Patents

Literature

64results about How to "Improve oil scraping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

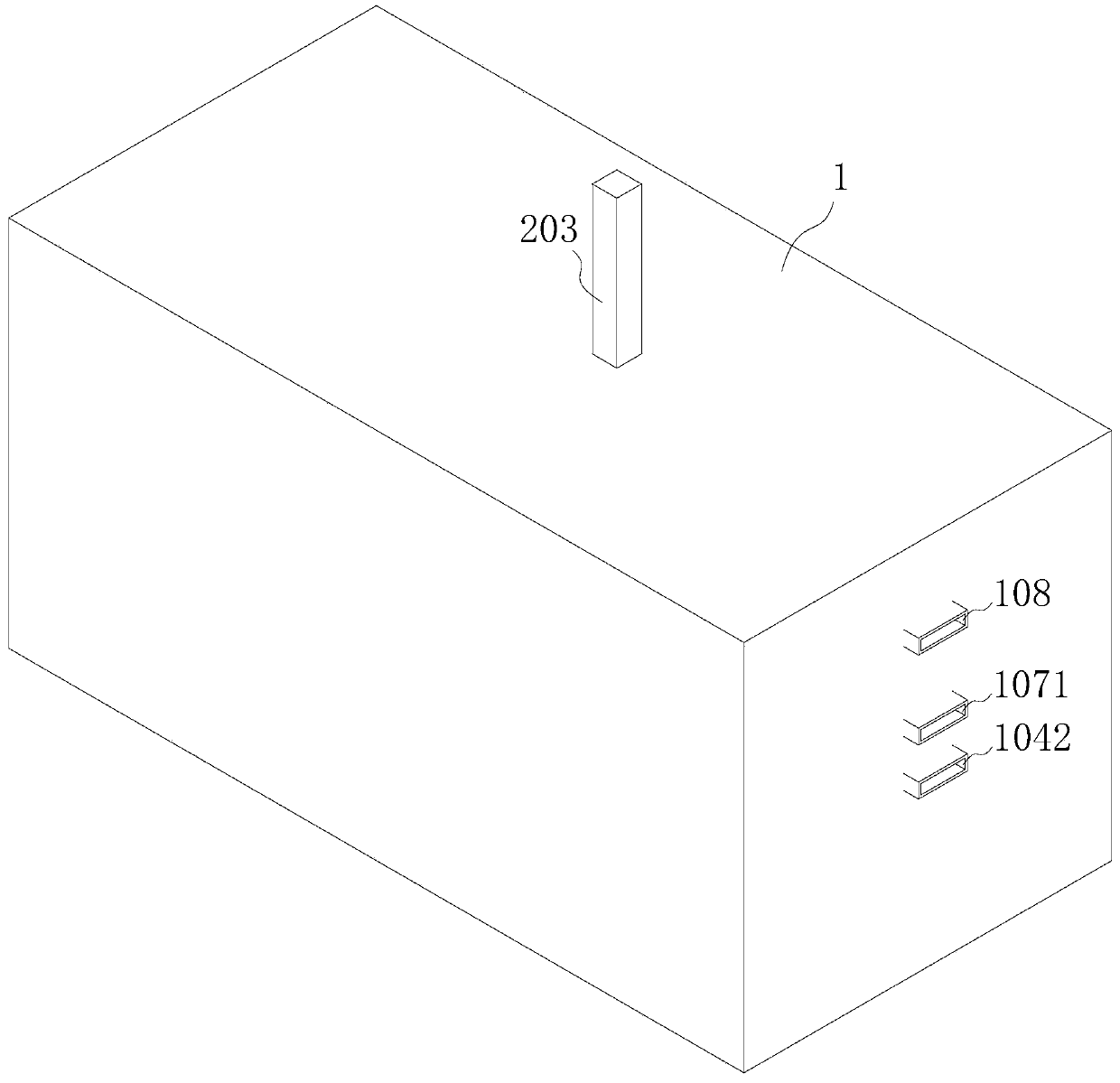

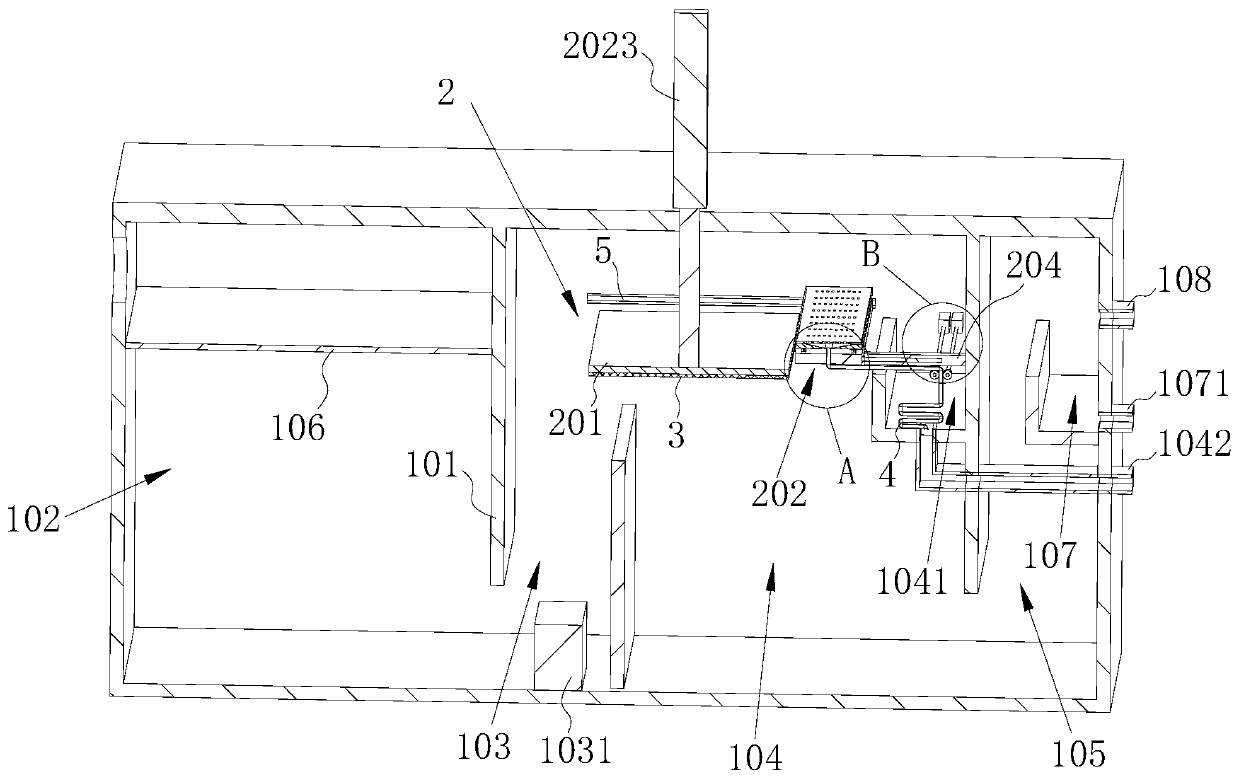

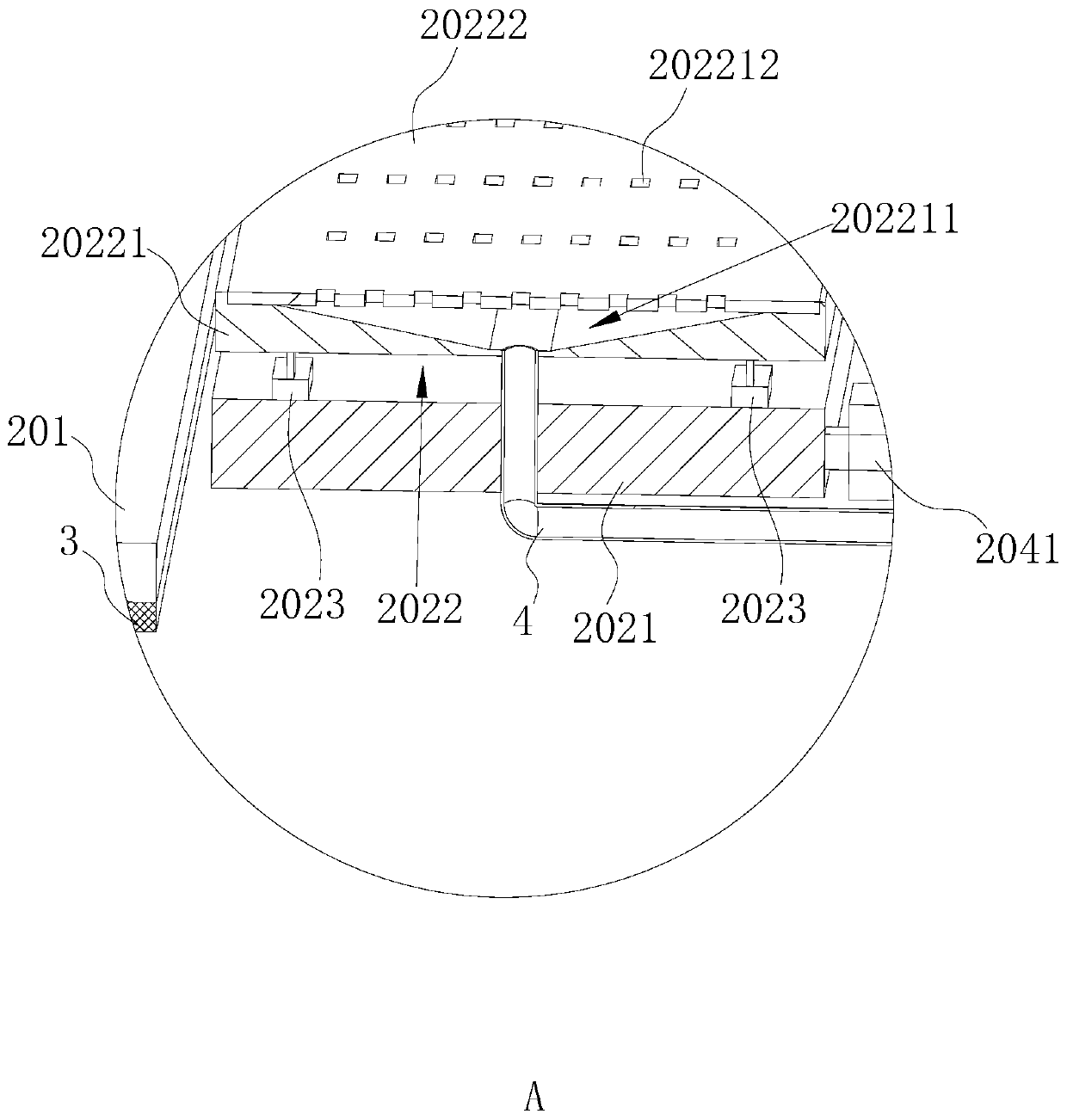

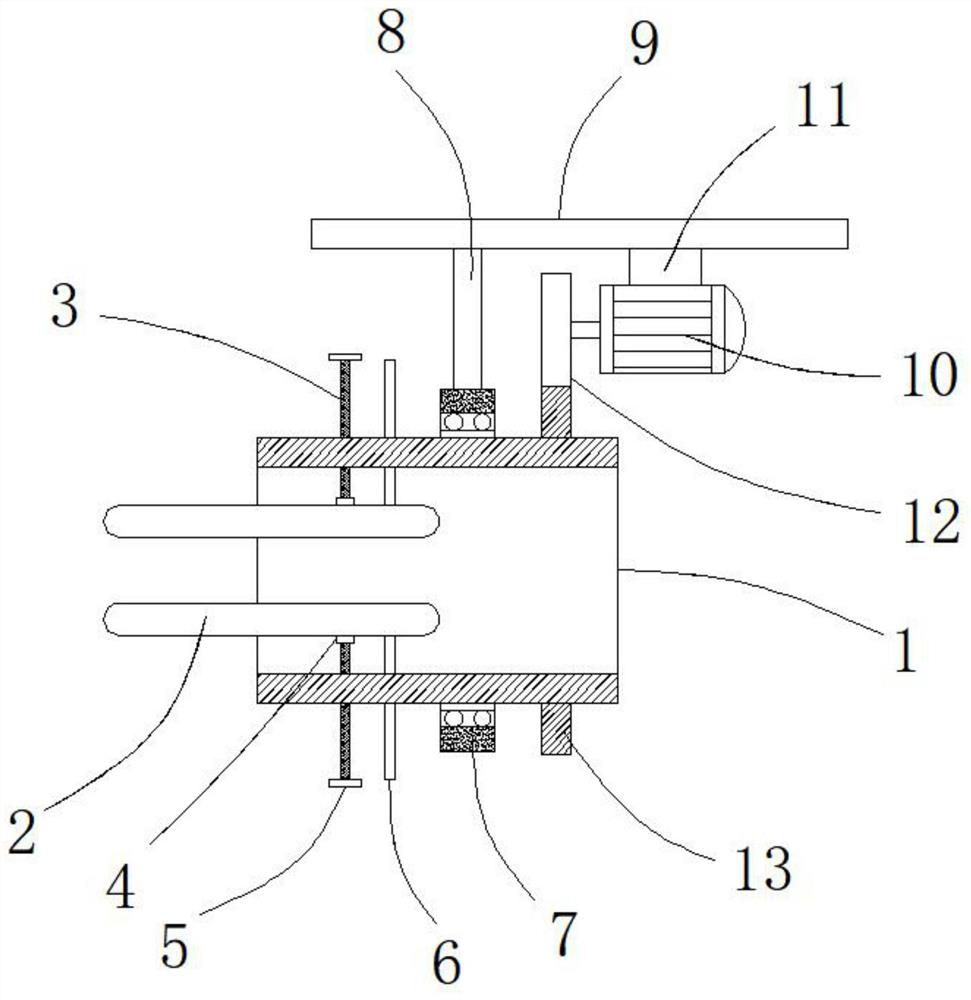

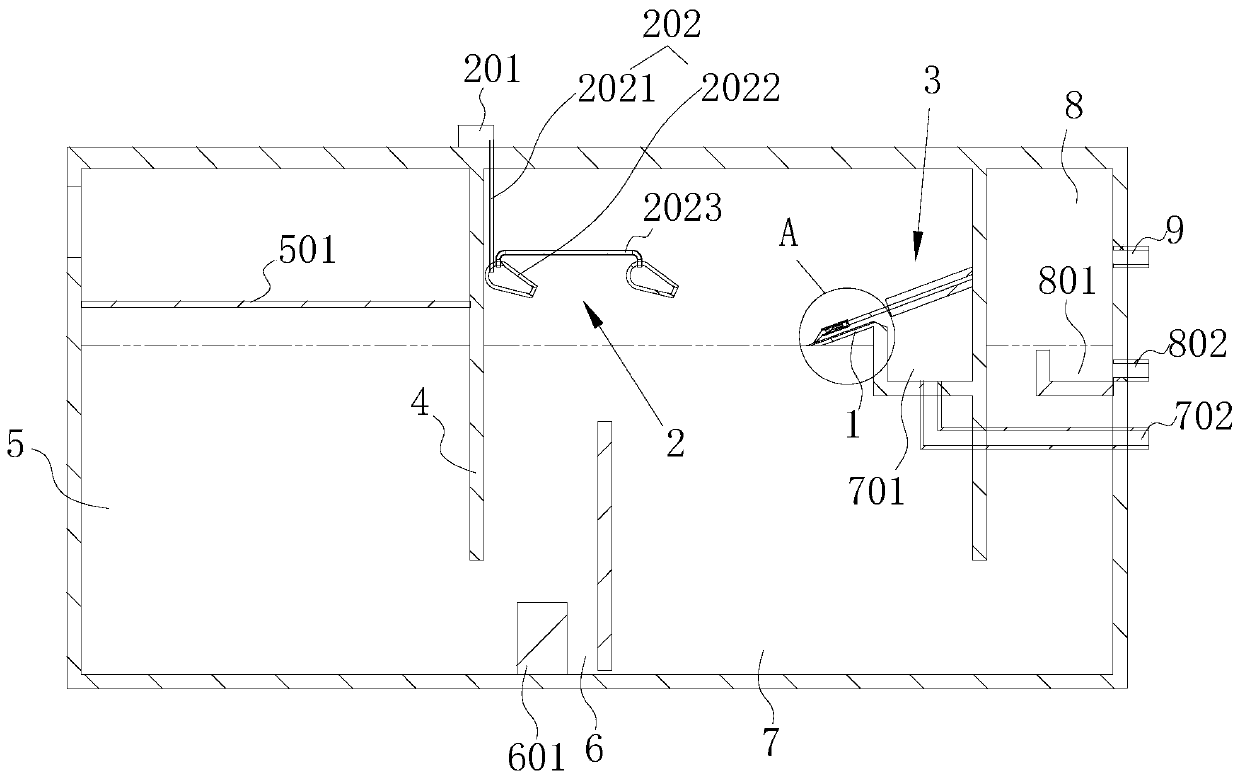

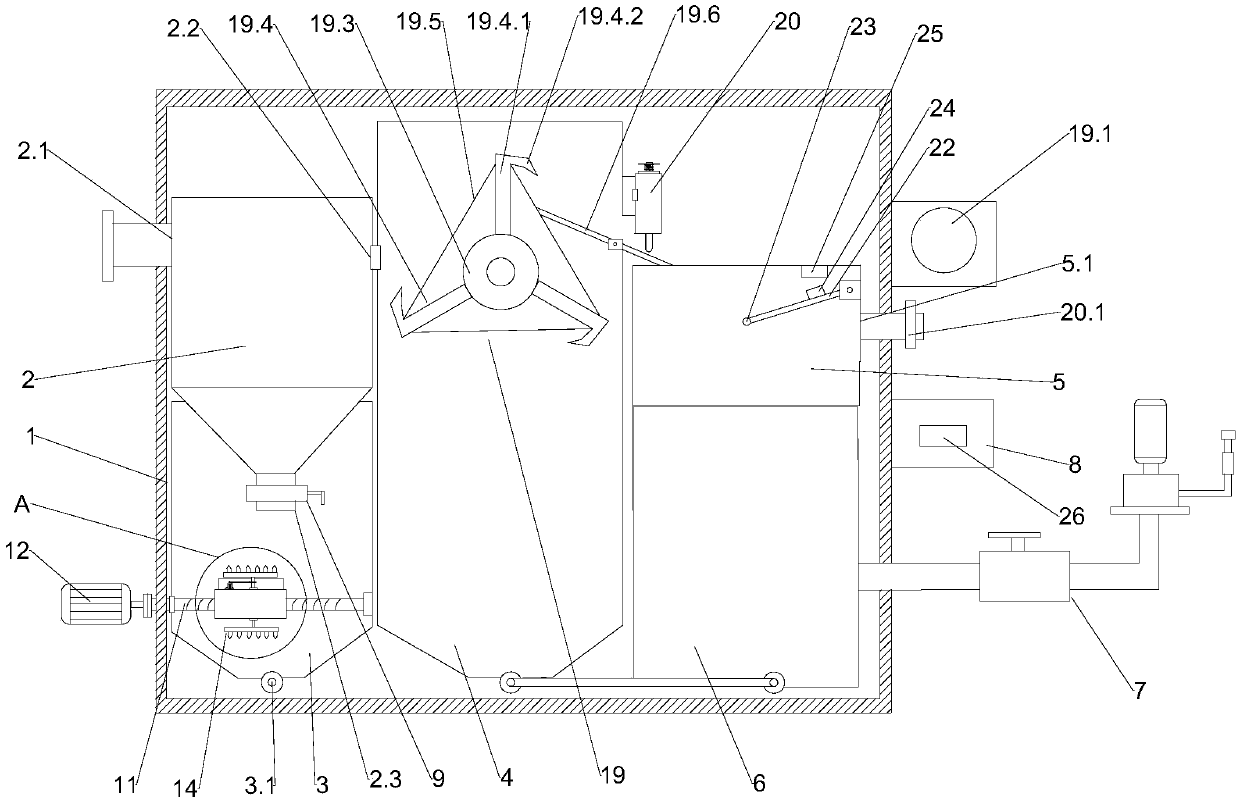

Oil separator

PendingCN110357205ABeneficial technical effectReduce the hassle of separationFatty/oily/floating substances removal devicesLiquid separationOil separationOil water

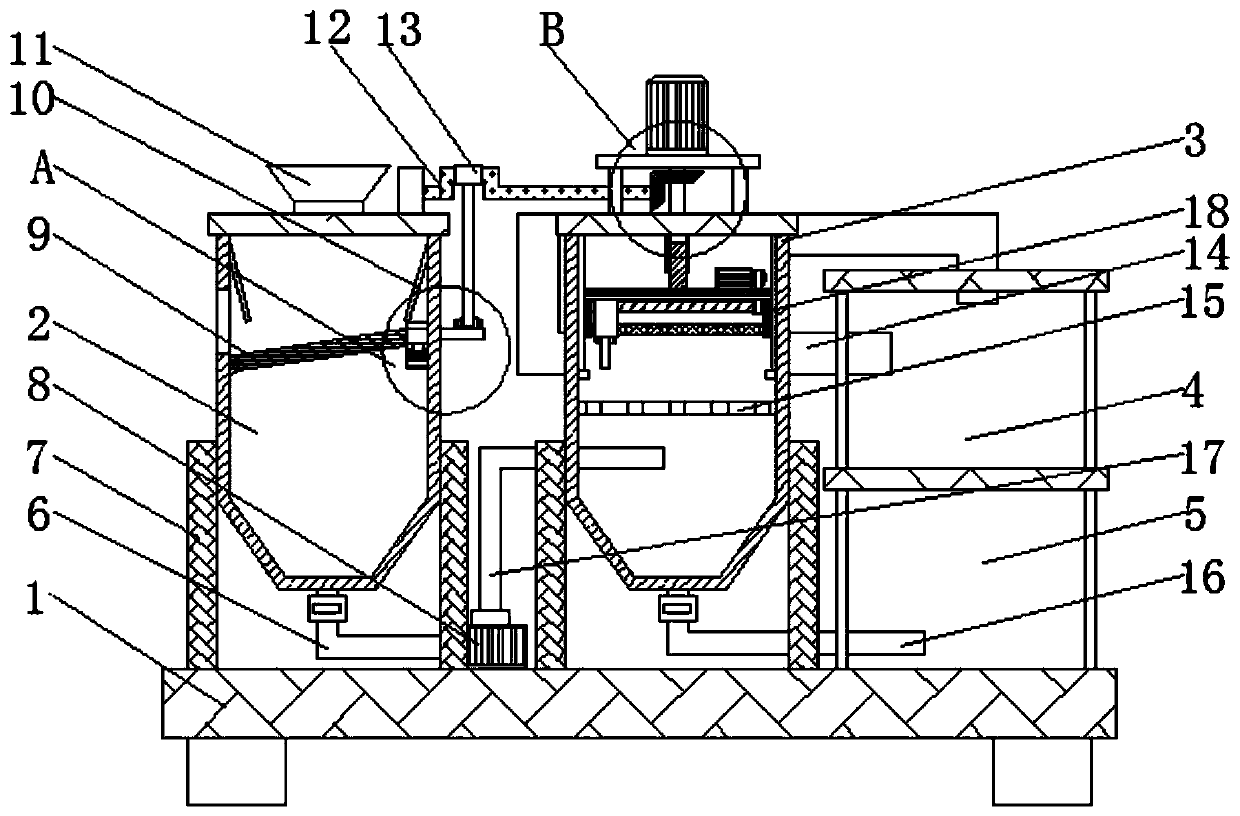

The invention discloses an oil separator. The oil separator comprises a box body, a solid-liquid separation chamber, a water-oil separation chamber and a water discharge chamber are arranged in the box body, an oil collection trough and an oil-water separation device are arranged in the oil-water separation chamber, the oil-water separation device comprises an oil adsorbing plate, an oil scrapingplate, a vertical driving assembly and a horizontal driving assembly, the lower surface of the oil adsorbing plate is provided with an oil adsorbing sponge layer, the oil-water separation device further comprises an oil guiding tube, one end of the oil guiding tube is connected with the oil scraping plate, the other end of the oil guiding tube extends to the oil collection trough, and the oil guiding tube receives oil scraped off by the oil scraping plate and guides the oil into the oil collecting trough. The vertical driving assembly drives the oil adsorbing plate to contact the liquid surface in the oil-water separation chamber, the oil adsorbing sponge layer adsorbs the oil, the vertical driving assembly drives the oil adsorbing plate to rise, the horizontal driving assembly drives theoil scraping plate to abut against the oil absorbing sponge layer, and the oil adsorbed by the oil adsorbing sponge layer is scraped by the oil scraping plate, goes through the oil guiding tube, and is collected into the oil collecting trough, so the water doped in the separated oil is reduced, and the trouble of secondary oil-water separation is reduced.

Owner:GUANGZHOU HENGDE ENVIRONMENTAL PROTECTION TECH

Piston device for internal combustion engines

ActiveUS20100162987A1Reduce fuel consumptionBig gapPiston ringsBraking action transmissionCombustionEngineering

A piston device for internal combustion engines includes a first compression ring and a second compression ring in an outer circumference of a piston, wherein the second compression ring includes a notch extending from the inner circumference to the outer circumference on a lower surface of at least one of a pair of ends of the ring, and a gap between the ring ends at the notch on the second compression ring is larger than a gap between the ring ends of the first compression ring, and a gap between the ring ends at the section other than the notch on the second compression ring is the same or smaller than the gap between the ring ends of the first compression ring, and the second compression ring contains an outer circumferential surface comprised of a tapered surface decreasing the ring radial thickness towards the upper side, and an axial parallel surface formed below the tapered surface. Instead of the axial parallel surface, the second compression ring may utilize a tapered surface with a taper angle smaller than the taper angle of the above tapered surface; or may utilize a tapered surface decreasing the ring radial thickness towards the lower side.

