Copper-based powder metallurgy plunger pump oil distribution disc material and preparation method thereof

A copper-based powder and plunger pump technology, which is applied in metal processing equipment, pump components, mechanical equipment, etc., can solve the problems that the mechanical strength of the copper alloy surface cannot meet the requirements, and cannot meet the requirements of the plunger pump, so as to improve the material Utilization rate, good tribological properties, good effect on friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

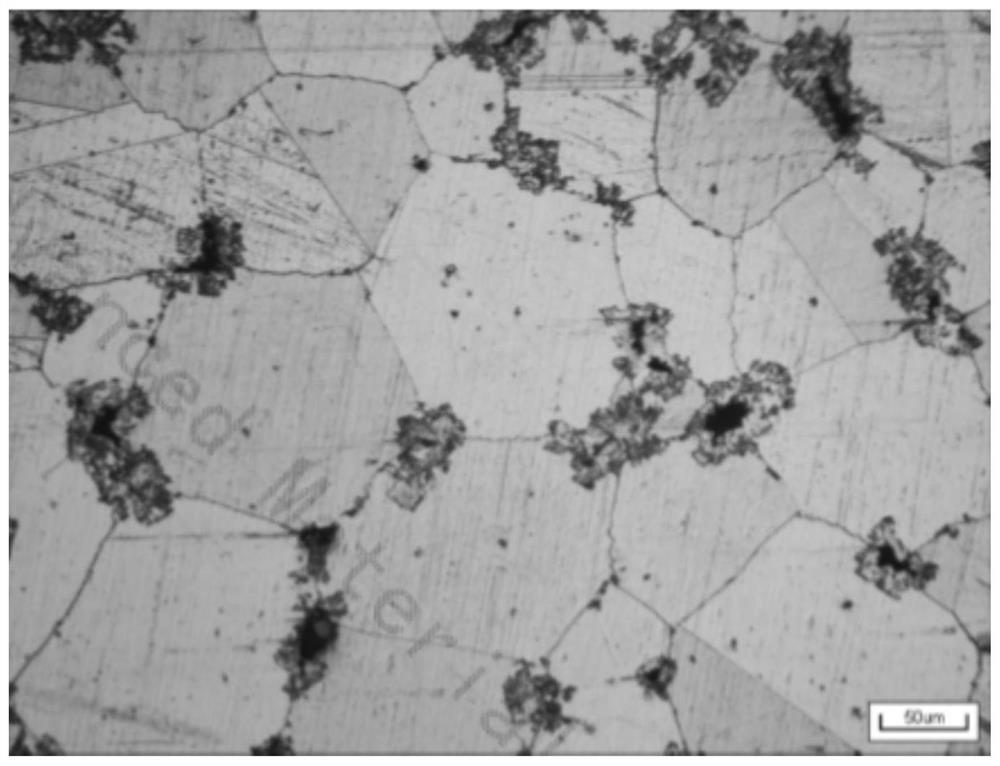

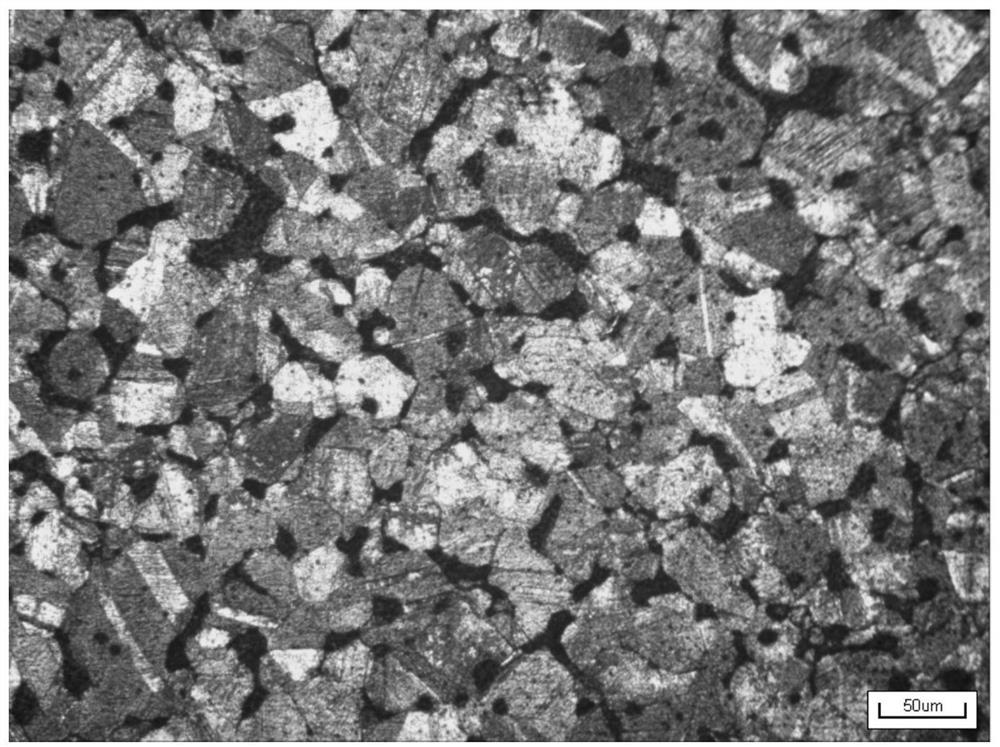

Method used

Image

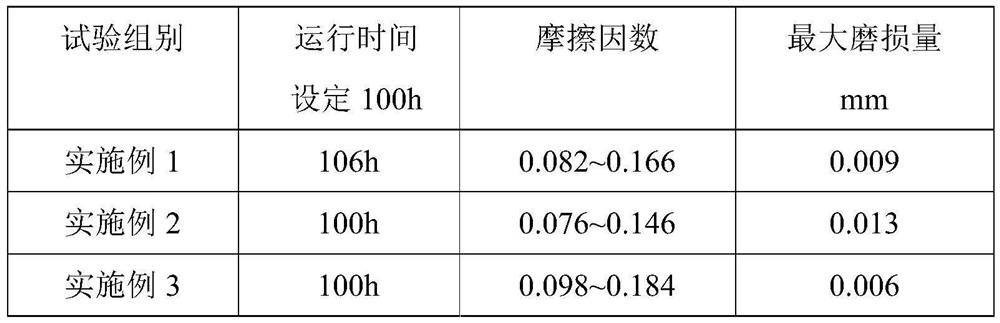

Examples

Embodiment 1

[0028] (1) Mixing: take by weight 3% nickel, 10% tin, 4% lead, 0.55% paraffin, 0.5% zinc stearate, and the balance is that copper powder is mixed to obtain copper-based mixed powder;

[0029] (2) Press forming: send the copper-based mixed powder into the hopper of the press and send it into the cavity of the mold through the feeding shoe for pressing, at a rate of 550MPa / cm 2 The pressure is pressed and formed to obtain a copper matrix compact with a compact density of 7.82g / cm 3 ;

[0030] (3) Sintering: Place the copper-plated steel plate on the top of the copper matrix compact, and put the whole into a sintering furnace for sintering. The sintering temperature is 890°C, and the sintering time is 60 minutes. 15% hydrogen is used as the reducing gas and 85% hydrogen is used as the reducing gas. Nitrogen is used as a protective atmosphere to obtain a copper alloy sintered compact;

[0031] (4) Shaping: put the copper alloy sintered billet into the cemented carbide mold, use ...

Embodiment 2

[0036] (1) Mixing: take by weight 2% nickel, 8% tin, 3% lead, 0.4% paraffin, 0.4% zinc stearate, and the balance is that copper powder is mixed to obtain copper-based mixed powder;

