Patents

Literature

57results about How to "Improve friction and wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

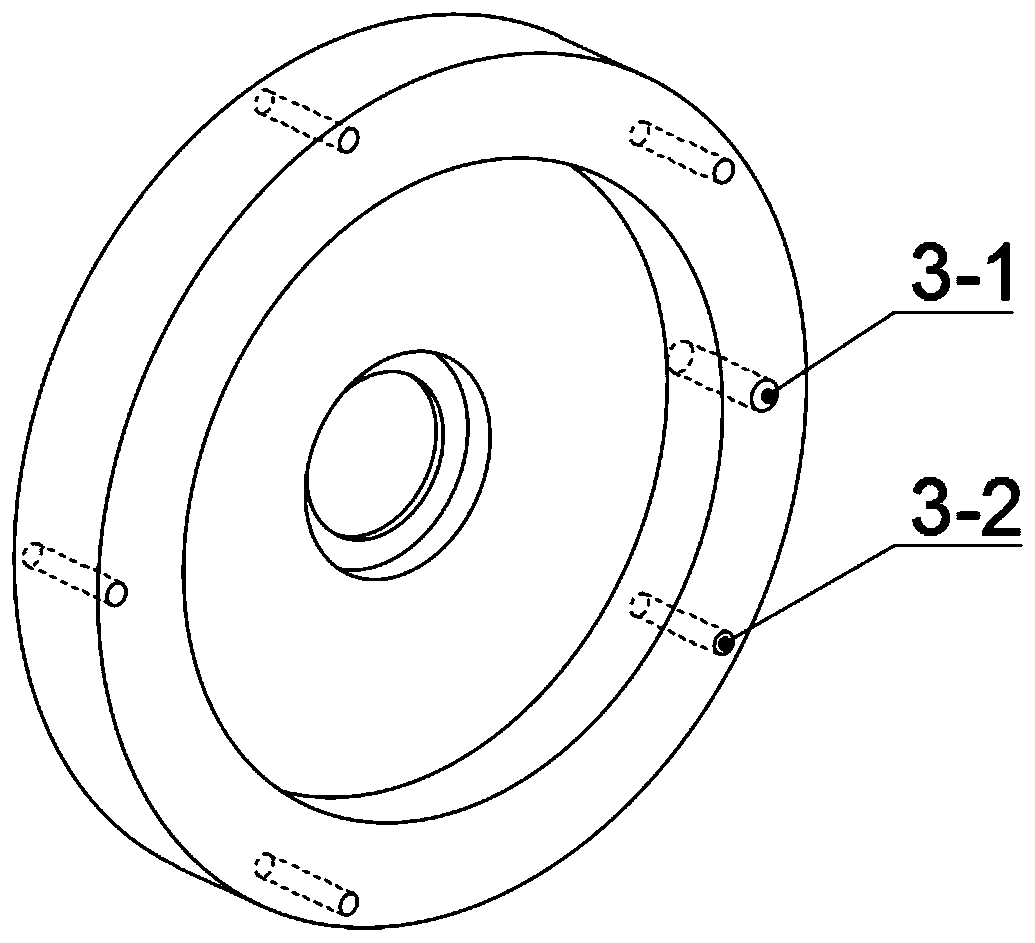

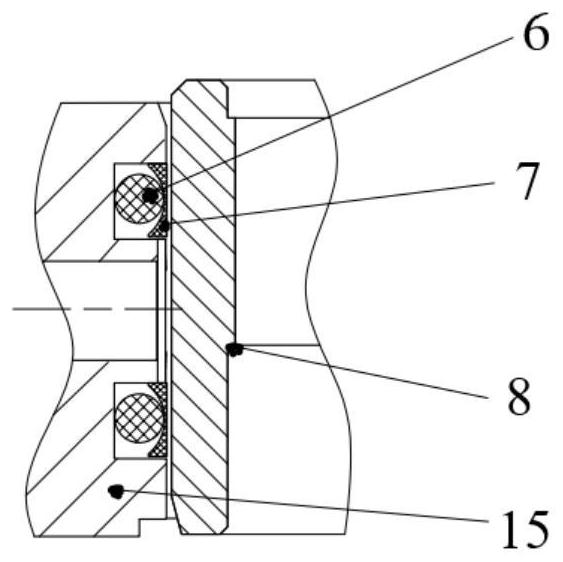

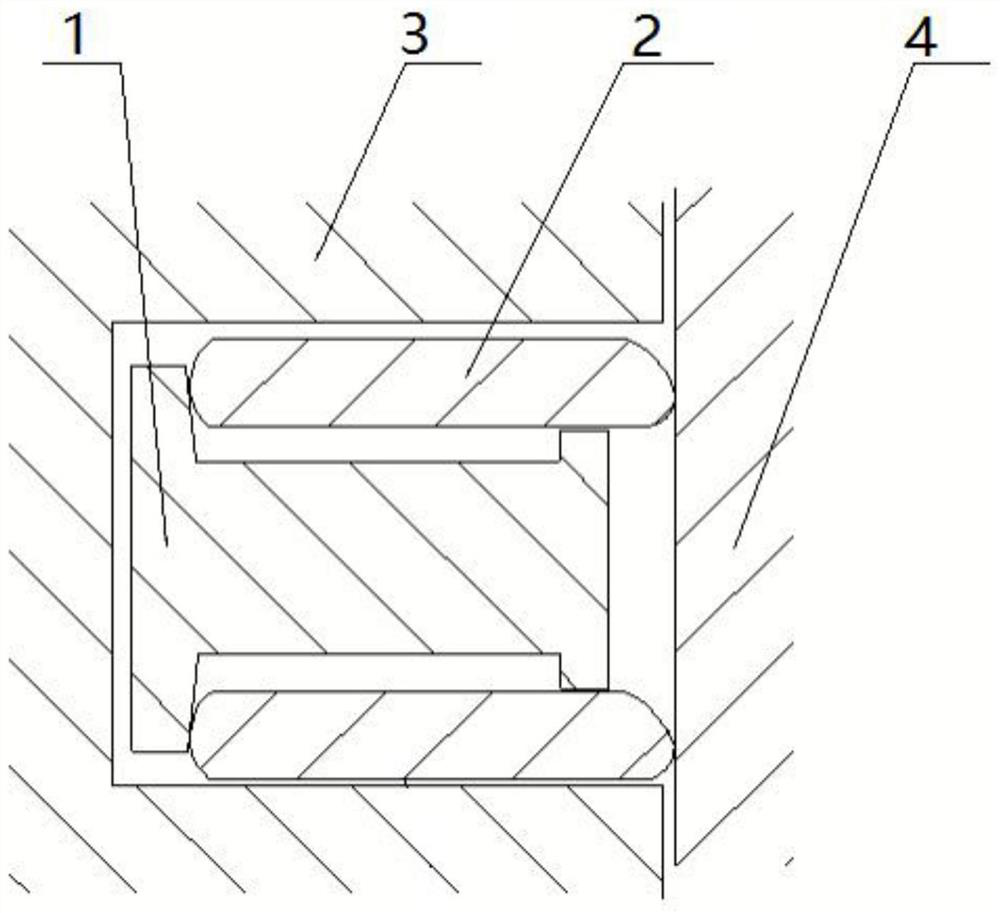

Water lubrication rubber alloy bearing

InactiveCN101334069AImprove performanceExtended service lifeBearing componentsChemical industryAlloy

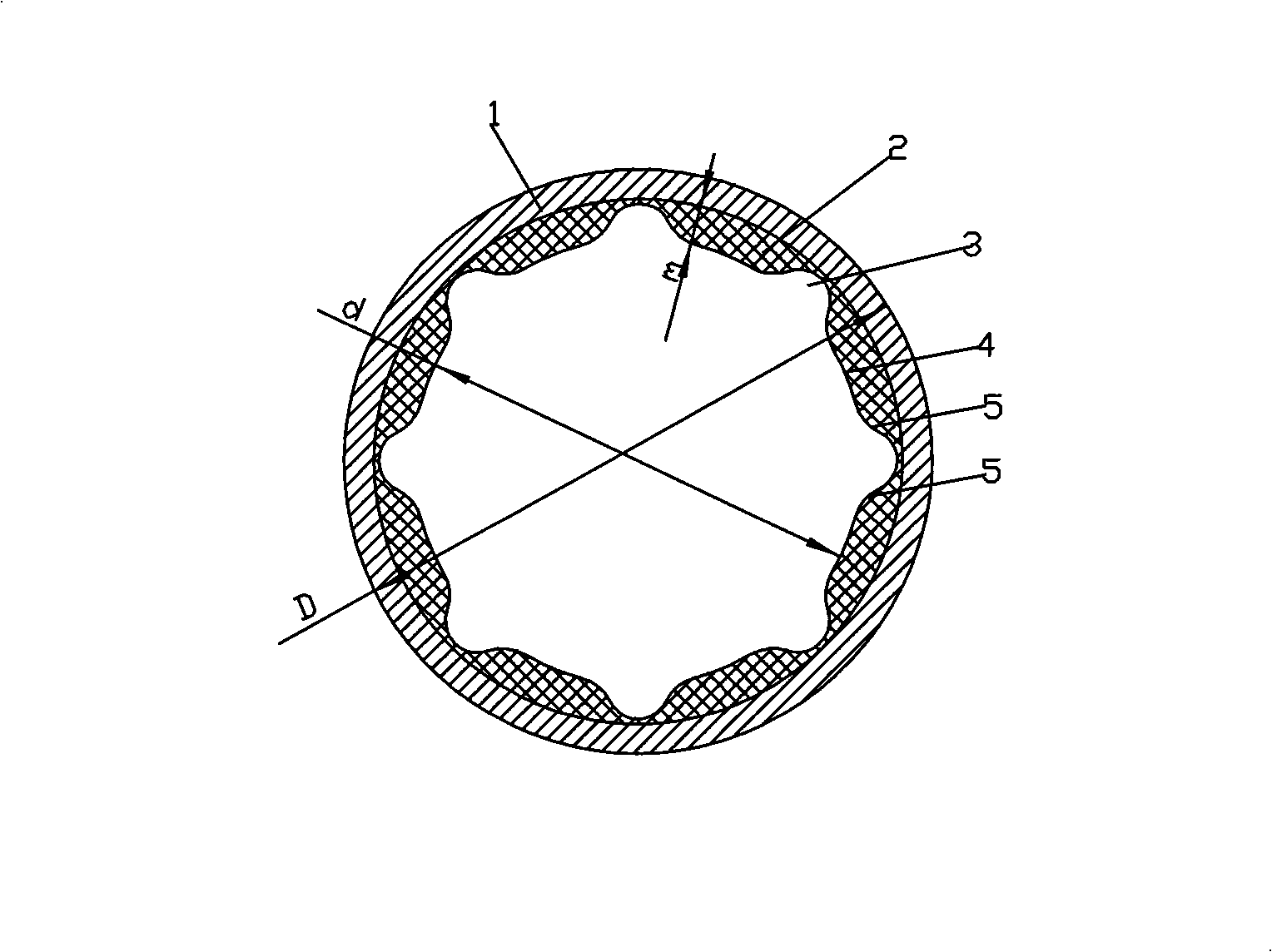

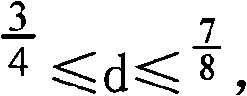

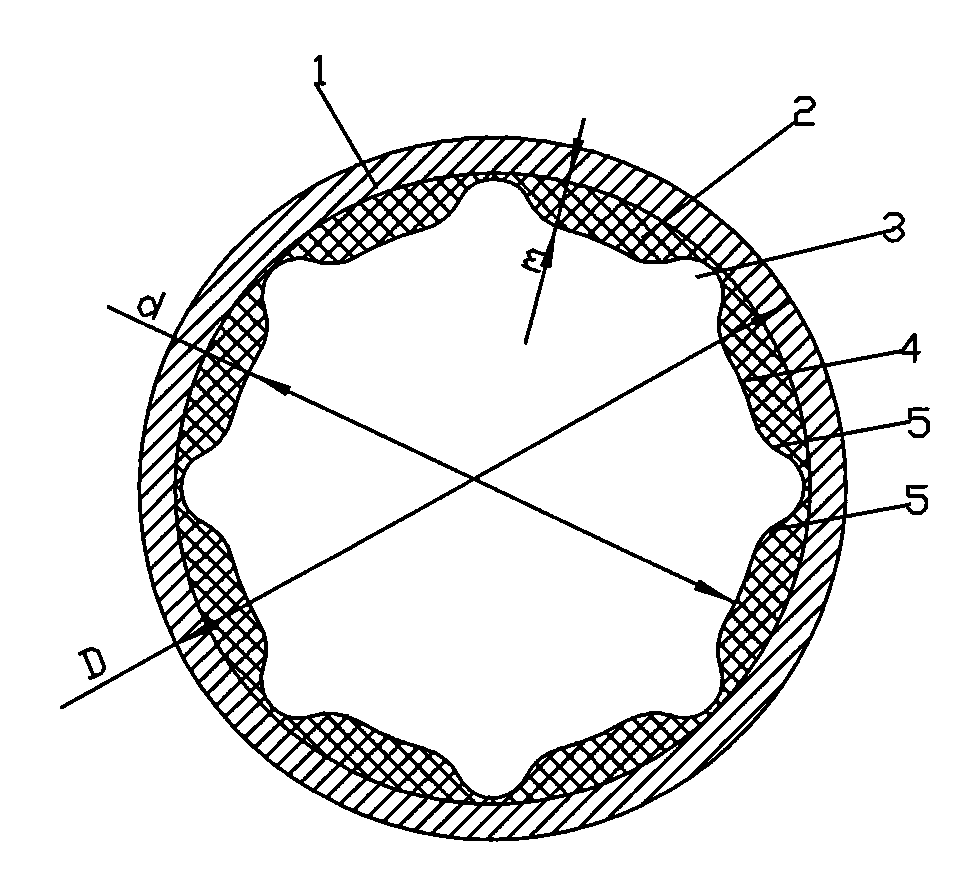

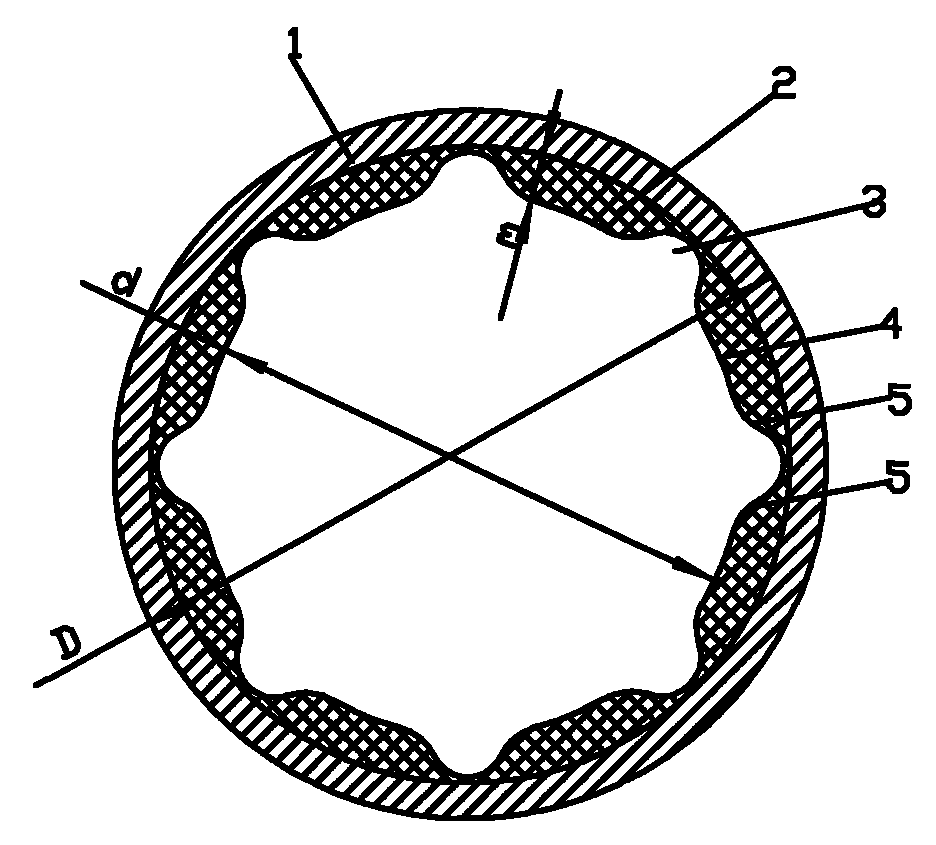

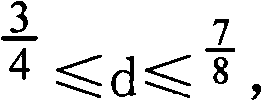

The invention discloses a water lubrication rubber alloy bearing, which comprises a water lubrication rubber alloy bushing and a bearing outer ring. The water lubrication rubber alloy bushing is bonded on the inner circumference of the bearing outer ring through die stamping and vulcanizing, the corresponding coincidence relation is adopted for the radial thickness m of the water lubrication rubber alloy bushing according to the difference of the internal diameter d of the water lubrication rubber alloy bushing. The affect of the radial thickness of the water lubrication rubber inner liner to the bearing capacity and the shock resistant capability of the bearing is comprehensively considered in the water lubrication rubber alloy bearing, the corresponding thickness of the water lubrication rubber inner liner is adopted according to bearings with different specifications, the bearing capacity of the bearing is obviously enhanced, the properties of surface deformation compatibility and elastic fluid dynamic pressure lubrication and the good silt, sand and impurities drainage capacity are strengthened, the service life of the water lubrication rubber alloy bearing is more than three times the similar bearing, the water lubrication rubber alloy bearing has the advantages of vibration damping, noise reduction, abrasion resistance, reliability, high efficiency, energy conservation and environmental friendliness and can be widely applied to the fields of the engineering equipments of machinery, marine vessel, petroleum, chemical industry, mine, water conservancy, agriculture and national defense.

Owner:重庆奔腾科技发展有限公司

High-carbon gray cast iron automobile brake disk and production method thereof

ActiveCN103225037AShorten the lengthConvenient lengthBraking discsFriction liningChemical compositionHigh carbon

The invention relates to a high-carbon gray cast iron automobile brake disk and a production method thereof. The high-carbon gray cast iron automobile brake disk comprises the following chemical components in percentage by weight: 3.7-3.8% of C, 0.5-0.8% of Mn, 0.3-0.5% of Cu, 0.1-0.2% of Cr, 0.2-0.4% of Mo, 1.6-2.0% of Si, 0.1-0.2% of N, 0.01-0.12% of P, 0.05-0.12% of S and the balance of Fe. The brake disk provided by the invention has the outstanding characteristics of small brake temperature rise, abrasion resistance, favorable heat fatigue resistance effect and the like; the performance of an automobile brake system can be obviously improved, and the service life can be obviously prolonged; and meanwhile, the potential safety hazard caused by ineffective brake due to high temperature can be effectively eliminated. Thus, the high-carbon gray cast iron automobile brake disk has high economic value.

