Composite fuel oil

A technology for fuel oil and solvent oil, applied in the direction of fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problem of difficult industrialization, and achieve the effect of low production cost, high cost performance and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

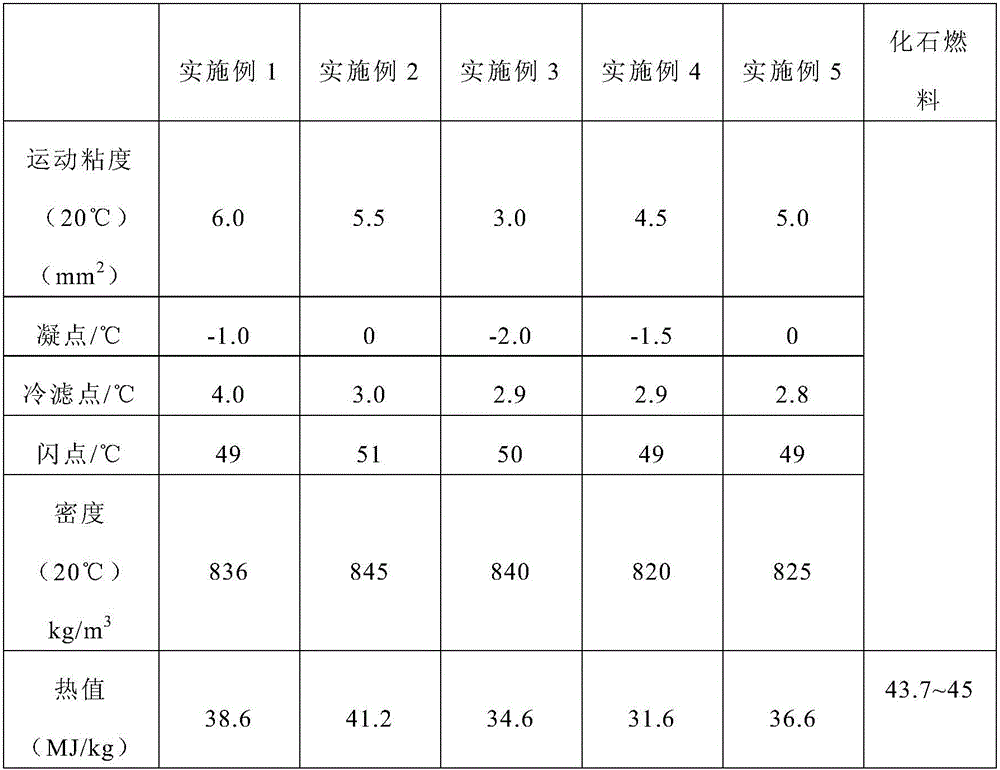

Embodiment 1

[0020] A kind of compound fuel oil, by mass percentage, comprises fossil fuel oil 60%, solvent oil 30%, waste oil 10%, and compound fuel oil also comprises the additive of 1‰, and additive is the mass part ratio and is compatibilizer: anti- Smoke agent: anti-coking agent: antioxidant: pour point depressant = 10:6:4:1:1 mixture, wherein in this implementation the compatibilizer is maleic anhydride grafted polyolefin elastomer, and the anti-smoke agent is mass Parts ratio naphthenate: isooctanoate: mixture of surfactant=2:2:1, surfactant is preferably sodium dodecylbenzene sulfonate, anti-coking agent is potassium periodate, anti-coking agent The oxidant is tea polyphenol palmitate, the pour point depressant is preferably methanol, the calorific value of the prepared composite fuel oil reaches 38.6MJ / kg, and the kinematic viscosity is 6.0mm 2 , and the freezing point is -1.0°C.

Embodiment 2

[0022] A kind of compound fuel oil, by mass percentage, comprises fossil fuel oil 70%, solvent naphtha 30% and the additive of 1 ‰, and additive is that the ratio of mass and number is compatibilizer: antismoke agent: anticoking agent: antioxidant=10 : the mixture of 8:5:1, in the present embodiment, the compatibilizer is preferably maleic anhydride grafted ethylene-vinyl acetate copolymer, and the anti-smoke agent is the ratio by mass and number of naphthenate: isooctanoate: Surfactant=2:2:1 mixture, the surfactant is preferably stearic acid, the coking agent is potassium permanganate, the antioxidant is hindered phenol, the pour point depressant is isooctanoate, and the prepared composite fuel oil The calorific value reaches 41.2MJ / kg, and the kinematic viscosity is 5.5mm 2 , the freezing point is 0°C.

Embodiment 3

[0024] A kind of compound fuel oil, comprises fossil fuel oil 50%, solvent naphtha 20%, waste oil 25%, coal tar 5% and 1‰ additive by mass percentage, additive is the mass part ratio and is compatibilizer: anti- Smoke agent: anti-coking agent: antioxidant: pour point depressant = 10:5:5:1:1 mixture, and the compatibilizer is preferably maleic anhydride grafted low-density polyethylene, and the anti-smoke agent is the mass-number ratio Naphthenate: isooctanoate: surfactant = 2:2:1 mixture, the surfactant is a mixture of stearic acid and sodium dodecylbenzenesulfonate, and the anti-coking agent is dicyclopentadiene Alkenyl iron, the antioxidant is amino compound, the pour point depressant is methanol, the calorific value of the prepared composite fuel oil reaches 34.6MJ / kg, and the kinematic viscosity is 3.0mm 2 , and the freezing point is -2.0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com