Bending-folding machine of sheet glass

A flat glass, bending and folding technology, used in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve problems such as inability to achieve, and achieve the effect of reducing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

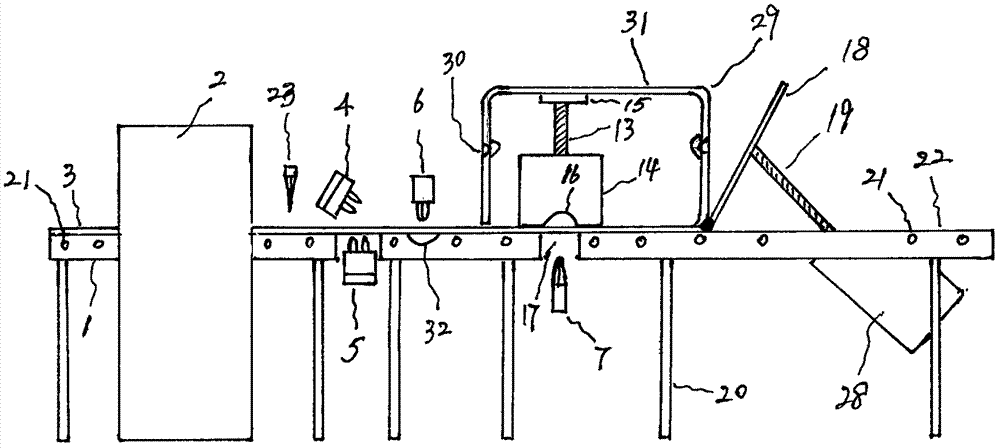

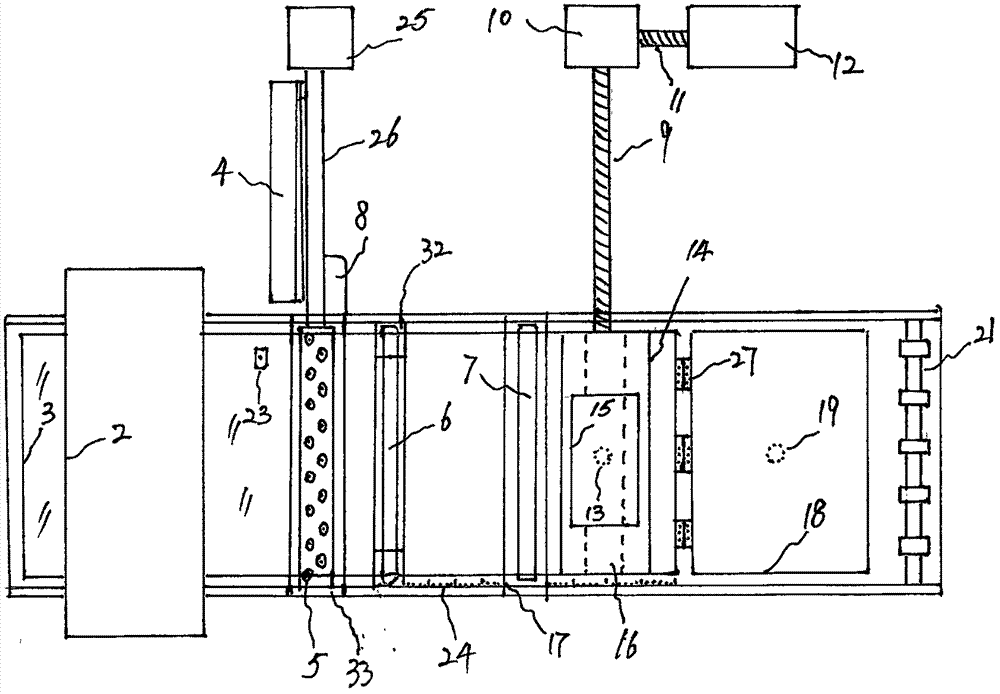

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0012] see figure 1 , the plate glass (3) on the glass roller assembly line (1) is sent to the hot melting furnace (2) by the electric roller (21) for preheating, and passes through the upper fire row (4) and the lower fire row (5) During the high-temperature combustion process to soften again, use the electric concave bar (6) at the pressure groove (32) to pre-thin the glass concave edge (29) that needs to be bent and shaped at 90 degrees, and the flat glass (3) needs When the glass is convex and curved (30), the electric top convex bar (7) can be used at the mouth of the assembly line (17) to push the flat glass (3) that has been processed and softened to the groove position (16) of the top convex bar. type; the flat glass (3) softened and thinned in three places in advance, drives the bending plate propulsion rod (19) with the bending plate pusher (28), and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com