Owner:河南淮海精诚工业科技有限公司

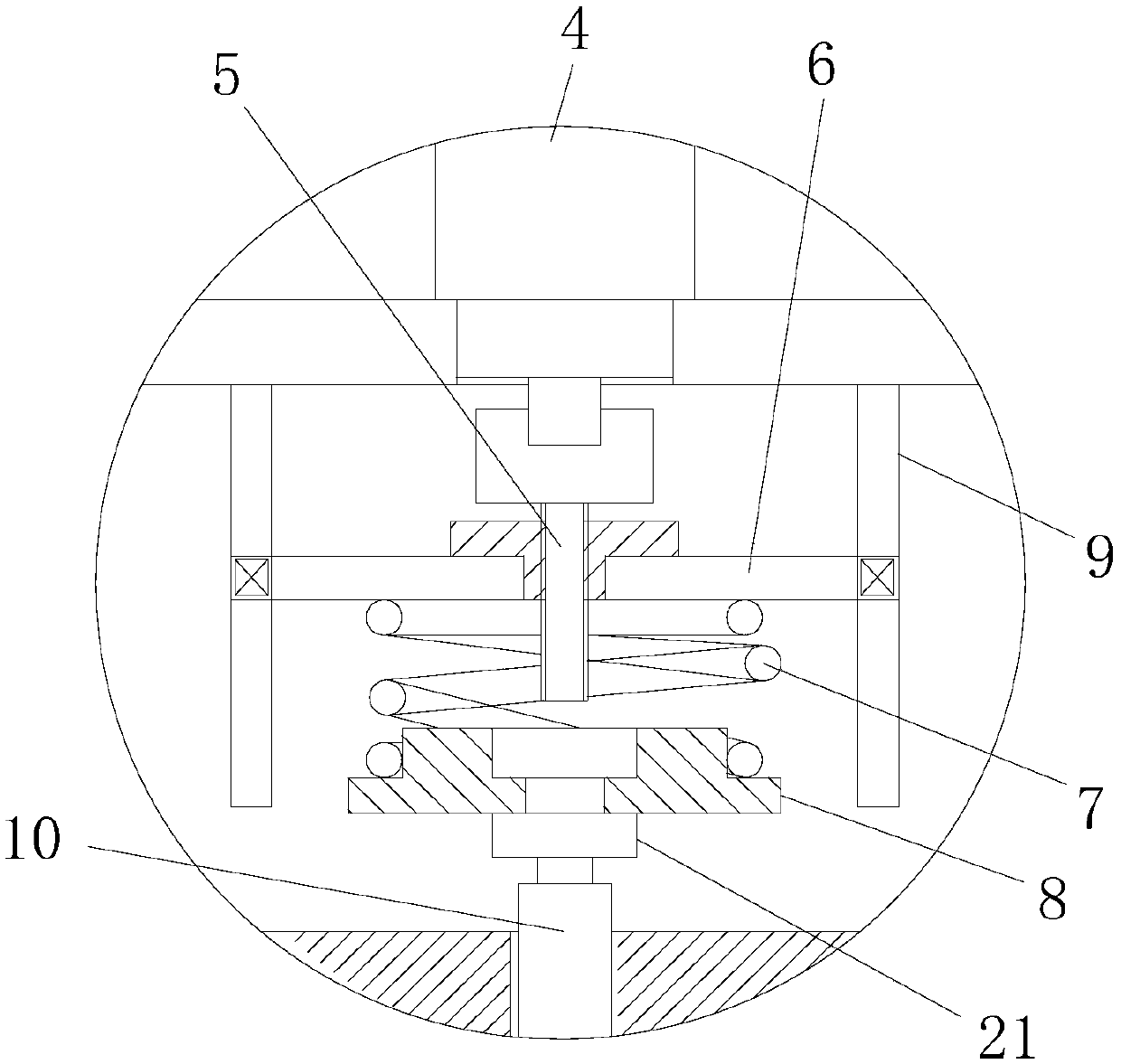

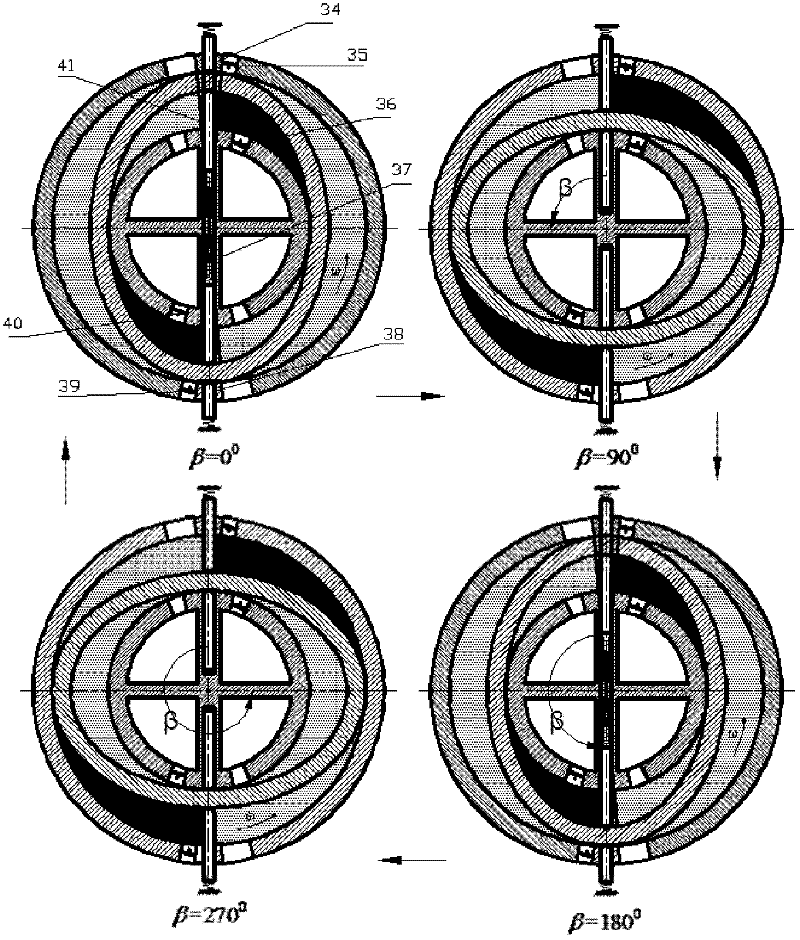

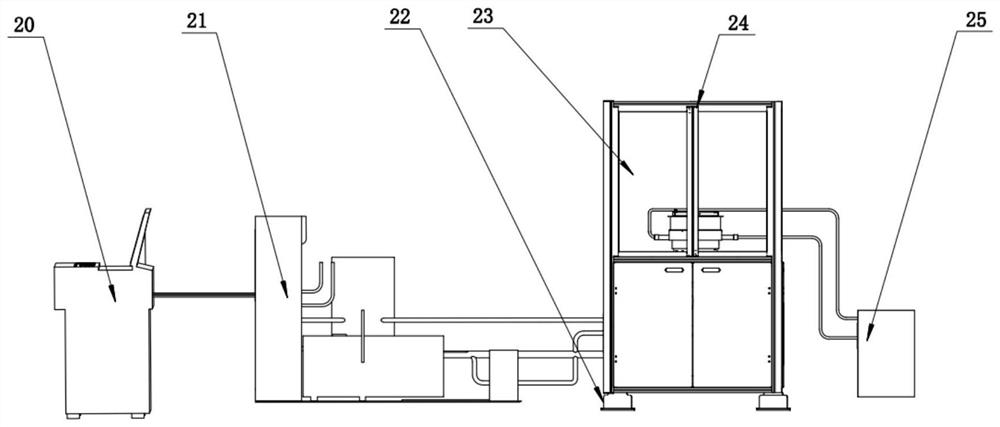

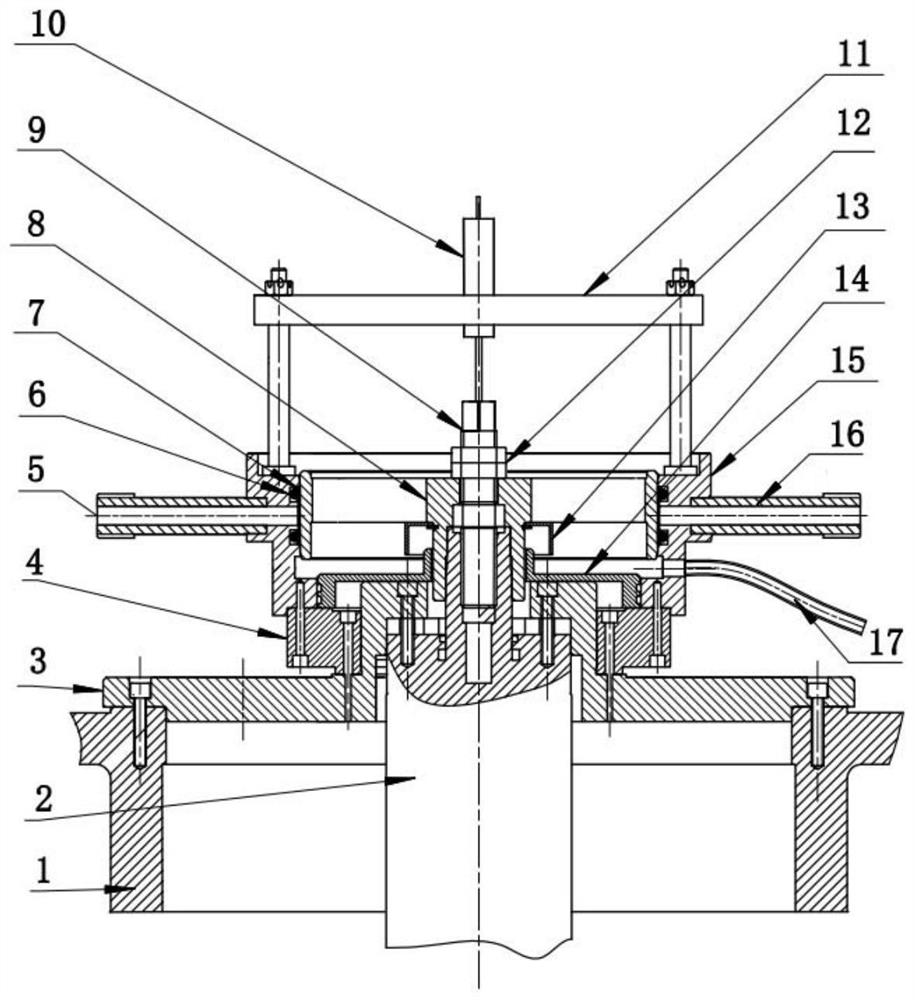

Multifunctional friction-wear test device and method for simulating space environment

PendingCN107831086AImprove friction and wearExplore friction and wearMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceSpace environmentEngineering

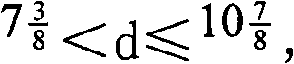

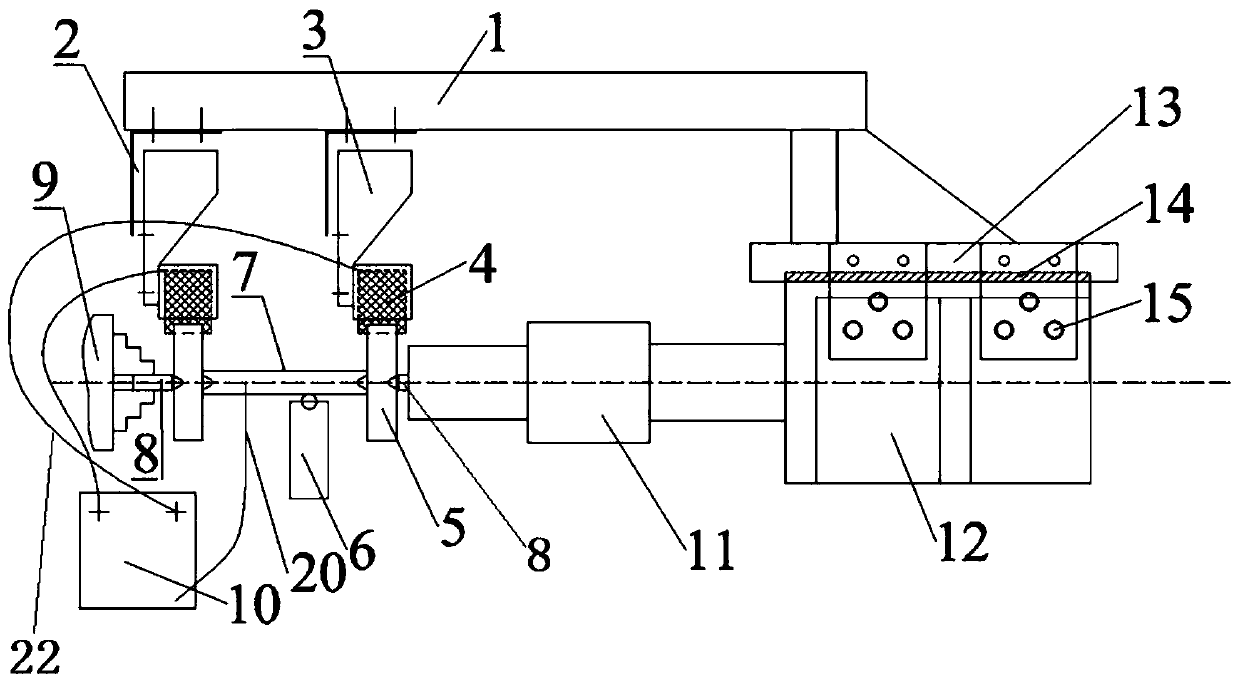

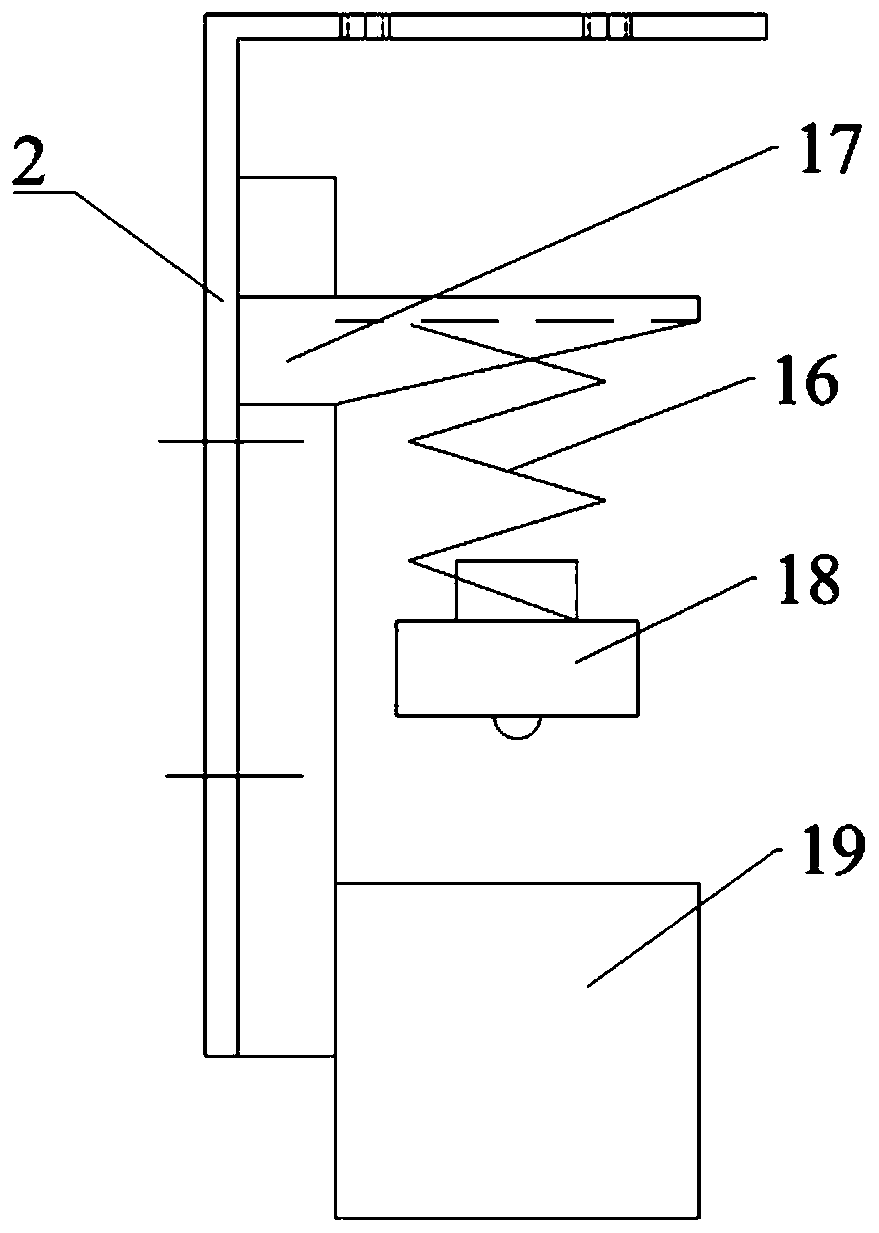

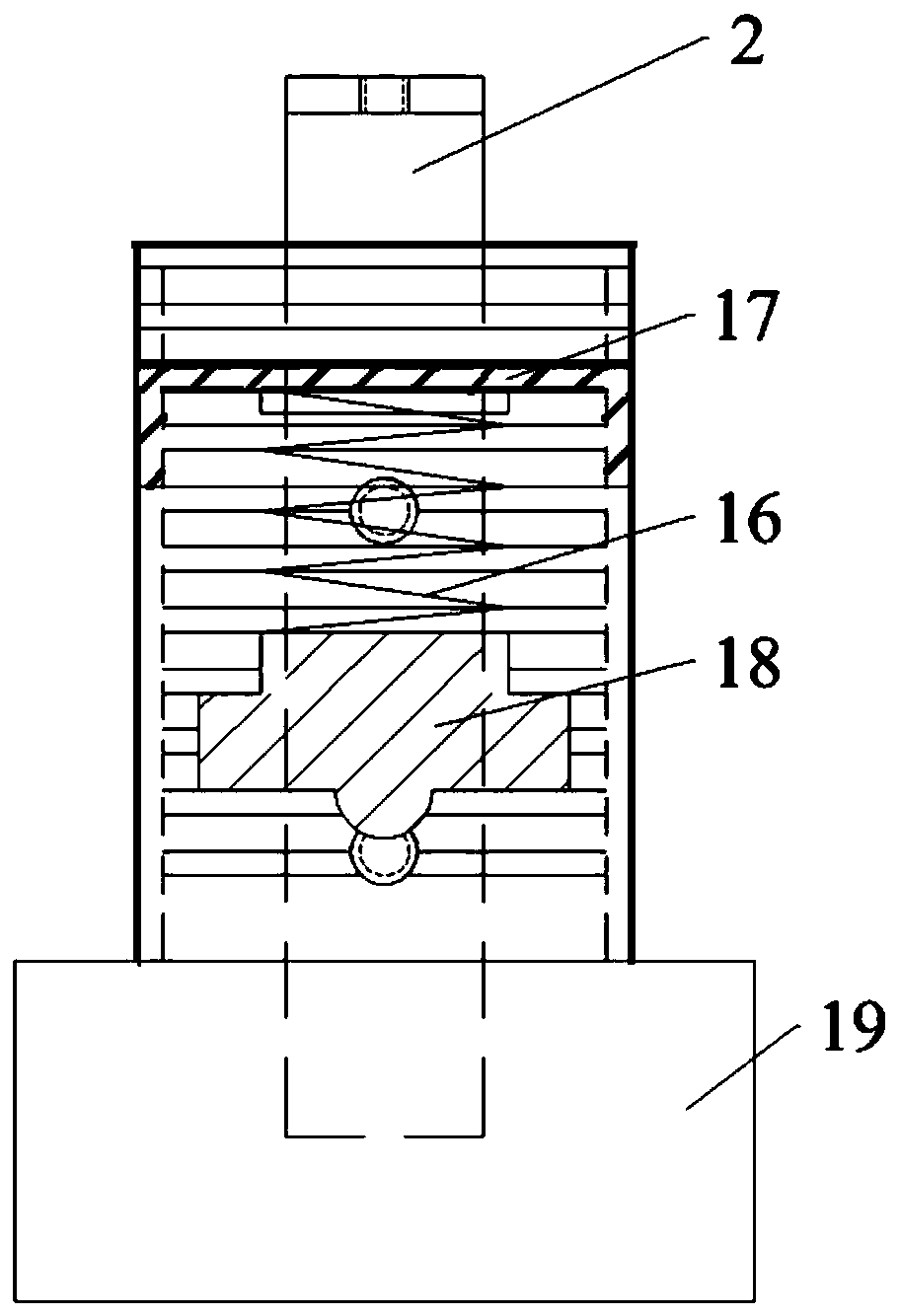

The invention discloses a multifunctional friction-wear test device and method for simulating a space environment. The multifunctional friction-wear test device for simulating the space environment comprises a load mechanism, a vacuum box, a friction force detection mechanism, an upper sample clamp, a lower sample mounting base, an ultraviolet generating device for irradiating ultraviolet for samples, a refrigerating system for decreasing temperature inside the vacuum box, a heating system for increasing the temperature inside the vacuum box and a lower sample driving system for driving the lower sample mounting base to drive a lower sample to rotate relative to an upper sample. The disadvantage that the friction-wear test of a space is comprehensively influenced by multiple factors of thespace environment in the prior art is compensated, the friction-wear condition of the material under the space environment is preferably explored, and specifically various environments, such as highvacuum, alternating temperature, heat radiation, and complex movement working conditions, such as alternating load, high and low speed and interrupt operation, of the mechanism, in the space environment can be simulated.

Owner:SOUTH CHINA UNIV OF TECH

High-wear-resistance high-impact-resistance polyamide-6-based nano composite material and preparation method thereof

The invention discloses a high-wear-resistance high-impact-resistance polyamide-6-based nano composite material and a preparation method thereof. The friction material comprises the following components in parts by weight: 55-75 parts of polyamide 6, 3-5 parts of modified nano titanium dioxide, 10-15 parts of composite solid lubricant, 3-8 parts of compatibilizer, 10-20 parts of flame retardant, 0.5-2 parts of antistatic agent, 0.05-0.5 part of antiaging agent and 0-1 part of surface modifier. The preparation method comprises the following steps: uniformly mixing all the materials according to parts by mass, and carrying out a fusion process to obtain the high-wear-resistance high-impact-resistance polyamide-6-based nano composite material. The friction material has the advantages of simple manufacturing technique, high wear resistance, high impact resistance, flame retardancy, static resistance, high / low temperature resistance, corrosion resistance, aging resistance, low cost and the like, overcomes the defect that the enhancement of a certain property of the material influences other physical property indexes in the prior art, and implements the high properties of the material.