[0037] (2) Press forming: send the copper-based mixed powder into the hopper of the press and send it into the cavity of the mold through the feeding shoe for pressing, at a rate of 500MPa / cm 2 The pressure is pressed and formed to obtain a copper matrix compact with a compact density of 7.74g / cm 3 ;

[0038] (3) Sintering: Place the copper-plated steel plate on the top of the copper matrix compact, and put the whole into a sintering furnace for sintering. The sintering temperature is 890°C, and the sintering time is 60 minutes. 15% hydrogen is used as the reducing gas and 85% hydrogen is used as the reducing gas. Nitrogen is used as a protective atmosphere to obtain a copper alloy sintered compact;

[0039] (4) Shaping: Put the copper alloy sintered billet into the cemented carbide mold, use 60...

Embodiment 3

[0043] (1) Mixing: take by weight 4% nickel, 12% tin, 5% lead, 0.6% paraffin, 0.65% zinc stearate, and the balance is that copper powder is mixed to obtain copper-based mixed powder;

[0044] (2) Press forming: send the copper-based mixed powder into the hopper of the press and send it into the cavity of the mold through the feeding shoe for pressing, at a rate of 600MPa / cm 2 The pressure is pressed and formed to obtain a copper matrix compact with a compact density of 8.0g / cm 3 ;

[0045] (3) Sintering: Place the copper-plated steel plate on the top of the copper substrate compact, and put the whole into a sintering furnace for sintering. The sintering temperature is 920°C, and the sintering time is 40 minutes. 15% hydrogen is used as the reducing gas and 85% Nitrogen is used as a protective atmosphere to obtain a copper alloy sintered compact;

[0046] (4) Shaping: put the copper alloy sintered billet into the cemented carbide mold, use 700MPa / cm 2 Finishing by shaping pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com