Fine particle polymerizer and high-efficiency dedusting defogging integrated system

A technology of fine particles and aggregators, applied in the field of flue gas purification, can solve problems such as inability to judge technical links, inability to diagnose and eliminate defects, and inability to achieve the effect of collaborative governance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

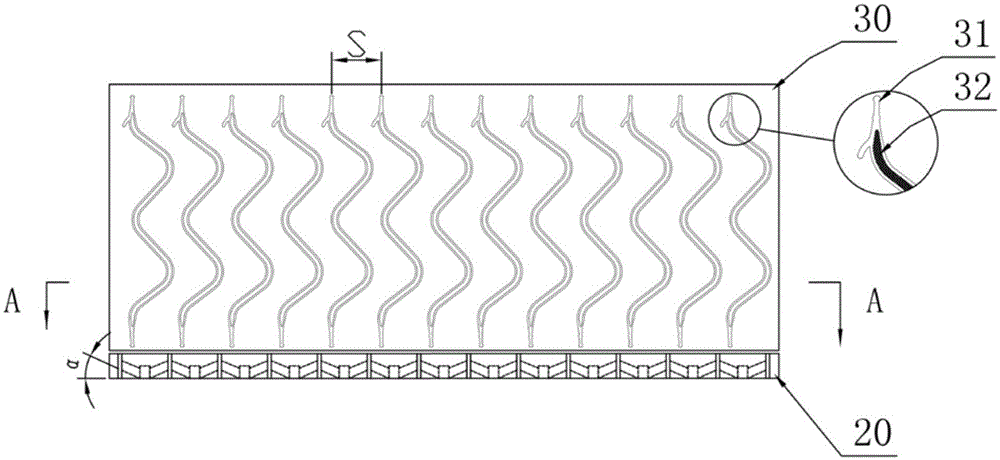

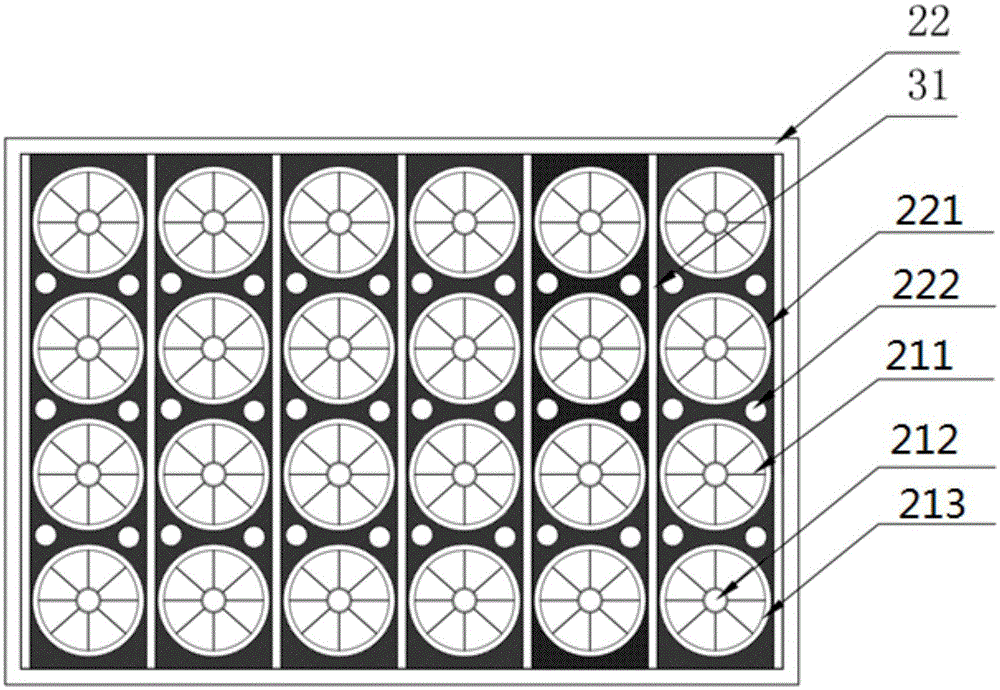

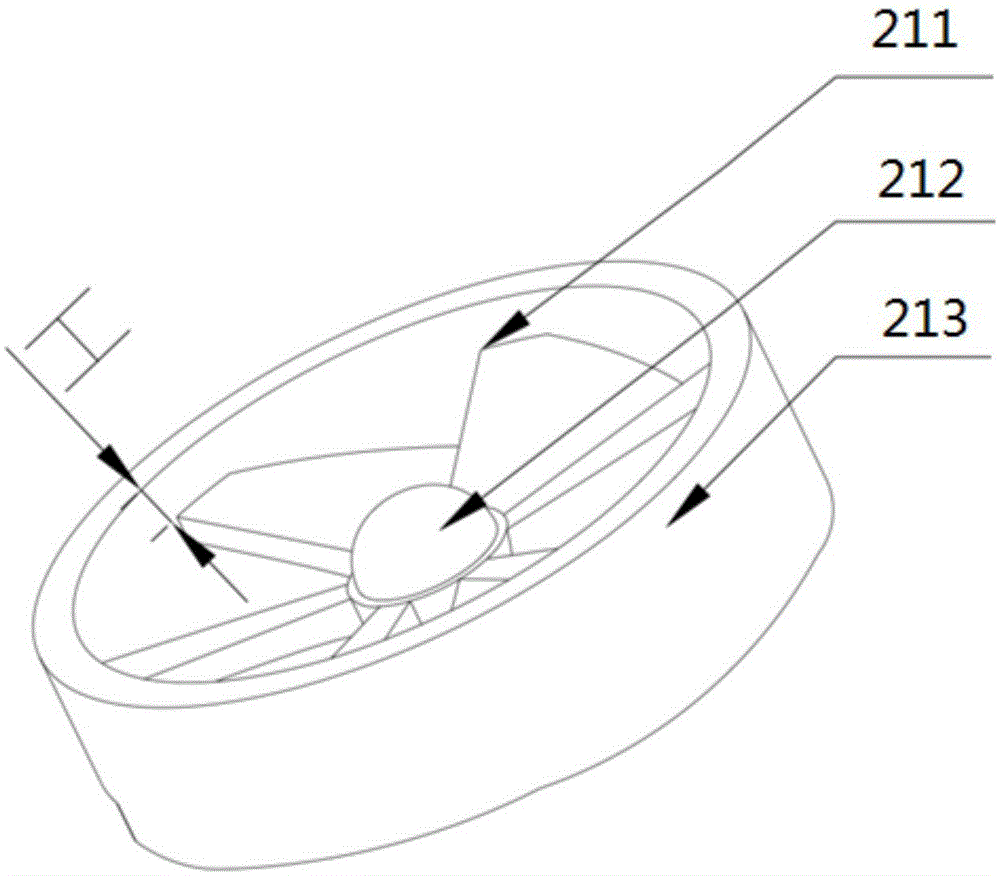

[0116] As attached figure 1 As shown, the first solution of the integrated high-efficiency dust removal and mist removal system of this embodiment is that the integrated dust removal and mist removal system is installed in the absorption tower. The system includes two parts: a fine particle polymerizer 20 and a condensation wet film centrifugal separator 30. The fine particle polymerizer 20 and the condensed wet film centrifugal separator 30 are arranged on the cross section of the flue gas flow containing fine particles. The plane where the fine particle aggregator 20 is located and the plane where the condensation wet film centrifugal separator 30 is located are substantially perpendicular to the direction of the flue gas flow.

[0117] The fine particle polymerizer 20 and the condensed wet film centrifugal separator 30 are installed on a layer of support beams.

[0118] The lower part of the fine particle polymerizer 20 and the upper part of the condensed wet film centrifugal se...

Embodiment 2

[0139] Such as Picture 9 As shown, the integrated dust removal and mist removal system of this embodiment includes a first-stage pre-processor 10, a fine particle polymerizer 20, a condensed wet film centrifugal separator 30 (or corrugated plate gas-liquid separator), and an ultra-fine separator 40. And all are installed in the absorption tower.

[0140] After the boiler tail gas passes through the electrostatic precipitator, the smoke and dust concentration is ≤20mg / Nm 3 Enter the desulfurization absorption tower 60. In the absorption tower 60, there are 3-6 layers of spraying layers 70 and possibly 1 or 2 layers of trays or FGD Plus 80. The flue gas passes through the trays or FGD Plus 80 and spraying layer 70 and then undergoes pretreatment in sequence Reactor 10, fine particle polymerizer 20, condensed wet film centrifugal separator 30, and ultrafine separator 40. Picture 9 The arrow in indicates the flow direction of the smoke.

[0141] The pre-separator 10 includes a prima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com