Owner:HUNAN CITY UNIV

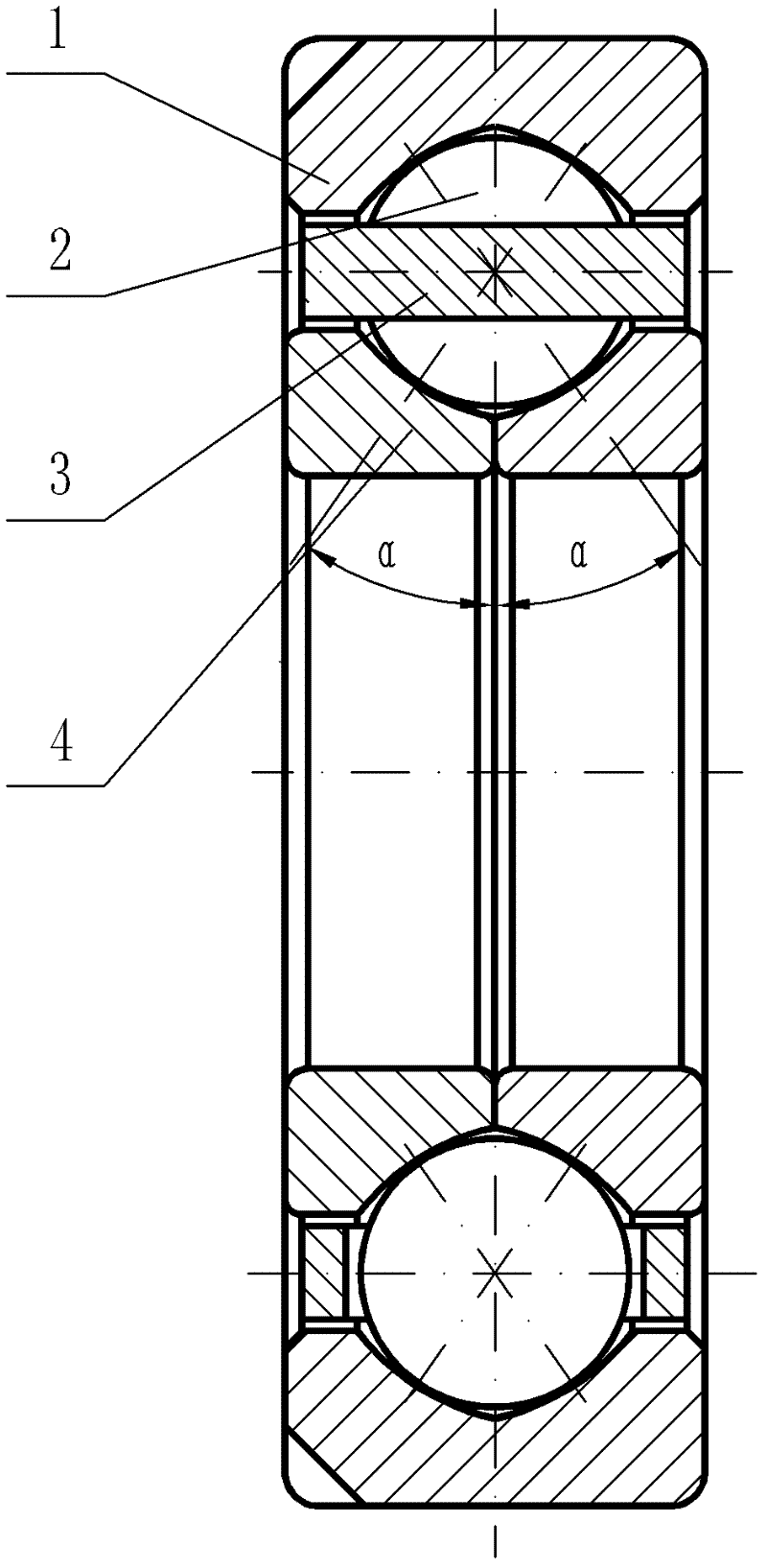

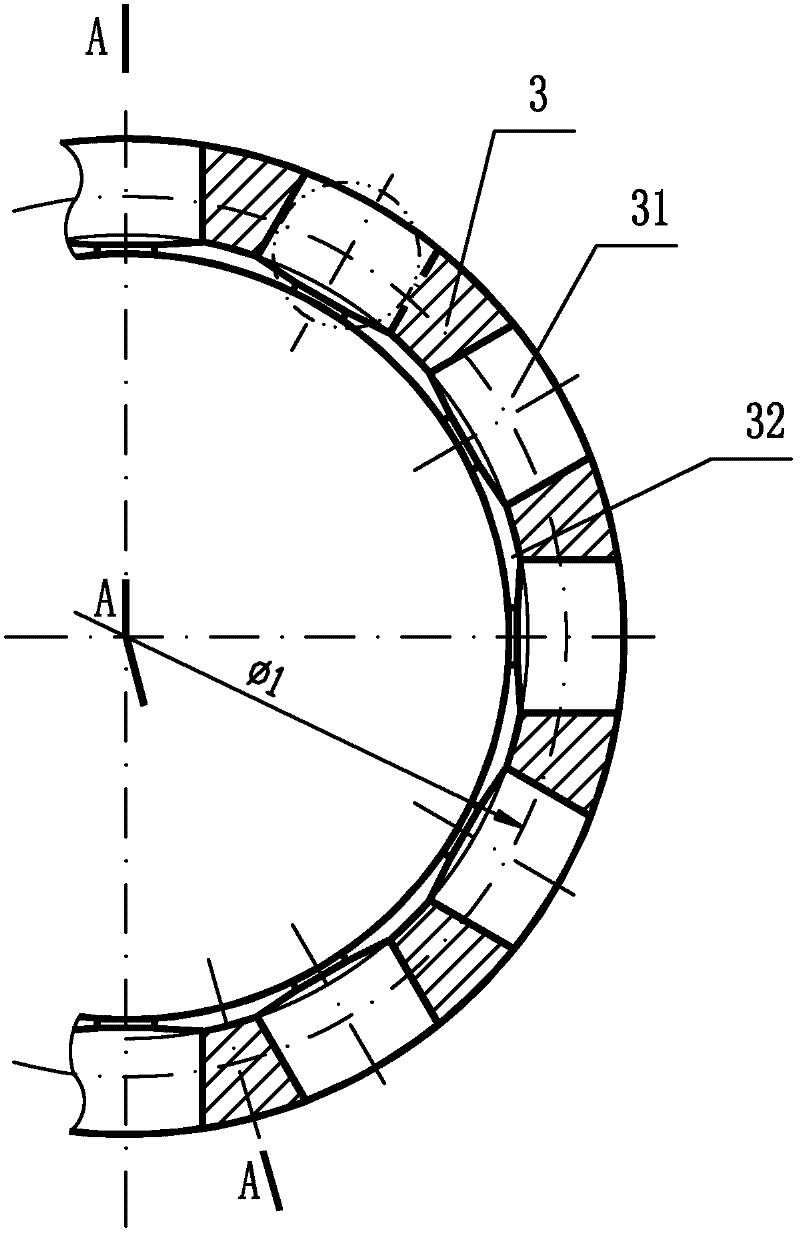

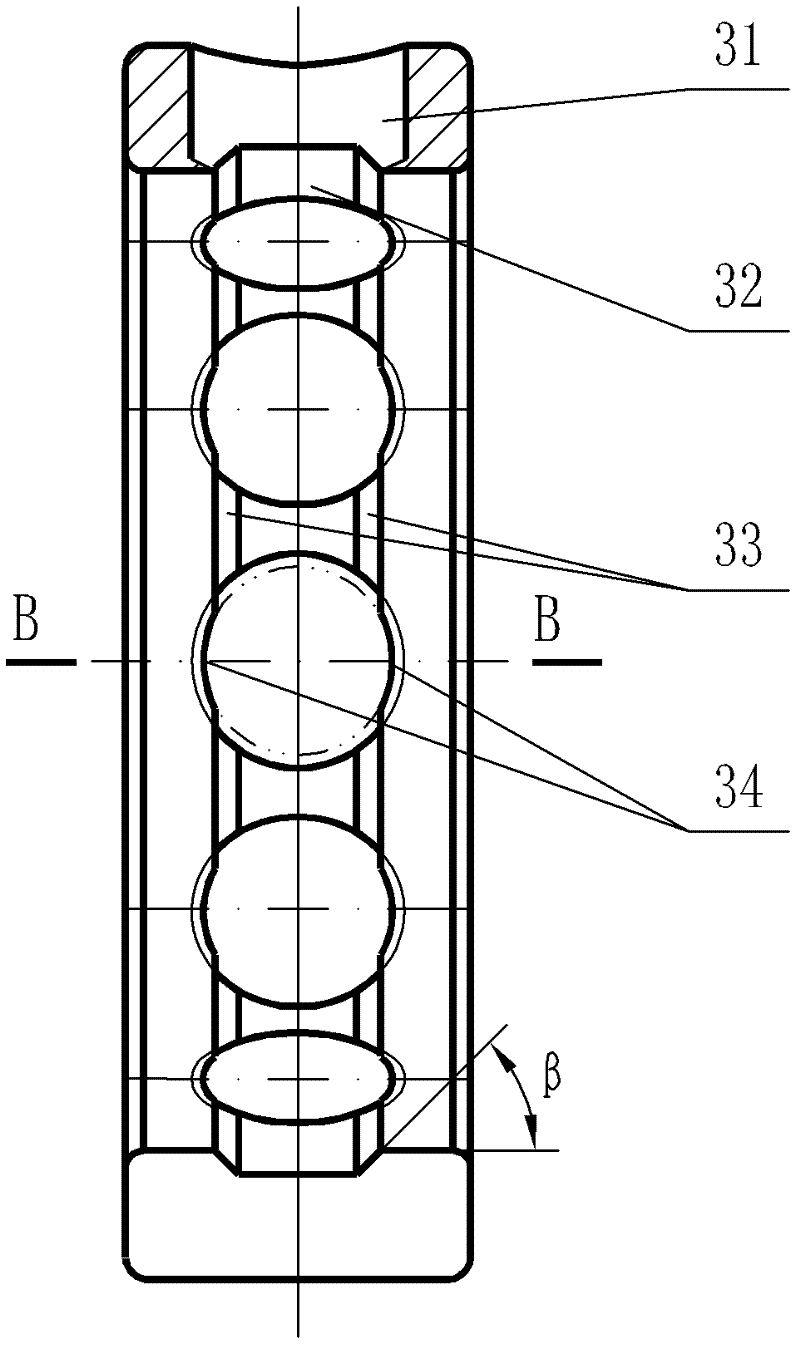

Four-point contact ball bearing

ActiveCN102242764ASimplify the assembly processImprove assembly efficiencyBall bearingsBearing componentsEngineeringFrictional resistance

The invention relates to a four-point contact ball bearing which comprises an outer ring, two separated inner rings, rolling bodies and a retainer, wherein pockets are uniformly distributed along the circumference of the retainer; the rolling bodies are respectively installed in pockets and arranged between the outer ring and the two inner rings; a fore shaft is formed at the inner side of each pocket on the retainer; each fore shaft comprises two arc-shaped merrowes which symmetrically expand to the central axis of the corresponding pocket; the total arc length of the two arc-shaped merrowesis two fifth or one third of the line contact arc length of the rolling bodies; and the arc-shaped merrowes and the hole walls of the pockets are in inclined plane transition. By the adoption of the invention, the assembly process can be simplified; the assembly efficiency and accuracy of the bearing are improved; the frictional resistance when the bearing operates is reduced; and the service life of the bearing is prolonged.

Owner:CHANGZHOU NRB CORP

High performance polyamide 6 based friction material and preparation method thereof

InactiveCN105385151AImprove thermal conductivityImprove mechanical propertiesManufacturing technologyPolymer science

The invention discloses a high performance polyamide 6 based friction material and a preparation method thereof. The friction material comprises the following components in percentage by weight: 55 to 65% of polyamide 6, 10 to 15% of chopped glass fiber, 10 to 15% of composite solid lubricant, 2 to 5% of compatibilizer, 10 to 15% of flame retardant, 0.5 to 2% of antistatic agent, 0.05 to 0.5% of anti-aging agent, and 0.5 to 1% of silane coupling agent. The friction material is prepared by the following steps: mixing all materials together according to the ratio mentioned above, and making the mixture into a high performance polyamide 6 based friction material through a fusion method. The friction material has the advantages of simple manufacturing technology, low wear rate, low friction coefficient, high strength, flame resistance, electrostatic resistance, high / low temperature resistance, corrosion resistance, aging resistance, and low cost.

Owner:CENT SOUTH UNIV

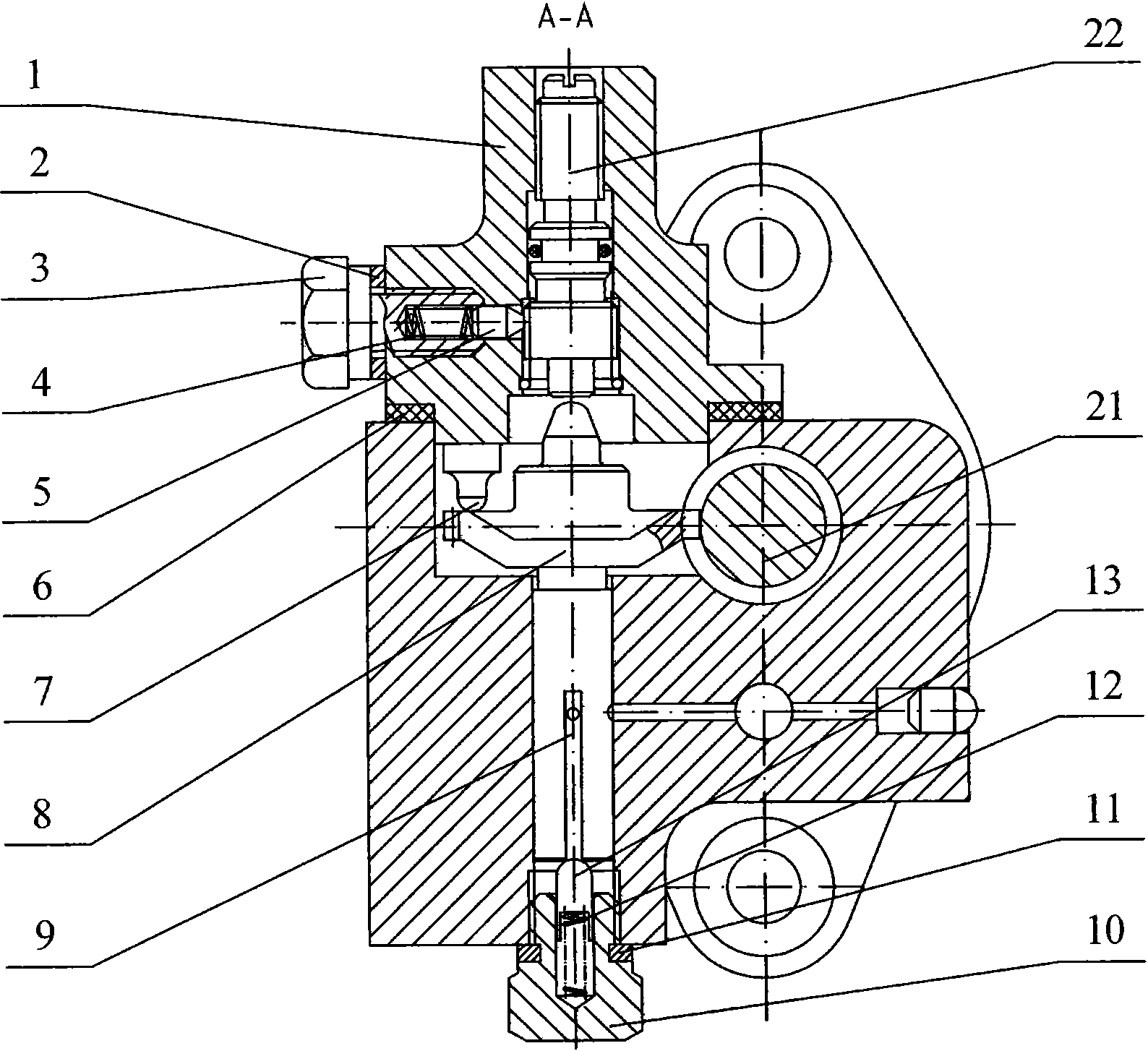

Diesel engine valve lubricating device

InactiveCN101818671AImprove friction and wearLubrication of auxillariesLubrication pressure controlGear wheelReciprocating motion

The invention relates to a diesel engine valve lubricating device which comprises an oil pumping system, a drive system and a flow regulating system. A wavy gear of the drive system and a plunger piston of the oil pumping system are made into a whole, and the upper end surface of the wavy gear is designed according to the motion rule of diesel engine air inlet and outlet valves. A shaft gear engaged with the wavy gear is driven by a diesel engine crankshaft to realize the match of the oil supplying frequency of lubricating oil and the air inlet and outlet frequencies of a diesel engine air distributing mechanism. The plunger piston of the oil pumping system and the wavy gear rotate together and also move up and down and to and fro according to the set rule of the upper end surface of the wavy gear under the coaction of a top pin, a plunger piston bottom pin, a reset spring and a limiting bolt so as to realize the discontinuous oil absorption and oil supply of the lubricating device. The stroke of the plunger piston can be controlled through regulating the position of a shaft to satisfy the requirement of the discontinuous oil supplying flow of the lubricating device. The lubricating device can improve the friction and wear conditions between a diesel engine valve and a valve seat and prolong the service life of a diesel engine.