Owner:TEIKOKU PISTON RING CO LTD

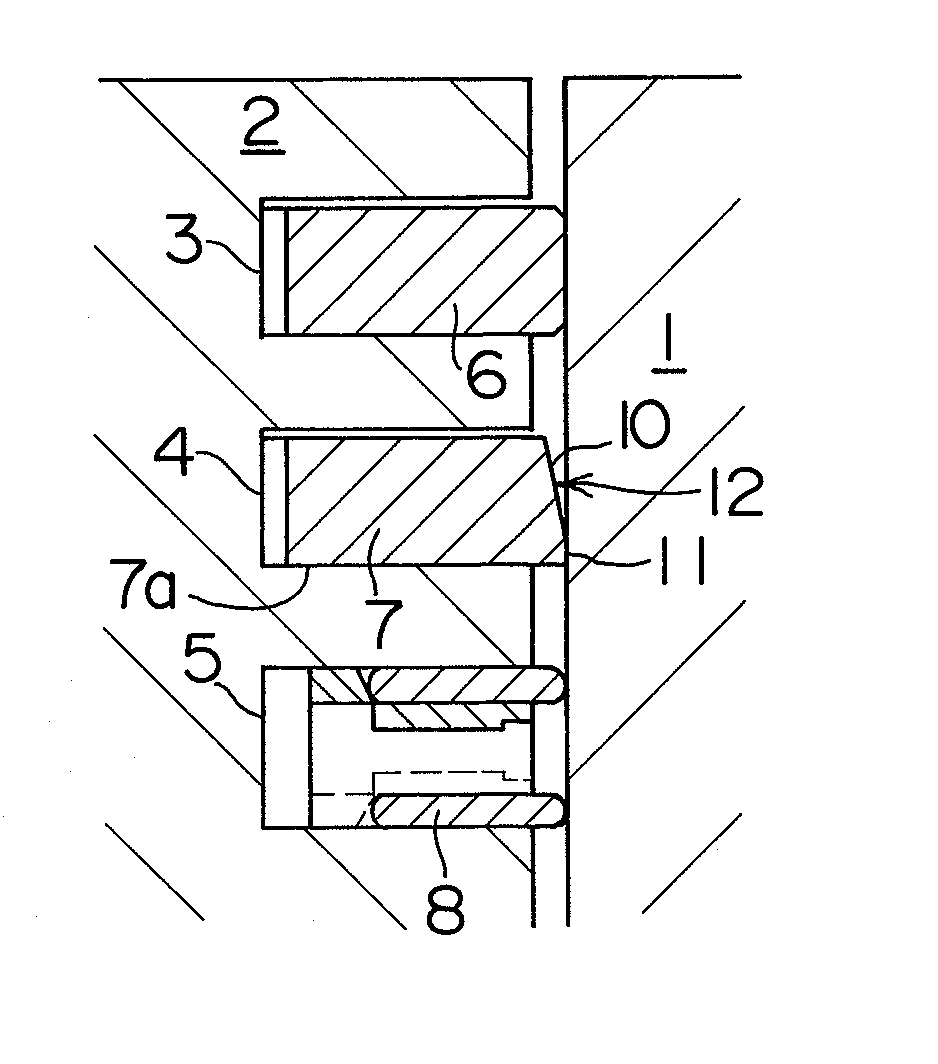

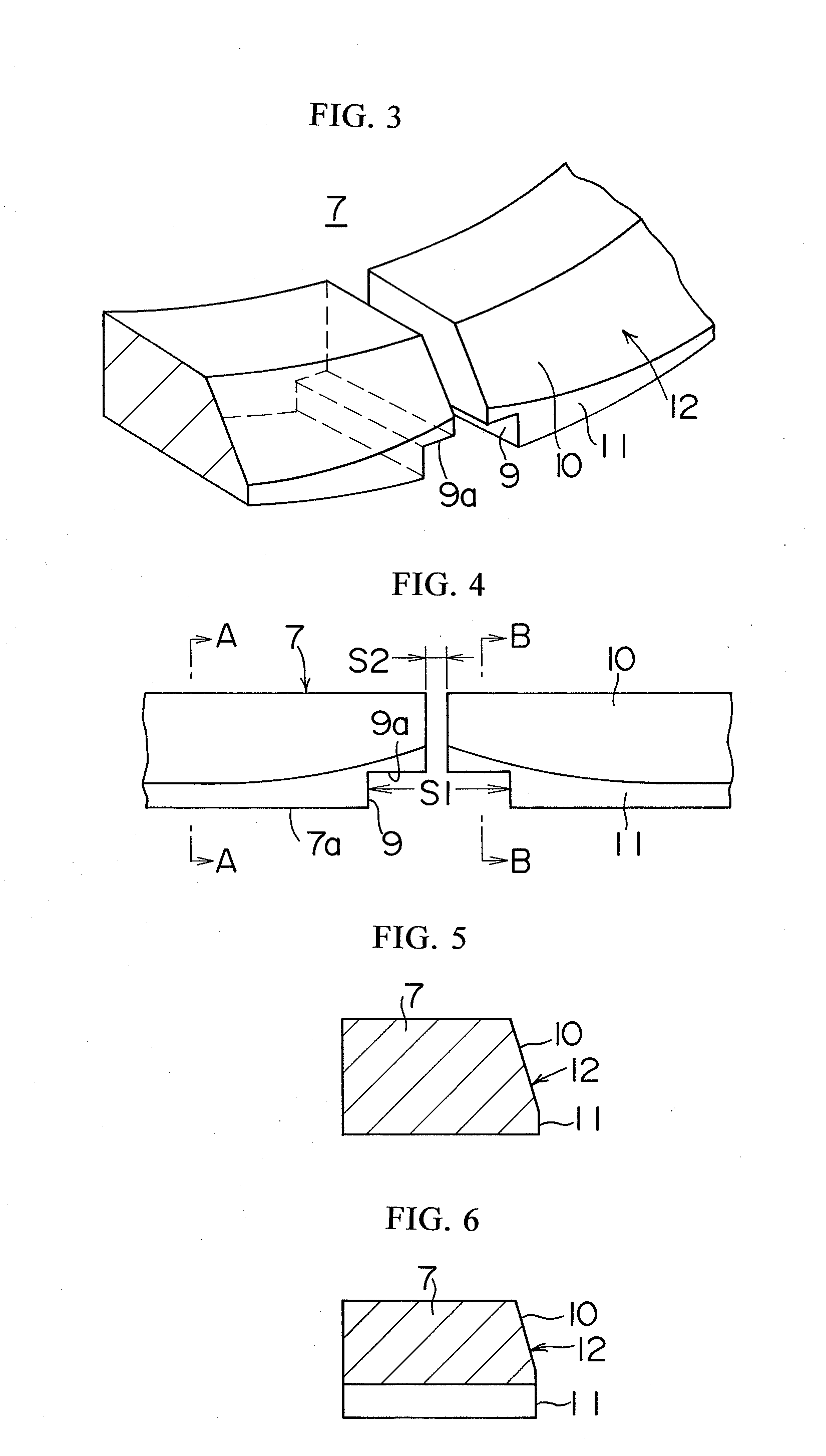

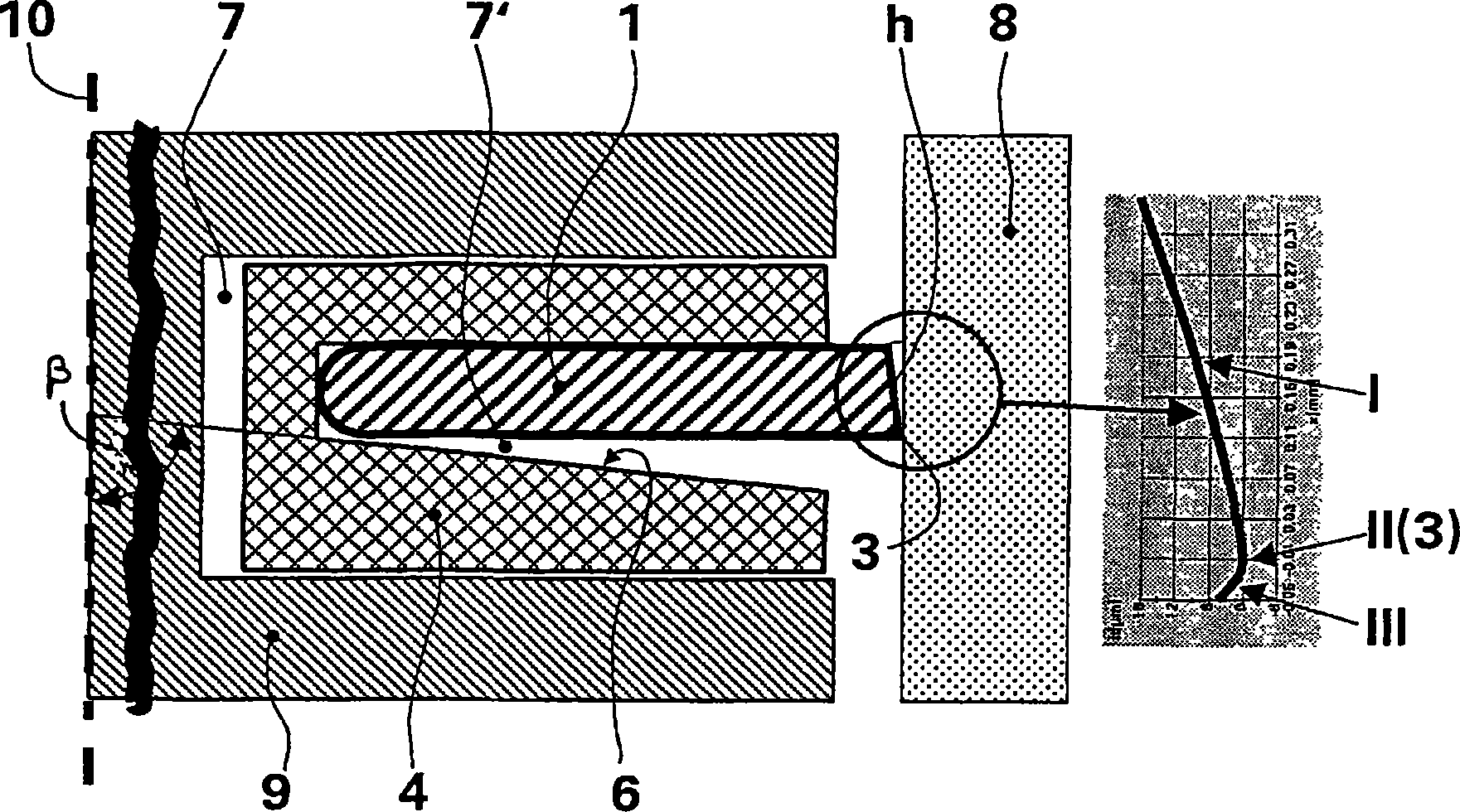

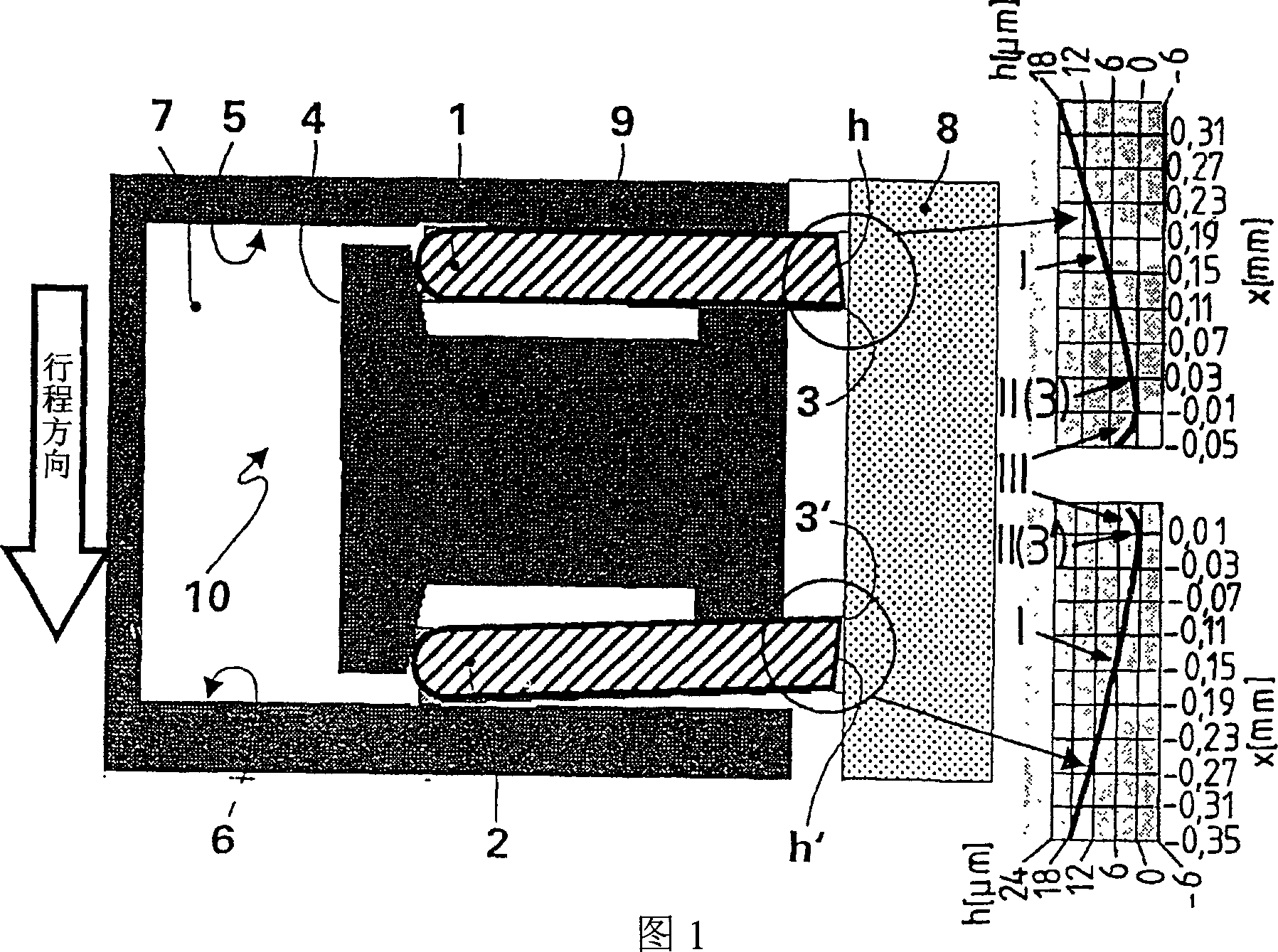

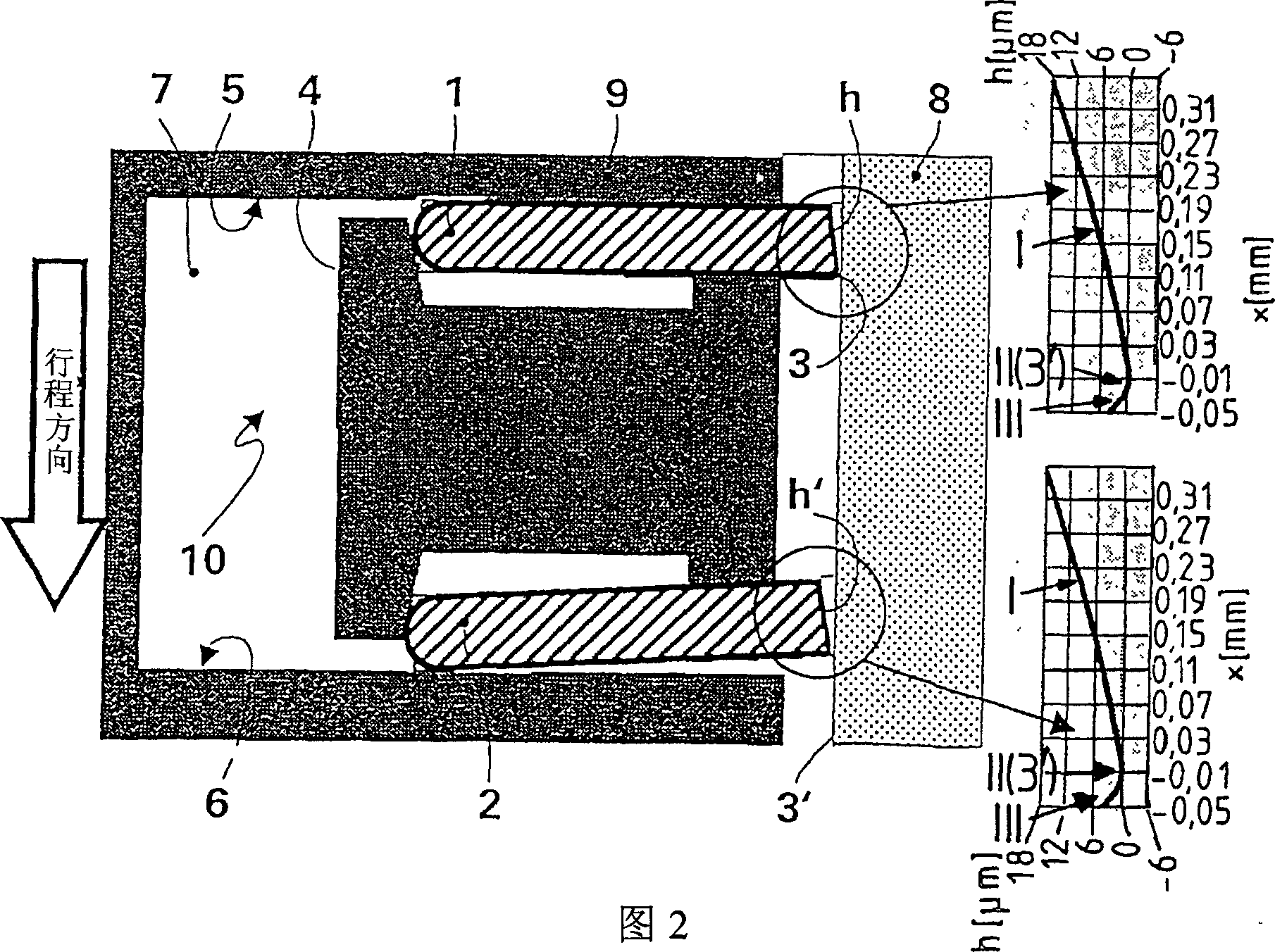

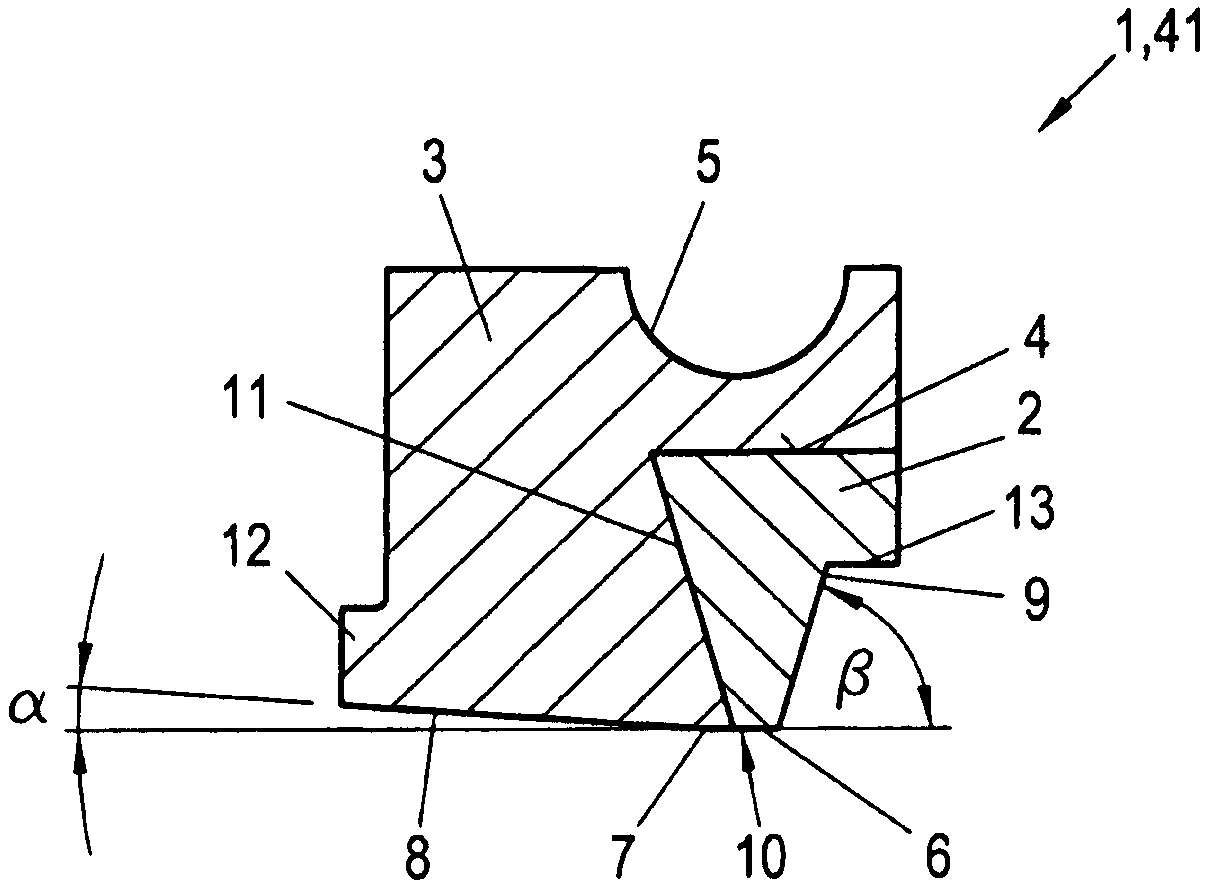

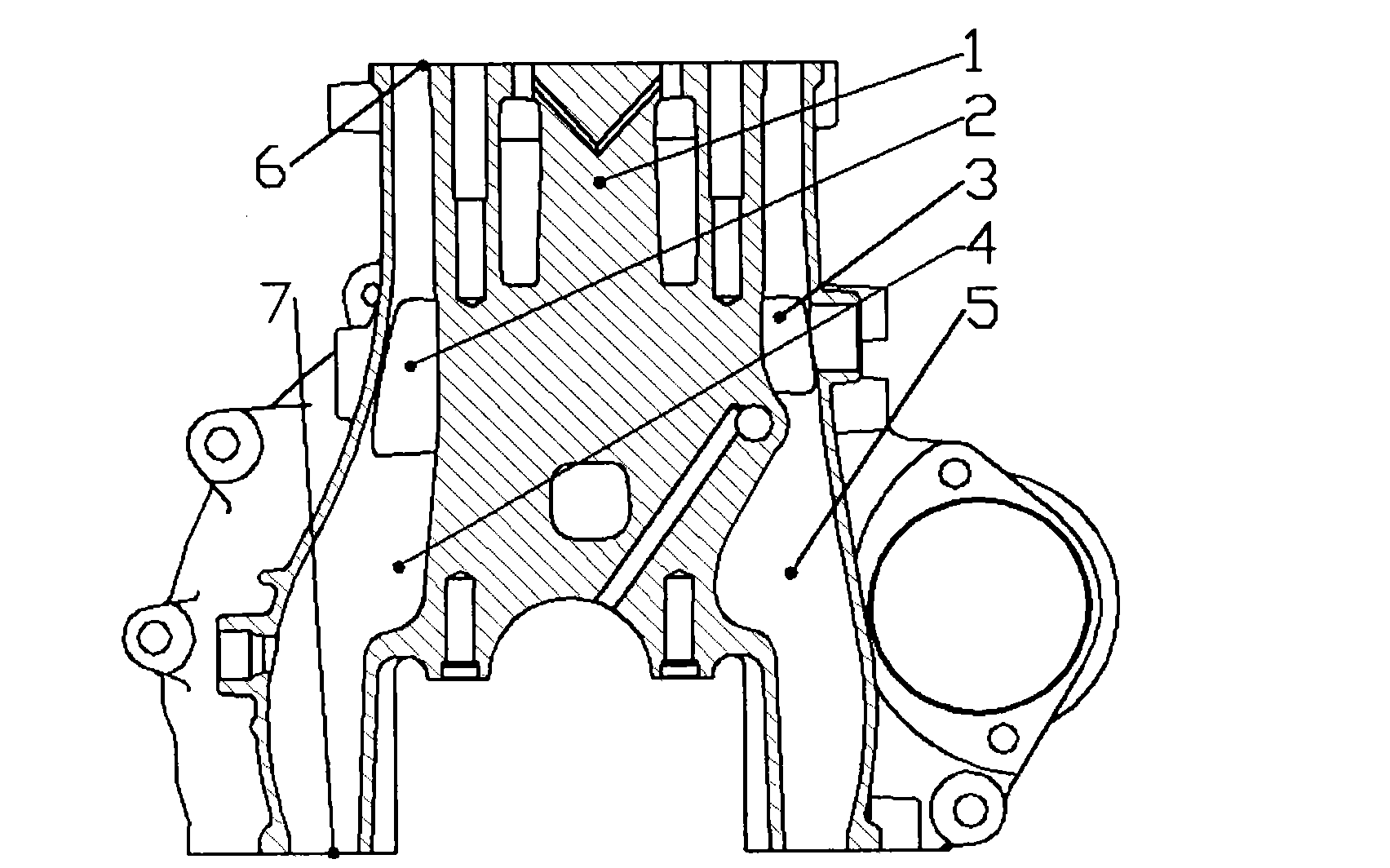

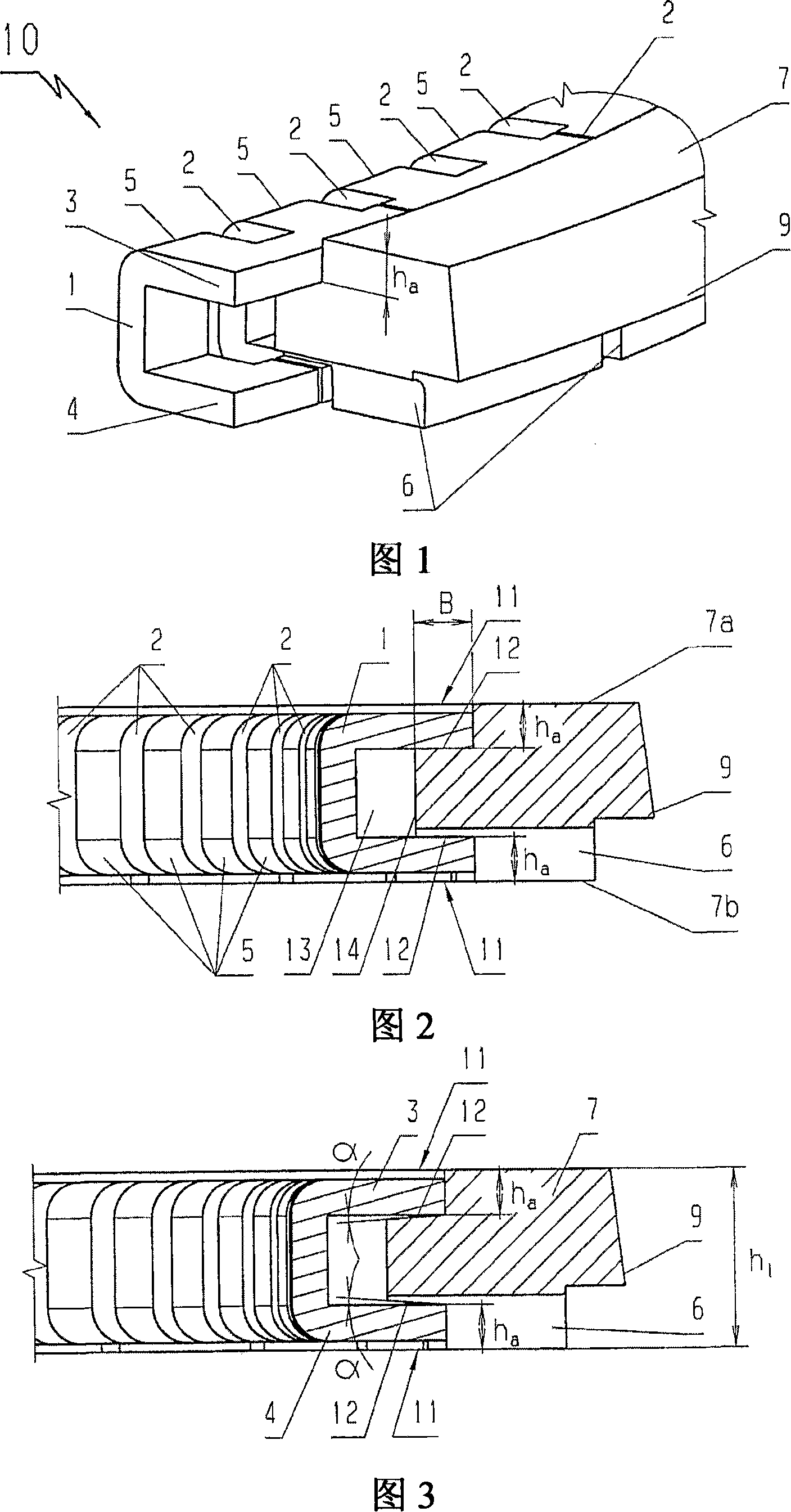

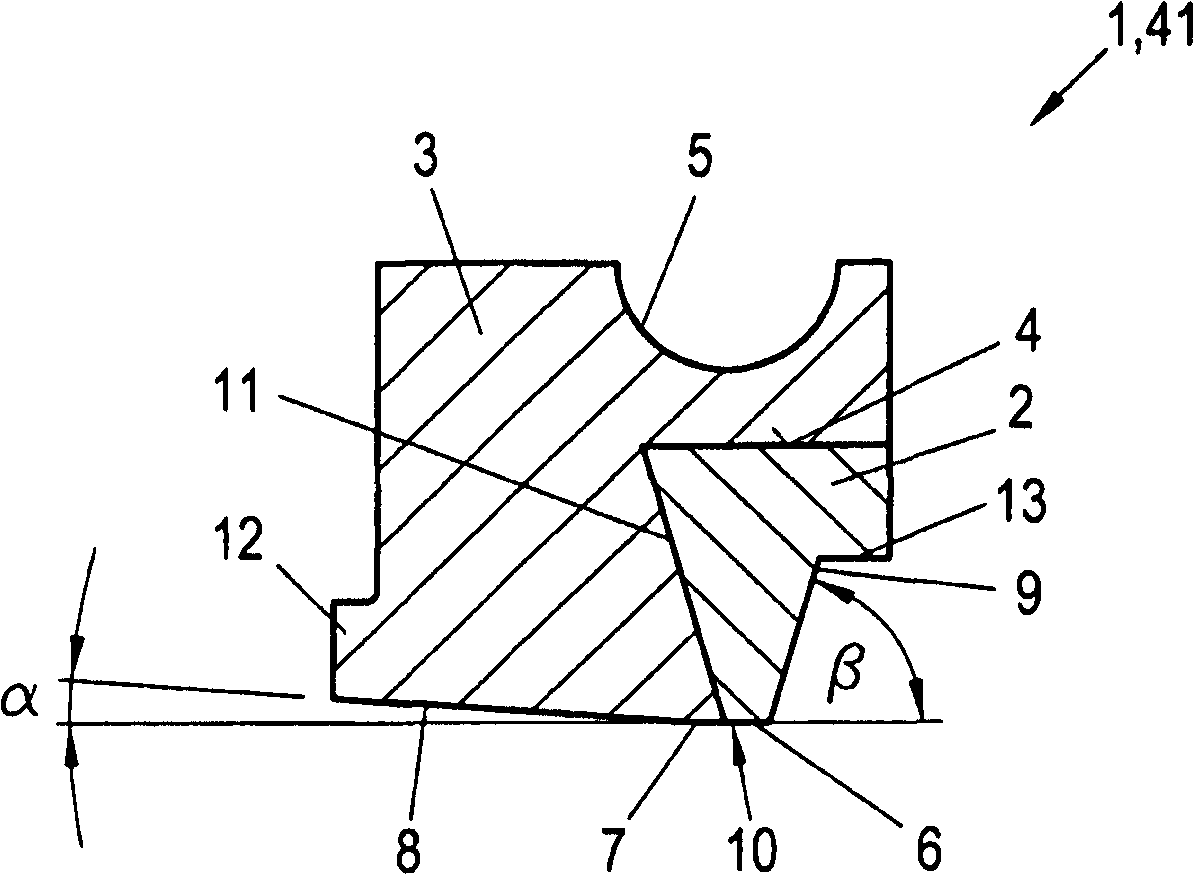

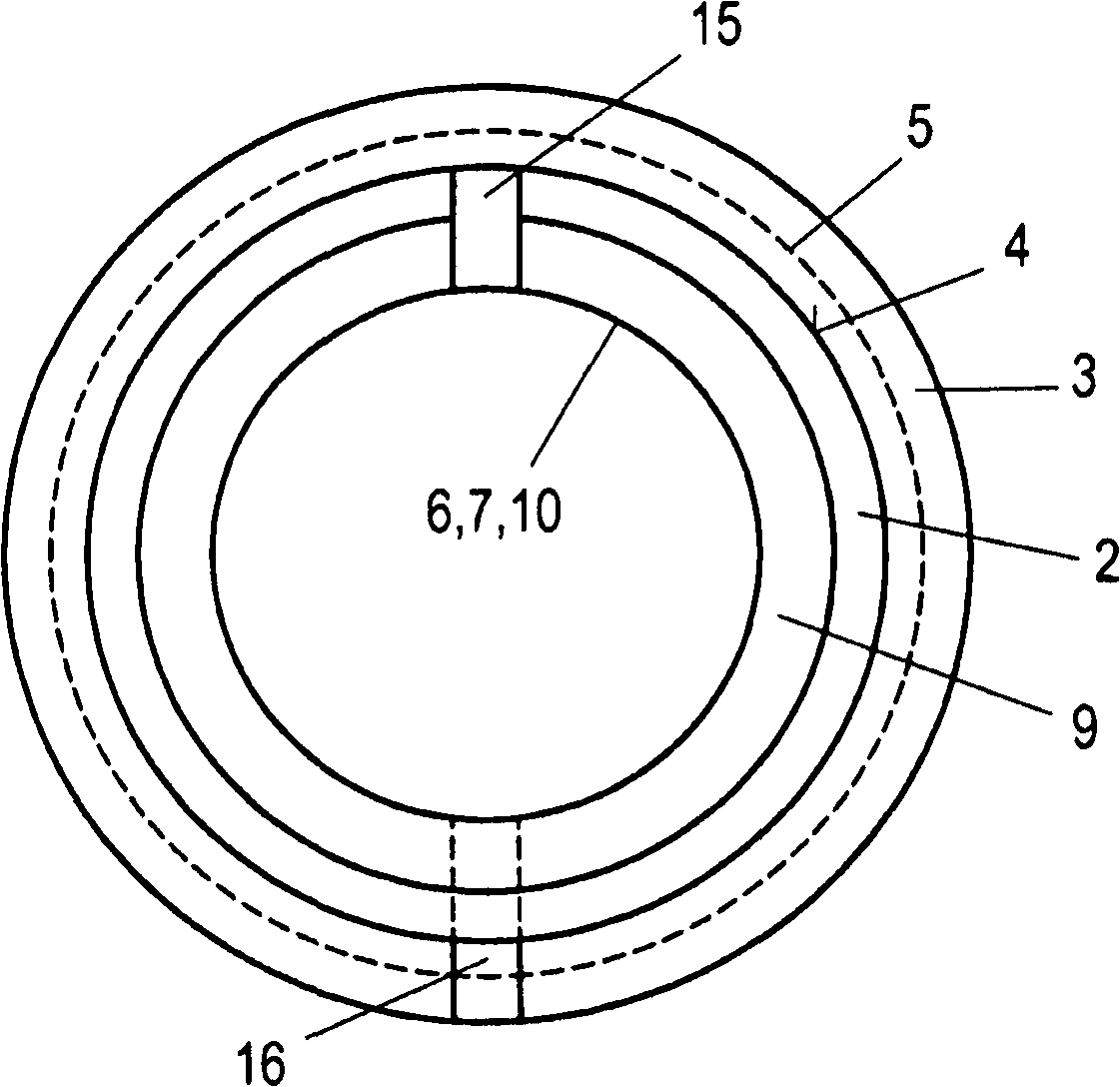

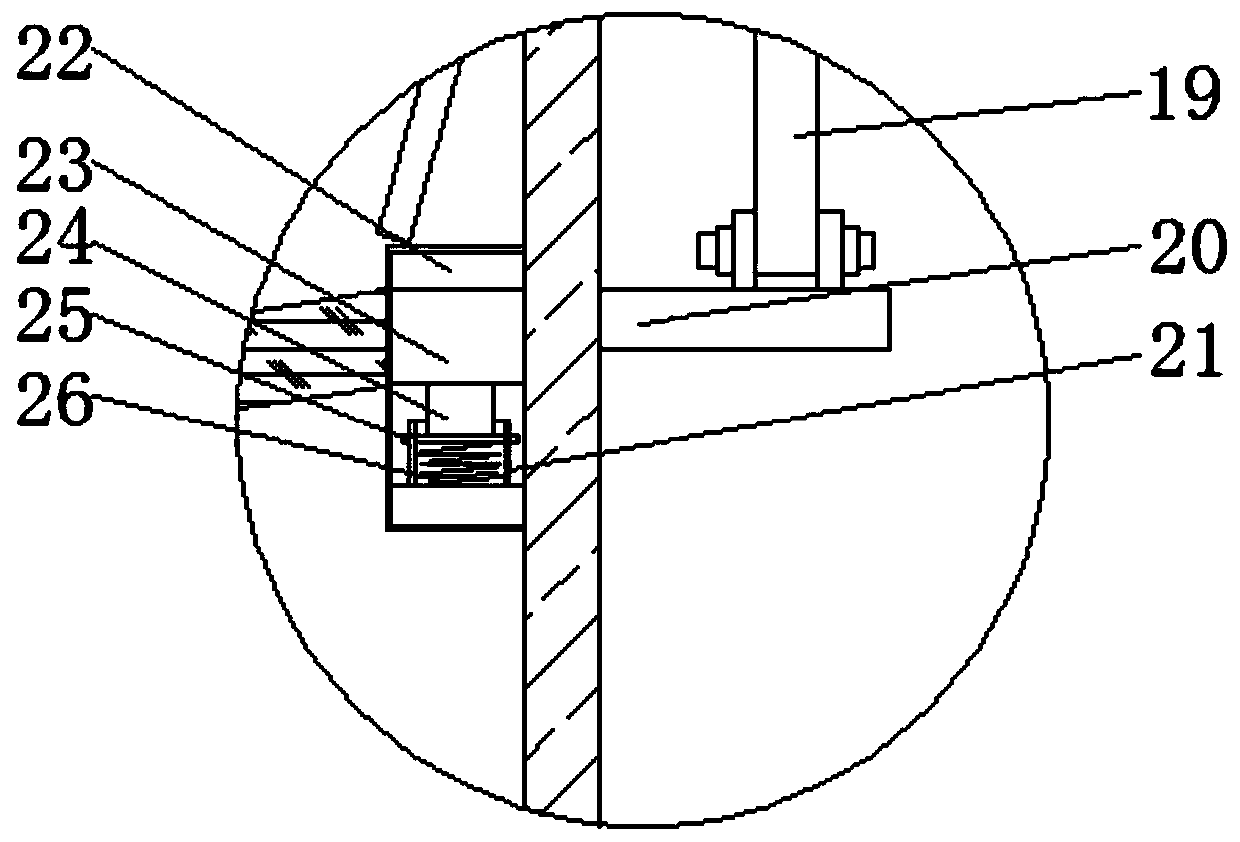

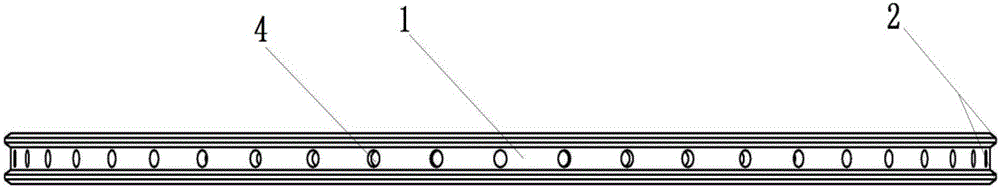

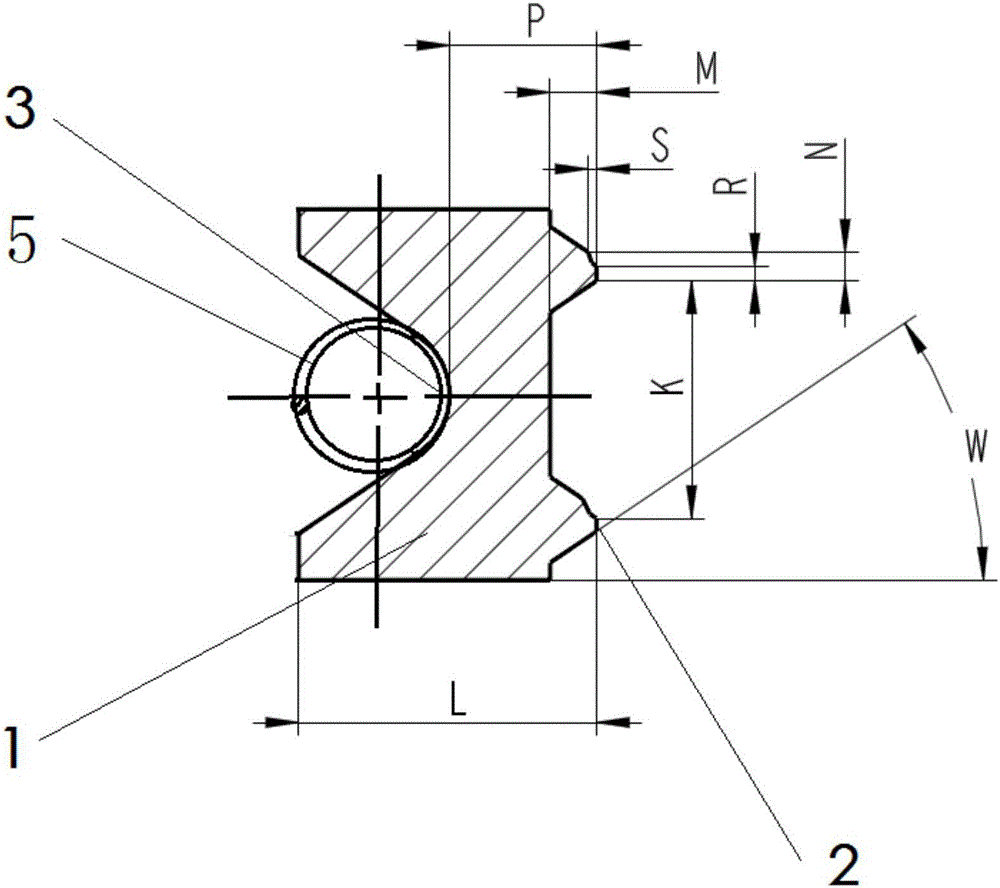

Oil scraper ring for pistons of internal combustion engines

The invention relates to an oil scraper ring for pistons of internal combustion engines, said oil scraper ring comprising a disc (1) that is provided with parallel flanks and a bearing surface (h) having an asymmetrical crowned form with a vertex line (3) extending over the periphery of the disc. A bracing spring (4) arranged in a ring groove (7) of the piston and comprising a spring groove side (6) opposing the piston head and a spring groove side (5) facing the piston head presses the disc (1) radially against the cylinder wall (8). The aim of the invention is to achieve an improved oil scraping action compared to that of prior art, while reducing the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides (5, 6) extends at an angle (ss) in relation to the piston axis (10) in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface (h) of the disc (1) being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring (1) is mounted in the piston, the vertex line (3) of the bearing surface (h) is oriented in the direction of the ring groove side (6) opposing the piston head.

Owner:MAHLE GMBH

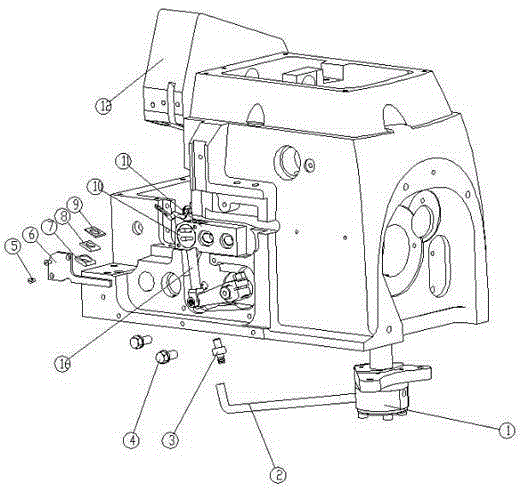

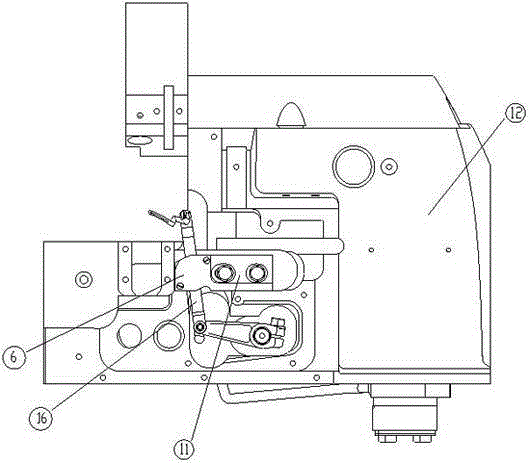

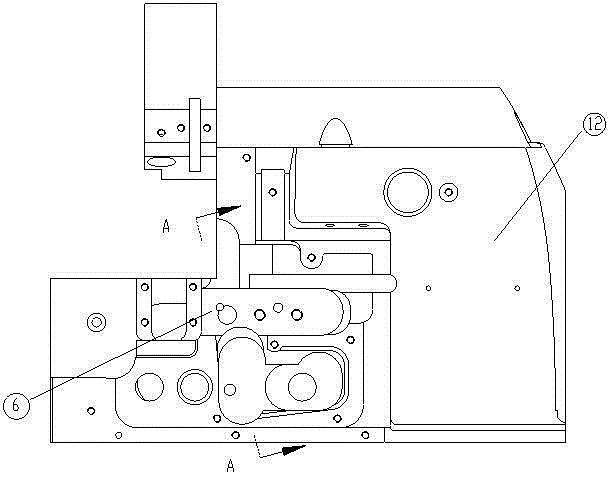

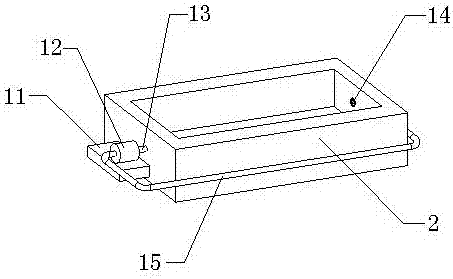

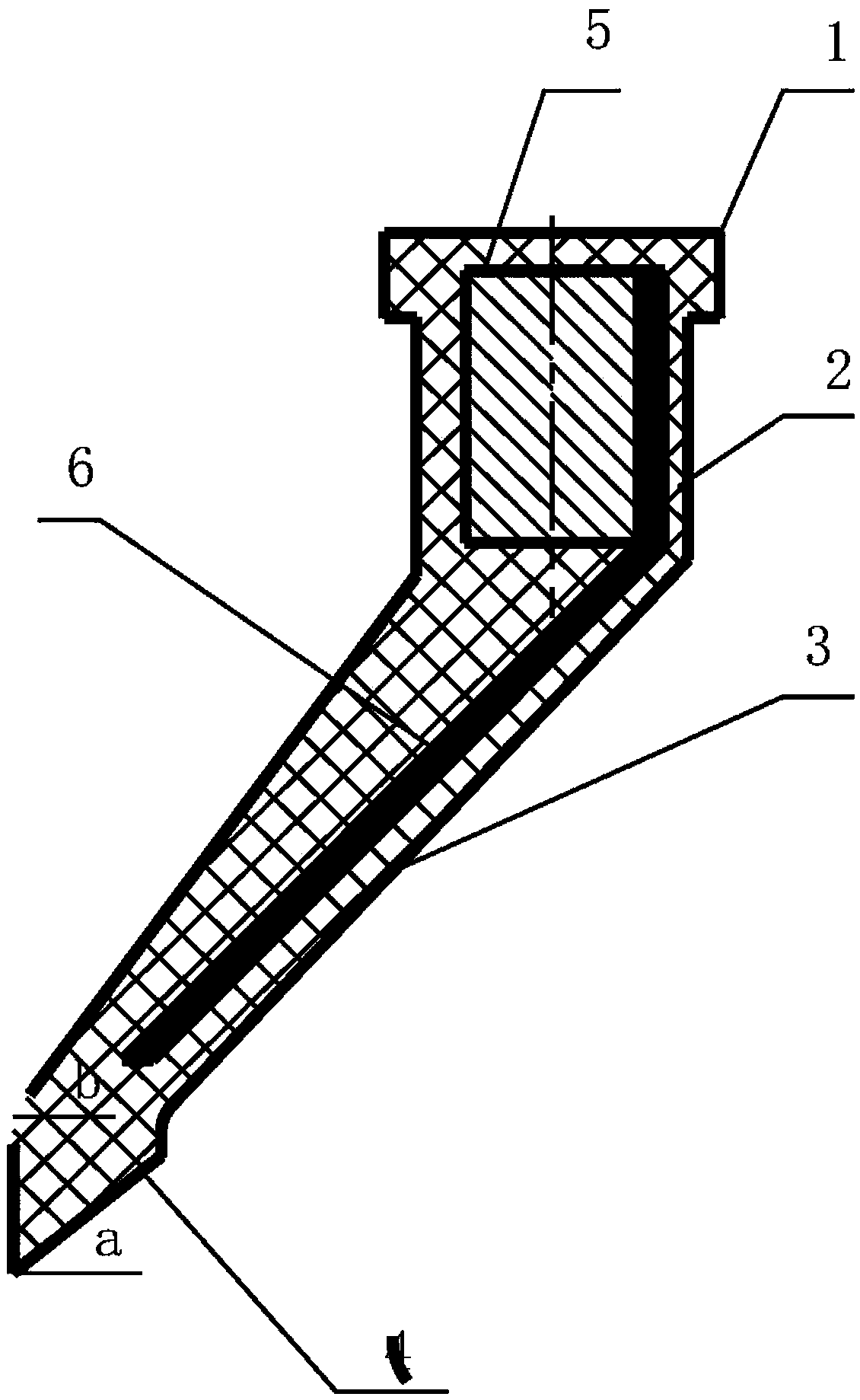

