Method for preparing composite anti-friction and anti-wear additive of graphene-loaded nanoparticles

A nano-particle, anti-friction and anti-wear technology, used in additives, petroleum industry, lubricating compositions, etc., to improve friction and wear problems, extend service life, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

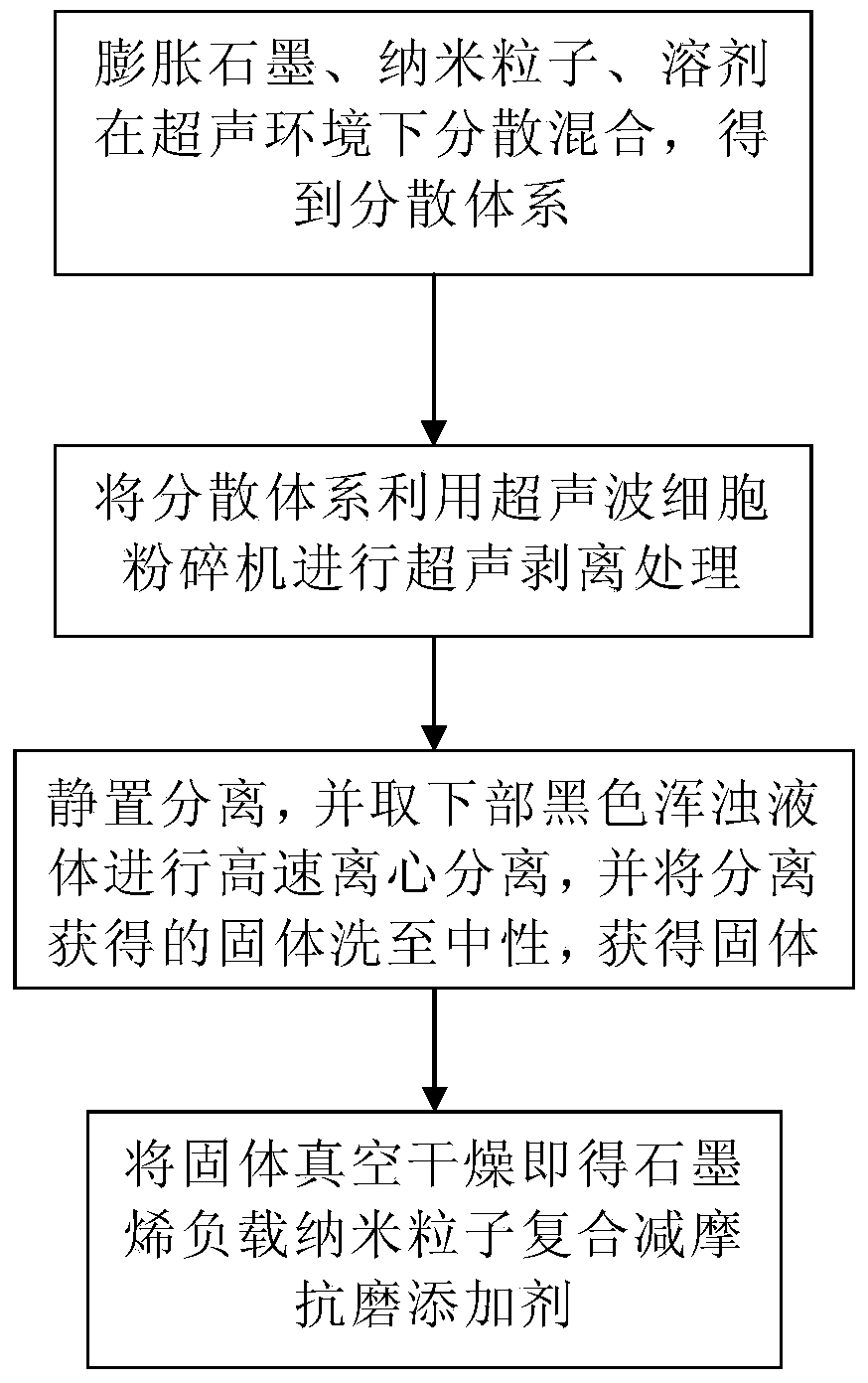

Method used

Image

Examples

Embodiment 1

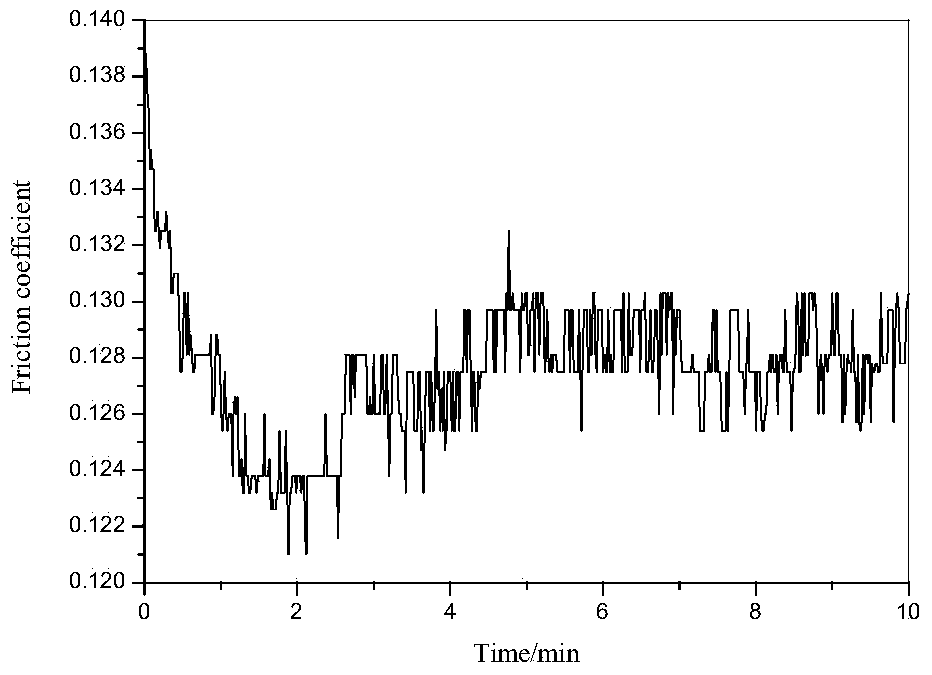

[0026] According to the mass of expanded graphite (g): nano Fe 3 o 4 The mass (g) of particle: the volume (L) of dimethyl sulfoxide is the ratio of 1:0.05:0.5, takes by weighing expanded graphite 0.44g, nanometer Fe 3 o 4 Particles 0.022g, measure dimethyl sulfoxide 0.22L, expand graphite and Fe with a particle size of 20nm 3 o 4 The particles are dispersed in dimethyl sulfoxide, ultrasonically dispersed in an ultrasonic material emulsification disperser for 10min, the diameter of the horn is 10mm, and the process parameters are: output power 150W, ultrasonic time 4s, interval time 2s. Then put it into an ultrasonic cell pulverizer for ultrasonic peeling, the diameter of the horn is 6mm, the working time is 3h, and the process parameters are: output power is 50W, ultrasonic time is 4s, and interval time is 2s. After the ultrasound is over, let it stand for 3 minutes, remove the black turbid liquid and perform high-speed centrifugation for 30 minutes, wash it with ethanol u...

Embodiment 2

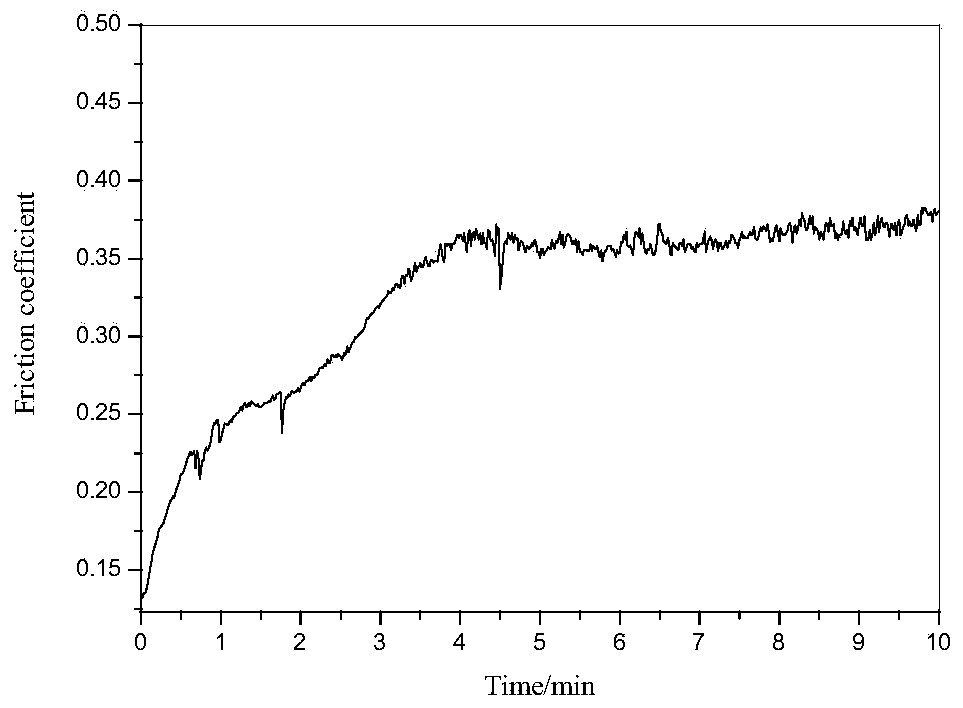