Owner:XIAMEN UNIV OF TECH +1

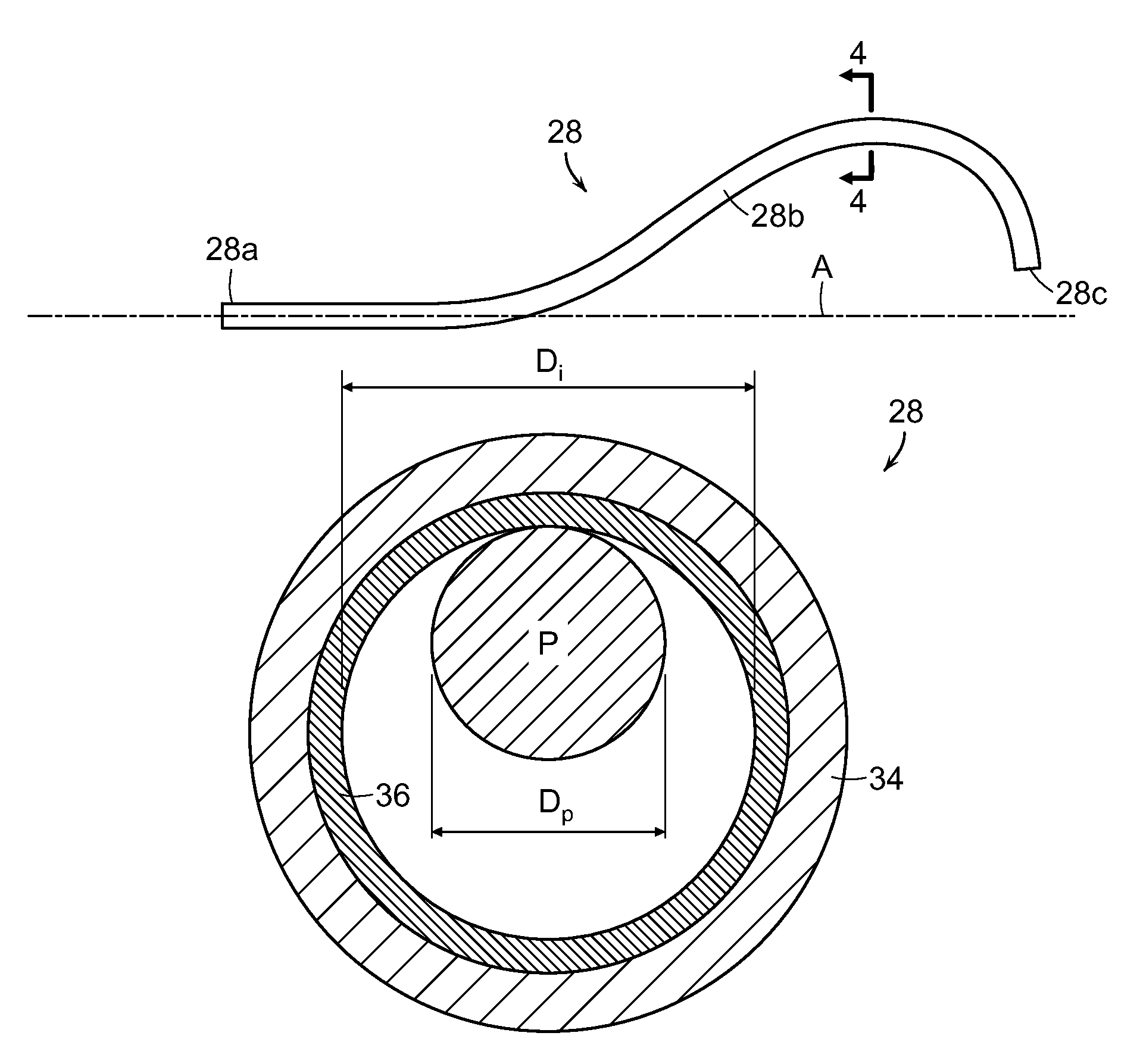

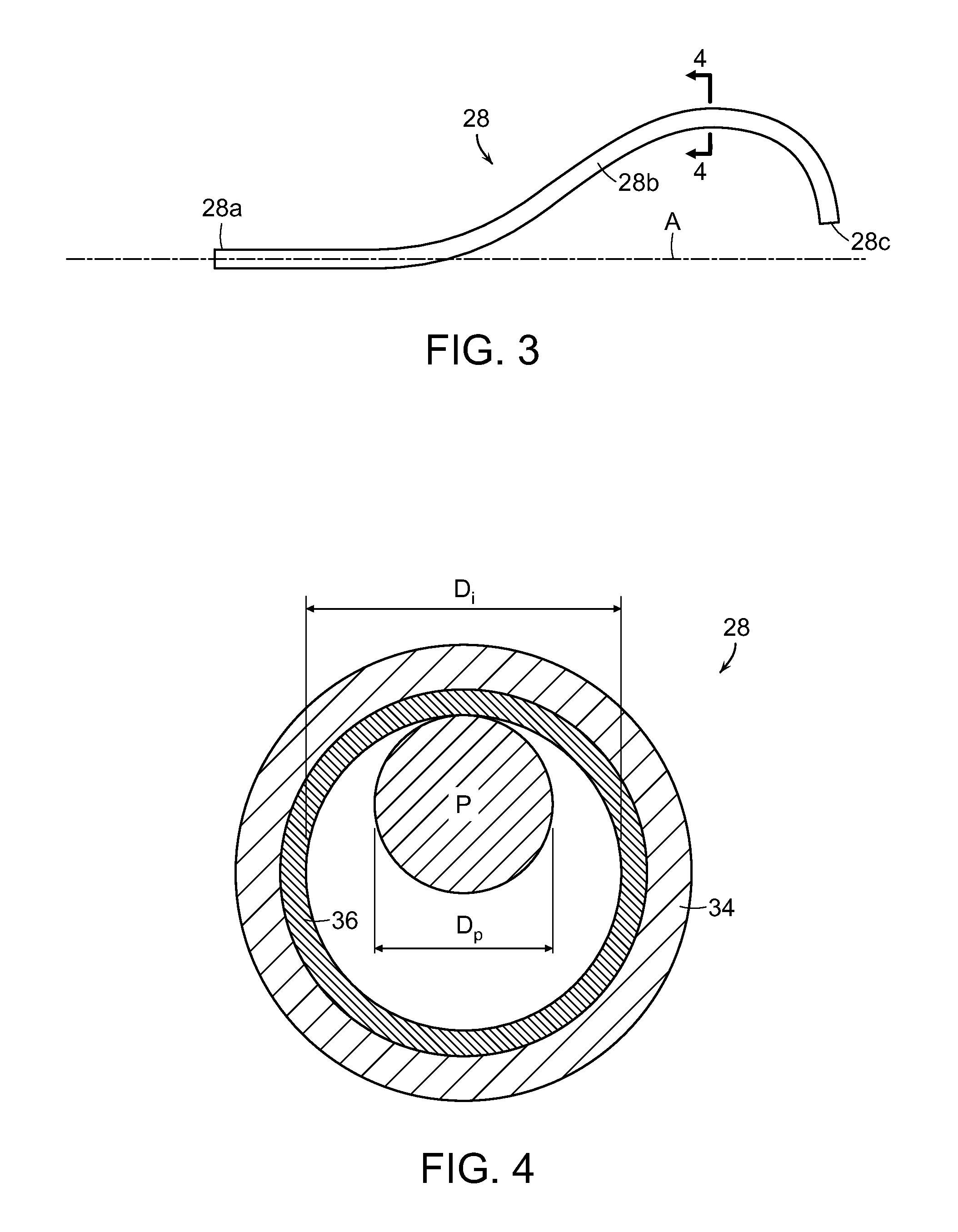

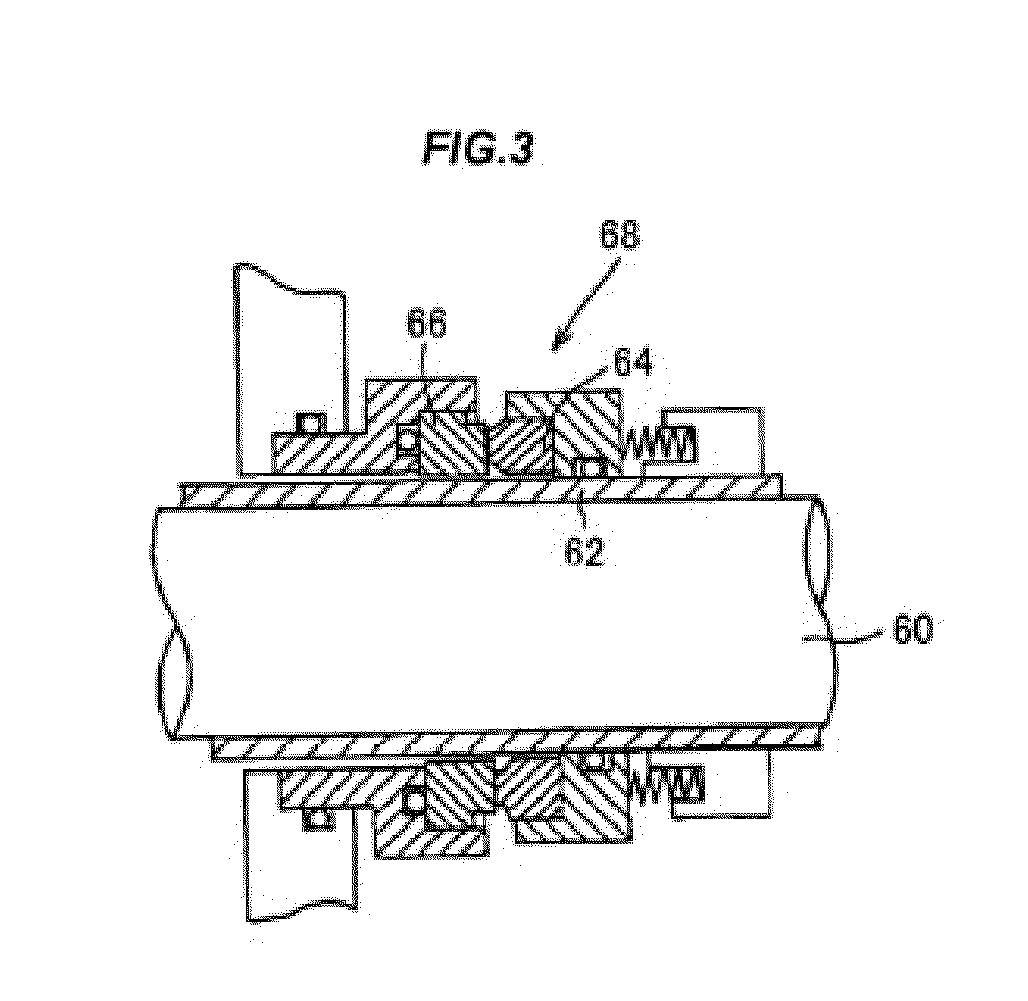

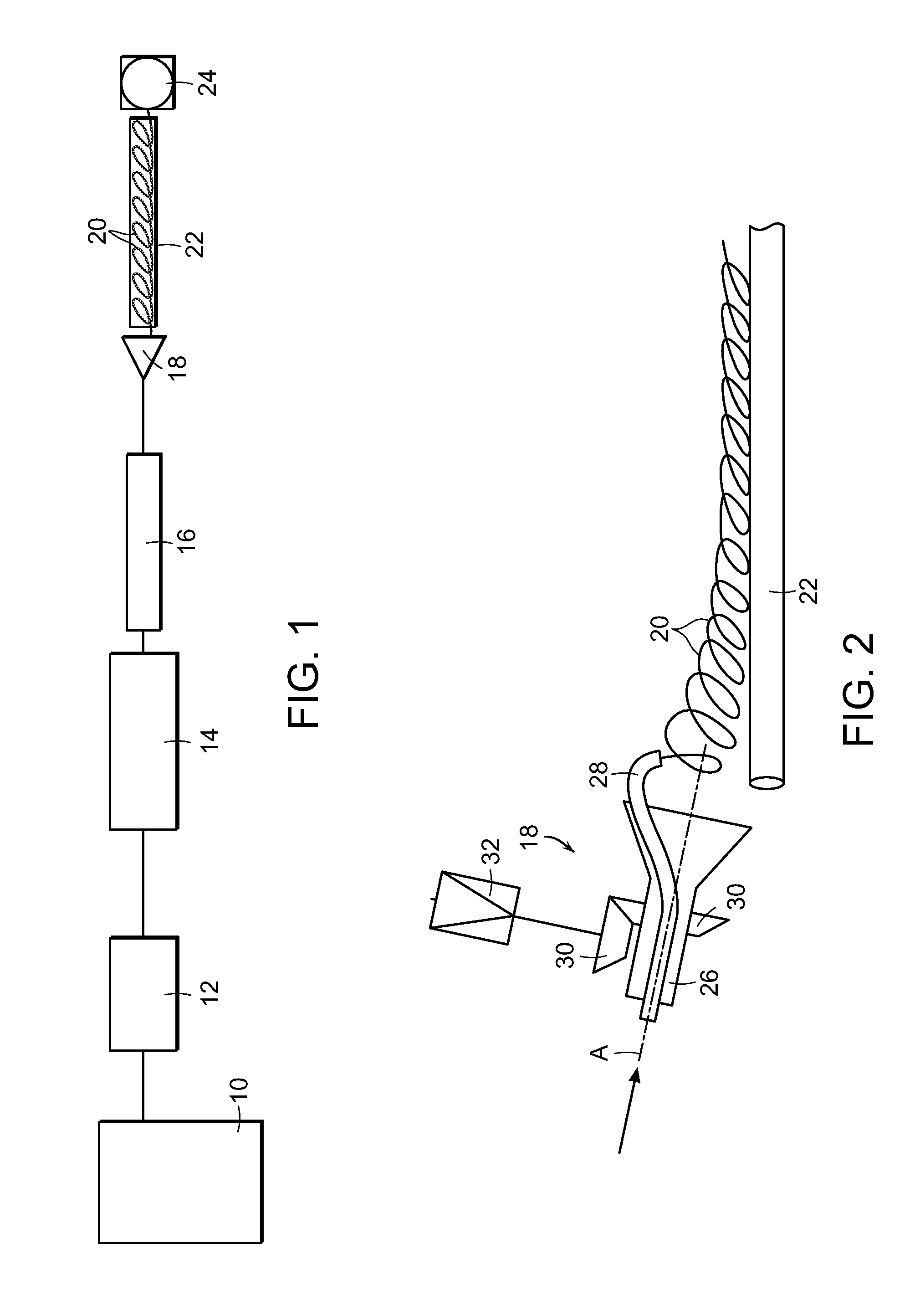

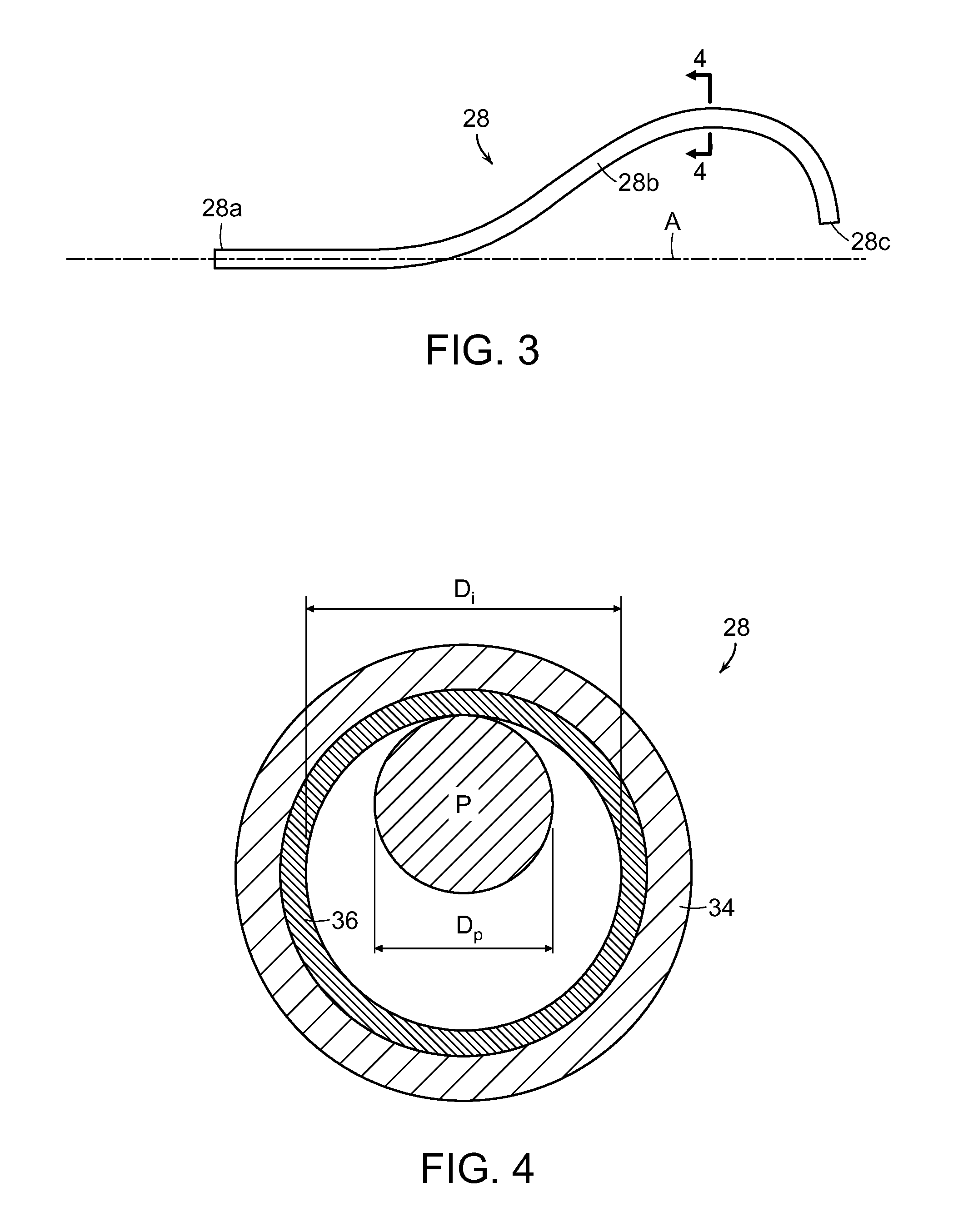

Boronized laying pipe

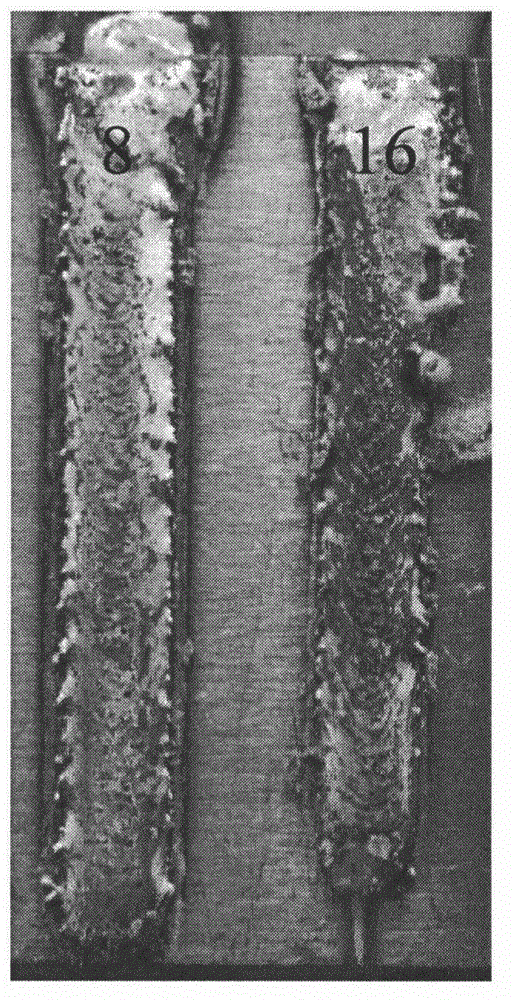

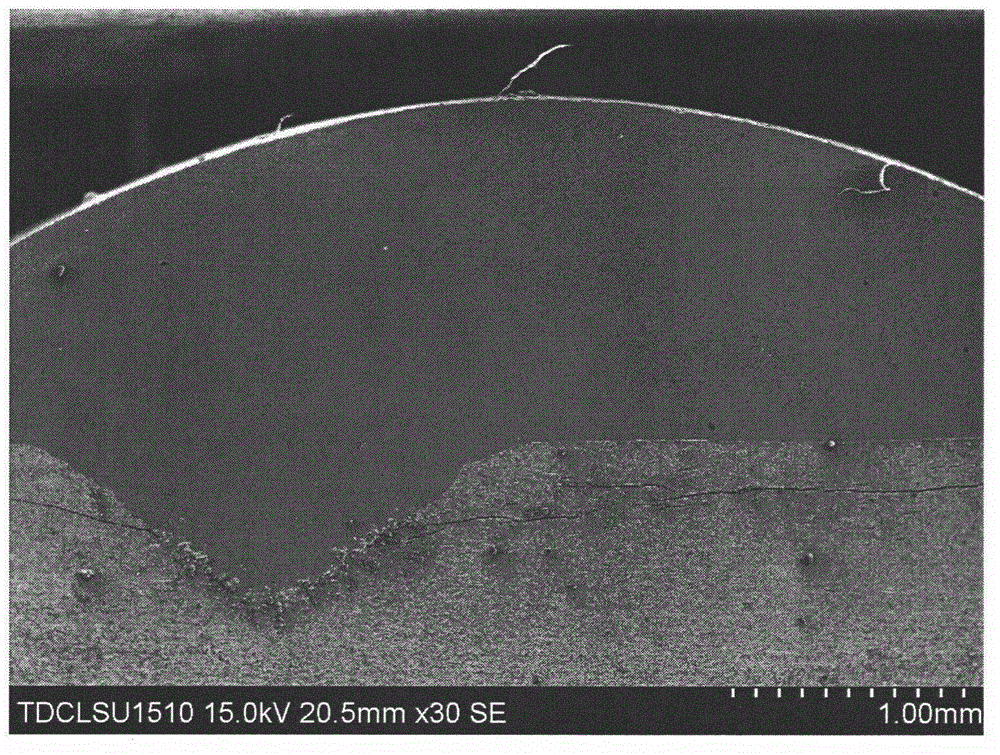

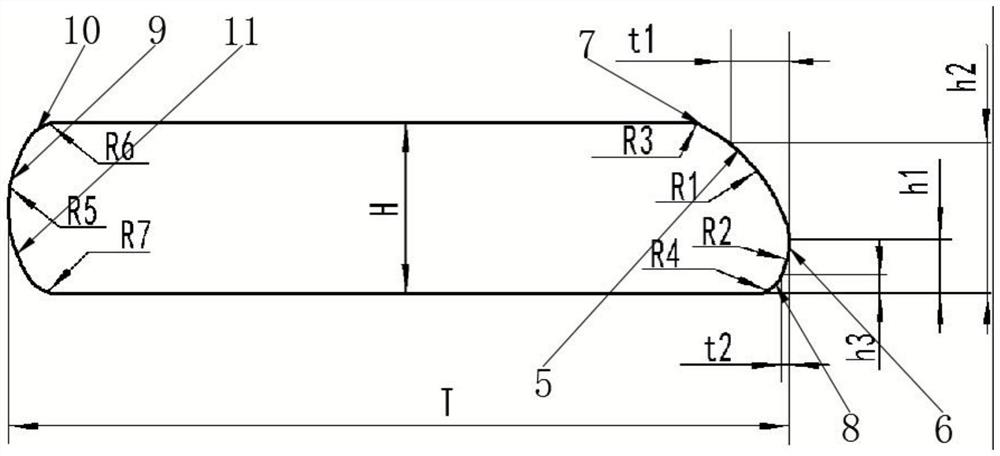

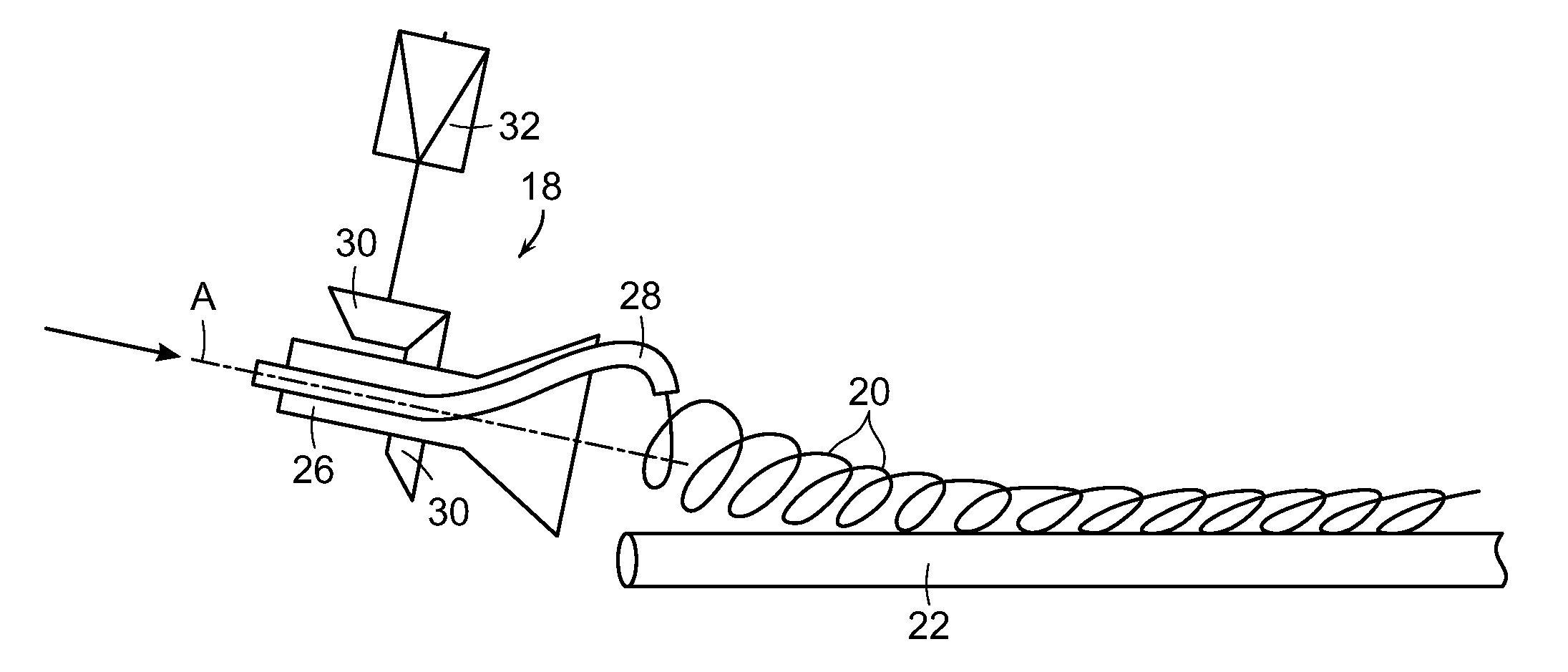

InactiveUS8316679B2Improve friction and wearExtended service lifeLiquid surface applicatorsMetal rolling stand detailsWear resistantEngineering

A laying pipe for use in the laying head of a rolling mill is configured for rotation about an axis, with an entry end aligned on that axis to receive a hot rolled product, and with a curved section leading to a delivery end spaced radially from that axis. The curved section defines a guide path configured to form the hot rolled product into a helical formation of rings. The laying pipe comprises a tubular ferrous wall having an interior surface comprising a wear resistant boronized layer against which the hot rolled product is confined for movement along the guide path.

