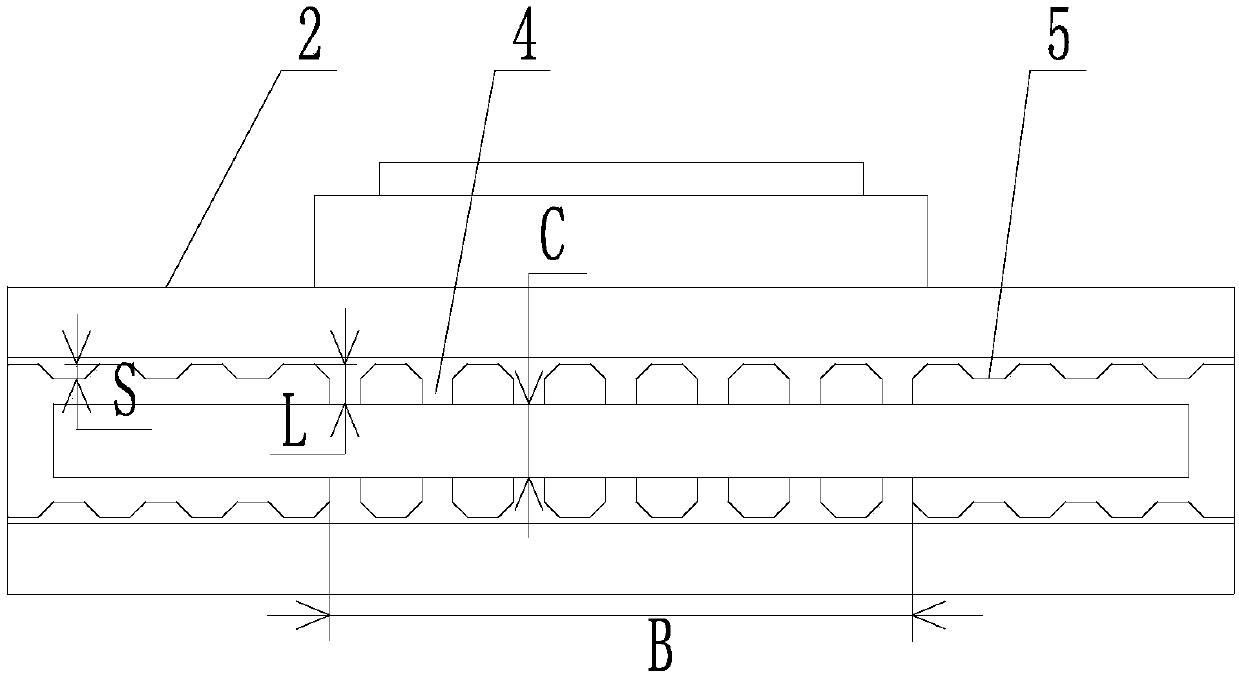

[0015] The invention relates to a bracket capable of fast bonding and curing with the window glass, which comprises a bracket body 1 and a pair of splints 2 arranged on the upper end of the bracket body 1. The inner wall of the splint 2 is provided with ribs, and the ribs and PU glue is arranged in the tank body formed by glass, the key is that a group of air holes 3 are arranged at intervals on the splint 2, and the ratio of the length J of the splint 2 to the distance N between the air holes 3 is 3 -6.

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] Specific examples, such as Figure 2-5 As shown, the length of splint 2 in the present embodiment is 40mm, the glass thickness is 4mm, the ratio of width B of middle main rib 4 to glass thickness C is 4-6, and the width B of middle main rib 4 and the length ratio of splint 2 are 0.4-0.6, the thickness of the splint 2 is about 2.5mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com