[0028] The dimethyl sulfoxide in embodiment 1 is changed into deionized water, and other processes remain unchanged, and graphene-supported Fe is obtained. 3 o 4 Nano particle composite anti-friction and anti-wear additive GN / Fe 3 o 4 . Weigh the prepared composite anti-friction and anti-wear additive GN / Fe 3 o 4 Dispersed in liquid paraffin, configured as GN / Fe with a concentration of 0.01wt% 3 o 4 Paraffin dispersion system, equipment and conditions used for the friction test are the same as in Example 1. Under load test 20N, GN / Fe 3 o 4 The relationship curve between the friction coefficient of the paraffin dispersion system and the test time is as follows figure 2 shown.

Embodiment 3

[0030] According to the mass of expanded graphite (g): nano-SiO 2 The mass (g) of particle: the volume (L) of dimethyl sulfoxide is the ratio of 1:0.05:0.5, takes by weighing expanded graphite 0.44g, nanometer SiO 2 Particles 0.022g, measure 0.22L dimethyl sulfoxide, expand graphite and SiO with a particle size of 20nm 2 The particles are dispersed in dimethyl sulfoxide, ultrasonically dispersed in an ultrasonic material emulsification disperser for 10min, the diameter of the horn is 10mm, and the process parameters are: output power 150W, ultrasonic time 4s, interval time 2s. Then put it into an ultrasonic cell pulverizer for ultrasonic peeling, the diameter of the horn is 6mm, the working time is 3h, and the process parameters are: output power is 50W, ultrasonic time is 4s, and interval time is 2s. After the ultrasonic wave is over, after standing still for 5 minutes, the black turbid liquid is removed and subjected to high-speed centrifugation for 20 minutes, washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com