Owner:PRIMETALS TECH USA

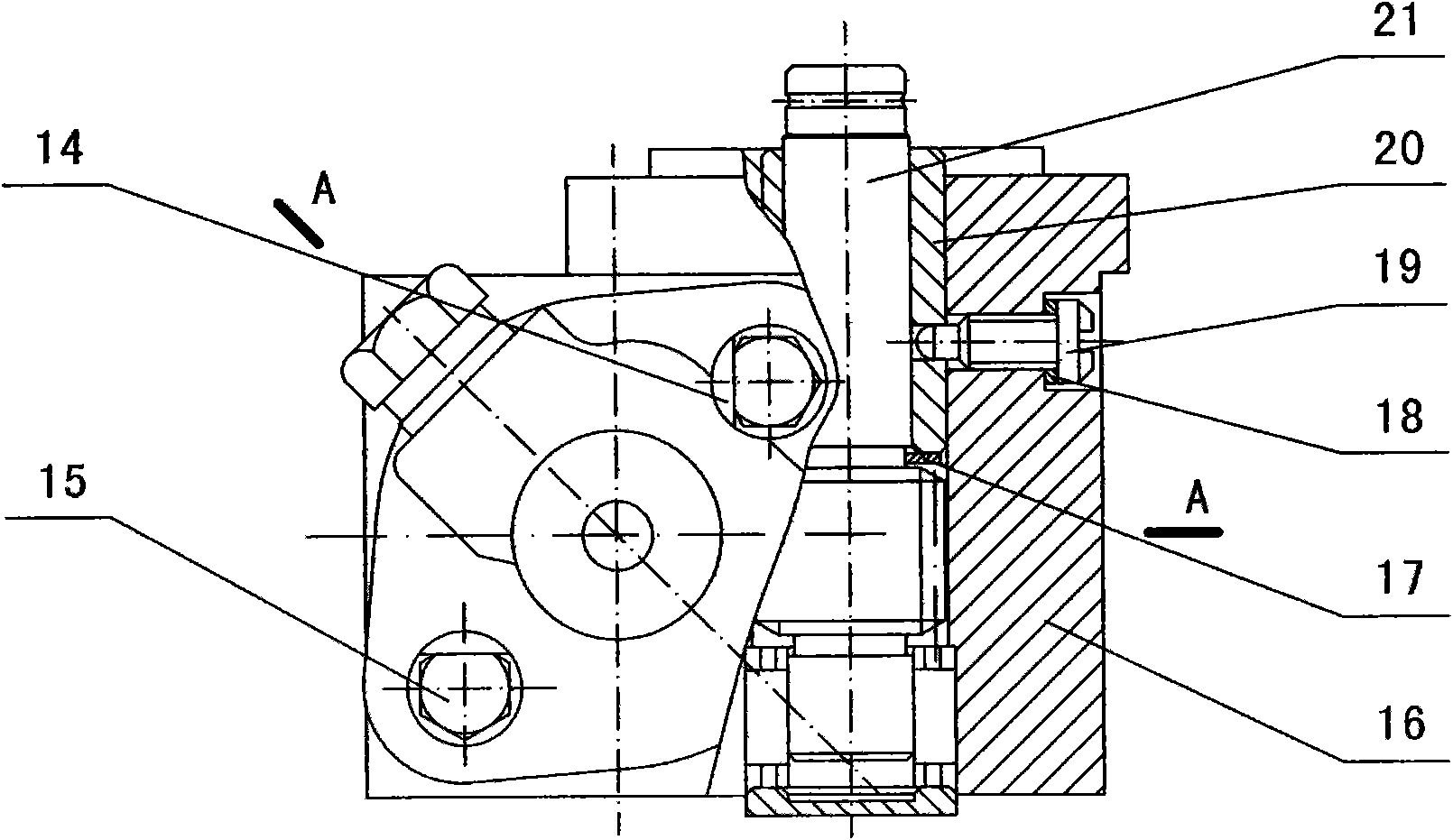

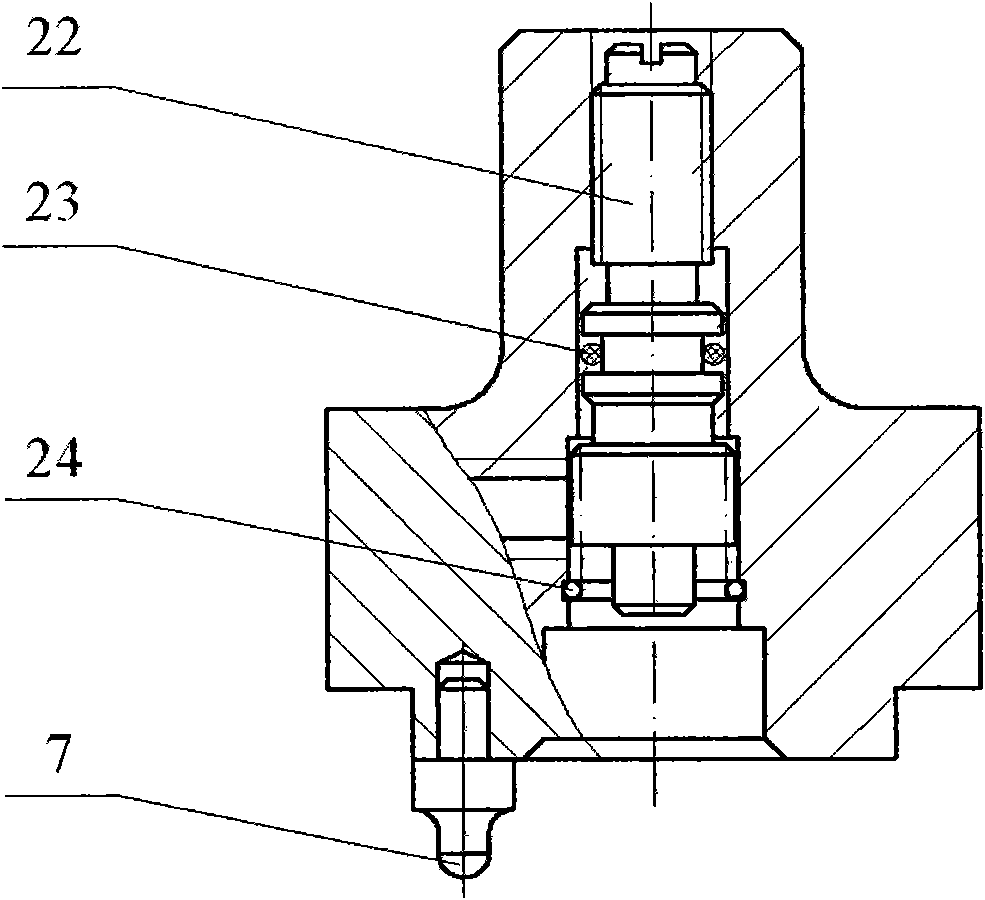

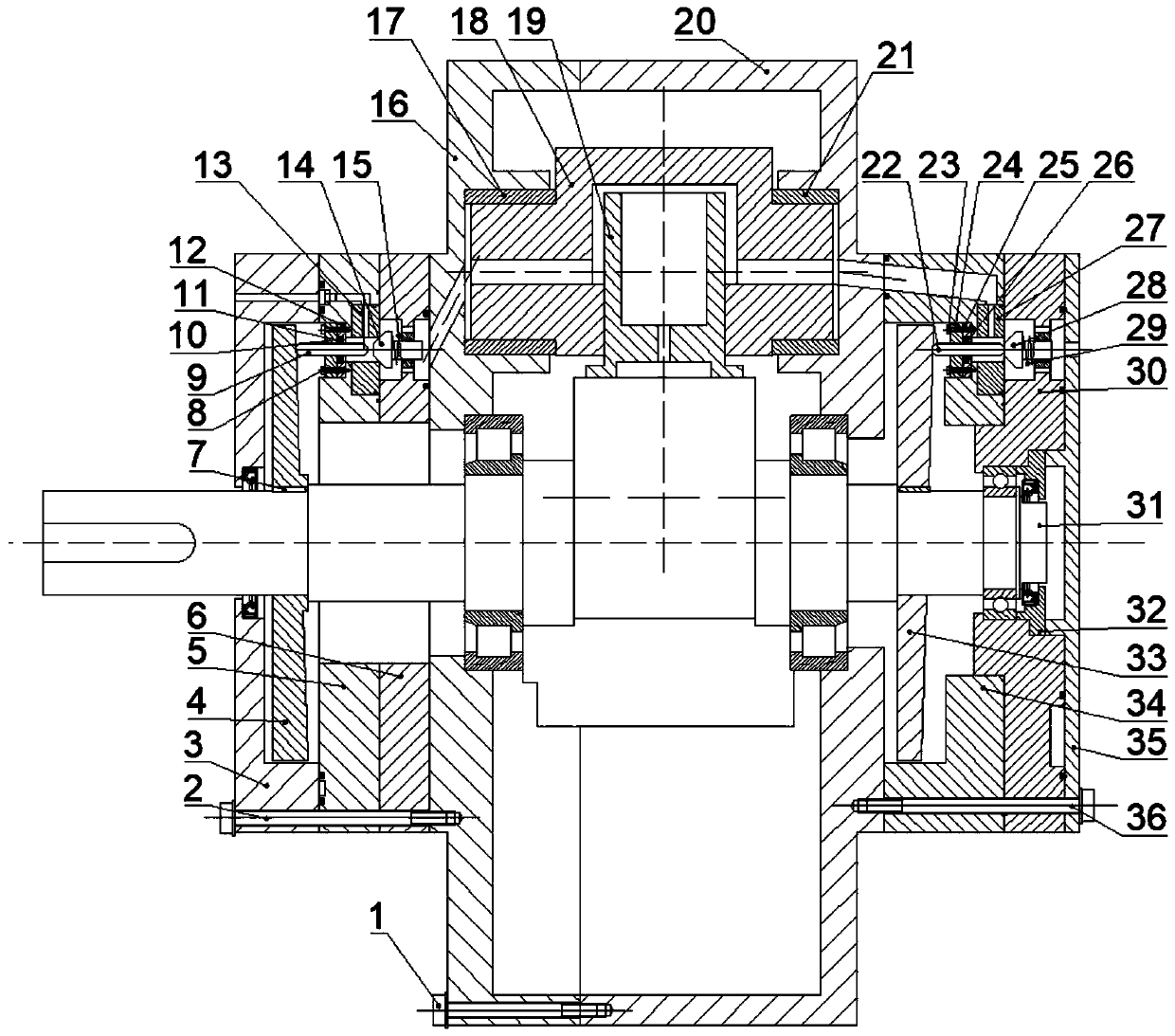

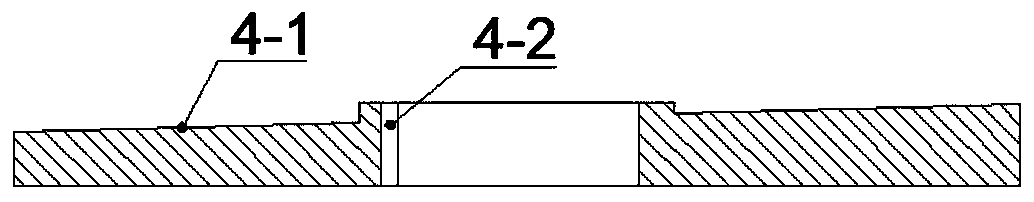

Radial plunger pump/motor and flow distribution structure thereof

ActiveCN110578684AImprove sealingImprove the problem of opening and closing lagPositive displacement pump componentsReciprocating piston enginesRadial piston pumpPhase difference

The invention discloses a flow distribution structure of a radial plunger pump / motor. The flow distribution structure comprises a left flow distribution assembly and a right flow distribution assembly. The left flow distribution assembly comprises a first flow distribution disc, a first guide rod, a first fixing piece and a first one-way valve, wherein the first flow distribution disc is mounted on a rotary shaft of the radial plunger pump / motor, the first guide rod is slidably arranged on the first fixing piece, the first one-way valve is fixed to the first fixing piece, one end of the firstguide rod is in abut joint with a slope of the first flow distribution disc, and the other end of the first guide rod is in abut joint with a valve element of the first one-way valve; the right flow distribution assembly is similar to the left flow distribution assembly; and a mounting phase difference between the first flow distribution disc and a second flow distribution disc of the right flow distribution assembly is 180 degrees. The flow distribution structure is suitable for flow distribution of an oil-pressure / water-pressure pump / motor plunger, can effectively eliminate volume efficiencylosses caused by a flow distribution module of a flow distribution structure of a common disc, and can solve the problem of severe flow-distribution wear of the common disc; in addition, when the flow distribution structure is used for flow distribution of the pump, pressure losses caused during liquid suction / discharging of the pump can effectively reduced; and the flow distribution structure has the advantages of being simple in structure and low in cost.

Owner:ZHEJIANG UNIV

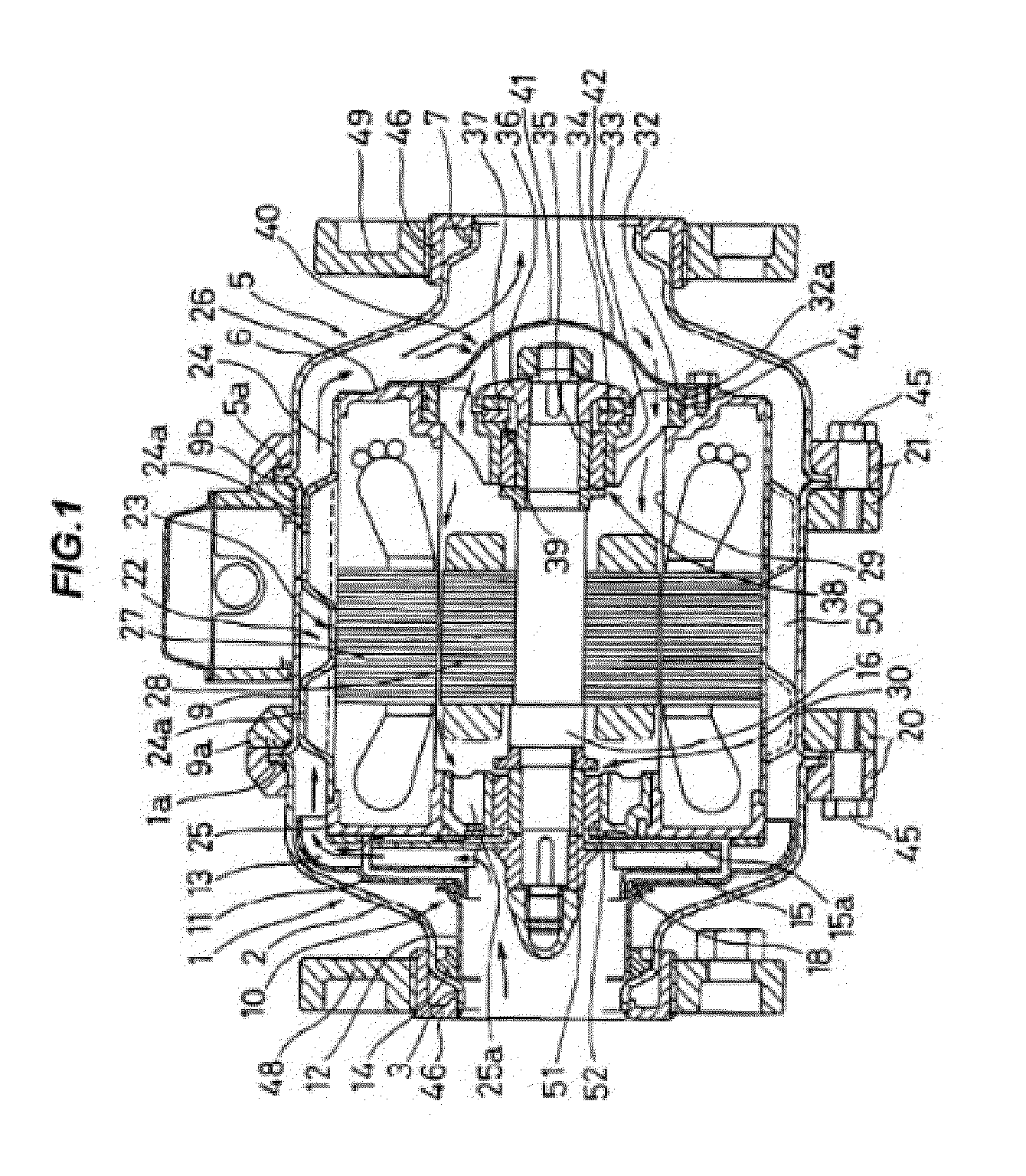

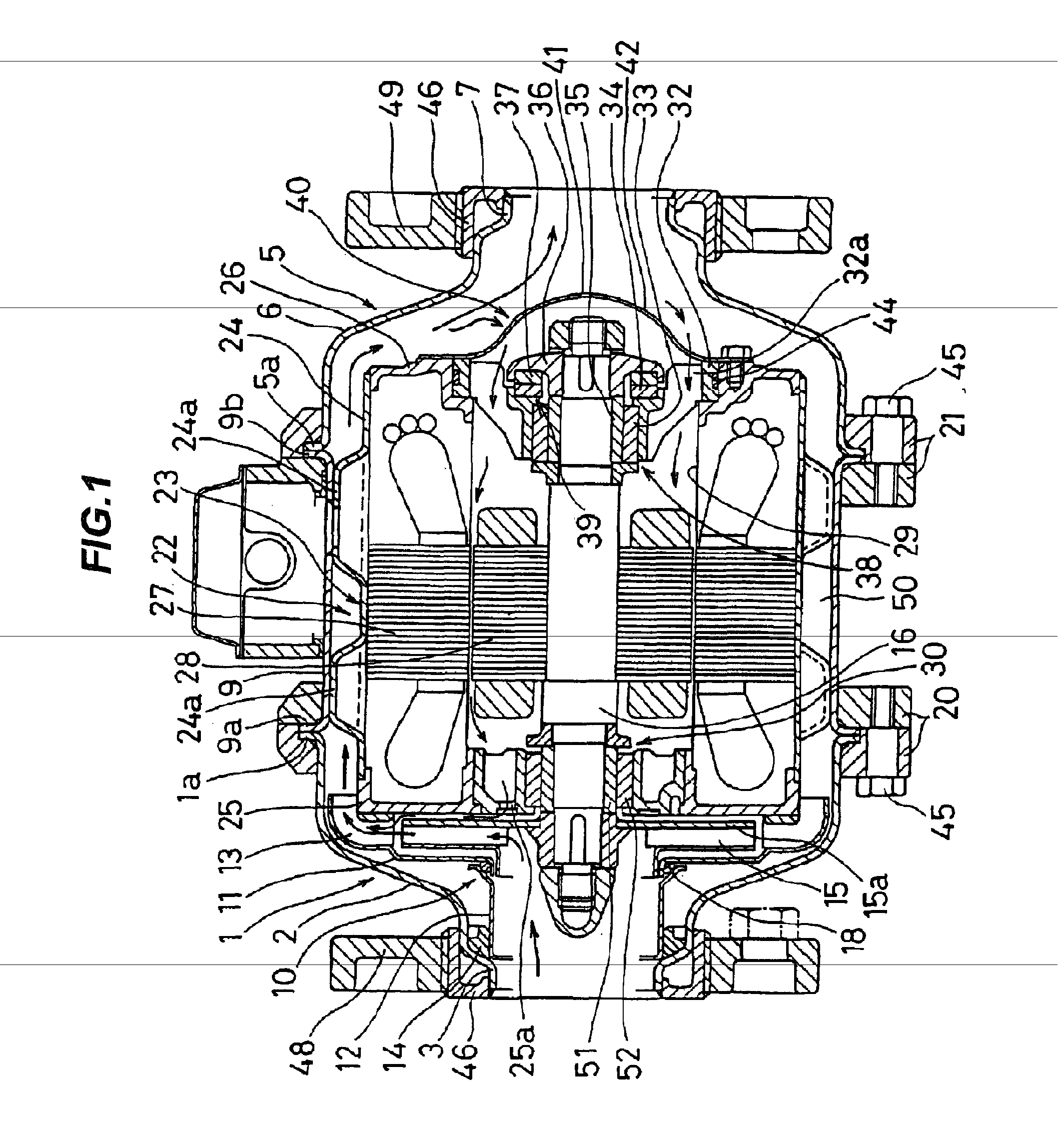

Double-cylinder rotary compressor

ActiveCN102410221AEven by forceReduce air pulsationRotary piston pumpsRotary piston liquid enginesEllipseSlip sheet

The invention relates to a double-cylinder rotary compressor. The rotary compressor comprises an outer air cylinder, an ellipse rotor, and an inner air cylinder which are concentrically installed, wherein an inner short shaft of the ellipse rotor is equal to the outer diameter of the inner air cylinder, and an outer long shaft of the ellipse rotor is equal to the inner diameter of the outer air cylinder; the external surface of the ellipse rotor and the inner wall surface of the outer air cylinder are tangent at any kinetic instant, the internal surface of the ellipse rotor and the outer side wall of the inner air cylinder are tangent, the inner air cylinder and the outer air cylinder are respectively provided with two pairs of slip sheets; the inner air cylinder is provided with two pairs of air inlet cavities and exhaust cavities; crescent volume is divided into two pairs of air inlet (liquid) cavities and compressing, exhaust (liquid) cavities by the inner air cylinder and the outer air cylinder so as to form four pairs of corresponding working volumes; and the inner air cylinder and the outer air cylinder are respectively provided with four pairs of air inlet ports and exhaust (liquid) ports. The double-cylinder rotary compressor provided by the invention has the advantages of high efficiency, no vibration, small volume, uniform stressing of a main shaft, small gas pulsation, simple structure, is stable in operation, and eliminates unbalanced force caused by rotation; and the double-cylinder rotary compressor can be used in different gas compressors, fluid pumps and vacuum pumps.

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

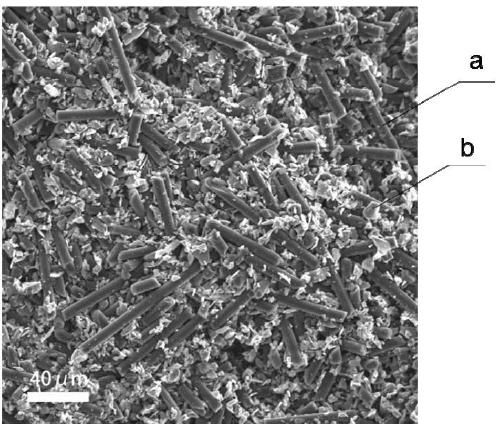

Preparation method of chopped carbon fiber reinforced Cf/SiC composite material

The invention relates to a preparation method of a chopped carbon fiber reinforced Cf / SiC composite material. The method comprises the following steps: mixing chopped carbon fibers, silicon carbide powder, a dispersant, a binder and water to obtain slurry; performing slip casting on the slurry to obtain a green body; performing heat treatment on the green body under vacuum conditions at 800-1200 DEG C for 0.5-2 h to obtain a preform; and embedding the preform by using silicon powder, and performing sintering under vacuum conditions at 1450-1700 DEG C for 0.5-2 h to obtain the chopped carbon fiber reinforced silicon carbide based composite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing C/W2B5 composite material

The processing steps are: a B4C powder with particle size 0.1 mum-20 mum, WC powder with particle size 0.1 mum-20 mum, conductex ratio of B4C:WC: conductex is (4-6):(7-9):(0-120), they are mixed by regular technology; b. mixed material is put in graphite model; c. the model is put into high vacuum heat-pressing furnace to be fired in vacuum or protection gas, firing temp. is 1600-2200 deg.C, pressure acting on graphite model is 15-45 Mpa, temp. -keeping time is 0.5-3 hours. The C / W2B5 compound material produced by this invention has compacting degree is greater than or equal to 96 percent, resistivity is less than or equal to 2.0 mu omega.m, room-temp. anti-bending strength is greater than or equal to 350 MPa, room-temp. breaking toughness is greater than or equal to 5 MPa.m1 / 2.

Owner:HARBIN INST OF TECH

Ceramics sliding member for use in pure water

InactiveUS20130209777A1Easy to manufactureMinimize damagePump componentsAnimal housingCrystal structureCeramic

A ceramics sliding member for use in ultrapure water or pure water of the present invention is made of a non-continuous-pore SiC sintered body. The non-continuous-pore SiC sintered body includes β-SiC at a ratio of 20% by weight or more thereto and has an average crystal structure whose aspect ratio is 2 or greater.

Owner:EBARA CORP +1

Modified ultrahigh molecular weight polyethylene composite material

InactiveCN107722419AImprove friction and wearImprove erosion resistanceSilica particlePolymer science

The invention discloses a modified ultrahigh molecular weight polyethylene composite material, and belongs to the field of high-molecular materials. The composite material comprises the following components: 80-120 parts of ultrahigh molecular weight polyethylene, 7-12 parts of nanometer silica, 5-10 parts of glass bead, and 0.1-0.8 parts of a silane coupling agent. Nanometer silica and glass beads are added into the ultrahigh molecular weight polyethylene, and nanometer silica particles and glass beads can block expansion of furrows and plastic deformation, and block embedding and cutting ofabrasive particles. A proper amount of nanometer silica particles are added in order to improve friction and wearing as well as anti-erosion performance of ultrahigh molecular weight polyethylene; glass beads can improve heat stability and anti-friction creep deformation performance of ultrahigh molecular weight polyethylene.

Owner:中玺新材料(安徽)有限公司

Ceramics sliding member for use in pure water

InactiveUS20100130343A1Easy to manufactureMinimize damageEngine sealsBearing componentsCrystal structureCeramic

A ceramics sliding member for use in ultrapure water or pure water of the present invention is made of an SiC sintered body. The SiC sintered body includes β-SiC at a ratio of 20% or more thereto and has an average crystal structure whose aspect ratio is 2 or greater.

Owner:EBARA CORP +1

Water lubrication rubber alloy bearing

InactiveCN101334069BImprove performanceExtended service lifeBearing componentsChemical industryMetallurgy

The invention discloses a water lubrication rubber alloy bearing, which comprises a water lubrication rubber alloy bushing and a bearing outer ring. The water lubrication rubber alloy bushing is bonded on the inner circumference of the bearing outer ring through die stamping and vulcanizing, the corresponding coincidence relation is adopted for the radial thickness m of the water lubrication rubber alloy bushing according to the difference of the internal diameter d of the water lubrication rubber alloy bushing. The affect of the radial thickness of the water lubrication rubber inner liner tothe bearing capacity and the shock resistant capability of the bearing is comprehensively considered in the water lubrication rubber alloy bearing, the corresponding thickness of the water lubrication rubber inner liner is adopted according to bearings with different specifications, the bearing capacity of the bearing is obviously enhanced, the properties of surface deformation compatibility and elastic fluid dynamic pressure lubrication and the good silt, sand and impurities drainage capacity are strengthened, the service life of the water lubrication rubber alloy bearing is more than three times the similar bearing, the water lubrication rubber alloy bearing has the advantages of vibration damping, noise reduction, abrasion resistance, reliability, high efficiency, energy conservation and environmental friendliness and can be widely applied to the fields of the engineering equipments of machinery, marine vessel, petroleum, chemical industry, mine, water conservancy, agriculture and national defense.