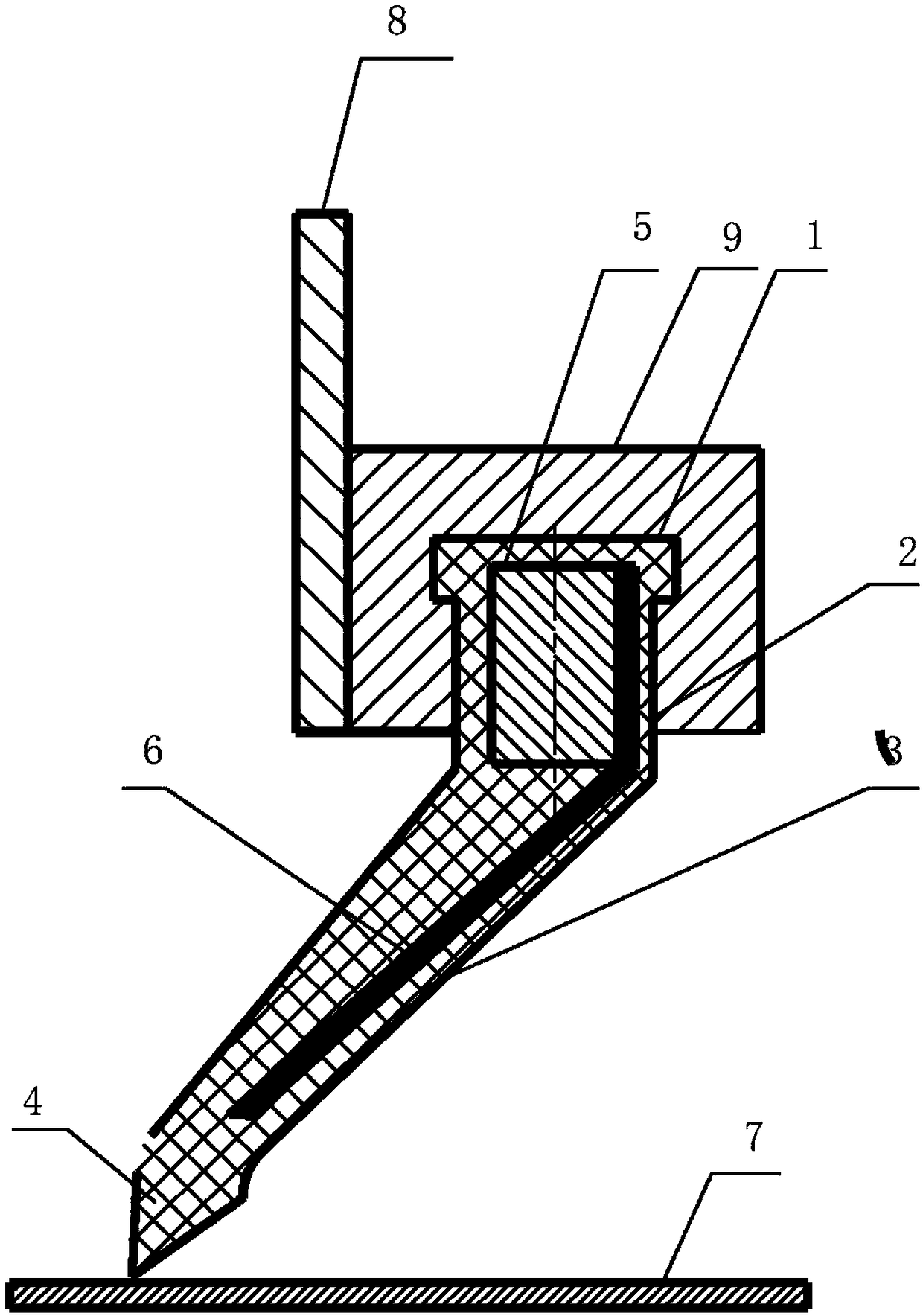

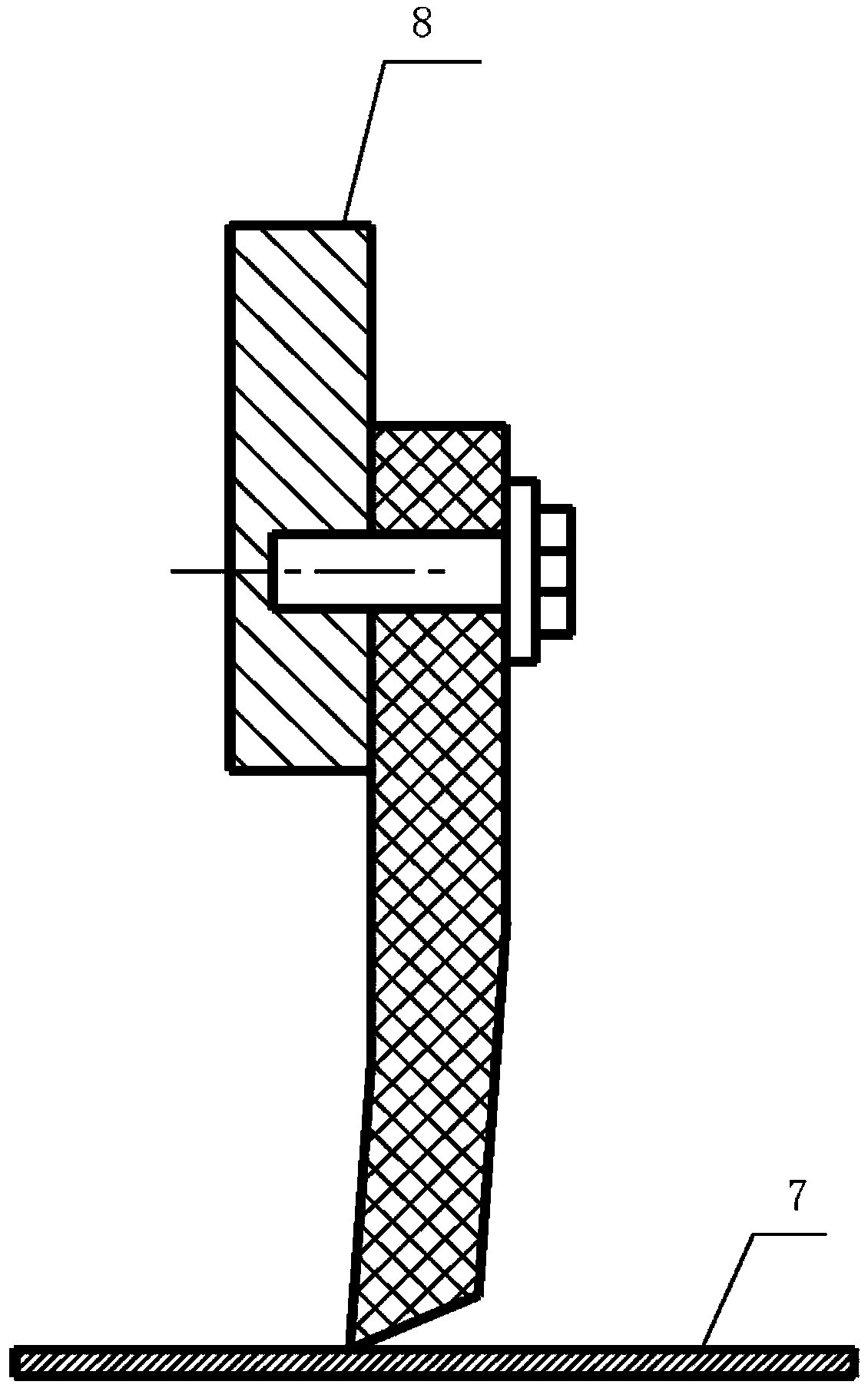

Oil leakage preventing device of upper bent needle of sewing machine

InactiveCN105420951AAvoid oil throwingEnsure oil absorption capacityLubrication/cooling devicesPetroleum engineeringOil absorption

The invention discloses an oil leakage preventing device of an upper bent needle of a sewing machine. The oil leakage preventing device comprises a machine shell, the upper bent needle, a bent needle slide block and a slide block base. The upper bent needle and the slide block base are assembled on the machine shell. The bent needle slide block is assembled in the slide block base. An oil scraping assembly and multiple pieces of oil cotton are arranged in the bent needle slide block. The oil cotton is located below the oil scraping assembly. The upper bent needle is axially and movably sleeved with the oil scraping assembly and the oil cotton. The position, provided with the oil scraping assembly and the oil cotton, of the bent needle slide block is provided with a closed cover plate. An oil discharge hole is formed in the bent needle slide block. An oil return hole communicated with the oil discharge hole is formed in the machine shell. An oil absorption assembly absorbing away oil stains is arranged at the oil return hole. The oil cotton and the oil scrapping assembly are designed on the upper bent needle. An oil scraping oil seal scraps down and absorbs away part of oil when the upper bent needle moves, the rest of oil is directly absorbed away by the oil cotton, the dual-layer protection is achieved, and it is avoided that the upper bent needle splashes oil; meanwhile, oil in the slide block can be absorbed away through an oil pump with force, the oil absorption capacity of the oil cotton is ensured, and the oil return effect is improved. The invention belongs to the technical field of oil leakage prevention of the sewing machine.

