TOUGH THREAD, core yarn, braided fabric and glove

A technology of strong thread and braid, applied in the field of strong thread and its core thread, braid and gloves, can solve the problems of wearer discomfort, easy exposure of hard fibers, discomfort of inorganic fibers, etc., and achieve a good skin touch , Excellent softness and fit, the effect of excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

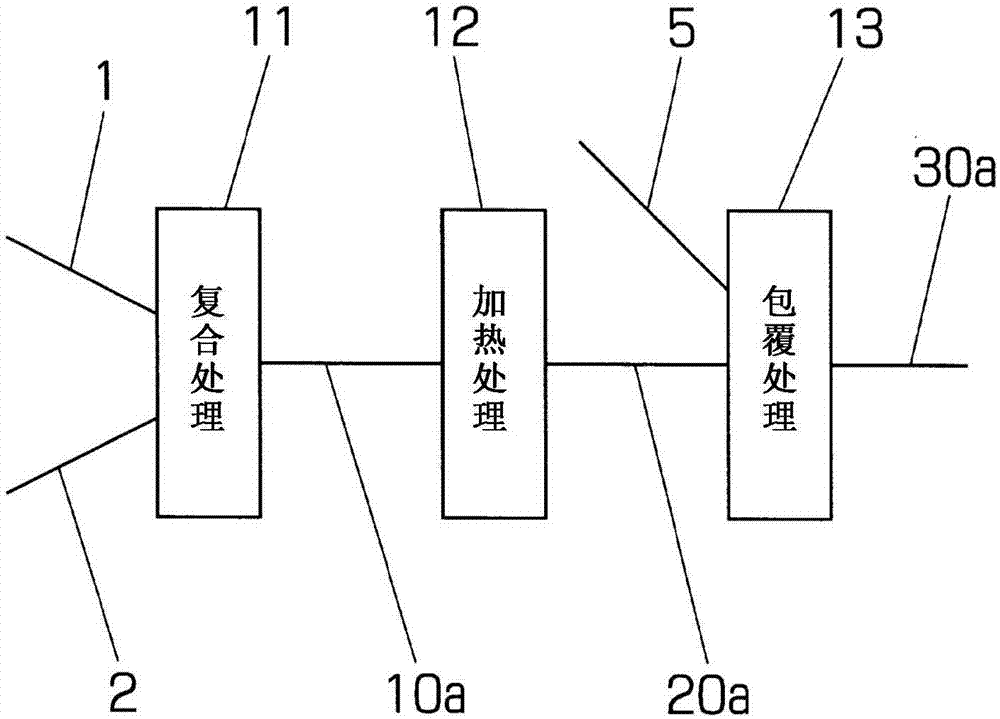

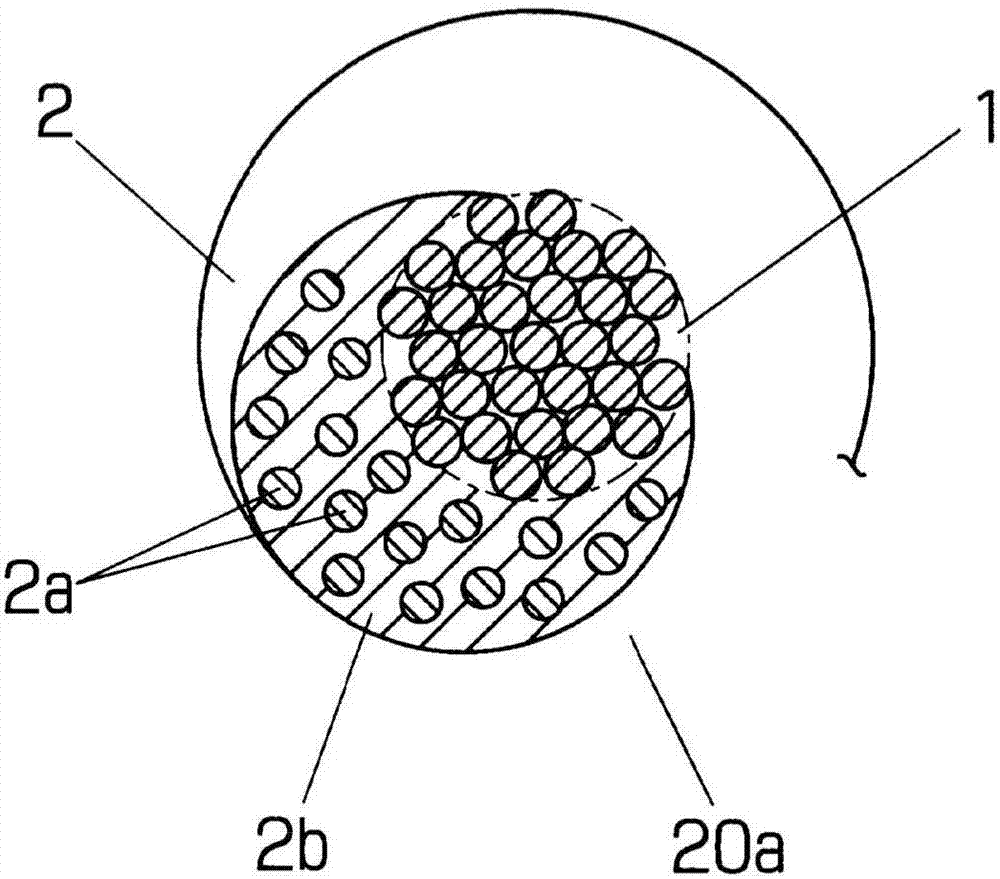

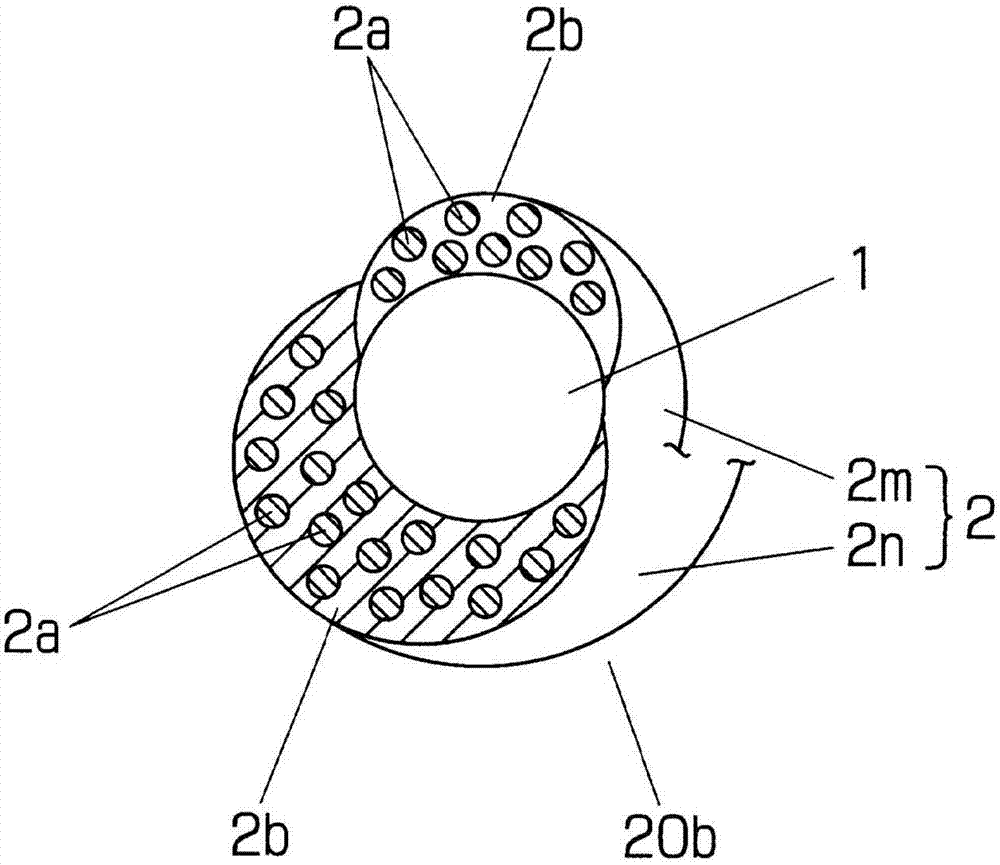

[0076] Embodiments of the present invention will be described below with reference to the drawings. In the figure, 1 is a hard fiber, 2 is a molten fiber, 3 is a lower layer fiber arranged between the hard fiber 1 and the molten fiber 2, and 10a is a combination (twisting or wrapping) of the hard fiber 1 and the molten fiber 2. 10c to 10f are composite wires made by combining hard fiber 1 and lower layer fiber 3 with molten fiber 2, and 20a and 20b are made by combining molten fiber 2 and hard 20c-20e are the core wires that fuse the melted fiber 2 of the melt 2b, the hard fiber 1 and the non-melted lower layer fiber 3 to form an integrated core wire, and 30a is the winding wire 5. Tenacious wires obtained from core wires 20a, 20b, 30c-30e are tough wires obtained by winding winding wire 5 around core wires 20c-20e; The core wires 20c to 20e are welded strong wires.

[0077] Figure 1 ~ Figure 4 It is a figure which shows the 1st and 2nd Example which do not have the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com