Owner:重庆奔腾科技发展有限公司

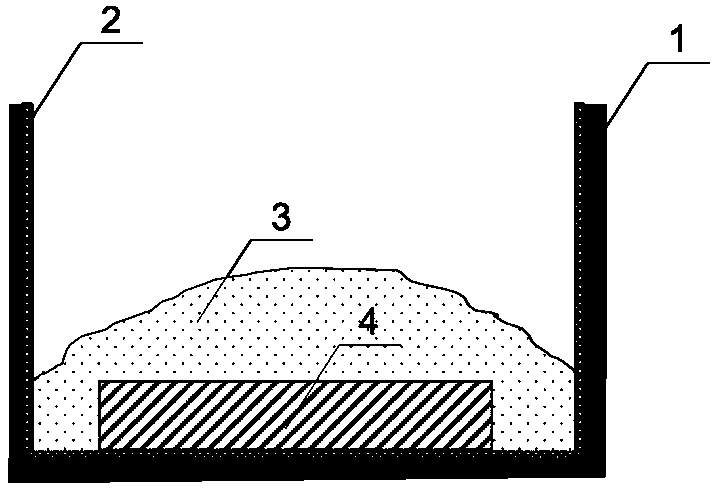

Preparation method for nickel-based glass fiber composite material based on laser cladding

InactiveCN104451663AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesShielding gasOptoelectronics

The invention discloses a laser cladding coating method for iron-based titanium carbide. The method is characterized by comprising the following steps: 1, selecting 45# steel as a cladding substrate, polishing to be smooth and clean by 600-mesh sand paper, thoroughly removing oil stains and rust on the surface of the substrate by an acetone solution; 2, drying nickel-based powder in a drying machine at 120 DEG C for 60 minutes; 3, arranging glass fibers on the substrate, and prearranging nickel-based powder on the surface of the 45# steel substrate, wherein the powder is 1-5 mm in thickness; 4, cladding by a high-power semiconductor laser device, wherein the laser power is 3,000 W. The selected and used optical spot is 2-8 mm in width, the focal length is 370 mm, the scanning speed is 8 mm / s or 16 mm / s, and argon gas is adopted as protection gas.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of multilayer nano-composite-class diamond films on surface of camshaft

InactiveCN103160780AReduce coefficient of frictionReduce wear rateVacuum evaporation coatingSputtering coatingComposite filmMicrometer

The invention discloses a preparation method of multilayer nano-composite-class diamond films on the surface of a camshaft. Due to the adoption of a high-frequency and high-power impulse magnetron sputtering technology, the multilayer nano-composite-class diamond films are deposited on the surface of the camshaft. The thicknesses of the composite films are 0.2-0.5 micrometer, the thickness of a bearing layer of the composite films is 1-3 micrometers, and the surface thickness of the composite films is 1-3 micrometers. The surface binding force of the composite film camshaft is up to 60N.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

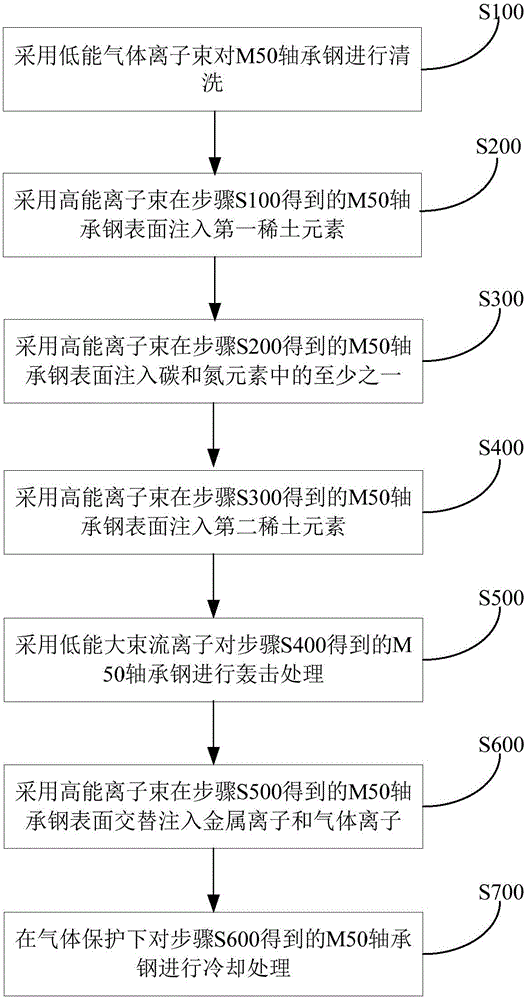

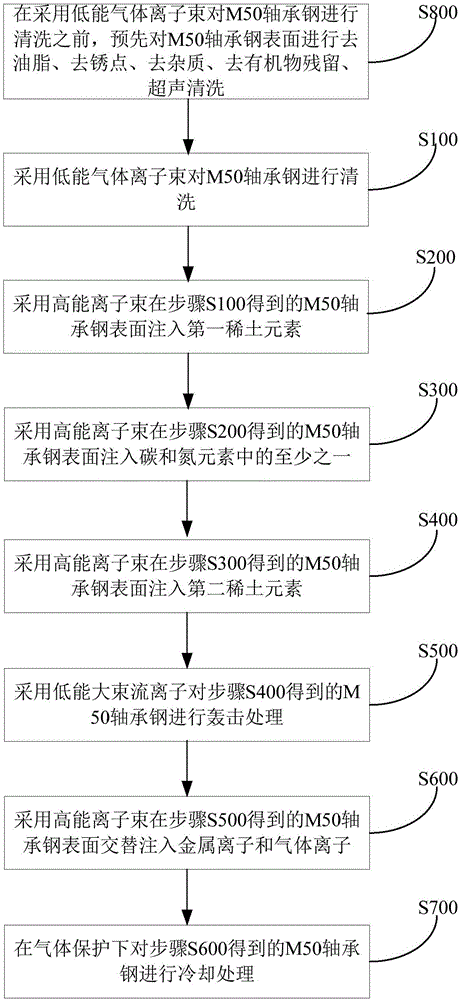

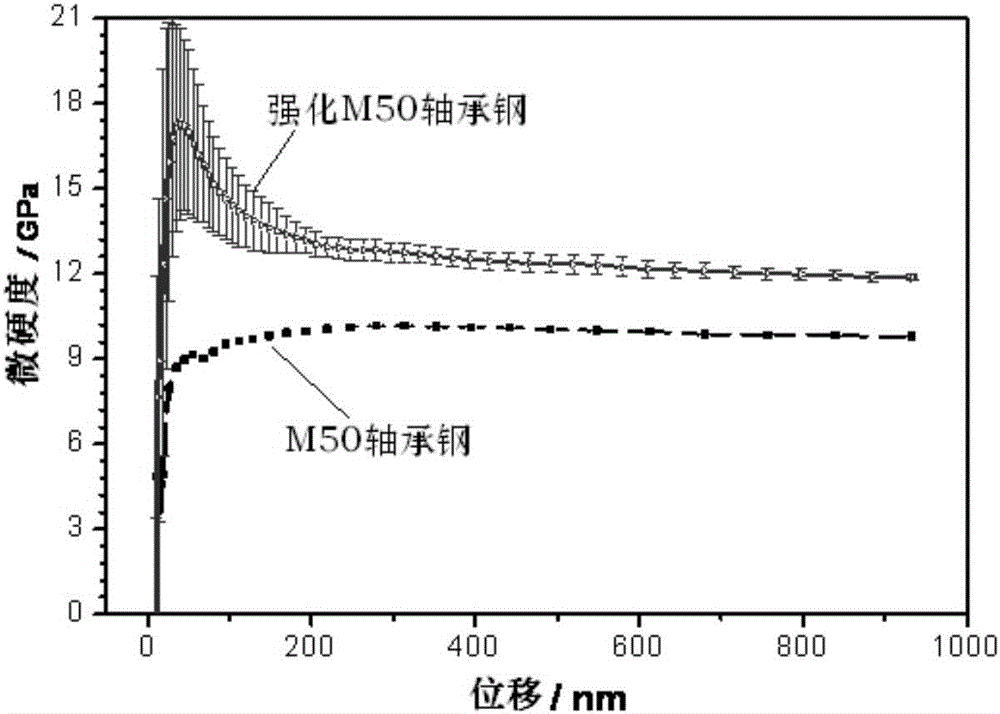

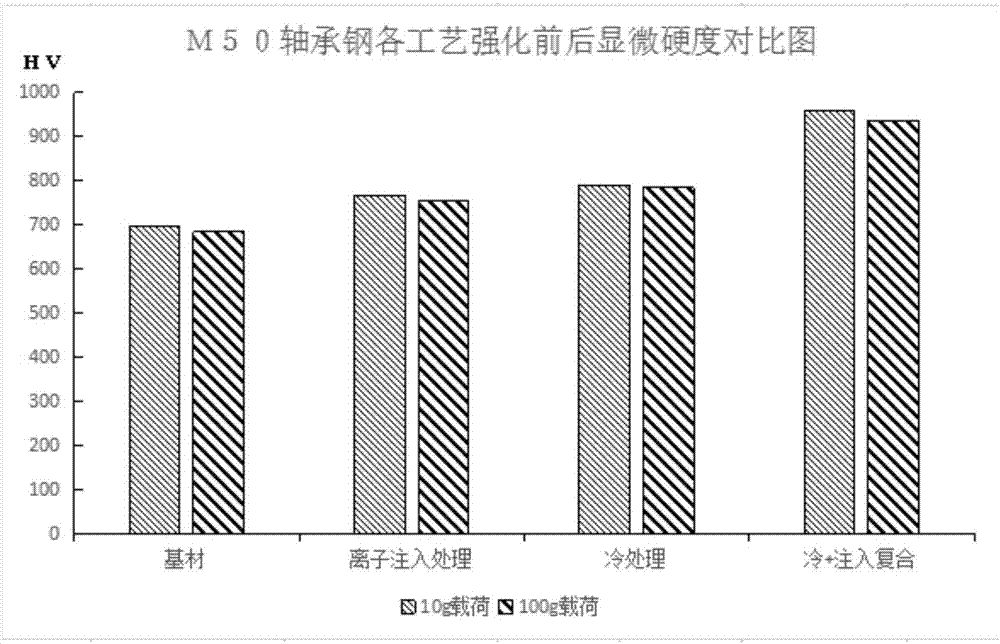

Method for treating M50 bearing steel, strengthened M50 bearing steel and bearing

ActiveCN106521406AImprove friction and wearImprove fatigue resistanceSolid state diffusion coatingRare-earth elementHigh energy

The invention discloses a method for treating M50 bearing steel, strengthened M50 bearing steel and a bearing. The method comprises the steps that firstly, a low-energy gas ion beam is used for cleaning the M50 bearing steel; secondly, a high-energy ion beam is adopted for injecting a first rare earth element into the surface of the M50 bearing steel obtained in the first step; thirdly, the high-energy ion beam is adopted for injecting at least one of the carbon element and the nitrogen element into the surface of the M50 bearing steel obtained in the second step; fourthly, the high-energy ion beam is adopted for injecting a second rare earth element into the surface of the M50 bearing steel obtained in the third step; fifthly, low-energy large beam ions are adopted for conducting bombardment treatment on the M50 bearing steel obtained in the fourth step; sixthly, the high-energy ion beam is adopted for alternately injecting metal ions and gas ions in the surface of the M50 bearing steel obtained in the fifth step; and seventhly, under gas protection, cooling treatment is conducted on the M50 bearing steel obtained in the sixth step, and the strengthened M50 bearing steel is obtained. By means of the method, friction and abrasion resistance, fatigue resistance, corrosion resistance and other comprehensive performance of an M50 bearing steel material can be greatly improved.

Owner:TSINGHUA UNIV

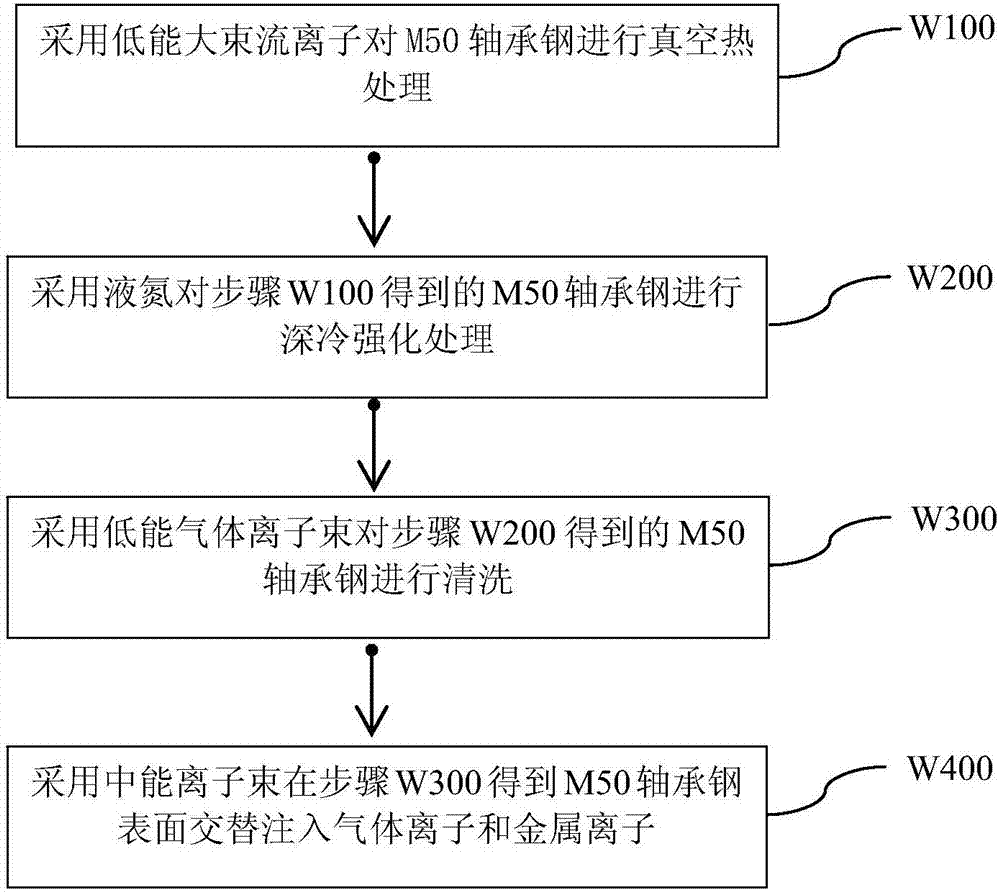

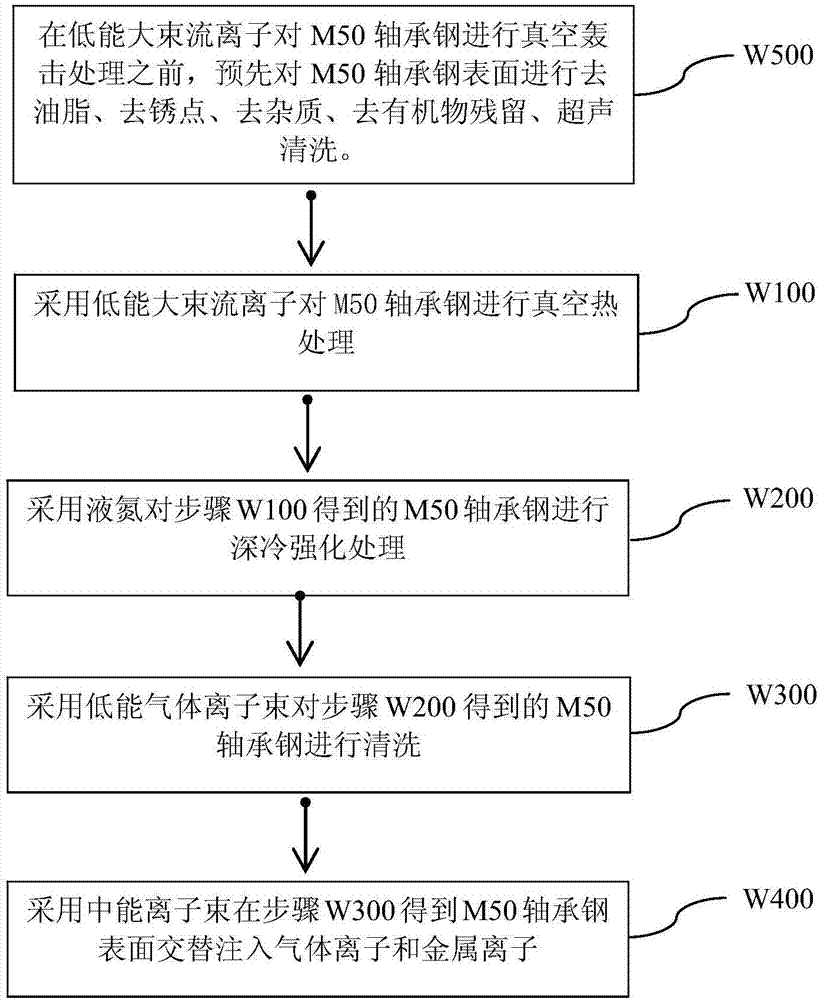

Ion beam and cryogenic composite strengthening method for M50 bearing steel

InactiveCN107287572AAdd depthImprove toughnessVacuum evaporation coatingSputtering coatingSurface layerMetallurgy

The invention discloses an ion beam and cryogenic composite strengthening method for M50 bearing steel. The cryogenic composite strengthening method comprises the following steps that (1), vacuum heat treatment is conducted on the bearing steel through low-energy large-beam gas ions; (2), cryogenic strengthening processing is conducted on the bearing steel obtained in the first step through liquid nitrogen; (3), the bearing steel processed in the second step is cleaned through gas ion beams; and (4), by the adoption of an ion implantation method, gas ions and metal ions are alternately injected into the surface of the bearing steel processed in the third step by the adoption of an ion injection method till the bearing steel is strengthened. According to the method, the ion injection layer depth and the sub deep surface layer strengthening depth of the M50 bearing steel material are increased greatly by the adoption of thermal processing and cold processing in combination with the ion injection strengthening technology, the friction wear performance and fatigue resistance performance of the M50 bearing steel are improved, and the strong and tough integrated material modified layer is formed.