Owner:JACK SEWING MASCH CO LTD

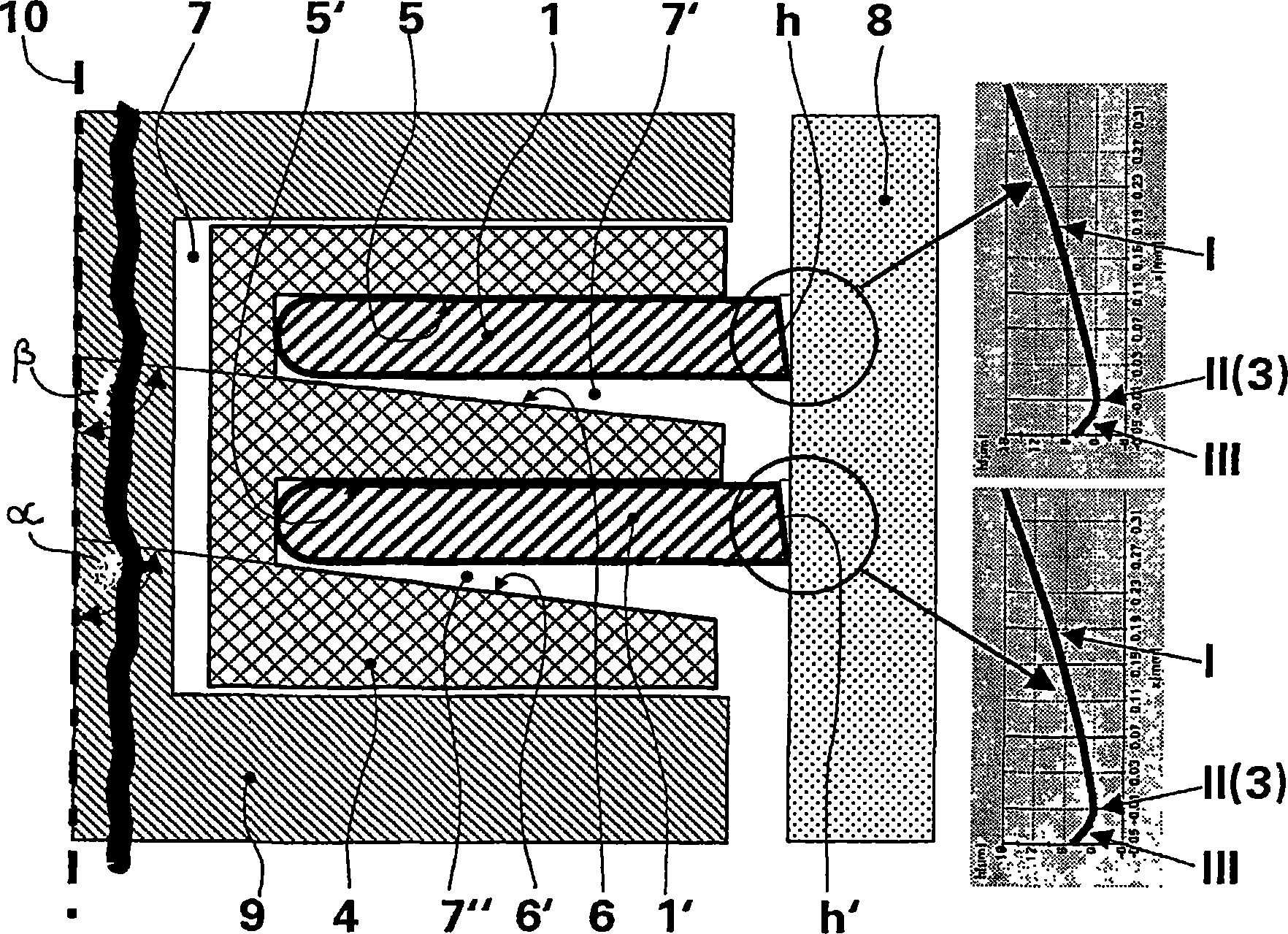

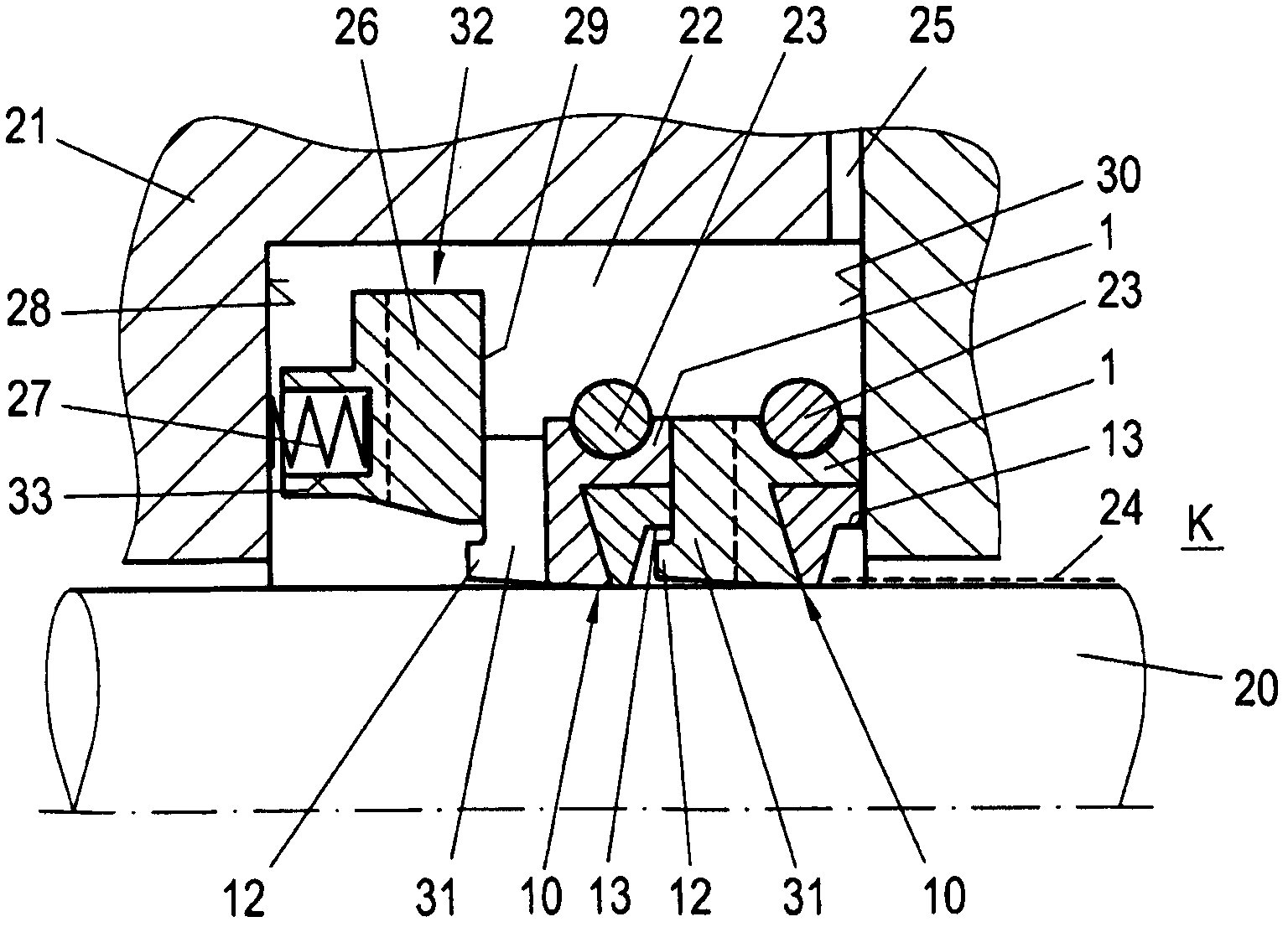

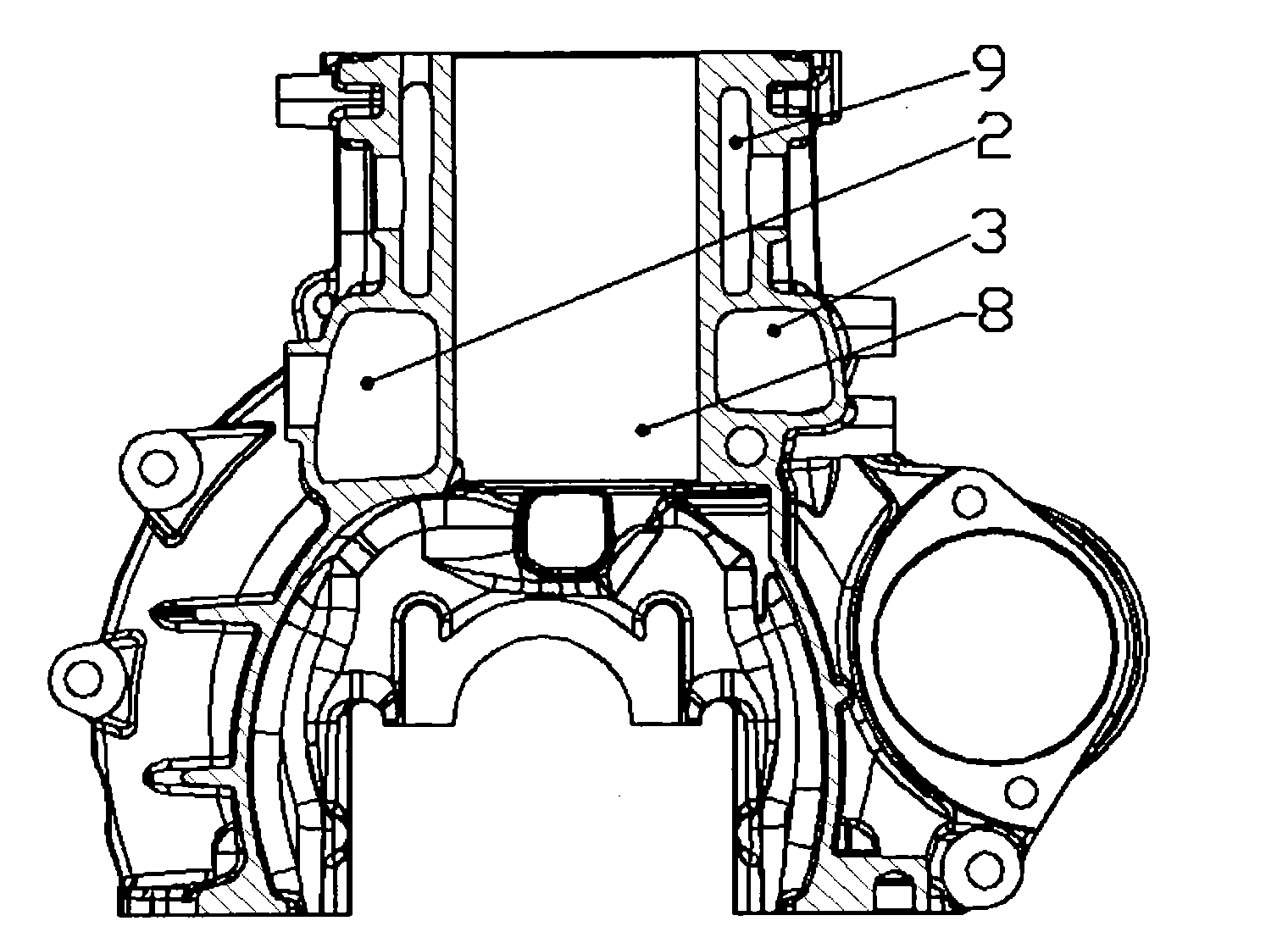

Multipart oil wiping ring for pistons of internal combustion engines

The invention relates to a multipart oil wiping ring for pistons of internal combustion engines, comprising two steel strip-type lamellae with parallel sides, the running surfaces of which are provided with a convexly asymmetric shape having a vertex line that extends across the circumference of the lamellae, and a bracing spring located between the lamellae, said bracing spring pressing the lamellae in an axial direction against one respective side of an annular groove in the piston and in a radial direction against the cylinder wall. The aim of the invention is to obtain an oil-wiping effect that is improved compared to prior art while reducing wear of the running surface. Said aim is achieved by configuring the running surfaces (h, h') of both lamellae so as to make the same correspond to a final contour approaching a condition of wear in the run-in state of the engine, the vertex lines (3, 3') of the running surfaces (h, h') being oriented counter to the direction of the center of the annular groove (3) in the mounted states of the oil ring (10) in the piston.

Owner:MAHLE GMBH

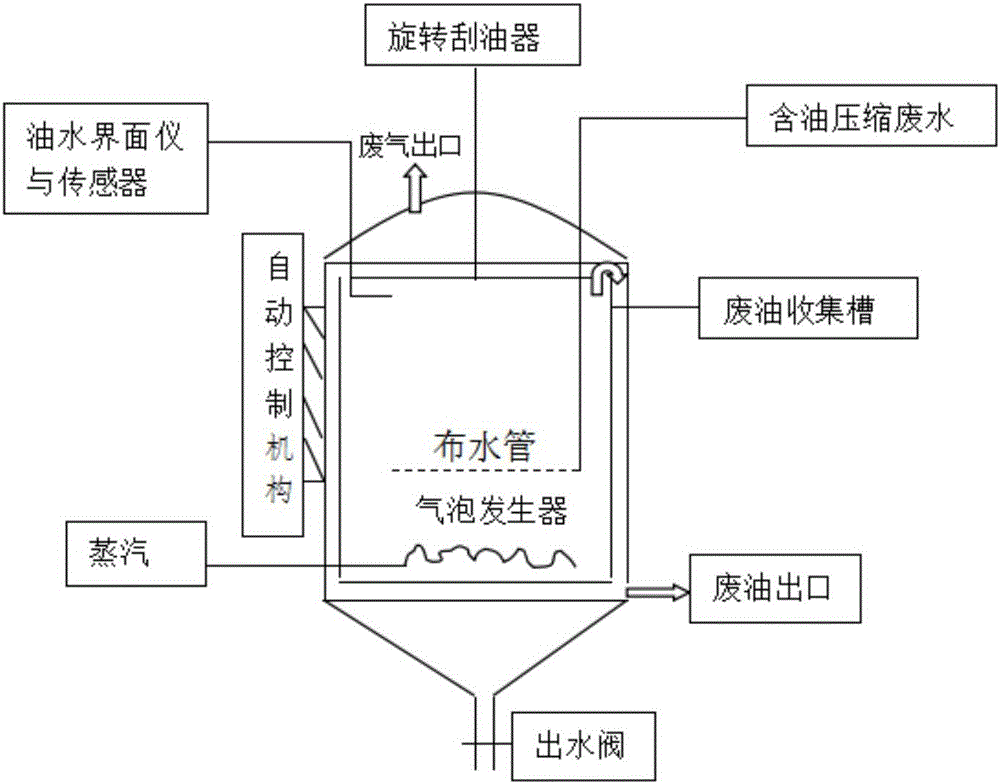

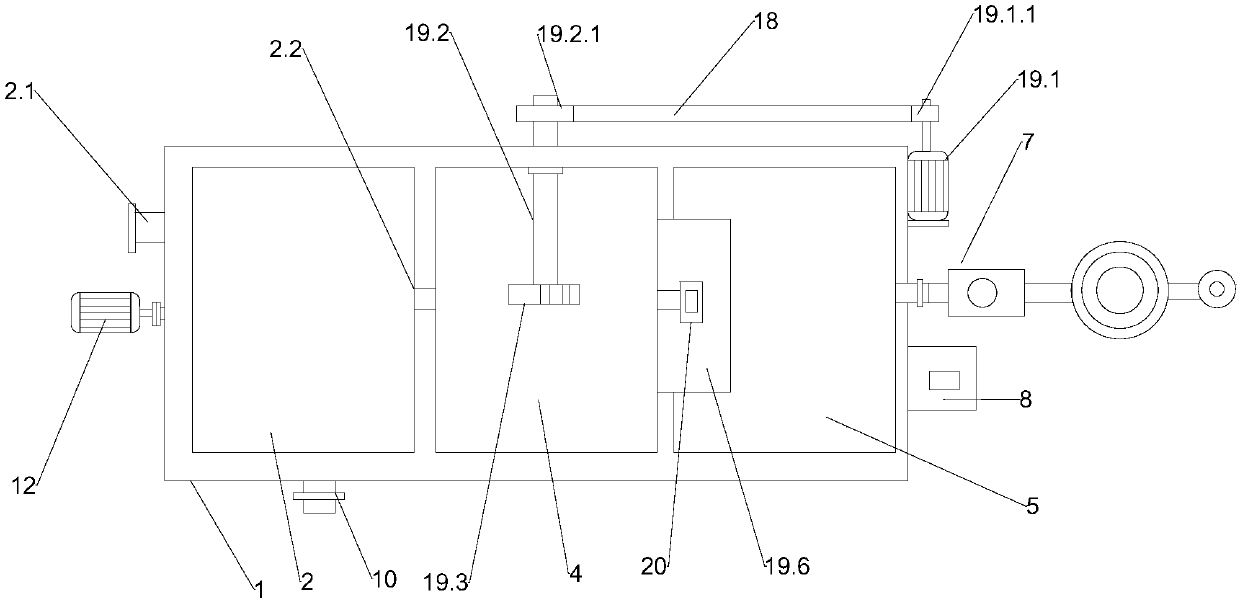

Kitchen waste oil-water separation apparatus and oil-water separation method thereof

PendingCN106673095AImprove oil-water separation rateImprove oil recycling rateFatty/oily/floating substances removal devicesWater/sewage treatment by heatingAutomatic controlMicro bubble

The invention discloses a kitchen waste oil-water separation apparatus. The kitchen waste oil-water separation apparatus comprises a vertical tank body, wherein an oil-water interface measurement instrument, a temperature sensor, a rotating oil scraper and a waste oil collection groove are arranged inside the tank body; a waste water inlet and a waste gas outlet are formed in the top of the tank body; a steam inlet and a waste oil outlet communicated with the waste oil collection groove are formed in the bottom of the side wall of the tank body, a micro-bubble generator connected with the steam inlet is also arranged inside the tank body, and bubbles are generated from steam by virtue of the micro-bubble generator to enable an oil component of oil-containing compressed waste water in the tank body to float; the floating oil component is scraped by the rotating oil scraper into the waste oil collection groove and then discharged by virtue of the waste oil outlet; and the bottom of the tank body is provided with a water outlet valve, the oil-water separation apparatus is also provided with an automatic control mechanism, and the automatic control mechanism is respectively electrically connected with the oil-water interface measurement instrument, the temperature sensor and the micro-bubble generator so as to automatically control the oil-water separation. The invention also discloses a method for separating oil and water of kitchen wastes by utilizing the kitchen waste oil-water separation apparatus.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

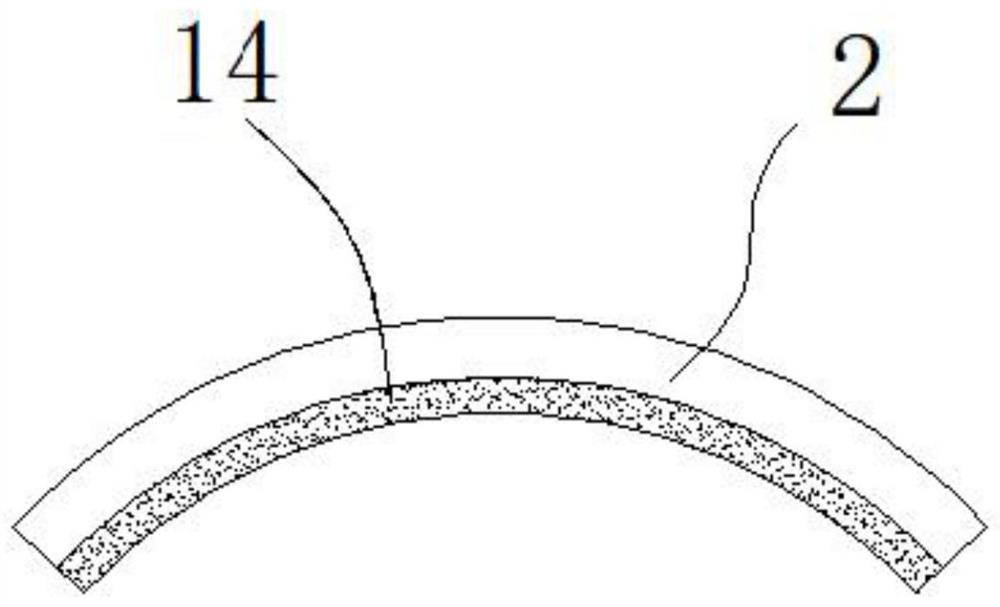

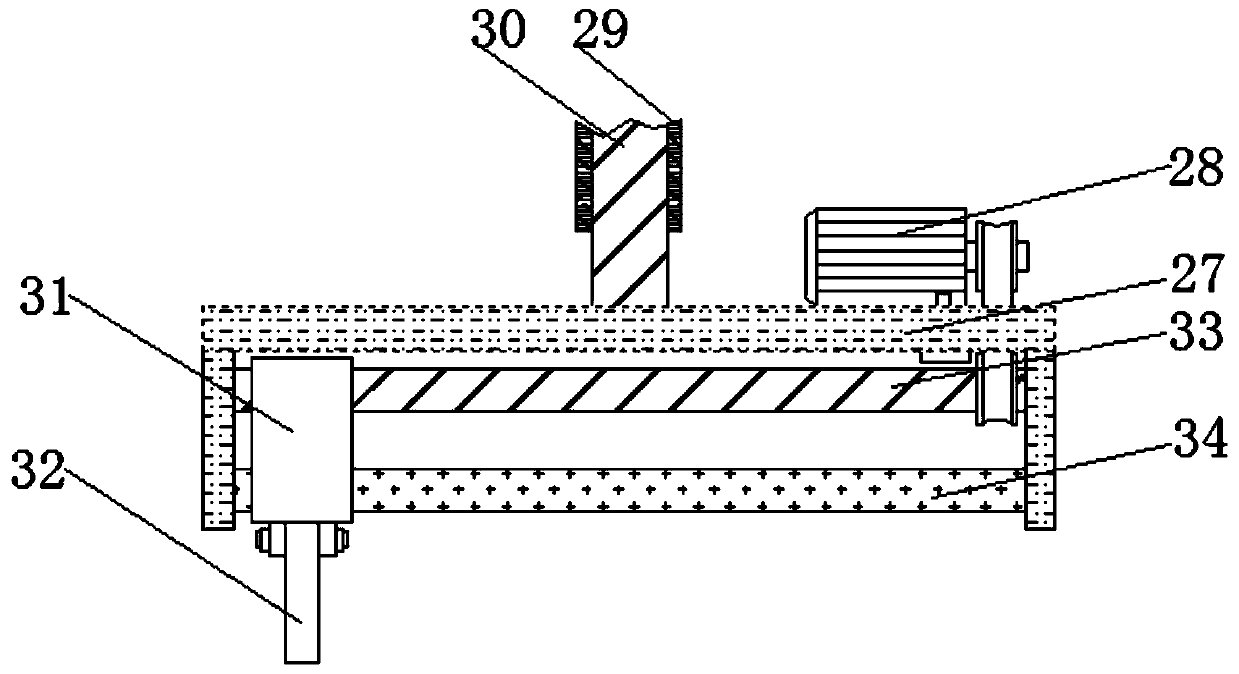

Steel wire rope oil scraping device and using method thereof

PendingCN112030584AAdaptableImprove the effectLiquid surface applicatorsRope making machinesComposite materialWire rope

The invention relates to the field of steel wire rope production, in particular to a steel wire rope oil scraping device and a using method thereof. The steel wire rope oil scraping device comprises apipe body, wherein four groups of arc-shaped plates are mounted in an inner cavity of the pipe body; screws rods are inserted into the four sides of the outer wall of the pipe body correspondingly, penetrate through the outer wall of the pipe body and are inserted into inner cavities of first bearings; and each screw rod is fixedly connected with the inner wall of the corresponding first bearing,and each bearing is fixedly mounted on the outer wall of the corresponding arc-shaped plate. The arc-shaped plates can be driven to adjust the positions by rotating the screw rods, so that the distance between the two arc-shaped plates can be adjusted, the device can adapt to steel wire ropes with different diameters, and the device is high in adaptability, practical and suitable for wide application and use.

Owner:山东固丝德夫金属制品有限公司

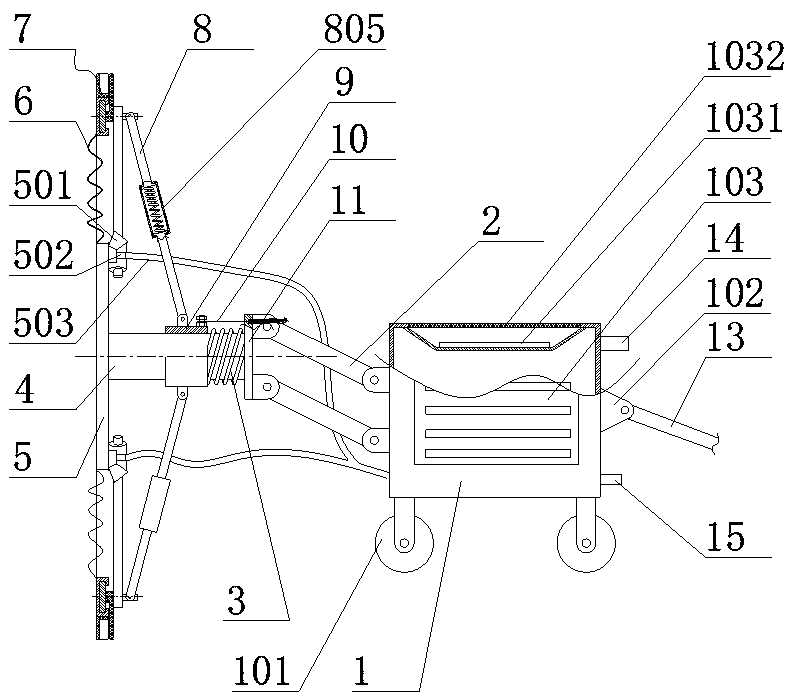

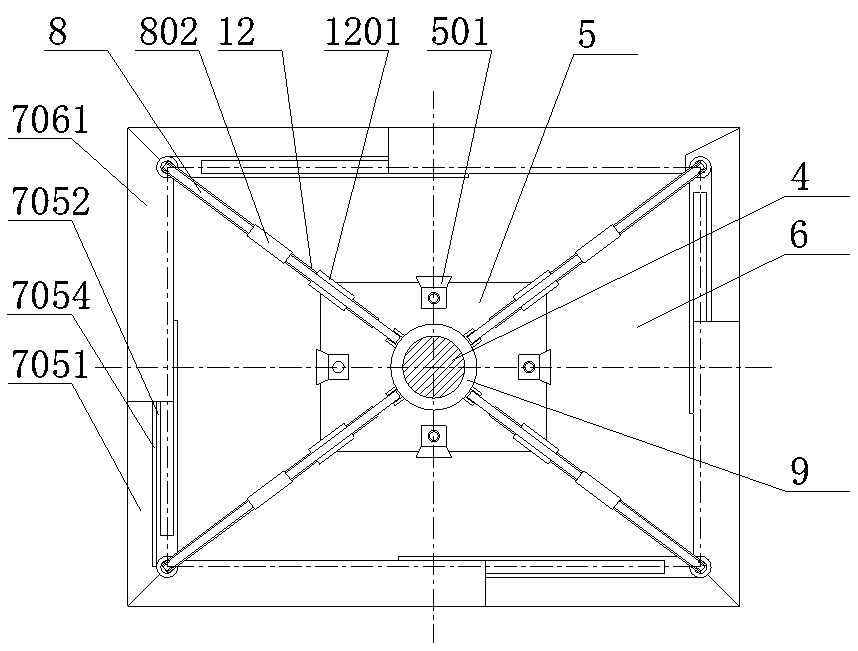

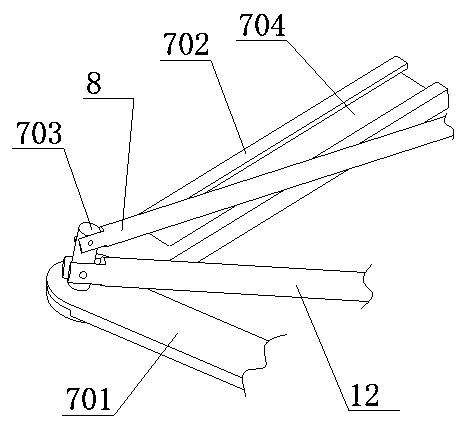

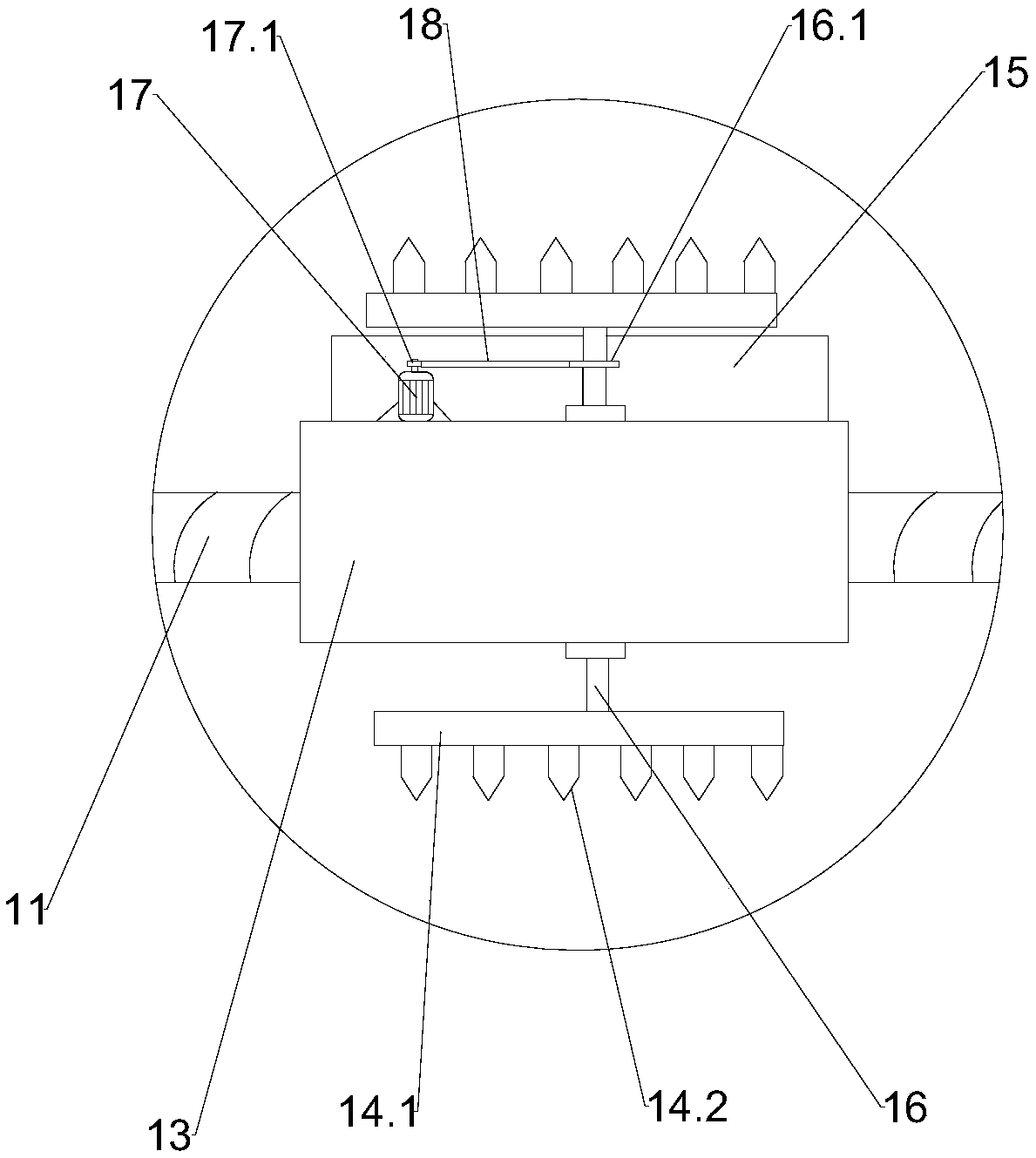

Catering flue oil dirt cleaning device

ActiveCN110918571AImprove oil scraping effectImprove versatilityHollow article cleaningSolid removalMechanical engineeringFlue

The invention relates to a catering flue oil dirt cleaning device. The cleaning device comprises an oil dirt scraping assembly, wherein the oil dirt scraping assembly comprises an oil scraping frame and a positioning assembly, the oil scraping frame comprises four oil scraping assemblies, each oil scraping assembly comprises a first telescopic rod, a second telescopic rod and a scraping strip, thefirst telescopic rod and the second telescopic rod are hinged through connecting columns, and the four oil scraping assemblies are assembled into a quadrilateral frame. When the cleaning device is plugged into a flue, oil dirt softener is sprayed to an inner wall of the flue to soften the oil dirt, then the oil scraping frame is controlled to be unfolded, the oil scraping frame is slowly pulled out, and thereby the softened oil dirt is scraped off from the inner wall of the flue; and a heating device is matched to heat and soften the oil dirt to further enhance the oil scraping effect.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