Owner:TSINGHUA UNIV

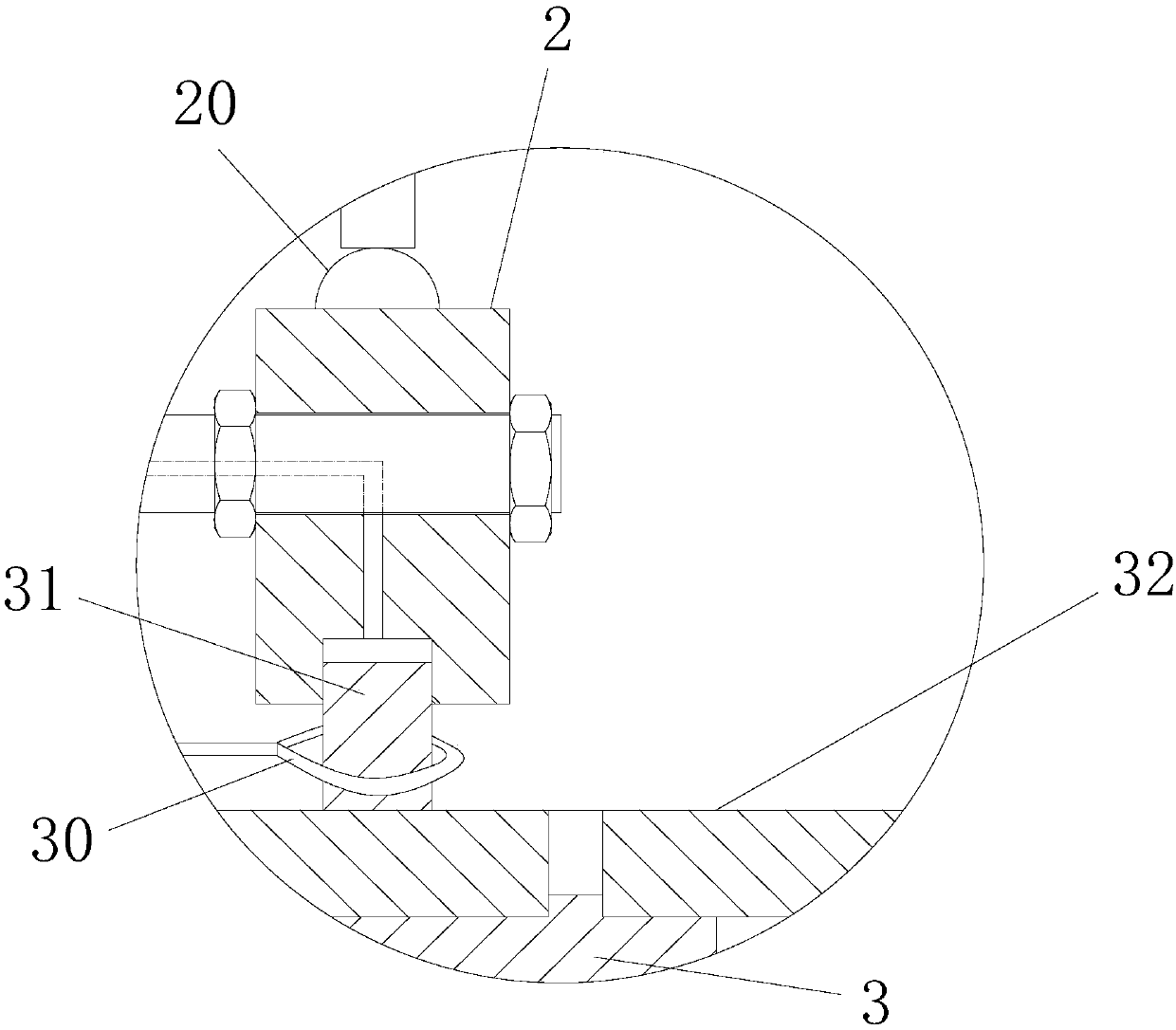

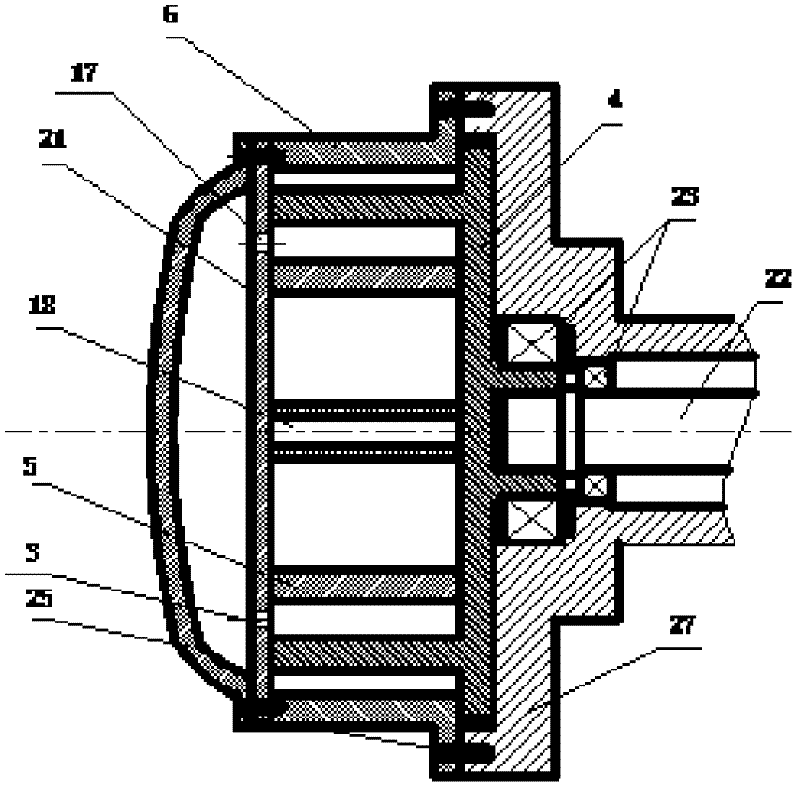

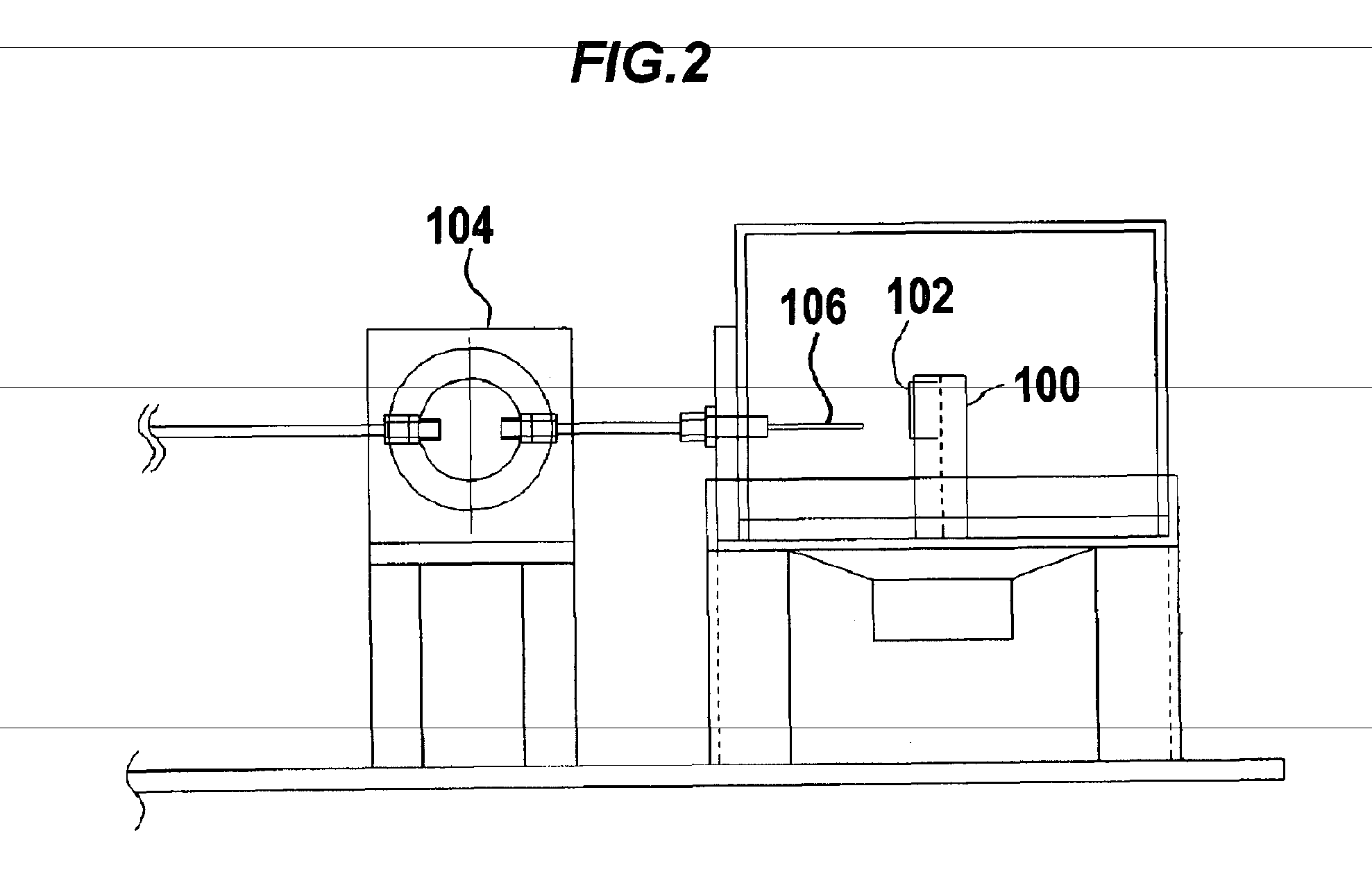

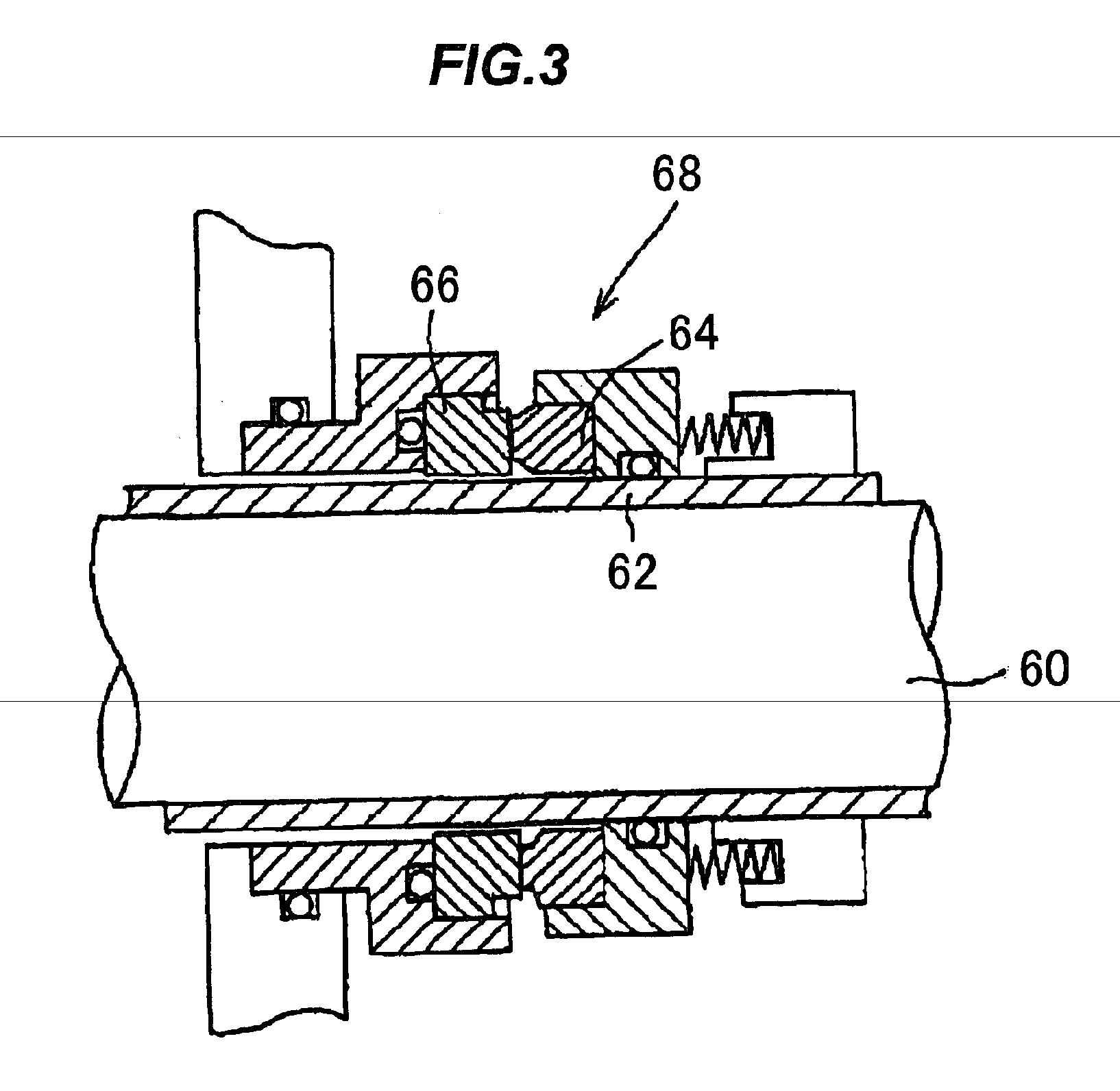

Auxiliary seal life verification testing machine for nuclear main pump shaft seal

ActiveCN112525514AAccelerated friction and wearAssess lifeMachine part testingNuclear energy generationPhysicsEngineering

The invention discloses an auxiliary seal life verification testing machine for a nuclear main pump shaft seal. The machine comprises a vibration main unit which includes a connecting disc, an actuator, a force measurement sensor, a double-groove static ring seat and an insertion part, wherein the actuator and the force measurement sensor are installed on the connecting disc, the double-groove static ring seat is located above the force measurement sensor, and the insertion part is installed on an output shaft of the actuator, and the double-groove static ring seat is provided with three ringgrooves. A middle annular groove is connected with a circulating water inlet pipe and a circulating water outlet pipe, the upper annular groove and the lower annular groove accommodate two groups of groove-shaped seals of a contrast test, each groove-shaped seal comprises an O ring and an O ring supporting ring, the O ring supporting rings abut against the outer cylindrical surface of the insertion part under the action of circulating water pressure, and the inserting part is driven by the actuator to reciprocate and rub with the two O ring supporting rings. The force measurement sensor measures a total friction force. An actuator oil source is used for providing a hydraulic medium for the reciprocating motion of the actuator; a water pressurizing and circulating system is used for continuously supplying high-pressure deionized water to the double-groove static ring seat; and a monitoring system is used for detecting vibration related parameters and controlling normal operation of theequipment.

Owner:中广核工程有限公司 +2

Preparation method of modified ultra-high molecular weight polyethylene composite

InactiveCN107641238AImprove friction and wearImprove erosion resistanceSilica particlePolymer science

The invention discloses a preparation method of a modified ultra-high molecular weight polyethylene composite, and belongs to the field of high polymer materials. The composite comprises 80-120 partsof ultra-high molecular weight polyethylene, 7-12 parts of nanosilicon dioxide, 5-10 parts of glass microsphere, and 0.1-0.8 part of silane coupling agent. The nanosilicon dioxide and the glass microsphere are added into the ultra-high molecular weight polyethylene, the nanosilicon dioxide particle and the glass microsphere blocks the extension and the plastic deformation of a furrow, and the embedding and the cutting of an abrasive particle are stopped. Proper amount of nanosilicon dioxide particle is filled to improve the frictional wear and the erosion resistance of the ultra-high molecularweight polyethylene, and the glass microsphere improves the thermal stability and the anti-friction croop property of the ultra-high molecular weight polyethylene.

Owner:中玺新材料(安徽)有限公司

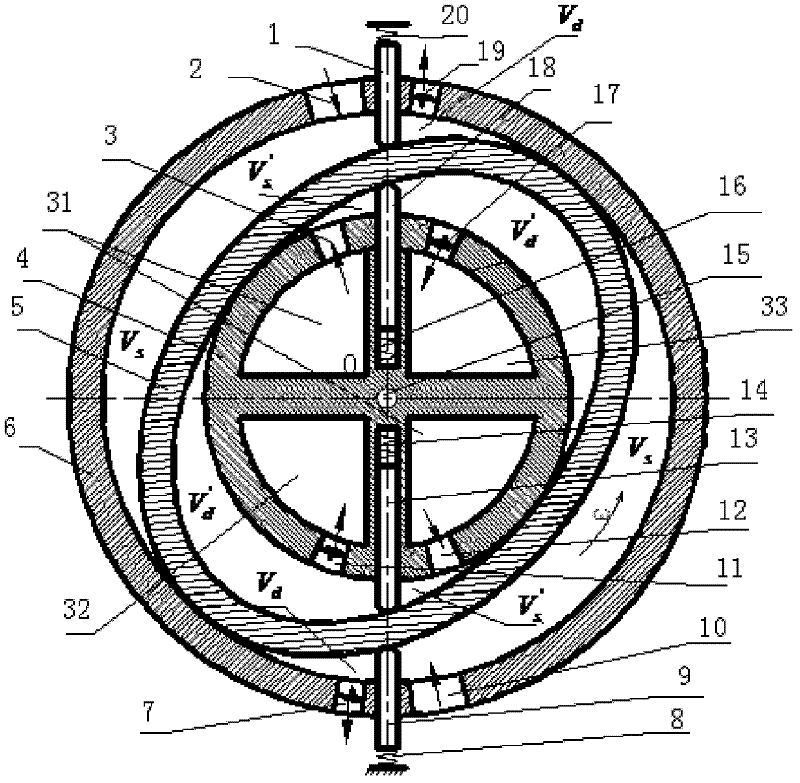

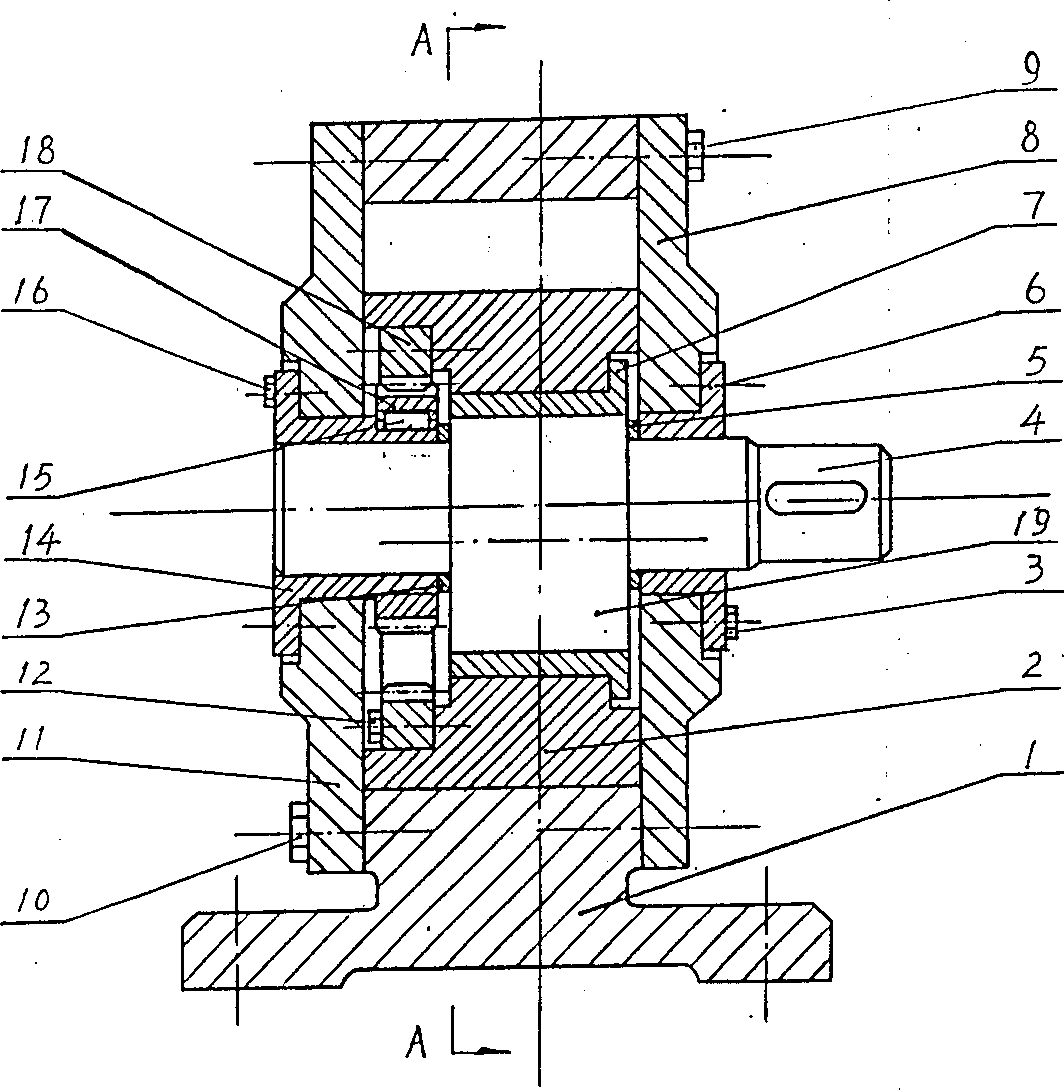

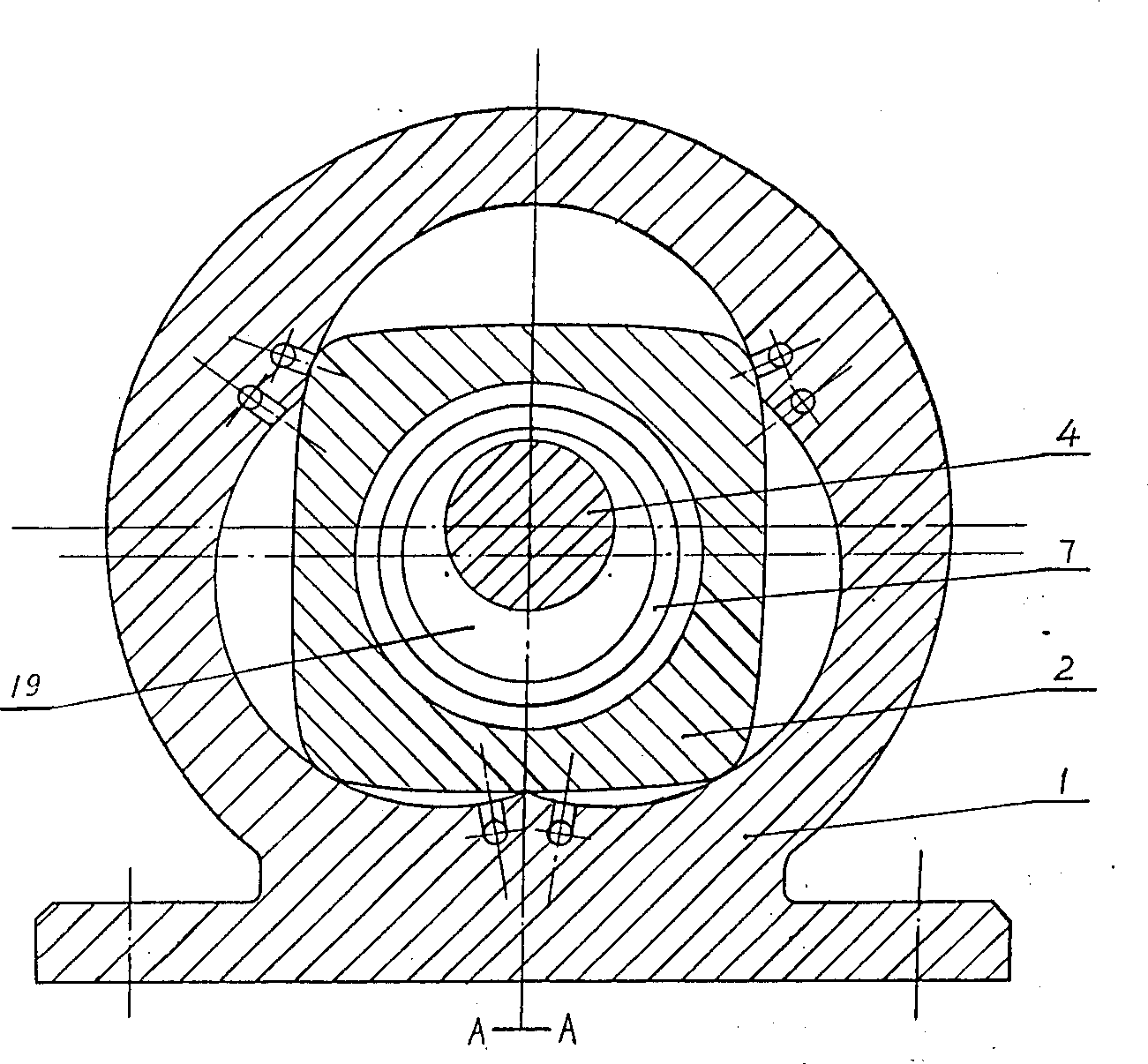

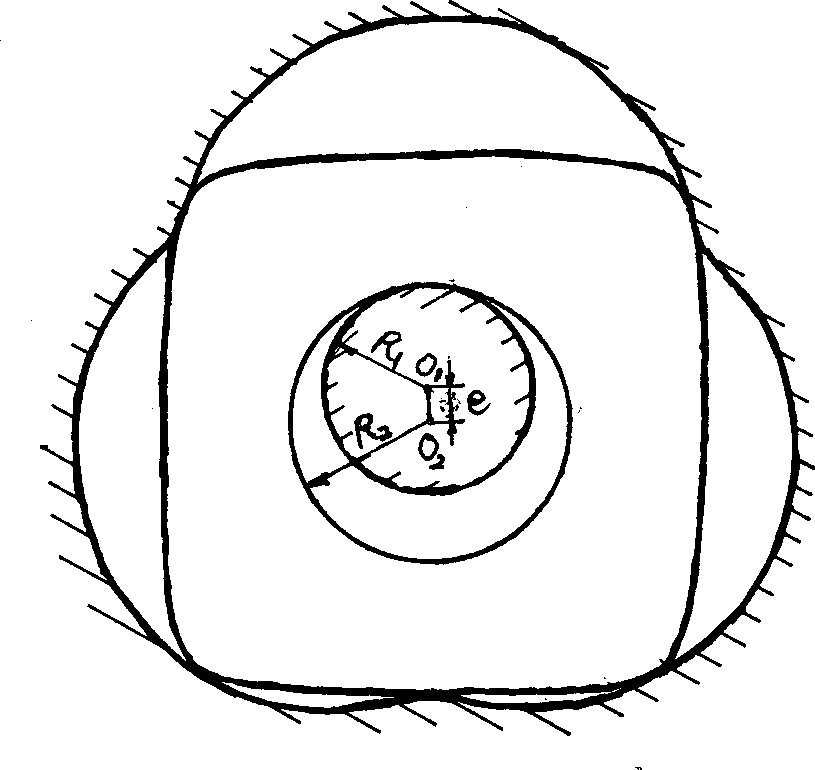

Secondary envelope surface type rotary air compressor

InactiveCN1363772AImprove sealingImprove friction and wearRotary piston pumpsRotary piston liquid enginesGas compressorSurface type

A secondary envelope type rotary gas compressor features that the corners of rotor is changed into arc recess crossed with the contour of rotor, the adjacent rotor contour is modified for smooth linking between the modified contour and rotor contour, and a cylinder is installed in each arc recess communicated with the lubricating system of bearing, resulting in rolling contact between rotor and stator. Its advantages include good size compensation, high antiwear and sealing performance and long service life.