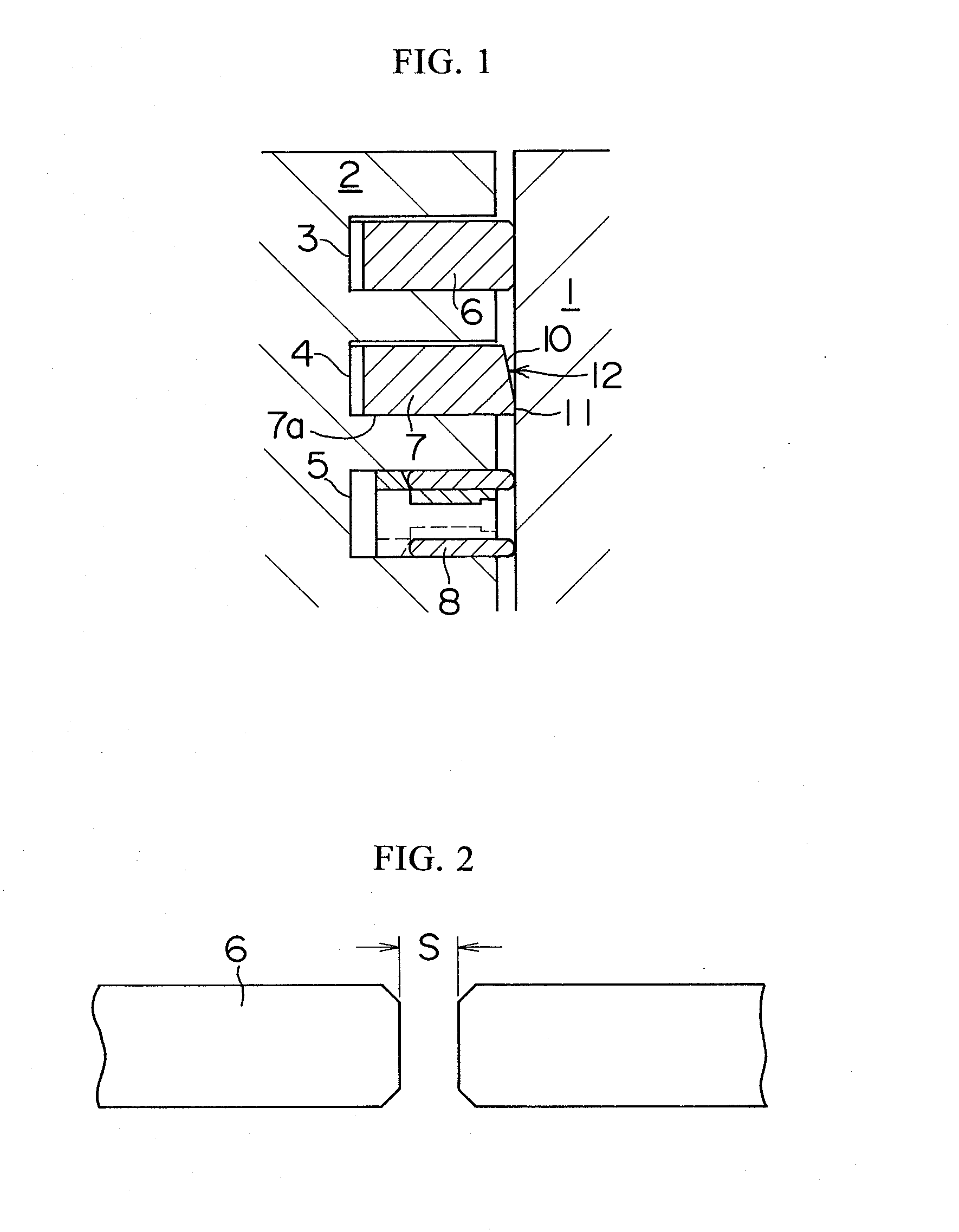

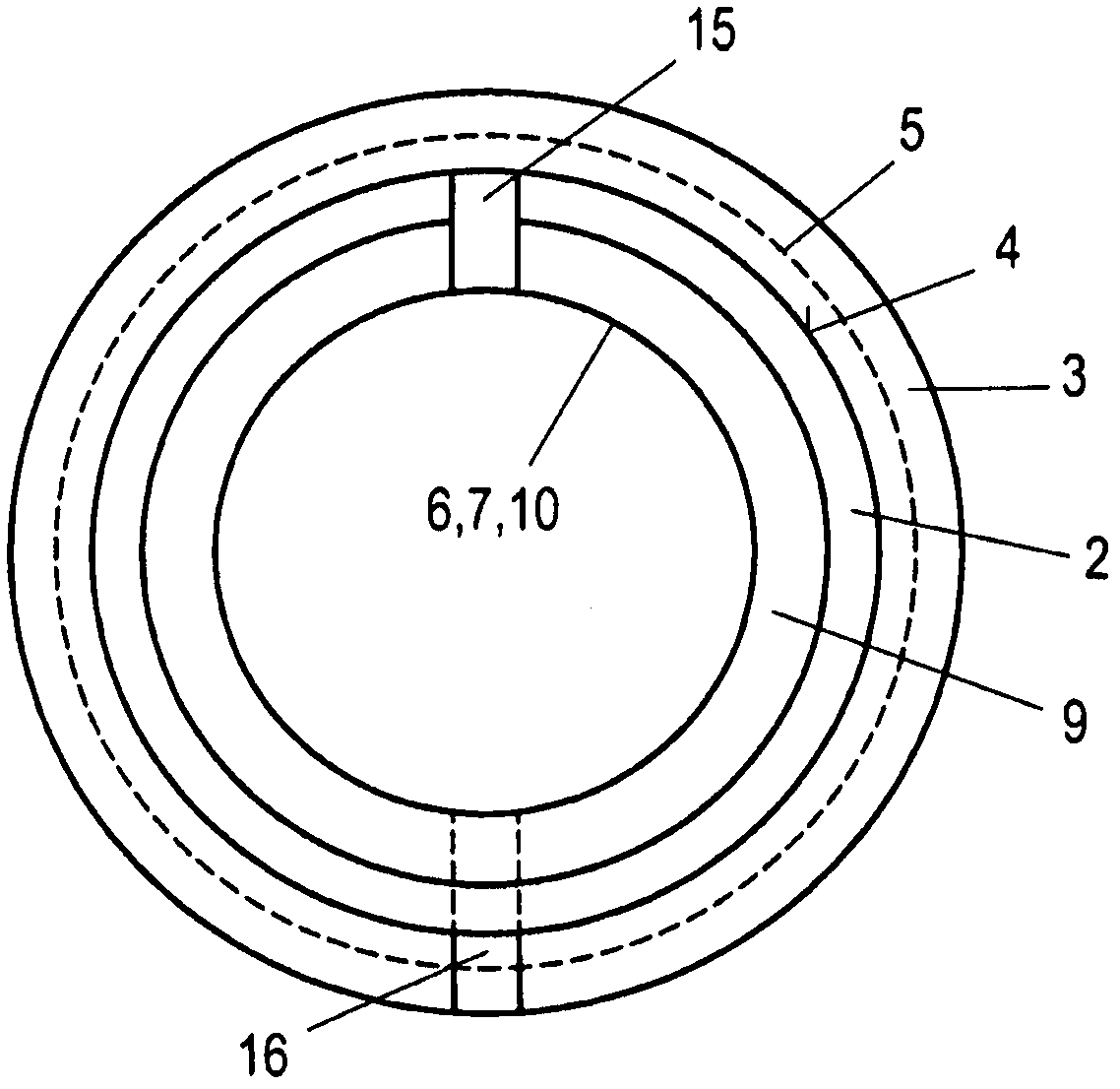

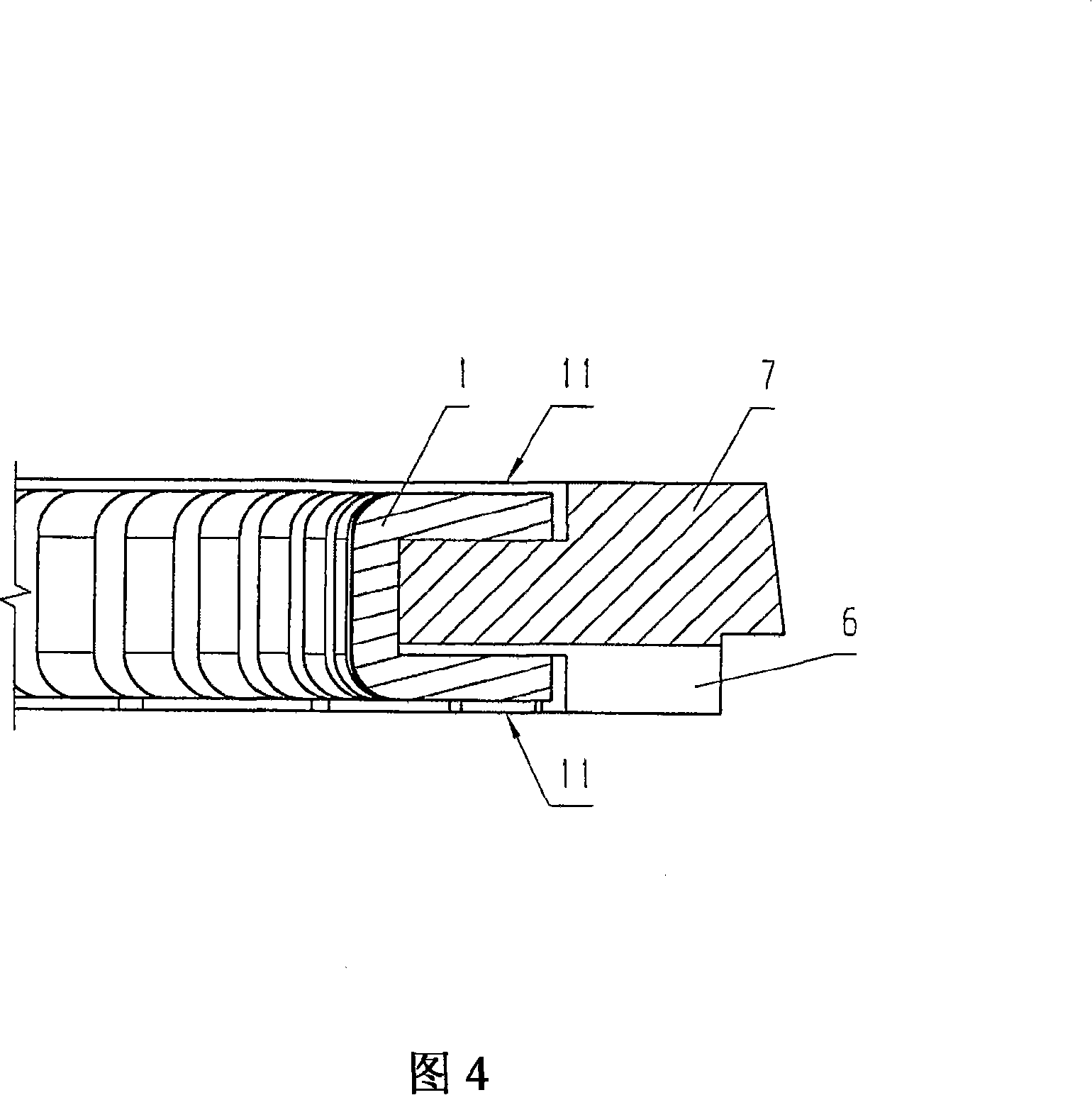

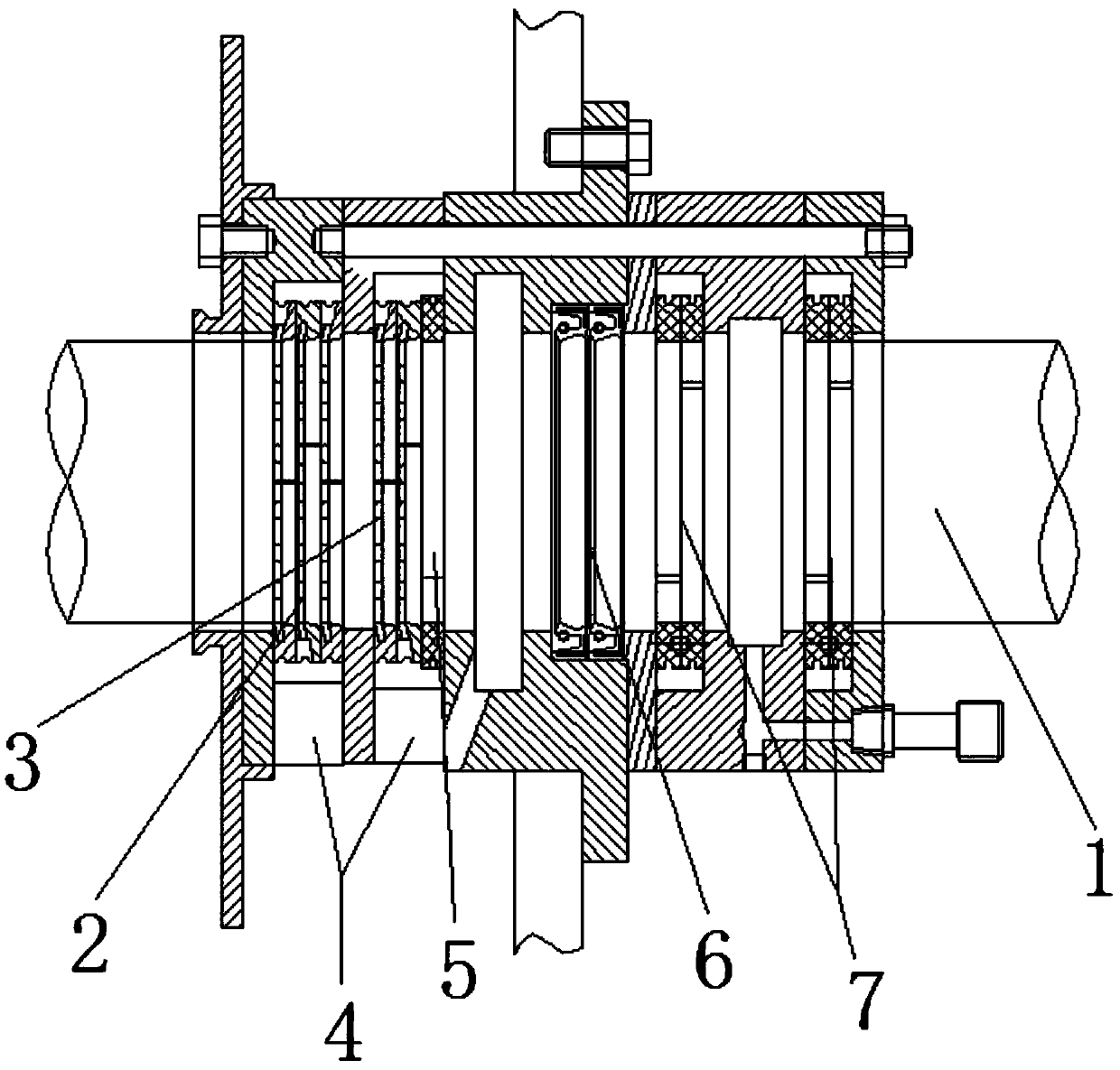

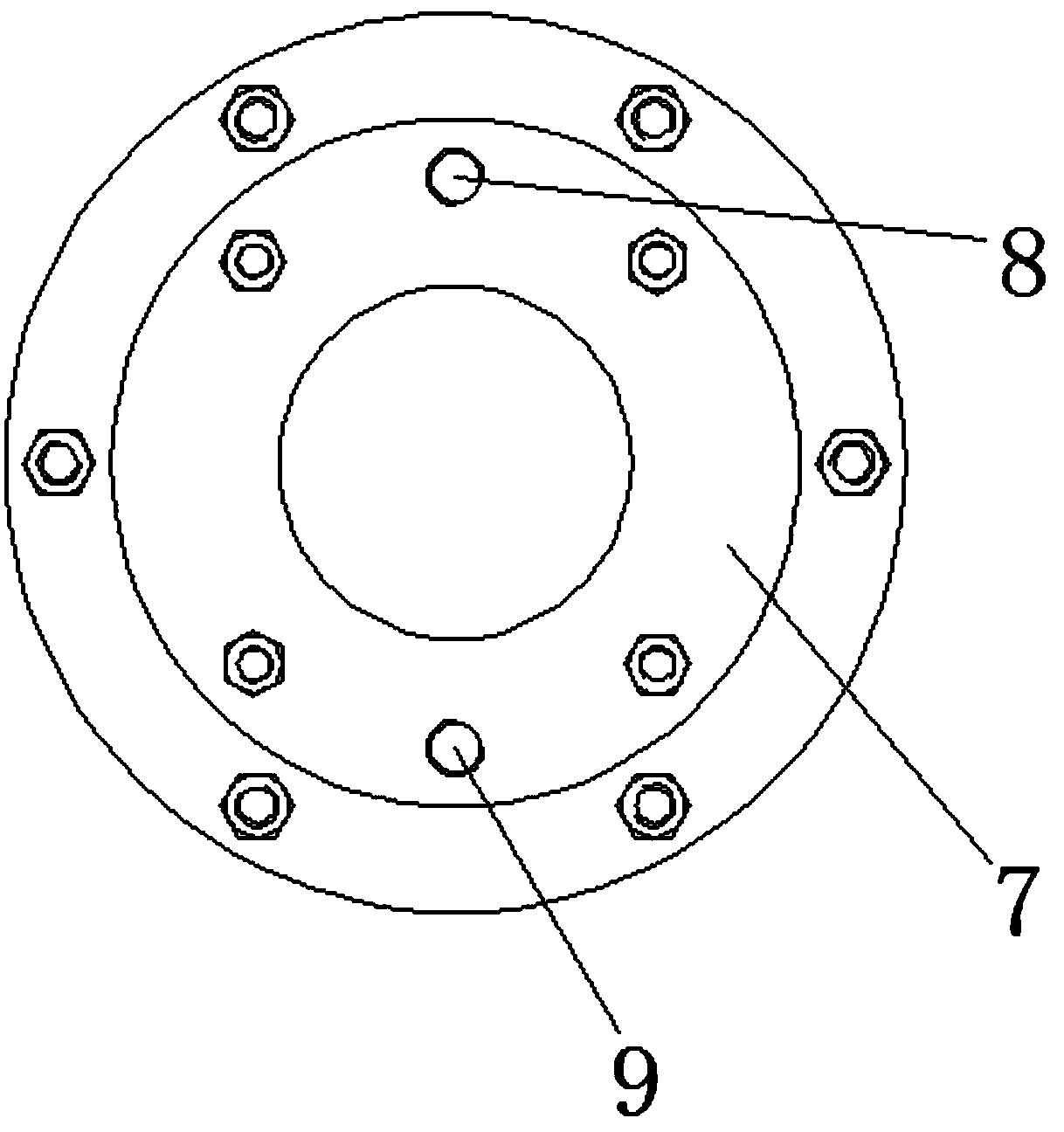

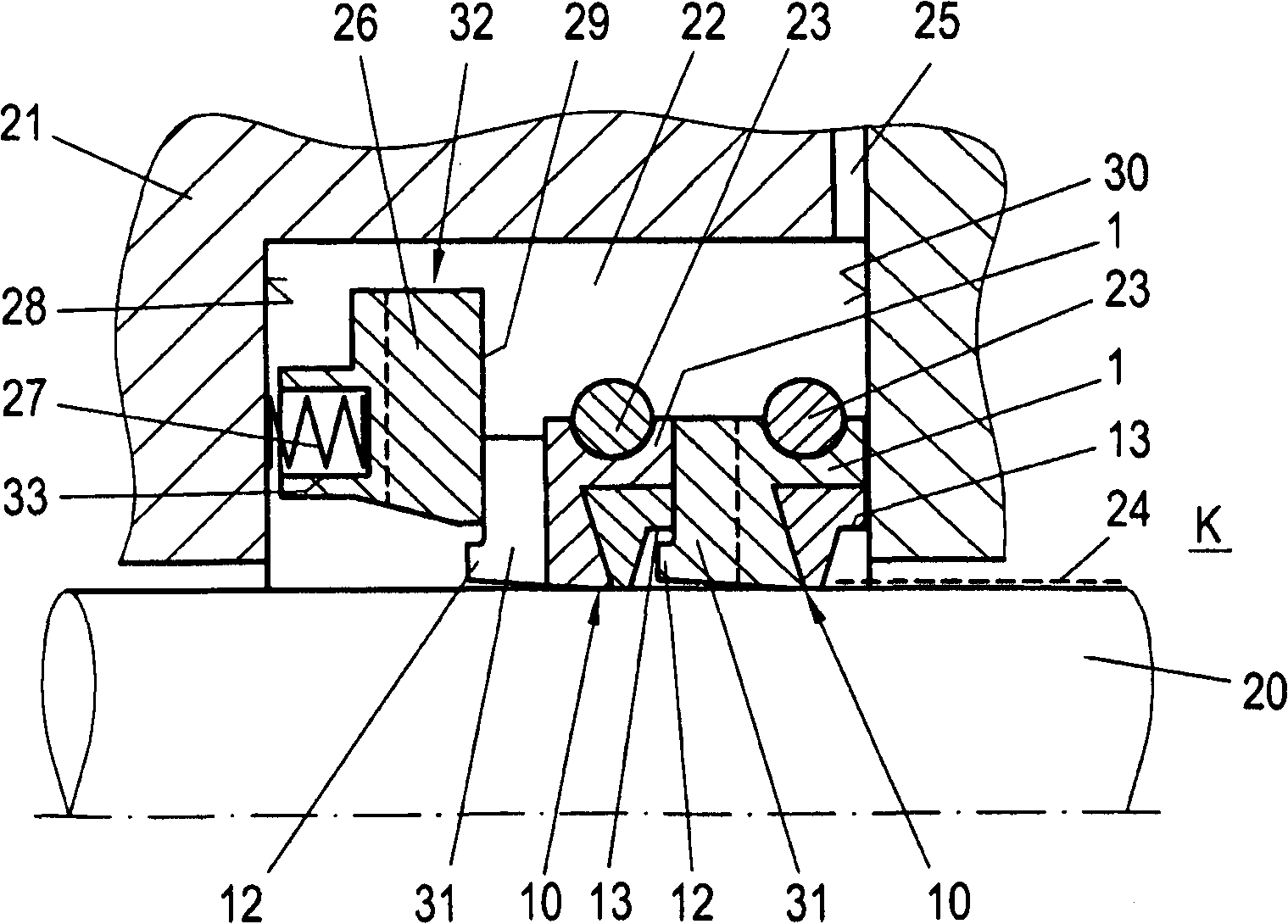

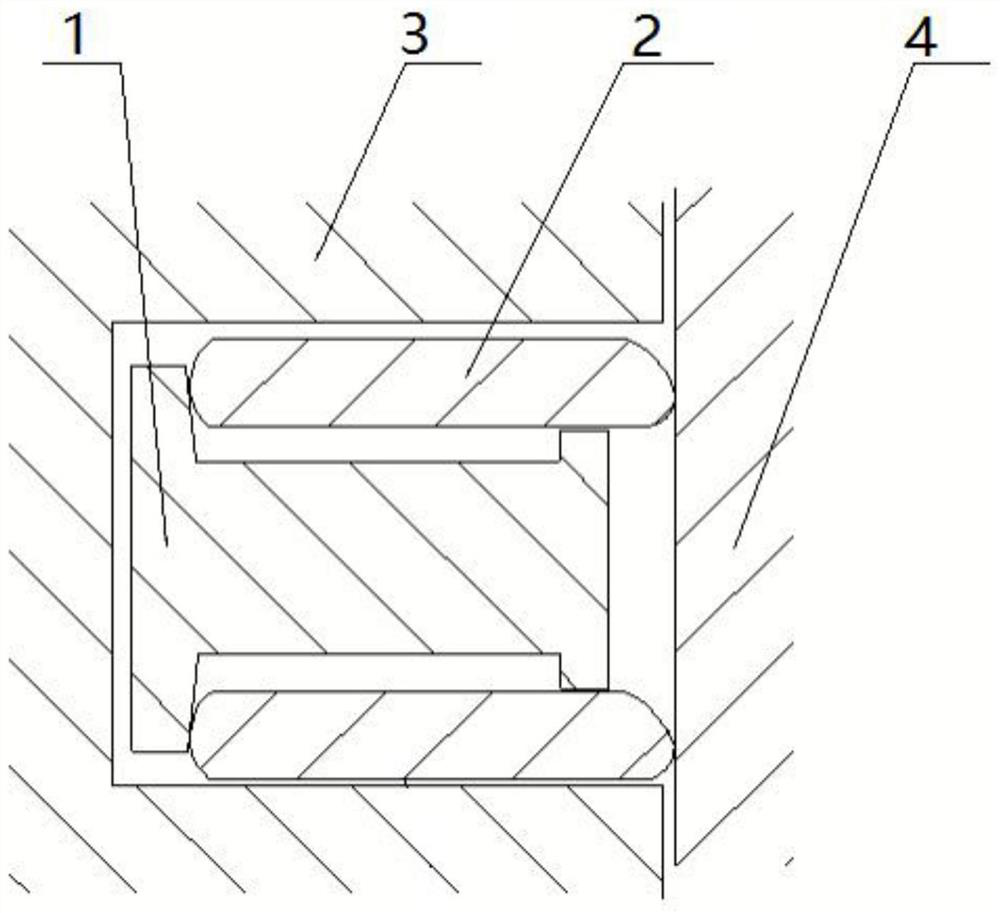

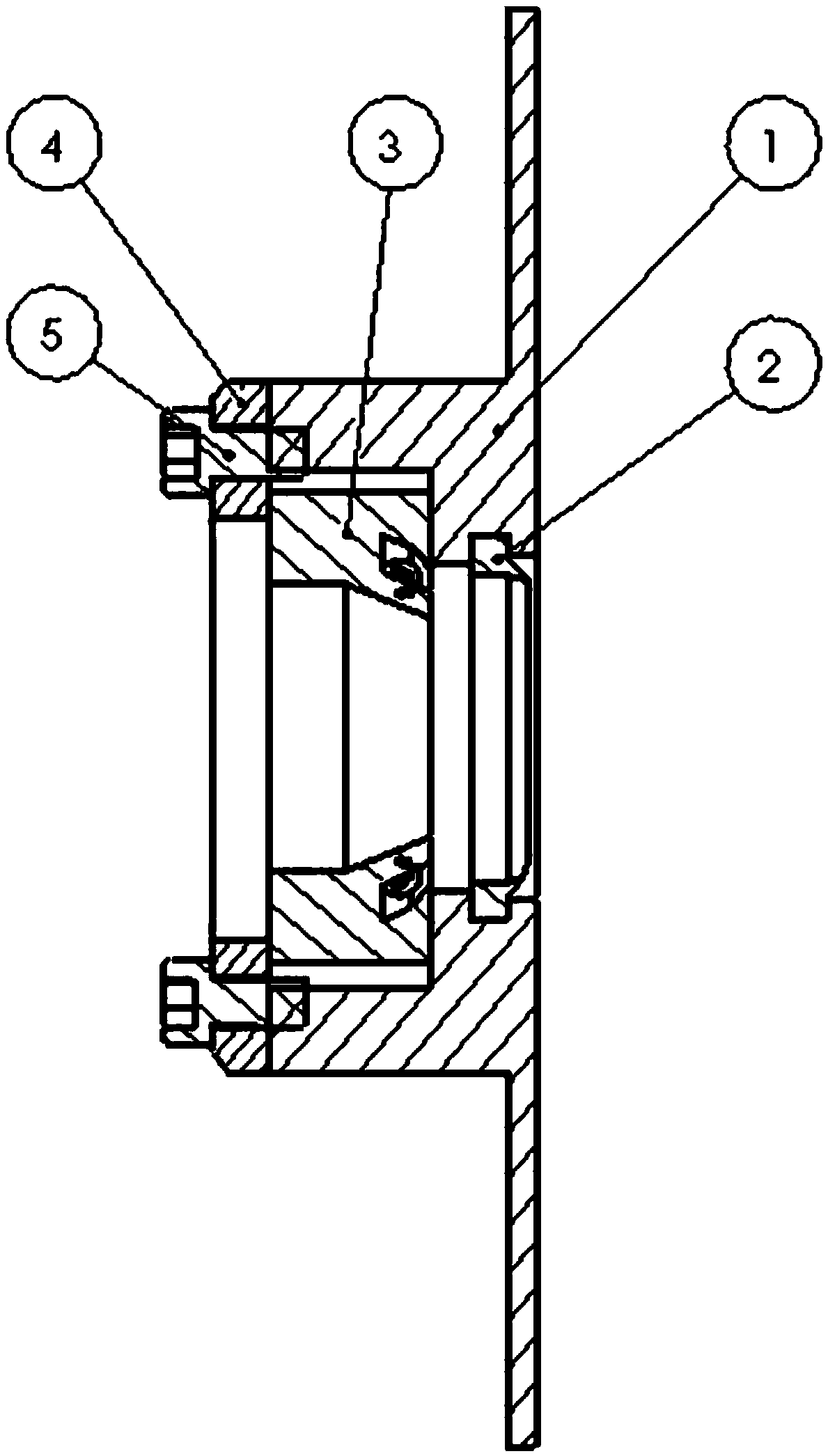

Wiper arrangement and compressor with such a wiper arrangement

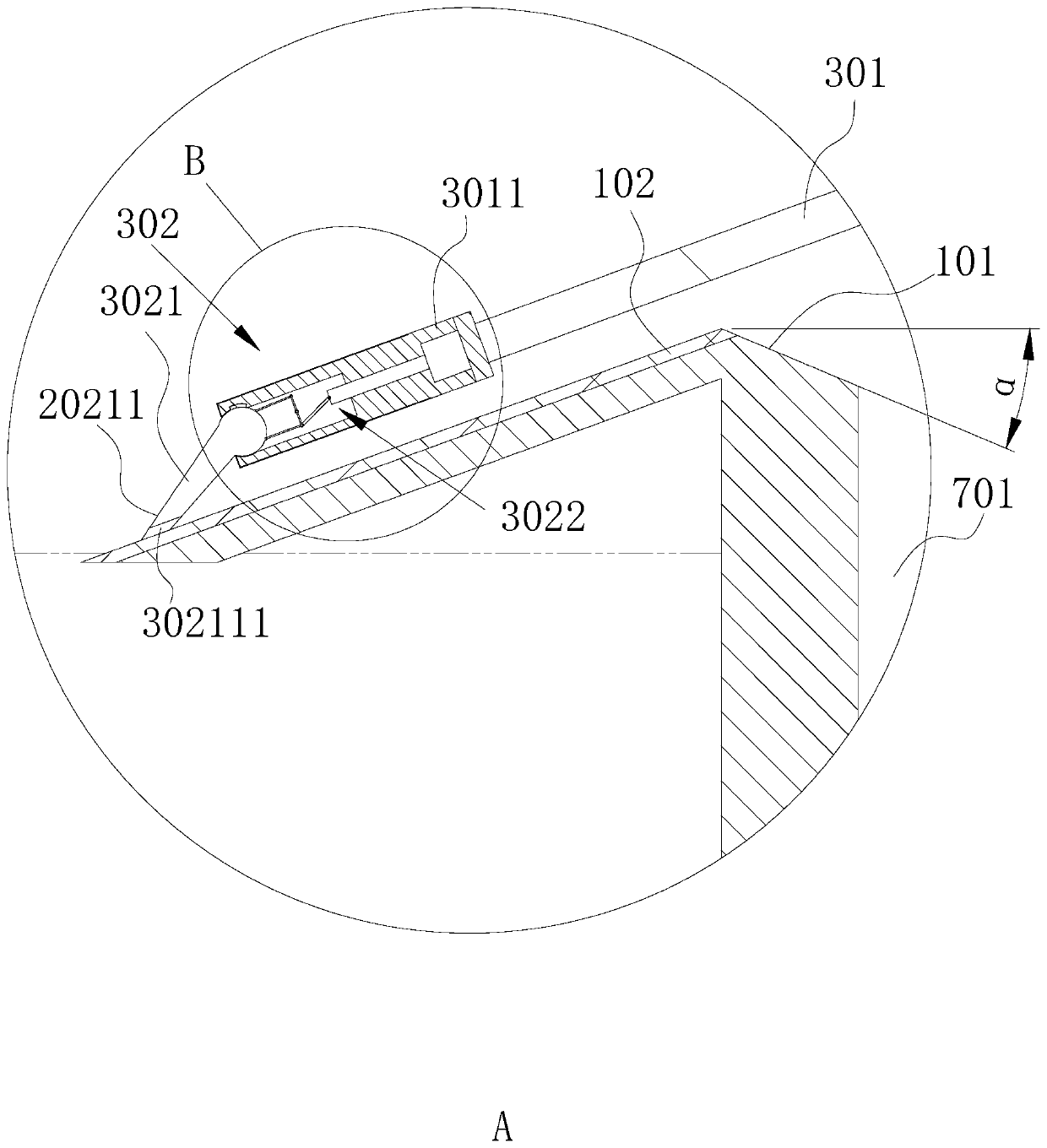

InactiveCN102162439AReduce wearImprove oil scraping effectEngine sealsPositive displacement pump componentsEngineeringMechanical engineering