Owner:重庆工学院 +1

Fluororesin and polyamide fiber composition, and sliding member made therefrom

ActiveUS20140378615A1Present inventionImprove friction and wearShaftsBearing componentsPolymer scienceAramides

Described herein are fluororesin compositions of melt processible fluororesin and wholly aromatic polyamide fibers. The wholly aromatic polyamide fibers have an average fiber diameter of 10-20 μm and an average fiber length of 100-1,000 μm. The compositions are melt processible and can be melt molded into sliding members having low wear when used with sliding counterparts made of metals such as aluminum, copper, zinc or nickel.

Owner:THE CHEMOURS CO FC LLC +1

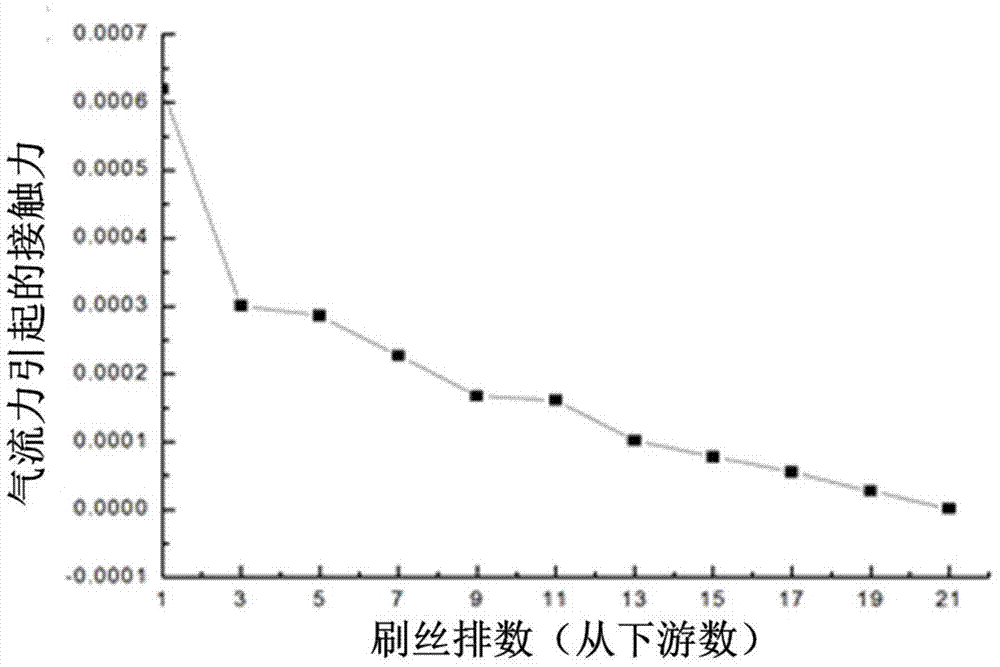

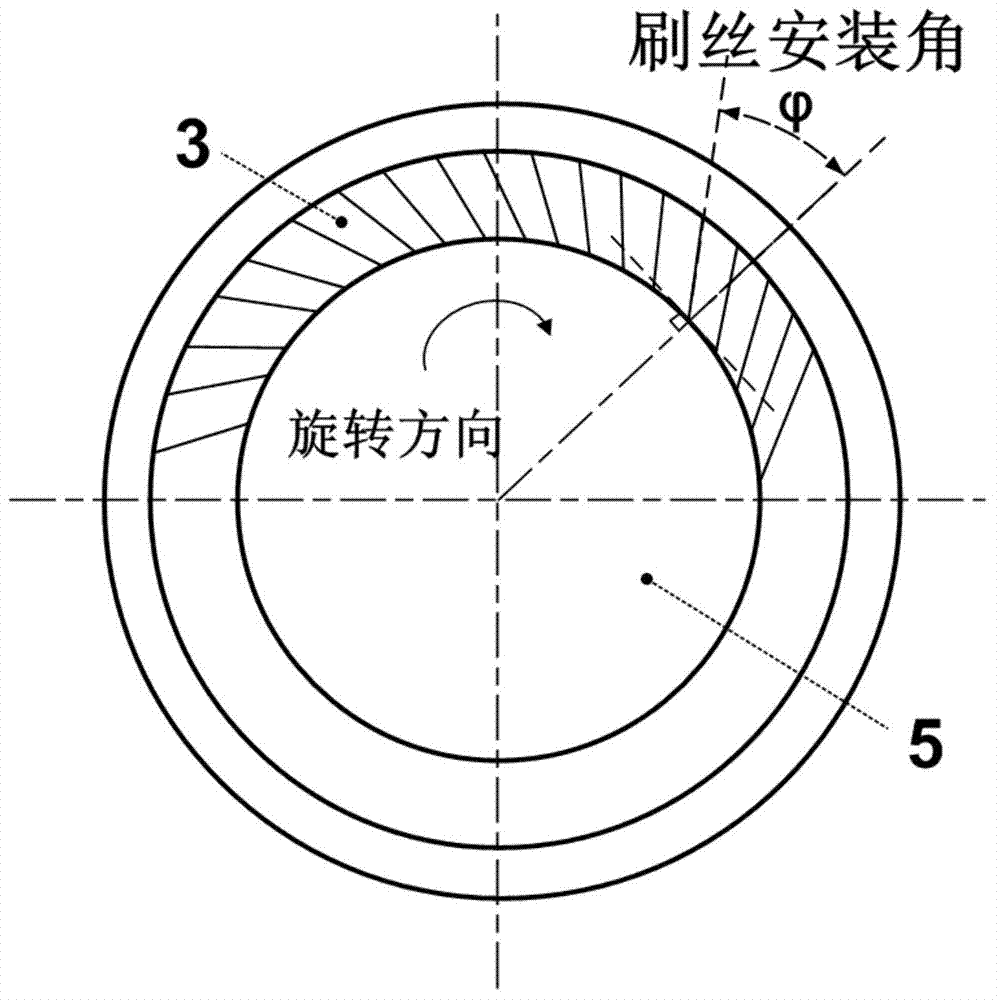

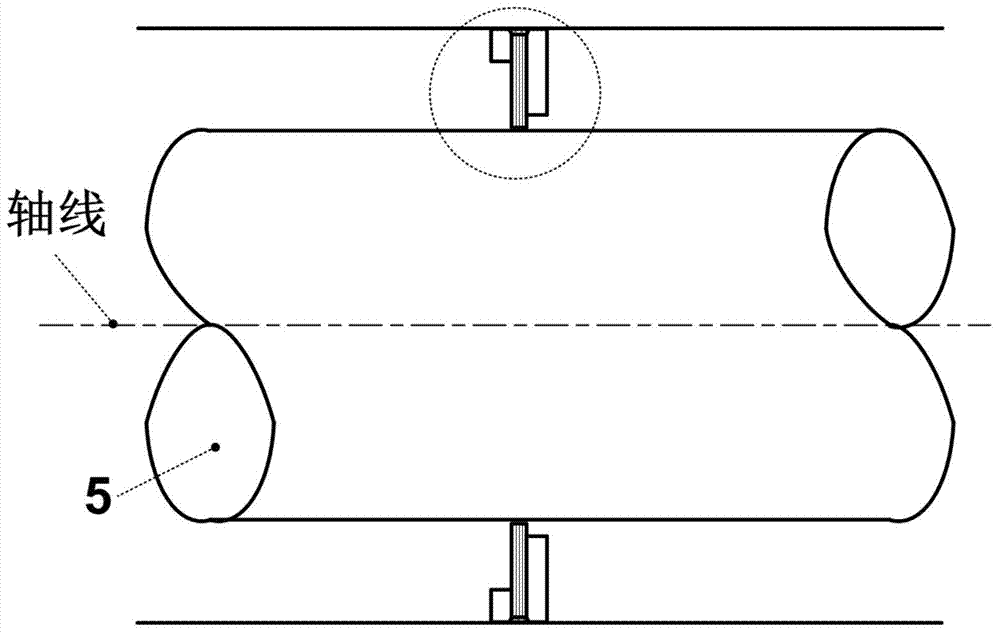

Low-wear brush type seal

InactiveCN103498705AImprove stabilityImprove securityLeakage preventionMachines/enginesRadial planeContact force

A low-wear brush type seal comprises a front baffle, a rear baffle and a brush wire bundle. The root portion of the brush wire bundle is clamped by the front baffle and the rear baffle, the brush wire bundle is blown down and is in contact with a rotor under upstream pressure, brush wires of a brush wire area are not flush in the radial direction of the rotor, and the lengths of the brush wires of the downstream of the brush wire bundle are smaller than those of the brush wires on the upstream, namely seen from the axial-radial plane of the rotor 5, the downstream free end of the brush wire bundle 3 exists; initial gaps between the downstream brush wires and the rotor 5 are larger than those between the upstream brush wires and the rotor 5, notches can specifically reduce wear friction between the brush wire bundle 3 and the rotor 5, and the downstream brush wires can still be blown off under pressure differences and make slight contact with the rotor or maintain a small gap with the rotor, so that leakage amount is not increased obviously. According to the low-wear brush type seal, contact force between the downstream brush wires and the rotor is specifically reduced, and wear between the brush wires and the rotor is greatly reduced.

Owner:TSINGHUA UNIV

Asymmetric doctor blade ring and three-combination piston oil ring and manufacture method of doctor blade ring

ActiveCN113153566AReduce oil consumptionImprove oil scraping effectPiston ringsGrinding drivesOil distributionPiston

The invention discloses an asymmetric doctor blade ring and three-combination piston oil ring and a manufacture method of a doctor blade ring. The asymmetric doctor blade ring and three-combination piston oil ring comprises a bushing ring body, two doctor blade ring base bodies, a piston and a cylinder sleeve, the excircle face of each doctor blade ring base body is of an asymmetric barrel face structure, the oil distribution area of the upper side of the excircle is increased, the oil storage amount is increased, and the thickness and uniformity of an oil film on a cylinder wall are increased. The lubricating condition is improved, the frictional wear between the ring and the cylinder wall is reduced, the friction faces of the ring and the cylinder sleeve are protected, and the friction noise is reduced. The oil distribution area is small when a doctor blade moves downwards, and therefore the thickness of an oil film on the surface of the cylinder sleeve is reduced, residual lubricating oil is reduced, and engine oil consumption of an engine is further reduced. By increasing the contact surface of the circular arc of the inner circular surface of the doctor blade ring and a bushing ring, the contact face pressure is reduced, and the abrasion of the bushing ring is effectively improved. By reducing the circular arc of the outer circular surface of the doctor blade ring, the contact face between the ring and the cylinder wall is reduced, the contact face pressure is increased, the oil scraping effect of the doctor blade ring is improved, and a positive effect on improving the oil consumption of the engine is achieved.

Owner:ANQING TP GOETZE PISTON RING

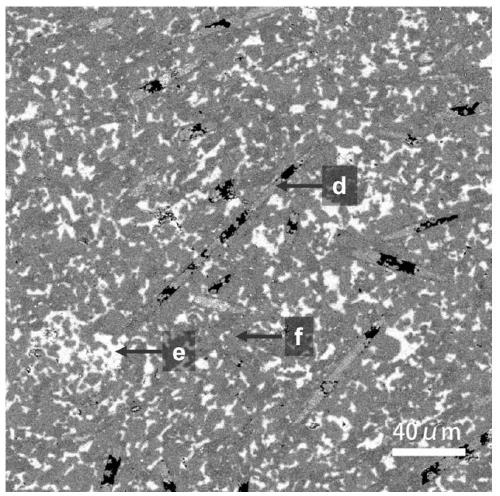

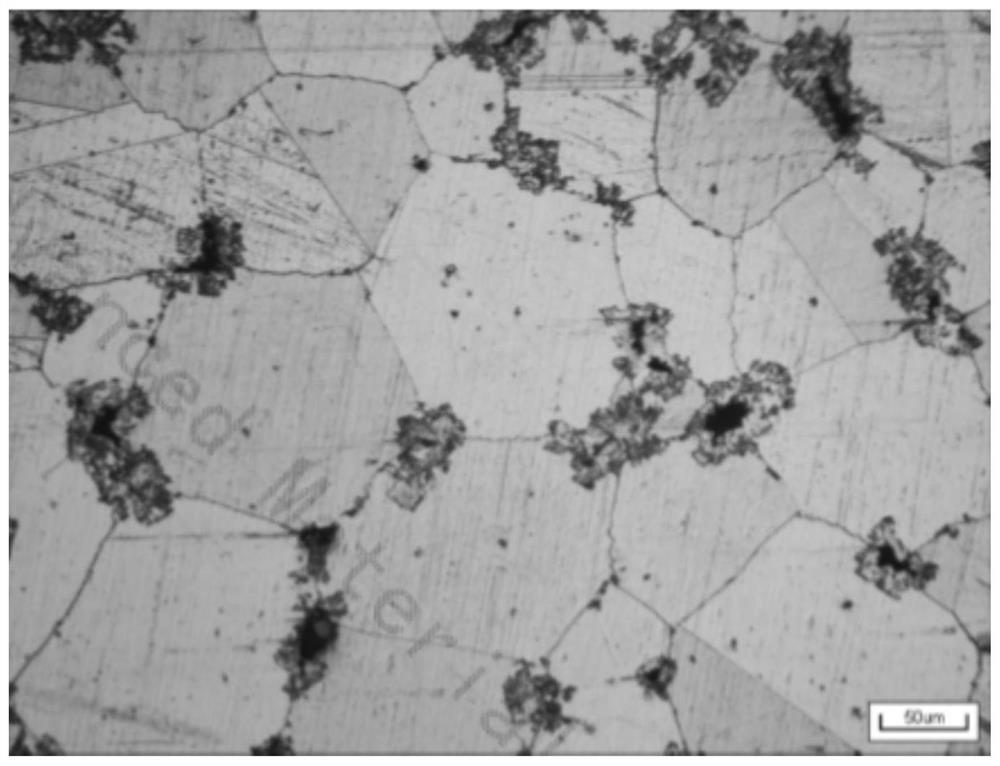

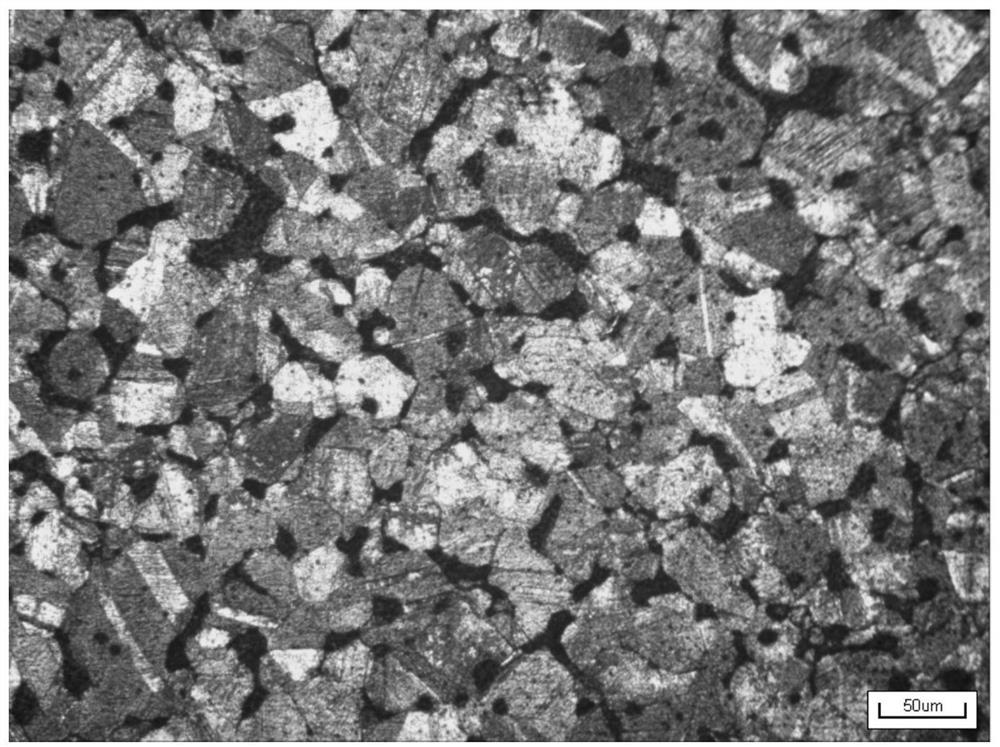

Copper-based powder metallurgy plunger pump oil distribution disc material and preparation method thereof

InactiveCN112548093AHigh hardnessWear resistancePositive displacement pump componentsTransportation and packagingCompression moldingOil distribution

The invention discloses a copper-based powder metallurgy plunger pump oil distribution disc material and a preparation method thereof. The preparation method comprises the steps that 2%-4% of nickel,8.0%-12.0% of tin, 3%-5% of lead, 0.4%-0.65% of binder, 0.4%-0.6% of lubricant and the balance copper powder are obtained according to the weight ratio and mixed to obtain copper-based mixed powder; and then compression molding, sintering, shaping, distressing and machining are sequentially carried out to obtain a finished product. The metallographic structure of the material prepared through themethod is mainly a high-temperature equiaxed single-phase structure, a copper-tin compound and elemental lead are distributed at a grain boundary, the copper-tin compound can improve the strength andhardness of the material and play a role in abrasion resistance, and the elemental lead plays a role in abrasion reduction, so that a very good using effect is achieved; the material prepared throughthe method has better tribological characteristics and better fatigue wear resistance and adhesive wear resistance; and the preparation method is simple in process, high in production efficiency and low in processing cost.

Owner:合肥波林新材料股份有限公司

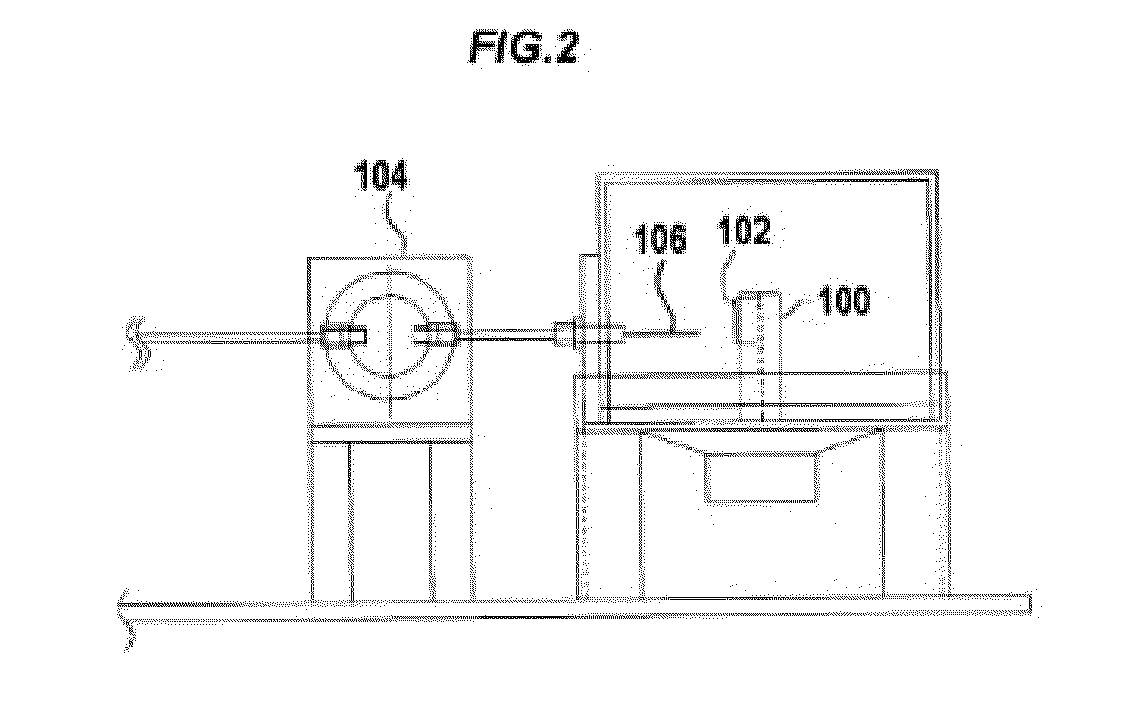

A high-frequency direct current heating auxiliary rolling processing device and processing method thereof

ActiveCN108406224BReduce deformation resistanceRolling processing effect is obviousMetal working apparatusClosed loopCopper electrode

The invention relates to a high-frequency direct-current heating auxiliary rolling device added on a machine tool. The high-frequency direct-current heating auxiliary rolling device comprises a rolling device, a heating component and a loading component; the rolling device is fixedly mounted on a cutter frame of the machine tool; and a rolling head is towards parts to be machined. The heating component comprises a high-frequency direct-current power supply, two copper electrodes and two electric brushes; and the high-frequency direct-current power supply, the two electric brushes, the two copper electrodes and the parts to be machined are connected through leads to form a closed loop. The loading component comprises an electric brush frame, two insulation fixed thimbles and an insulation revolving thimble; and in the horizontal direction of the machine tool, a machine tool tail base, the insulation revolving thimble, the first insulation fixed thimble, the first copper electrode, the parts to be machined, the second copper electrode, the second insulation fixed thimble and a power tool power chuck are coaxially clamped in sequence. The invention further relates to a machining method of the high-frequency direct-current heating auxiliary rolling device. The device is simple in structure, convenient to operate and high in practicability, and belongs to the field of metal machining equipment.

Owner:SOUTH CHINA UNIV OF TECH

A kind of tung oil modified phenolic resin automobile brake pad

The invention discloses a tung oil modified phenolic resin automobile brake block, which comprises the following ingredients in parts by weight: 12 to 14 parts of tung oil modified phenolic resin, 5 to 6 parts of steel fiber, 5 to 6 parts of glass fiber, 5 to 6 parts of carbon fiber, 7 to 10 parts of aromatic poly amide fiber, 2 to 3 parts of copper fiber, 5 to 6 parts of wollastonite, 5 to 10 parts of expanded vermiculite, 4 to 10 parts of mica powder, 5 to 8 parts of titanium oxide, 30 to 35 parts of barite, 8 to 12 parts of molybdenum disulfide, 10 to 13 parts of porous ceramic balls and 6 to 8 parts of polyurea formaldehyde dicyclopentadiene microcapsules. The tung oil modified phenolic resin automobile brake block provided by the invention has the advantages that the toughness is good, the hardness is proper, the wear resistance is realized, the heat resistance performance is excellent, and the preparing process is simple.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Boronized laying pipe

InactiveUS20120079862A1Improve friction and wearExtended service lifeLiquid surface applicatorsMetal rolling stand detailsEngineeringMechanical engineering

A laying pipe for use in the laying head of a rolling mill is configured for rotation about an axis, with an entry end aligned on that axis to receive a hot rolled product, and with a curved section leading to a delivery end spaced radially from that axis. The curved section defines a guide path configured to form the hot rolled product into a helical formation of rings. The laying pipe comprises a tubular ferrous wall having an interior surface comprising a wear resistant boronized layer against which the hot rolled product is confined for movement along the guide path.

Owner:PRIMETALS TECH USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com