The invention relates to a wiper arrangement and compressor with such a wiper arrangement. Conventional wiper arrangements with cut rings suffer from unavoidable leakage and, in particular in an embodiment as metallic wiper ring with a sharp wiping edge, scratch on the surface of the piston rod which can be damaged in this manner. In order to eliminate these problems, a wiper arrangement with a wiper ring 2 which is split in the circumferential direction and an L-shaped cover ring 3 which is split in the circumferential direction is proposed, wherein the splitting points 16, 15 of the cover ring 3 and the wiper ring 2 are arranged offset to each other in the circumferential direction, and the wiper ring 2 is arranged abutting axially as well as radially in the recess 4 of the L-shaped cover ring 3, and the radially inner circumferential surfaces 6, 7 of the wiper ring 2 and the cover ring 3 form a common radially inner wiping surface 10.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

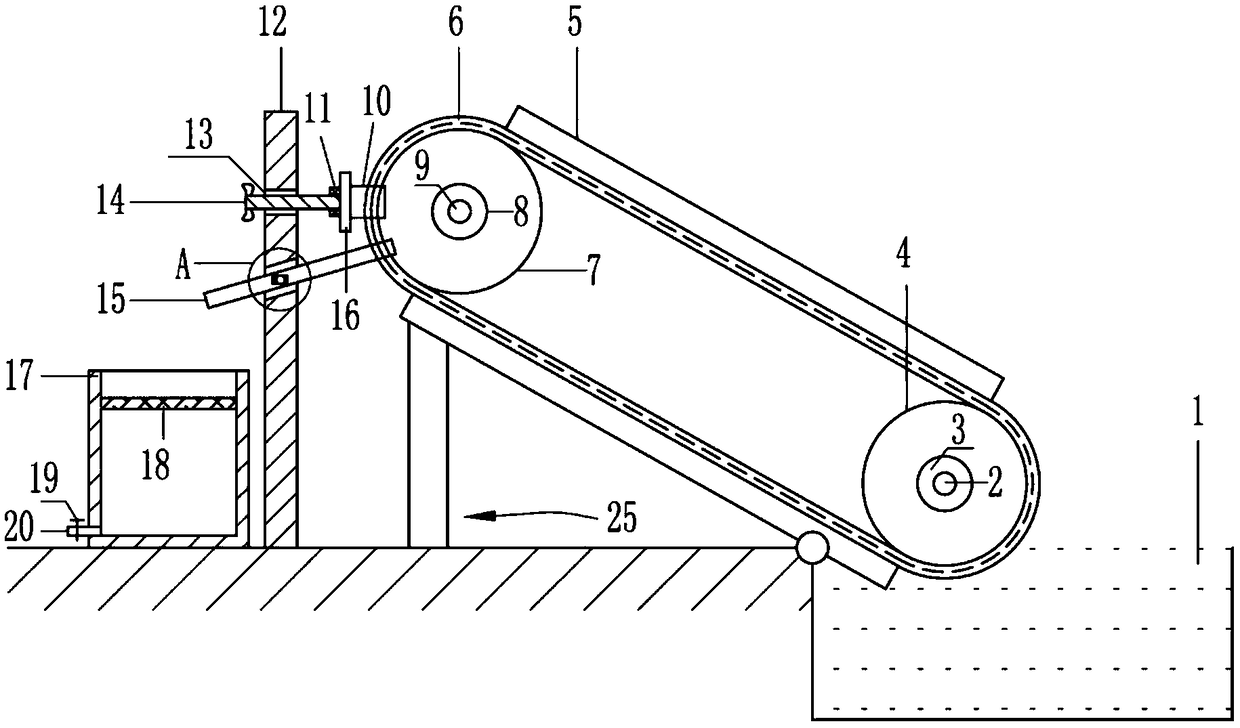

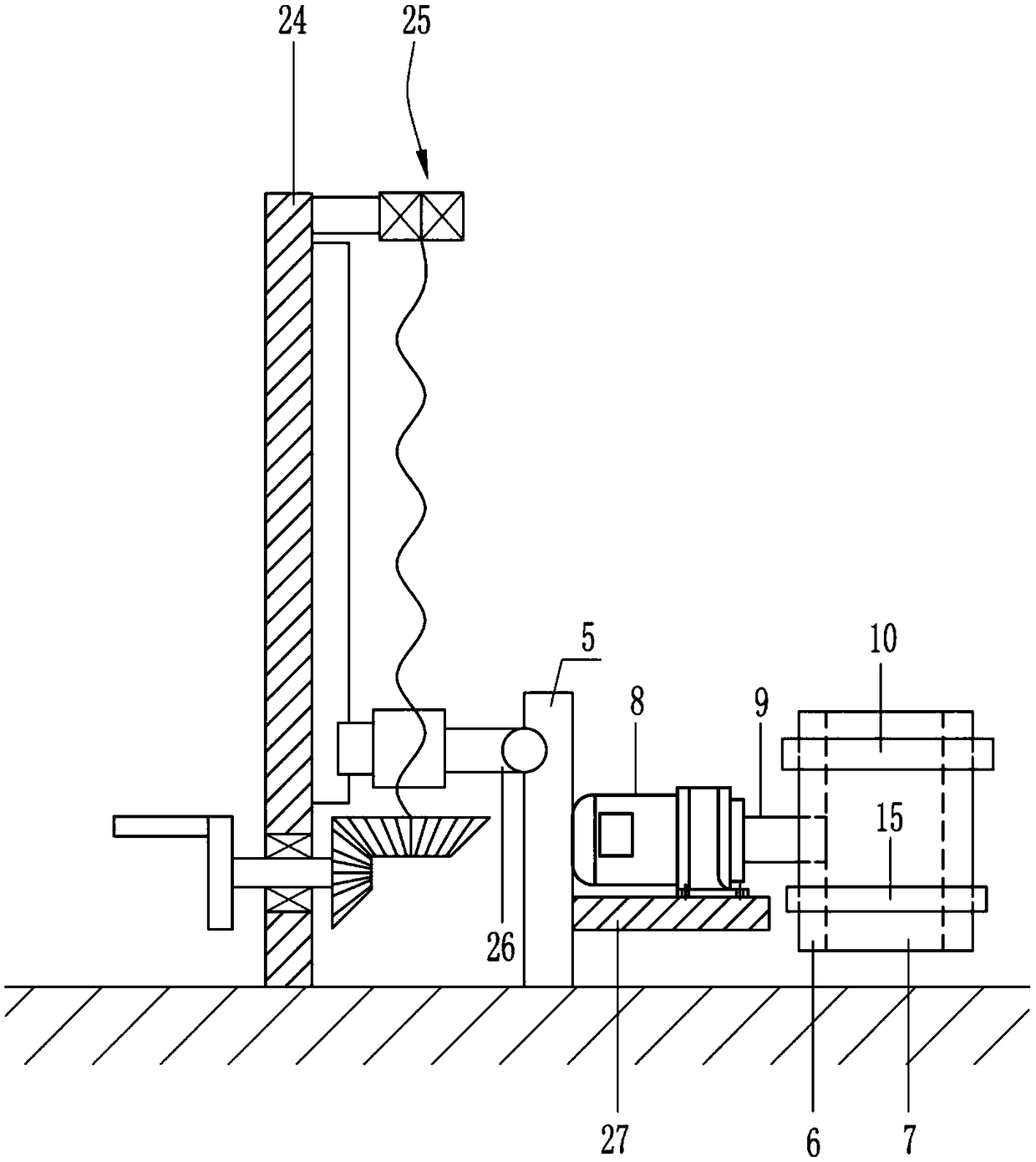

Oily waste water treatment system

InactiveCN107285429AIncomplete cleaningEasy to handleFatty/oily/floating substances removal devicesTreatment involving filtrationFailure rateWater treatment system

The present invention provides an oily wastewater treatment system, which comprises a round roller 1, a motor, a round roller 2, a transmission belt, a fixed plate 1, an oil scraper, a fixed plate 2 and a collection box. The rear end of the round roller 1 is assembled on the The upper position of the front end surface of the vertical plate, the motor is installed at the upper position of the front end surface of the second vertical plate, and the first round roller is connected with the second round roller through a transmission belt. This design realizes the purpose of automatically adjusting the tension of the conveyor belt in the present invention. The collection box is arranged on the lower side of the oil scraper, the first fixed plate is installed on the right end surface of the vertical plate one, the second fixed plate is installed on the right end surface of the vertical plate two, the rear side of the lower end surface of the oil scraper is connected with the fixed plate The upper surface of the first end fits together, and the front side of the lower end of the oil scraper is attached to the upper end face of the second fixed plate. This design increases the sterilization function of the present invention. The present invention has high working efficiency, small footprint, low failure rate, and high stability. Well, high reliability.

Owner:惠天昱

Cold-rolled steel pipe outer surface oil removal device and cold-rolled steel pipe production system

PendingCN109047344ASimple structureLow costWork cleaning devicesMetal rolling arrangementsEngineeringSteel tube

The invention belongs to the technical field of cold-rolled steel pipes, and discloses a cold-rolled steel pipe outer surface oil removal device. The cold-rolled steel pipe outer surface oil removal device comprises a support, a thread rope and a power assembly, the steel pipe penetrates through the support, the power assembly is arranged on the support, the thread rope is driven by the power assembly to rotate around the steel pipe, and the thread rope is attached to the steel pipe by at least a circle; and oil on the surface of the steel pipe is removed along with the relative movement between the steel pipe and the thread rope. The invention further discloses a cold-rolled steel pipe production system. The cold-rolled steel pipe production system comprises a cold-rolled steel pipe machine, the above cold-rolled steel pipe outer surface oil removal device and an oil receiving disc; the steel pipe discharged from the cold-rolled steel pipe machine enters the cold-rolled steel pipe outer surface oil removal device, then the oil on the outer surface of the steel pipe is removed, and the oil is collected by the oil receiving disc. The cold-rolled steel pipe outer surface oil removaldevice and the cold-rolled steel pipe production system are reasonable in structural design, low in manufacturing cost and small in occupied area, and can be suitable for the steel pipes with different diameters without replacing parts.

Owner:洛阳恒诺锚固技术有限公司

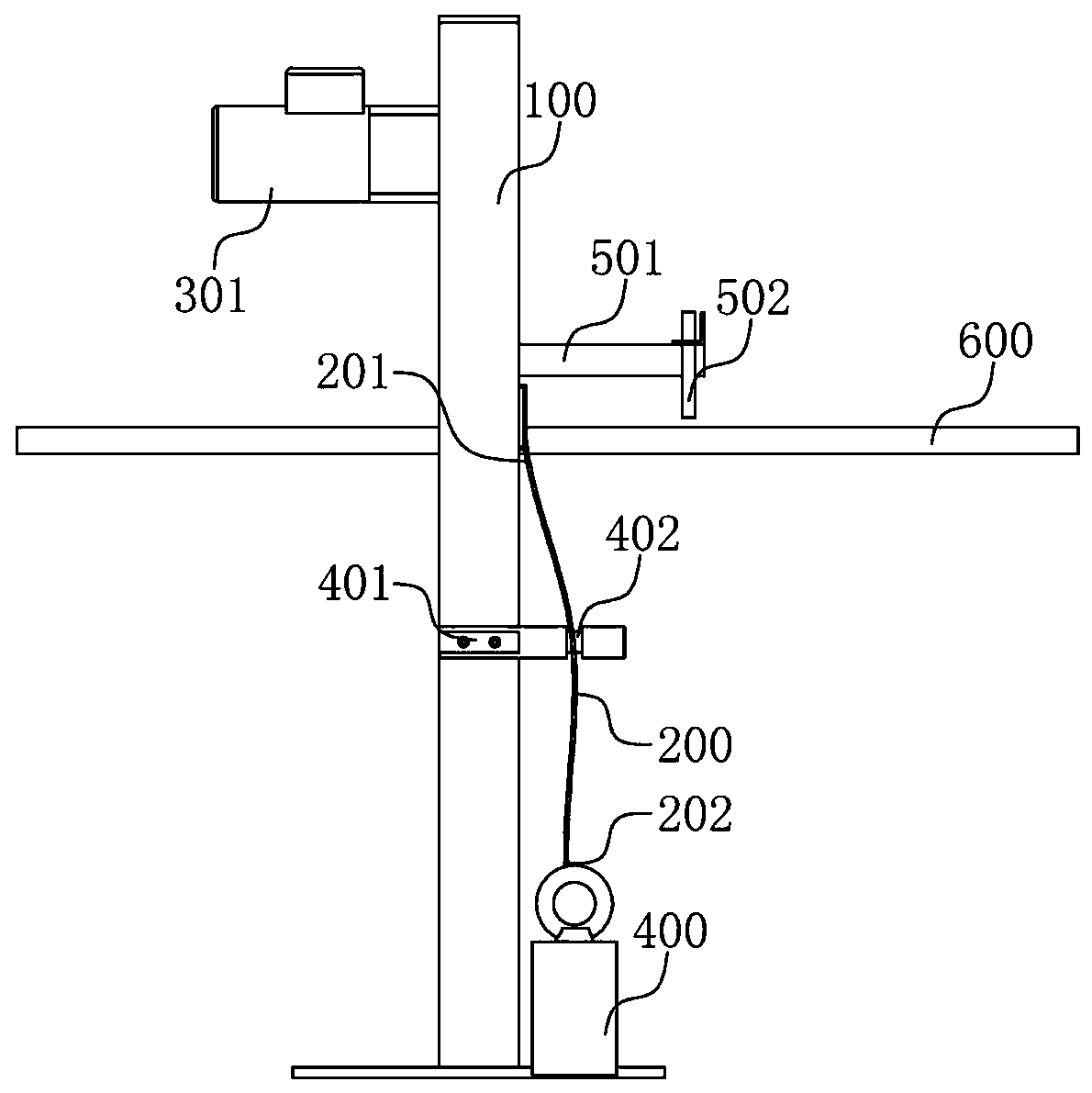

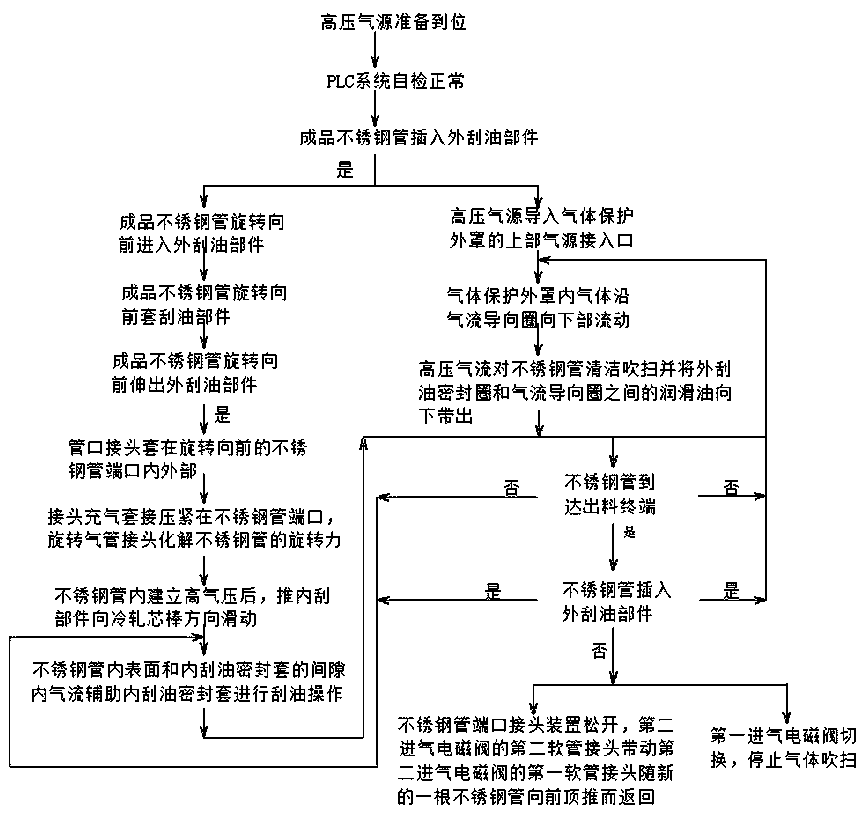

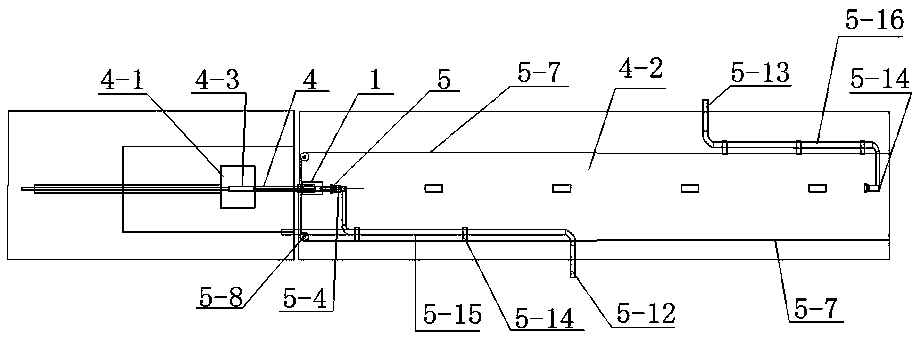

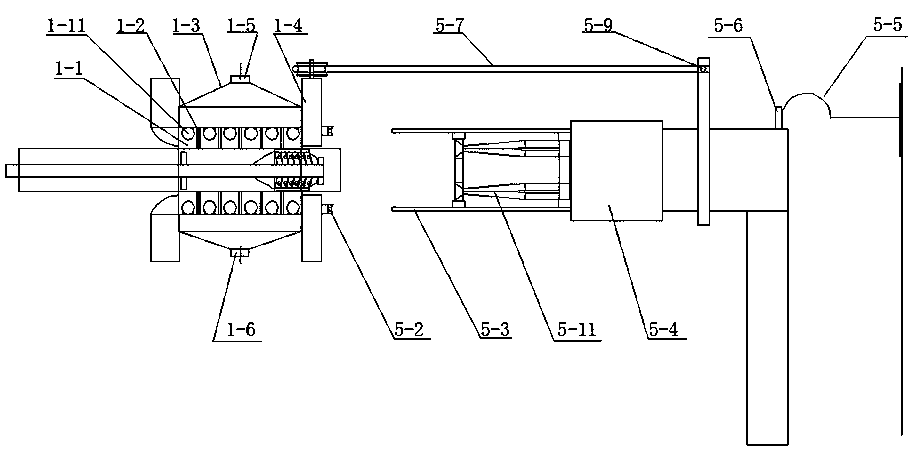

Stainless steel pipe cold rolling oil removing device and method

PendingCN110665981AReduce the overall heightIncrease wiper pressureWork cleaning devicesMetal rolling arrangementsMetallurgySS - Stainless steel

The invention discloses a stainless steel pipe cold rolling oil removing device and method. The stainless steel pipe cold rolling oil removing process and the stainless steel pipe cold rolling processare carried out simultaneously. According to the oil removing method, oil scraping operation is carried out on the outer surface and the inner surface of a finished stainless steel pipe in the discharging process of the stainless steel pipe cold rolling technology, and a method of adopting a sealing ring for increasing spring pressure and a high-pressure airflow as an auxiliary are used for oil removing of the inner and outer surfaces of the stainless steel pipe, so that the difficulty of lubricating oil pollution and oil discharging of the stainless steel pipe in the cold rolling process ofthe stainless steel pipe is solved, and favorable conditions are created for the improvement of a degreasing effect of the stainless steel pipe in the next step.

Owner:太原中金天威不锈钢管股份有限公司

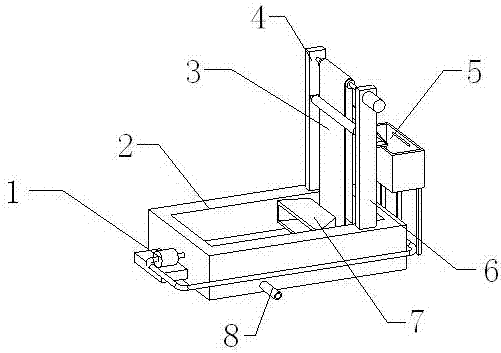

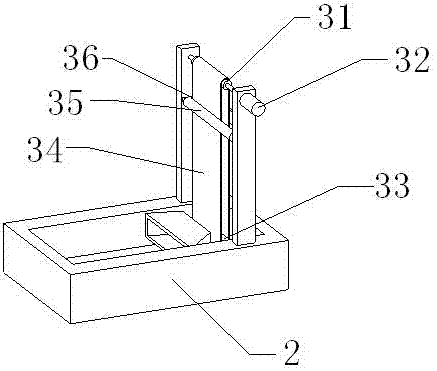

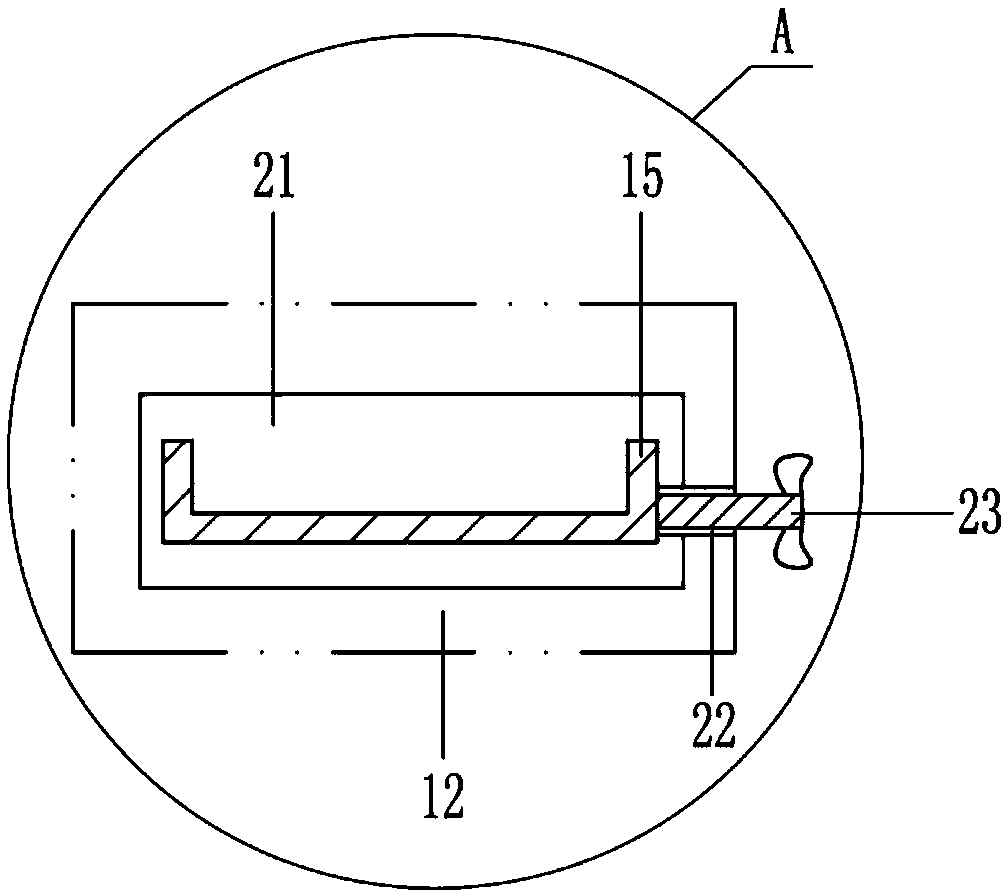

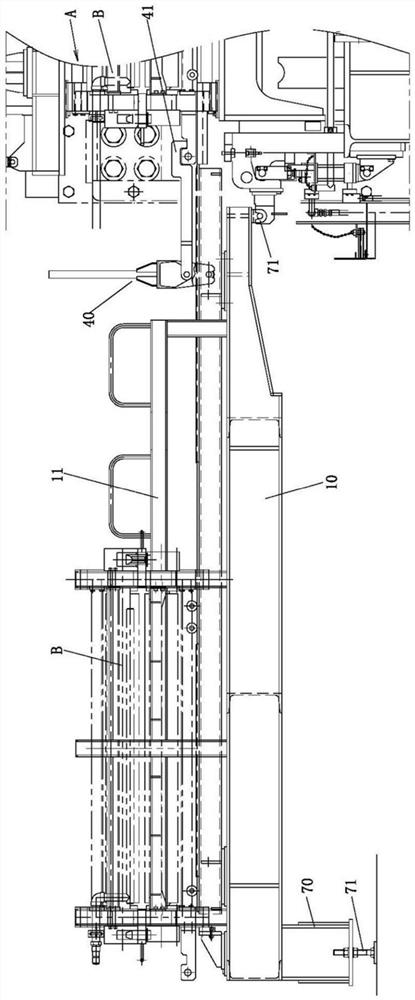

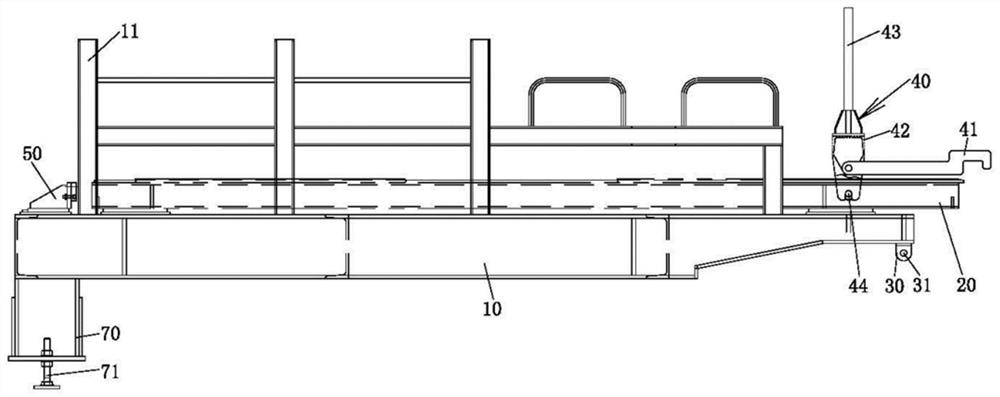

Degreasing apparatus for industrial wastewater treatment

InactiveCN109110871AEasy to operateMove preciselyFatty/oily/floating substances removal devicesLiquid separationIndustrial engineeringIndustrial wastewater treatment

The invention relates to a degreasing apparatus, particularly to a degreasing apparatus for industrial wastewater treatment. The technical problem to be solved by the present invention is to provide adegreasing apparatus for industrial wastewater treatment, wherein the height of the degreasing belt can be adjusted according to the liquid level of a wastewater pool so as to achieve the optimal degreasing effect, and workers can conveniently operate. The degreasing apparatus comprise a wastewater pool, a first rotating shaft, a first bearing seat, a first guiding wheel, a lifting plate, a degreasing belt, a second guiding wheel, a motor, a second rotating shaft, a scraping sheet, a second bearing seat, a first installing plate, a first butterfly bolt, a collecting hopper, a connecting plate, a collecting frame and a mesh plate. According to the present invention, with the degreasing apparatus, the height of the degreasing belt can be adjusted according to the liquid level of the wastewater pool so as to achieve the optimal degreasing effect, and workers can conveniently operate.

Owner:于德泉

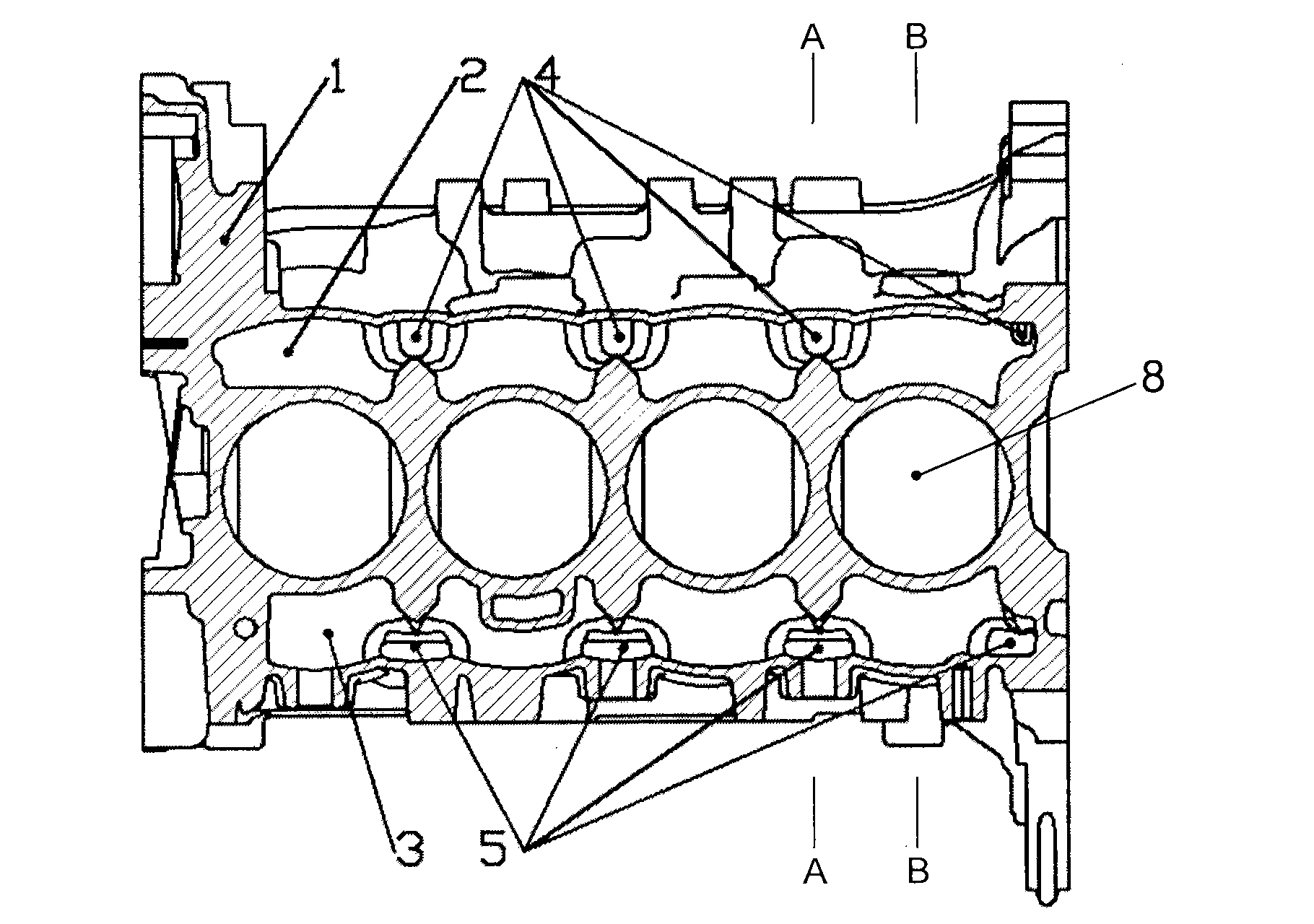

Cylinder body of diesel engine

InactiveCN102102598AIncrease stiffnessReduce distortionCylinder headsCylindersCombustion noiseCrankcase

The invention relates to a cylinder structure of a diesel engine, comprising a cylinder body, wherein both sides of the cylinder body, extending along a crankshaft direction, are respectively arranged to be vertical to gas circulation channels of a crankshaft case and engine oil return channels which are arranged in the crankshaft direction, every two gas leakage channels of the crankshaft case are communicated along the crankshaft direction, and every two engine oil return channels are communicated along the crankshaft direction. The cylinder structure of the diesel engine can efficiently enhance the rigidity of the cylinder body, lower deformation of a cylinder hole in the running process of the diesel engine and also lower the combustion noise of the engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

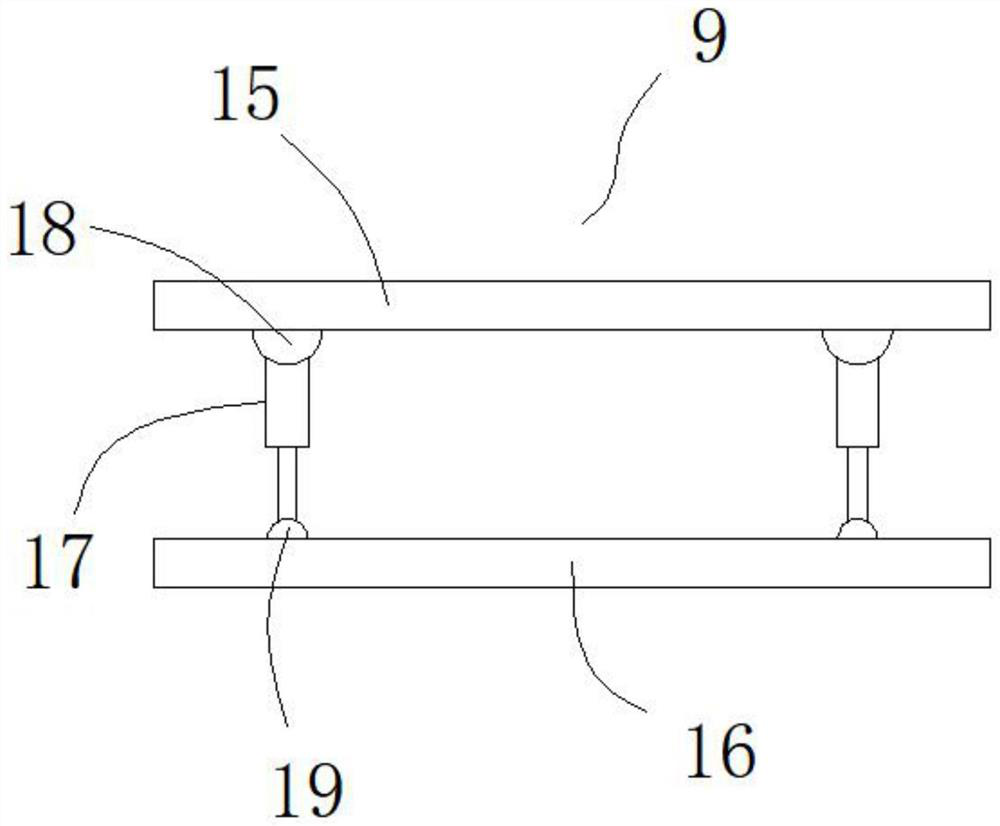

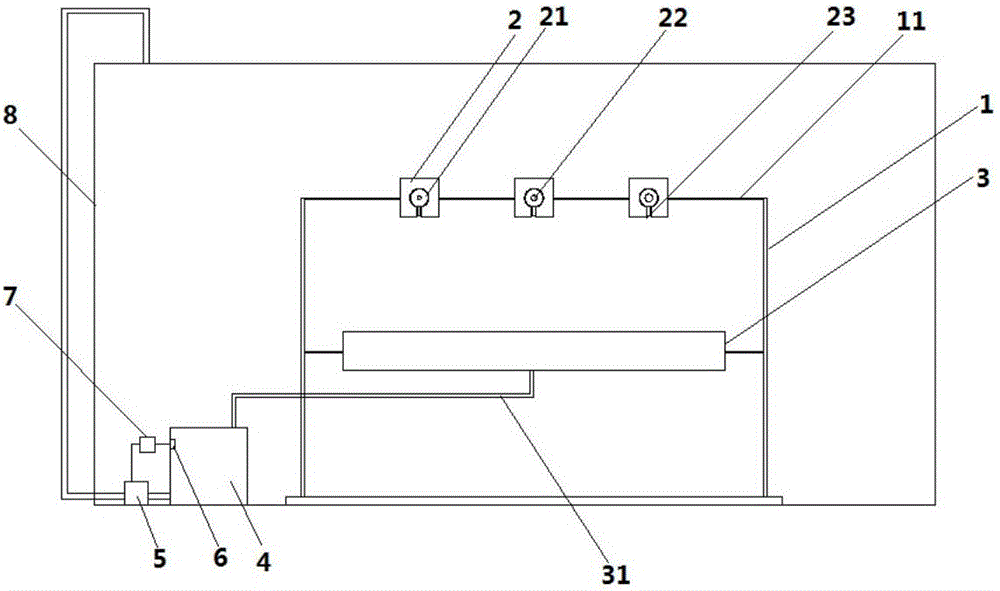

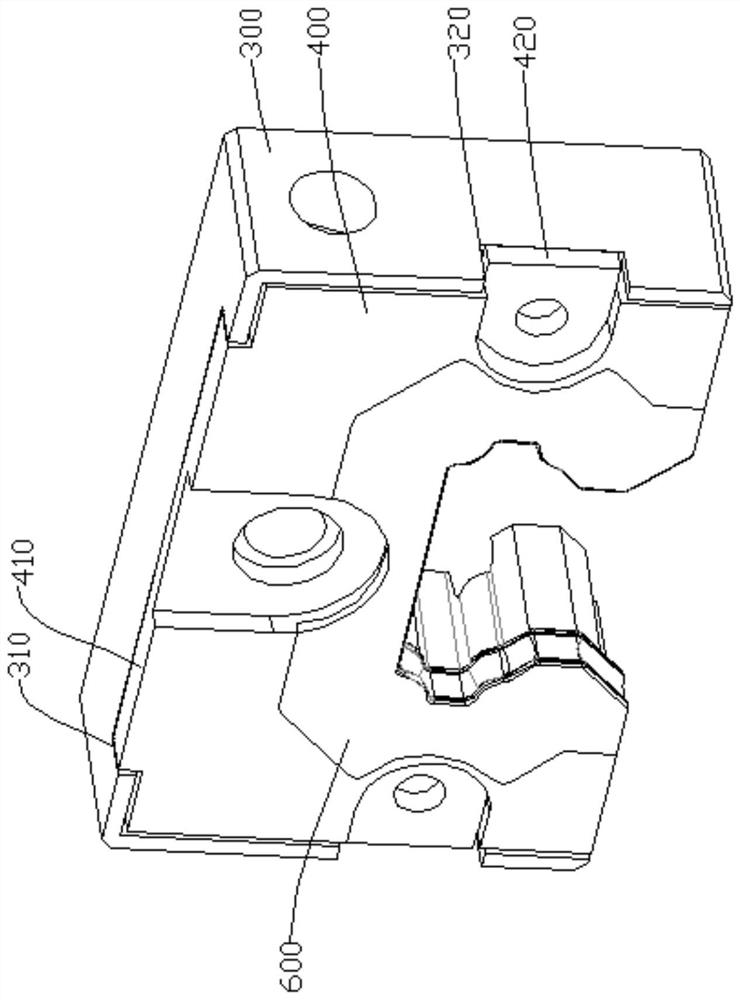

Oil-water separation component of oil separator

PendingCN110282771ABeneficial technical effectReduce disturbanceFatty/oily/floating substances removal devicesSpecific water treatment objectivesEngineeringOil water

The invention discloses an oil-water separation component of an oil separator. The oil-water separation component comprises an oil attaching plate, a pneumatic conveying component and an oil scraping component, wherein an oil suction sponge layer is arranged on the surface of the oil attaching plate, the pneumatic conveying component comprises a gas supply device and a gas outlet pipe, the gas outlet pipe is connected with the gas supply device, a gas outlet of the gas outlet pipe is arranged toward a liquid surface and blows an oil layer on the liquid surface to the oil attaching plate, the oil scraping assembly comprises a telescopic driving member and an oil scraping portion, and the telescopic driving member drives the scraping portion to reciprocate along the surface of the oil attaching plate and to scrape the oil layer on the oil attaching plate into an oil collecting tank. By pneumatic conveying, during liquid conveying, disturbance to liquid in the oil separator is reduced, and the liquid is maintained in a layered state to be conveyed to the oil attaching plate, so that the oil layer is attached to the oil attaching plate, and then, the oil is scraped into the oil collecting tank by the oil scraping assembly to complete oil-water separation; the separation effect is good, water mixed in the separated oil is reduced, and the trouble of needing further oil-water separation is reduced.

Owner:广东普施德泽环保股份有限公司

Oil scraping device

ActiveCN111421004AImprove oil scraping effectIncrease rolling speedMetal rolling stand detailsWork cleaning devicesSpray nozzleStructural engineering

The invention relates to an oil scraping device. The device comprises a plurality of groups of oil scraping rollers, upper mounting frames, lower mounting frames, lifting drivers, a first scraping mechanism and first purging mechanisms. Each oil scraping roller group is composed of an upper roller assembly and a lower roller assembly opposite to the upper roller assembly, the upper roller assemblies are matched with the upper mounting frames correspondingly, and the lower roller assemblies are matched with the lower mounting frames correspondingly. The lifting drivers are connected with the upper mounting frames and / or the lower mounting frames correspondingly. The first scraping mechanism is located at the inlet end of the whole oil scraping device. The first purging mechanisms are arranged on one sides of the oil scraping rollers correspondingly and each comprise a first pipeline and first spray nozzles used for performing gas purging on the surface of strip steel. The first spray nozzles are arranged on the corresponding first pipelines. Each first purging mechanism further comprises one or more second spray nozzles used for performing gas purging on roller bodies of the oil scraping rollers. The second spray nozzles are connected with the corresponding first pipelines. The oil scraping device has the advantage that the oil scraping efficiency is improved.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Two-part oil scraper ring for internal combustion engines

Owner:MAHLE INT GMBH

Oil and water separator

InactiveCN108671584AEasy to recycleAvoid cloggingLiquid separation auxillary apparatusNon-miscible liquid separationOil–water separatorImpurity

The invention discloses an oil and water separator. The oil and water separator comprises a box body, a settling tank, an oil scraping tank, an oil collecting tank, a water collecting tank, a water drainage pump unit and a control box, wherein an impurity treatment tank is arranged in the box body; an oil scraper is arranged in the oil scraping tank; the oil collecting tank and the water collecting tank are arranged at one side of the oil scraping tank; the oil collecting tank is used for receiving the oil above the oil scraping tank; the lower parts of the water collecting tank and the oil collecting tank are communicated and collects the water in the oil scraping tank; the water drainage pump unit is communicated with the water collecting tank; a thread shaft is transversely arranged atthe bottom part of the impurity treatment tank, is rotationally connected with the impurity treatment tank, and is connected with a first motor; the thread shaft is connected with a movable block by threads, and the movable block is rotationally connected with a cutting device. The oil and water separator has the advantages that the impurities are cut and crushed by the impurity treatment tank, soas to prevent the impurities from stacking and blocking an impurity discharge port; the crushed impurities can be directly used as a feed, and the impurities can be conveniently recycled in the laterperiod.

Owner:程建玲

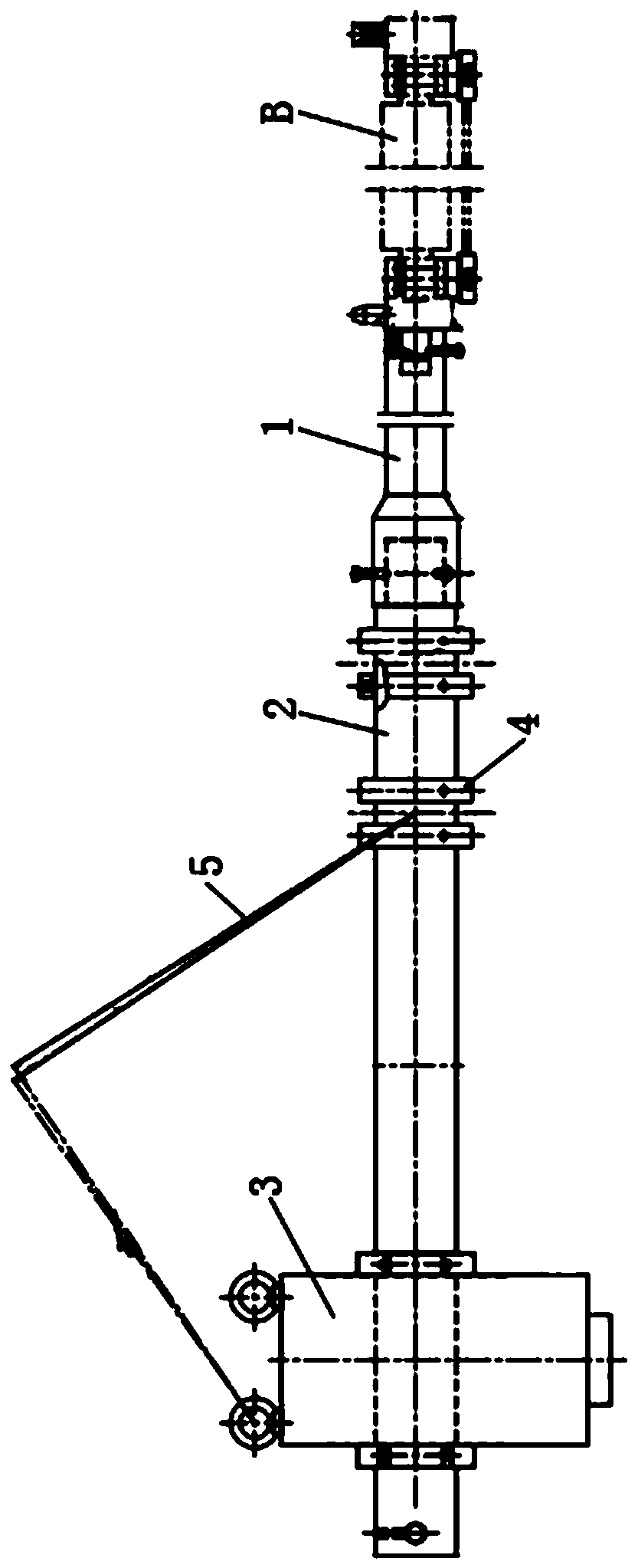

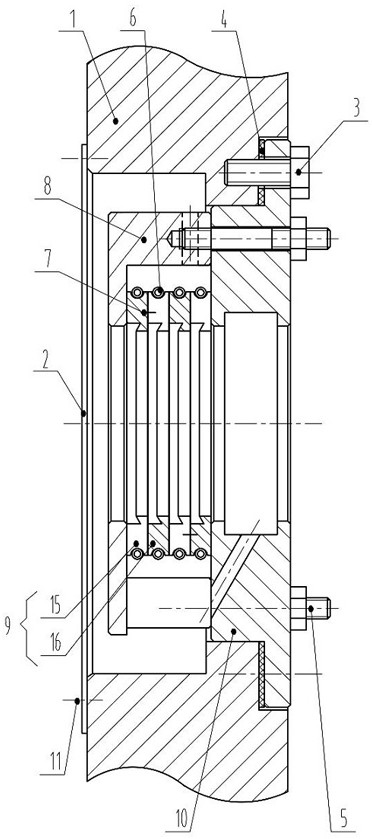

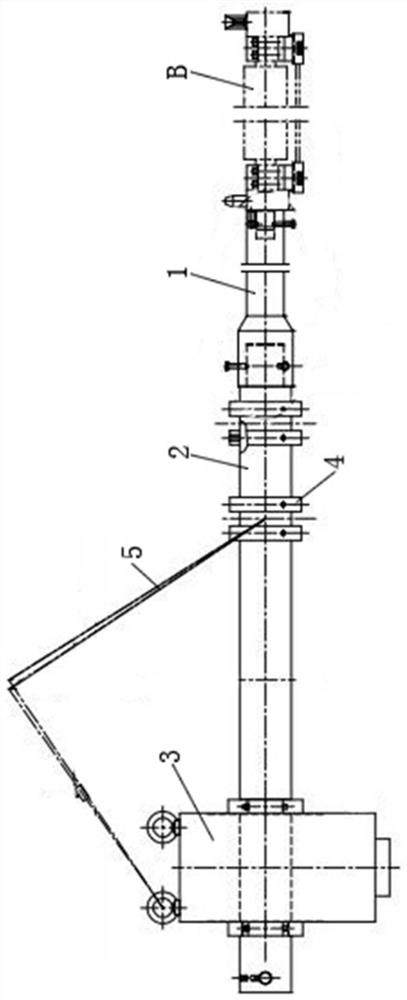

Large reciprocating type oil scraping ring assembly of process compressor

InactiveCN107859610AReduce leakageReduce pollutionPositive displacement pump componentsPositive-displacement liquid enginesNitrogen gasPollution

The invention provides a large reciprocating type oil scraping ring assembly of a process compressor. The large reciprocating type oil scraping ring assembly comprises a compressor body, wherein a piston rod is arranged in the compressor body; a first oil scraping ring and a second oil scraping ring are arranged on the piston rod; an oil scraping box is arranged at the periphery of each oil scraping ring; a pulsation sealing ring is arranged at one side of the second oil scraping ring; one side, away from the first oil scraping ring, of the second oil scraping ring is equipped with an oil seal; and a dynamic sealing ring is arranged on a position, at one side away from the oil scraping rings of the oil seal, of the piston rod. A nitrogen gas inlet and a nitrogen gas outlet are formed in the surface of the dynamic sealing ring; the nitrogen gas inlet and the nitrogen gas outlet correspond to each other in position; and a distance from the nitrogen gas inlet to the center point of the dynamic sealing ring is equal to that from the nitrogen gas outlet to the center point of the dynamic sealing ring. The large reciprocating type oil scraping ring assembly strengthens the oil scraping effect, is relatively less in leaked amount of lubricating oil, greatly reduces resource waste and process gas pollution, caused by leakage of the lubricating oil, and is very practical.

Owner:芜湖市风蝉电竞文化传媒有限公司

Wiper arrangement and compressor with such a wiper arrangement

InactiveCN102162438AReduce wearGood oil scraperEngine sealsPositive displacement pump componentsMechanical engineeringPiston rod

The invention relates to a wiper arrangement and compressor with such a wiper arrangement. Conventional wiper arrangements with cut rings suffer from unavoidable leakage and, in particular in an embodiment as metallic wiper ring with a sharp wiping edge, scratch on the surface of the piston rod which can be damaged in this manner. In order to eliminate these problems, a wiper arrangement is proposed in which the radially inner circumferential surfaces 6, 7 of the wiper ring 2 and the cover ring 3 form a common radially inner wiping surface 10 and on the cover ring 3 or the on the wiper ring 2, an intake surface 8 is provided which is adjacent to the wiping surface 10 and which is inclined radially outwardly at an angle [alpha], preferably between 2 DEG and 15 DEG , with respect to the wiping surface 10.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

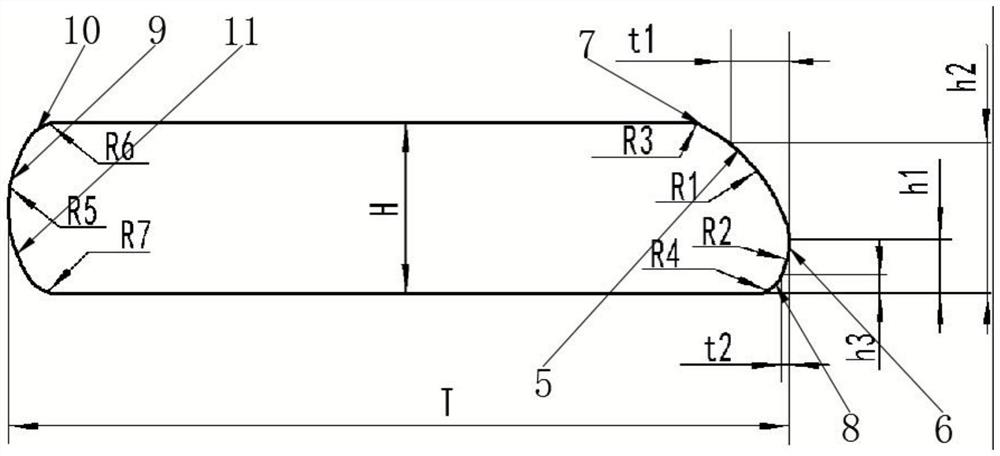

Asymmetric doctor blade ring and three-combination piston oil ring and manufacture method of doctor blade ring

ActiveCN113153566AReduce oil consumptionImprove oil scraping effectPiston ringsGrinding drivesOil distributionPiston

The invention discloses an asymmetric doctor blade ring and three-combination piston oil ring and a manufacture method of a doctor blade ring. The asymmetric doctor blade ring and three-combination piston oil ring comprises a bushing ring body, two doctor blade ring base bodies, a piston and a cylinder sleeve, the excircle face of each doctor blade ring base body is of an asymmetric barrel face structure, the oil distribution area of the upper side of the excircle is increased, the oil storage amount is increased, and the thickness and uniformity of an oil film on a cylinder wall are increased. The lubricating condition is improved, the frictional wear between the ring and the cylinder wall is reduced, the friction faces of the ring and the cylinder sleeve are protected, and the friction noise is reduced. The oil distribution area is small when a doctor blade moves downwards, and therefore the thickness of an oil film on the surface of the cylinder sleeve is reduced, residual lubricating oil is reduced, and engine oil consumption of an engine is further reduced. By increasing the contact surface of the circular arc of the inner circular surface of the doctor blade ring and a bushing ring, the contact face pressure is reduced, and the abrasion of the bushing ring is effectively improved. By reducing the circular arc of the outer circular surface of the doctor blade ring, the contact face between the ring and the cylinder wall is reduced, the contact face pressure is increased, the oil scraping effect of the doctor blade ring is improved, and a positive effect on improving the oil consumption of the engine is achieved.

Owner:ANQING TP GOETZE PISTON RING

Internet of Things oil-water separator

InactiveCN111068399AImprove filtering effectAvoid affecting the separation effectLiquid separationFiltration circuitsOil waterOil–water separator

The invention relates to the technical field of Internet of Things. The invention further discloses an Internet of Things oil-water separator comprising a fixed base; a water pump is fixedly mounted on one side of the upper end of the surface of the fixed base; wherein two supporting frames are fixedly mounted on one side of the upper end of the surface of the fixed base; a filtering tank and a separation tank are fixedly mounted at the middle positions of the two supporting frames; a discharging pipe is mounted in the middle of the lower end of the filtering tank; one end of the discharging pipe is fixedly connected with the water pump; the other end of the water pump is fixedly connected with the separation tank through a connecting pipe; a water collecting tank is fixedly mounted on oneside of the upper end of the surface of the fixed base; a water outlet pipe is fixedly installed on one side of the water collecting tank, one end of the water outlet pipe is fixedly connected with the lower end of the separation tank, an oil collecting tank is fixedly installed at the upper end of the water collecting tank, an oil outlet pipe is fixedly installed at one end of the oil collectingtank, and through arrangement of the filtering tank and the separation tank, the whole device has a very good oil-liquid separation effect.

Owner:徐州普瑞赛思物联网科技有限公司

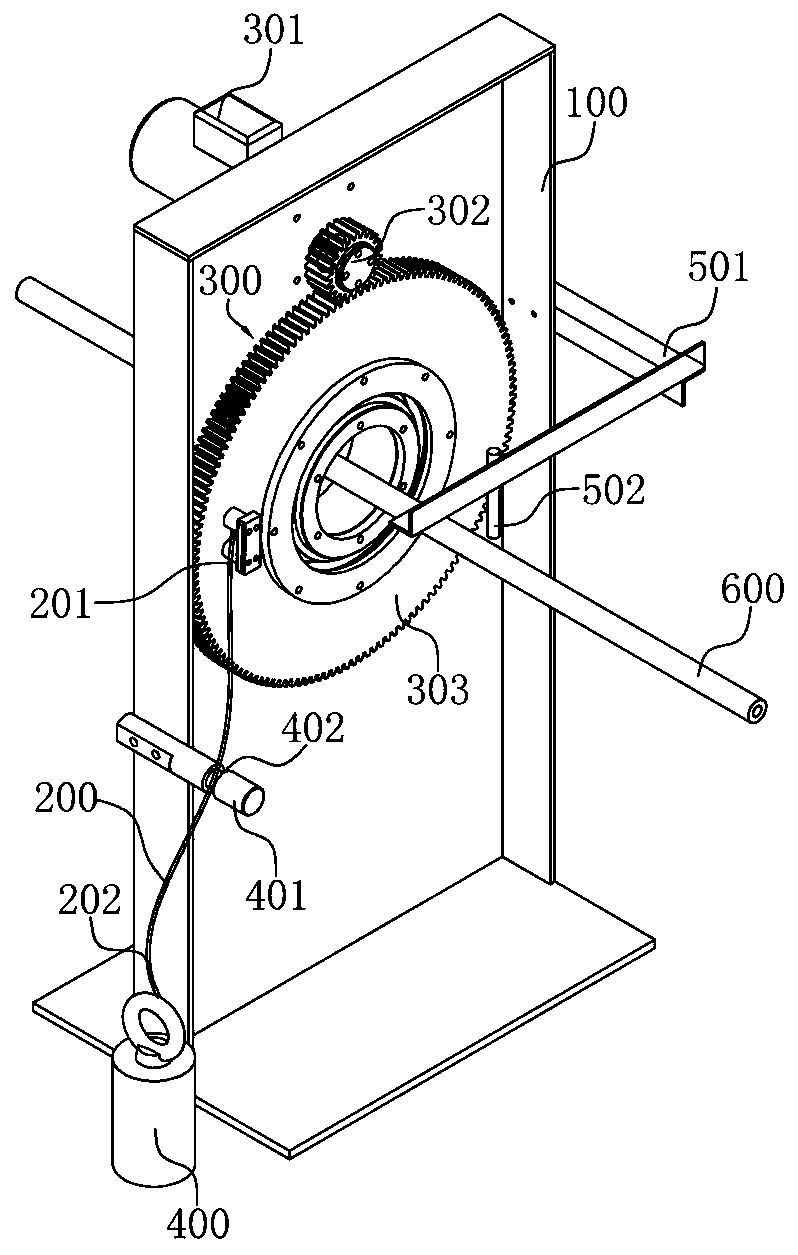

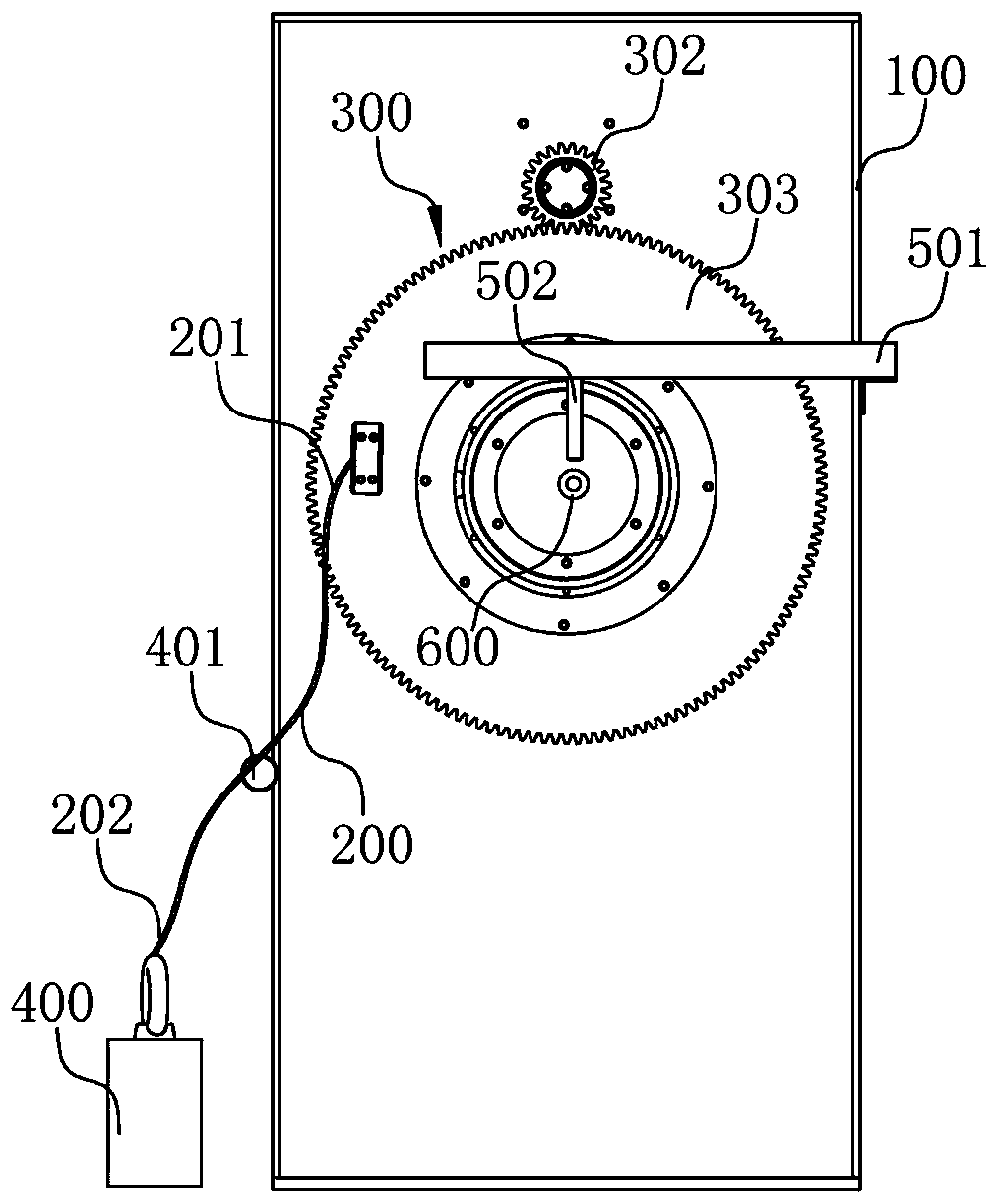

Automatic copper wire oil scraping and recovering device

The invention discloses an automatic copper wire oil scraping and recovering device which comprises a rack, an oil scraping block, an oil guide groove and an oil collecting pool. The rack is provided with a cross beam, and an installation seat is arranged on the cross beam. The back face of the oil scraping block is tightly attached to the installation seat and is fixed to the installation seat through a bolt structure. A circular groove is formed in the front face of the oil scraping block, and a wire penetrating hole penetrating the front face and the back face of the oil scraping block is formed in the bottom of the groove. A bar-shaped groove communicating with the circular groove is further formed in the front face of the oil scraping block. A notch of the bar-shaped groove is vertically downward, and the oil guide groove is installed and fixed in the position, under the notch, of the rack. An oil discharging pipe is arranged at the bottom of the oil guide groove. The other end of the oil discharging pipe is connected in the oil collecting pool, and an oil pump is connected to the bottom of the oil collecting pool through a guide pipe. A liquid level sensor is installed and fixed to the inner side wall of the oil collecting pool. The automatic copper wire oil scraping and recovering device is simple in structure, convenient to install and manufacture, low in manufacturing cost, good in oil scraping effect and capable of keeping cleanliness of a production line and automatically supplementing recovered drawing oil into an oil pool of a wire stretching machine.

Owner:ANHUI JIANGNAN MINGFANG ELECTRONICS TECH

Oil scraping device for silicon steel

PendingCN108144974AAvoid wavyQuick installationWork cleaning devicesMetal rolling arrangementsFiberRight triangle

The invention discloses an oil scraping device for silicon steel. The device comprises an installation clamping groove and an oil scraping strip. The oil scraping strip penetrates into the installation clamping groove, the installation clamping groove is fixed to equipment, the oil scraping strip comprises a boss, a vertical section, an inclined section and a lip opening which are connected in sequence, the oil scraping strip further comprises a high-strength steel belt and a fiber enhancement layer, the high-strength steel belt is in the boss and the vertical section, the upper end of the fiber enhancement layer is on one side of the high-strength steel belt, the lower end of the fiber enhancement layer stretches into the inclined section close to the lip opening, the boss, the vertical section, the inclined section and the lip opening located on the outer side of the high-strength steel belt and the fiber enhancement layer are made from special wear-resisting rubber through heat vulcanization, the section of the lip opening is in an inverted right triangle shape, the included angle a between the inclined edge of the lip opening and the horizontal plane is 15-25 degrees, and the included angle b between the inclined section and the horizontal plane is 30-45 degrees. By using the oil scraping device for silicon steel, the service life is obviously prolonged, the replacement frequency is low, and the using cost is greatly reduced.

Owner:北京市城南橡塑技术研究所

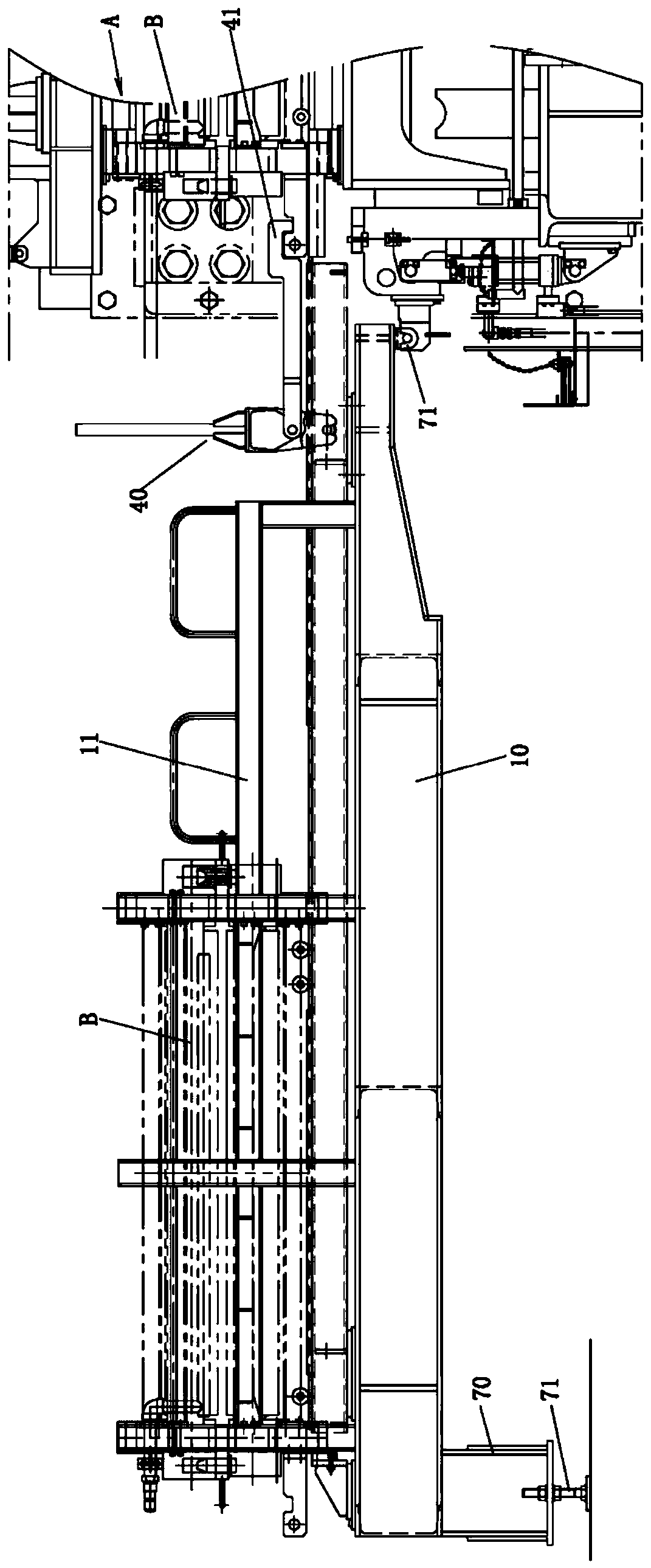

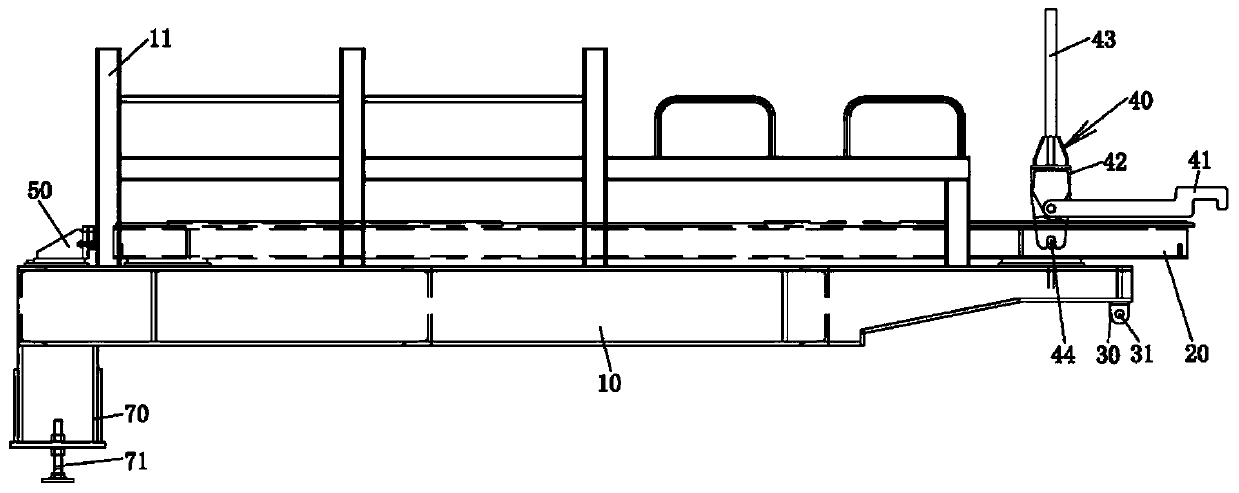

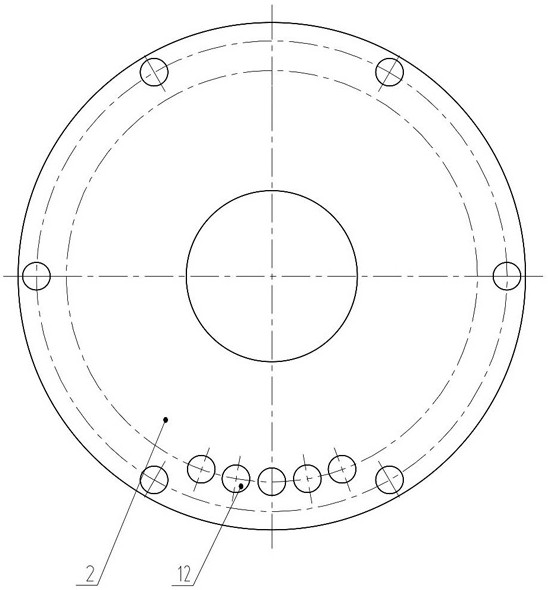

Reciprocating compressor oil scraping structure

ActiveCN112610451AReduce leakageReduce gapPositive displacement pump componentsPositive-displacement liquid enginesMechanical engineeringPetroleum engineering

The invention discloses a reciprocating compressor oil scraping structure. The reciprocating compressor oil scraping structure comprises a connecting cylinder, an oil scraping ring assembly is arranged on the connecting cylinder in a penetrating manner, the oil scraping ring assembly comprises an oil scraping flange, an oil scraping box, oil scraping ring pairs and springs, the oil scraping flange is fixedly connected with the oil scraping box through bolts, the two oil scraping ring pairs are arranged in the oil scraping box in a penetrating manner, and each oil scraping ring pair comprises two oil scraping rings, wherein the two oil scraping rings are the first oil scraping ring and the second oil scraping ring respectively, each oil scraping ring is composed of a three-section structure, oil scraping ring gaps are formed between sections, the oil scraping ring gaps in the first oil scraping ring and the oil scraping ring gaps in the second oil scraping ring are placed in a staggered manner, the circumferential positions of the oil scraping rings are fixed through positioning pins, and the springs are embedded into the outer sides of the oil scraping rings; and an oil baffle plate is arranged at one side of the connecting cylinder. The reciprocating compressor oil scraping structure can solve the problems that an existing oil scraping structure is incomplete in oil scraping, low in oil scraping efficiency, unsmooth in oil return and inconstant in oil scraping effect.

Owner:WEIFANG DASHAN PETRIFACTION MACHINERY

Piston ring with good oil scraping function

InactiveCN106194485AIncrease widthEfficient scrapingPiston ringsMachines/enginesCombustionPiston ring

The invention provides a piston ring with a good oil scraping function. The piston ring is structurally characterized in that two symmetrical scraper blades are arranged on the outer circular face of the piston ring, the top end of each scraper blade is designed to be in a stepped shape, the minimum distance of each step is 0.01 mm, and the height of each step is 0.14 mm; a groove is formed in the inner circular face of the piston ring, and N small oil return holes evenly distributed are formed in the outer circular face of the piston ring; the shape structure of the top end of each scraper blade is in the stepped shape, and engine oil on the inner wall of a cylinder jacket can be effectively scrapped clearly; and the oil film thickness can be improved effectively and the friction work can be lowered effectively due to the small stepped area of the scraper blades, the width of the scraper blades cannot become larger suddenly even if the piston ring operates for a long time, and parts of the fine scraper blades are worn off. By the adoption of the structure, the deformation of the piston ring is small, the degree of fitting with the inner wall of the cylinder jacket is higher, a gap between the piston ring and the cylinder jacket is reduced, it is avoided that lubricating oil enters an air cylinder along the gap to be involved in combustion, and the emission level of an engine can be lowered effectively.

Owner:东风朝阳朝柴动力有限公司

Novel oil scraping device for natural gas compressor

PendingCN109296520AImprove oil scraping effectPositive displacement pump componentsEngine componentsPiston rodPetroleum engineering

The invention discloses a novel oil scraping device for a natural gas compressor. According to the technical scheme, the device comprises an oil baffle plate, an oil pre-scraping ring, a main oil scraping ring and a cover plate, wherein the oil pre-scraping ring and the main oil pre-scraping ring are correspondingly arranged in the oil baffle plate; the cover plate is in contact with the main oilscraping ring and is closely connected to the oil baffle plate through a fastener; the oil pre-scraping ring is arranged at one end, opposite to the cover plate, of the oil baffle plate; the oil pre-scraping ring is coaxial with the main oil scraping ring and sleeves a piston rod of the compressor; an annular groove which is connected to an oil scraping part is formed in the main oil scraping ring; and a compressing spring through which the oil scraping part is close to the piston rod is arranged in the annular groove. The device adopting the abovementioned scheme is good in oil scraping effect and long in service life.

Owner:太仓恩知机械科技有限公司

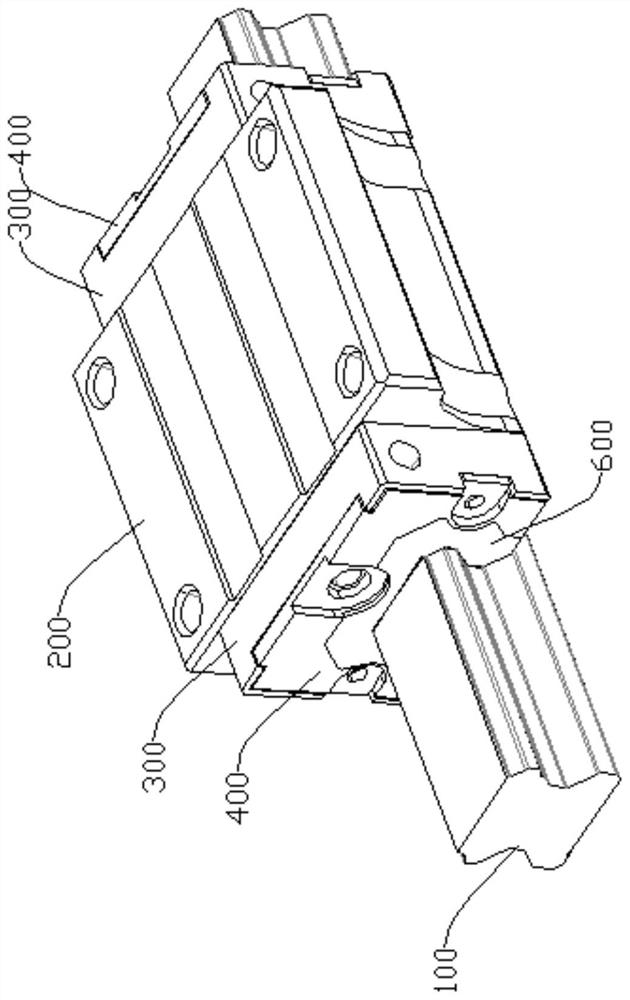

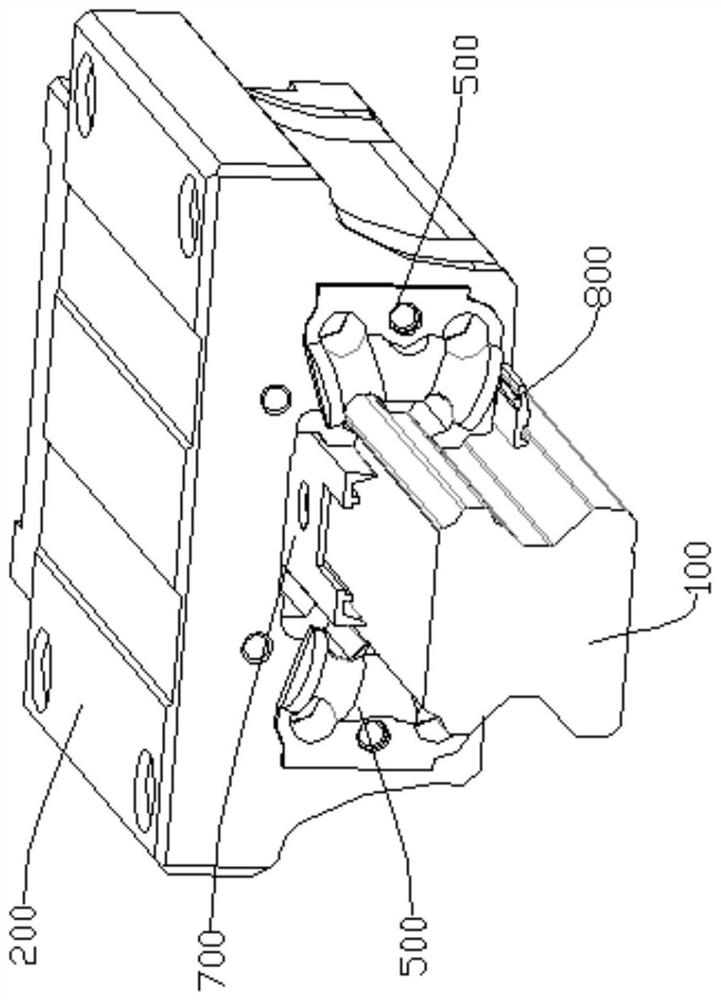

Integral dustproof structure for linear sliding rail

InactiveCN113236667AAffect mobilityEasy to useEngine sealsLinear bearingsForeign matterStructural engineering

The invention relates to the technical field of dust prevention of linear sliding rails, in particular to an integral dustproof structure for a linear sliding rail. The integral dustproof structure for the linear sliding rail comprises a sliding block, a first sliding rail groove is formed in the middle of the lower end face of the sliding block, a sliding rail capable of sliding relative to the sliding block is arranged in the first sliding rail groove, and ball modules are arranged on the left side and the right side of the first sliding rail groove respectively; an upper dustproof piece mounting groove is formed between the upper portions of the two ball modules, and an upper dustproof piece is arranged in the upper dustproof piece mounting groove; and lower dustproof piece mounting grooves are formed in the left sides and the right sides of the lower portions of the two ball modules correspondingly, and lower dustproof pieces are arranged in the lower dustproof piece mounting grooves. Through the integral dustproof design of an end cover, an oil seal piece, the upper dustproof piece and the lower dustproof pieces, foreign matter is prevented from entering a gap between the sliding block and the sliding rail to affect the movement performance of the linear sliding rail, the use performance of the linear sliding rail is improved, and the service life of the linear sliding rail is prolonged.

Owner:得发科精密制造无锡有限公司

oil scraper

ActiveCN111421004BImprove oil scraping effectIncrease rolling speedMetal rolling stand detailsWork cleaning devicesPetroleum engineeringNozzle

The invention relates to an oil scraping device, which includes multiple groups of scraping rollers, an upper mounting frame, a lower mounting frame, a lifting driver, a first scraping mechanism, and a first blowing mechanism. Each group of scraping rollers consists of an upper roller assembly and a The upper roller assembly is composed of the lower roller assembly opposite to the upper roller assembly. The upper roller assembly cooperates with the upper mounting frame, the lower roller assembly cooperates with the lower mounting frame, and the lifting drive is connected with the upper mounting frame and / or the lower mounting frame. The first scraping mechanism is located on the entire scraping frame. The inlet port of the oil device, the first blowing mechanism is arranged on one side of the oil scraping roller, the first blowing mechanism includes a first pipeline and a first nozzle for gas blowing the surface of the strip, and the first nozzle is arranged on the first On the pipeline, the first purging mechanism also includes one or more second nozzles for gas purging the roller body of the oil scraping roller, and the second nozzles are connected with the first pipeline. The invention has the advantage of improving oil scraping efficiency.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

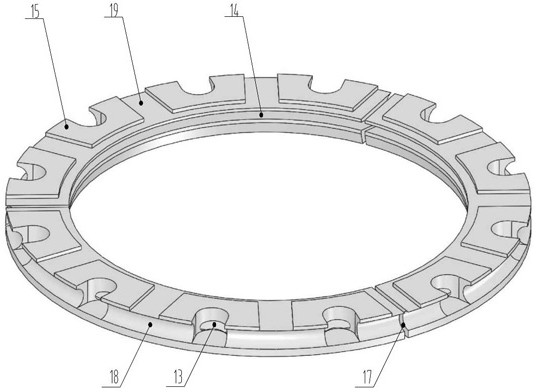

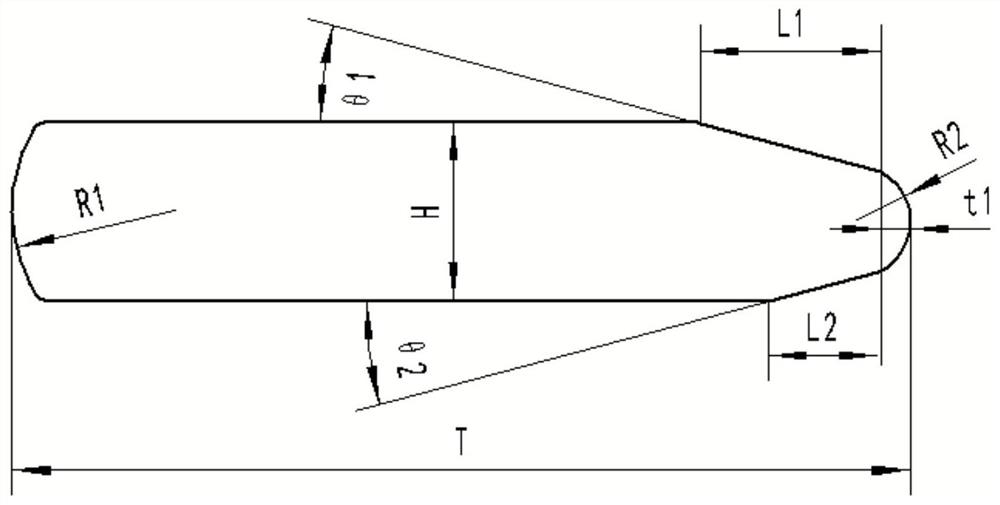

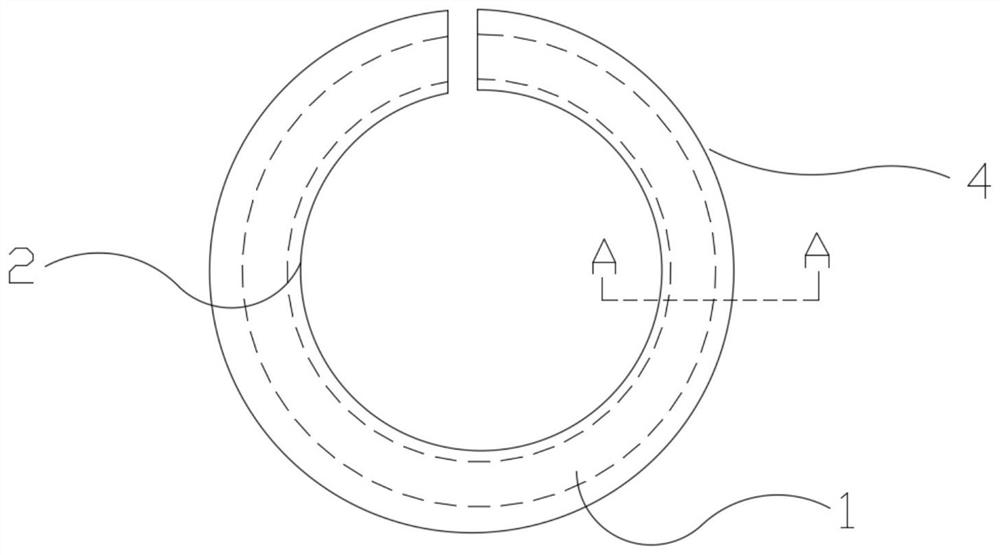

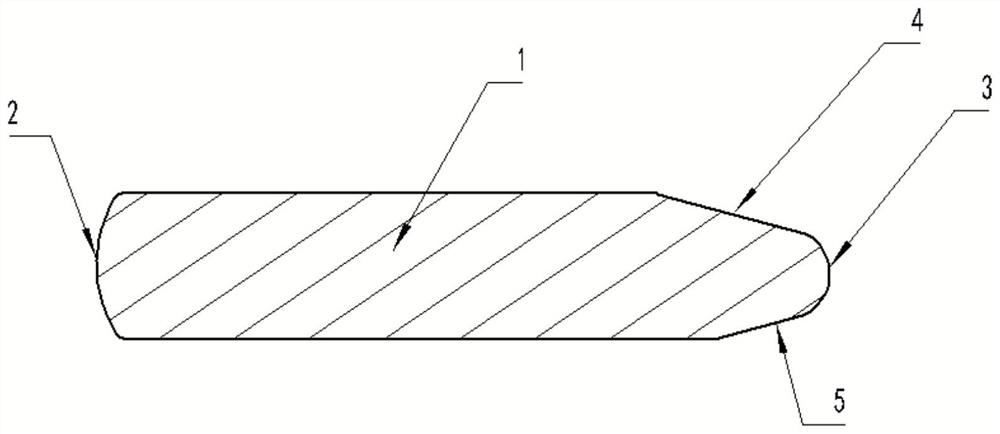

Scraper ring, three-combination piston oil ring and scraper ring preparation method

ActiveCN112178186AIncrease contact surfaceImprove oil scraping effectPiston ringsWire ringsStructural engineeringMechanical engineering

The invention discloses a scraper ring, a three-combination piston oil ring and a scraper ring preparation method. The scraper ring comprises a scraper ring base body with the upper surface and the lower surface being parallel to each other. The annular inner side of the scraper ring base body extends to form an inner circular face arc, and the radius of the inner circular face arc is R1. The annular outer side of the scraper ring base body extends to form an outer circular face arc, the radius of the outer circular face arc is R2, and the arc width of the outer circular face arc is t1. The outer circular face arc is connected with the upper surface and the lower surface of the scraper ring base body through transition slopes, the length of the upper transition slope connected with the upper surface of the scraper ring base body is L1, and the length of the lower transition slope connected with the lower surface of the scraper ring base body is L2. R1 is equal to 0.7 H to 0.9 H, R2 isequal to 0.25 H to 0.4 H, t1 is equal to 0.6 R2 to 0.8 R2, L1 is equal to 0.45 H to 0.65 H, and L2 is equal to 0.3 H to 0.4 H, wherein H is the height of the scraper ring base body, and the value range of H is 0.3 mm to 0.5 mm.

Owner:ANQING TP GOETZE PISTON RING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com