Piston ring with good oil scraping function

A piston ring, a good technology, applied in the field of piston rings, can solve the problems of poor sealing of engine parts, poor valve guide oil seal effect, affecting engine emission level, etc., to improve oil consumption, small deformation, and improve oil film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

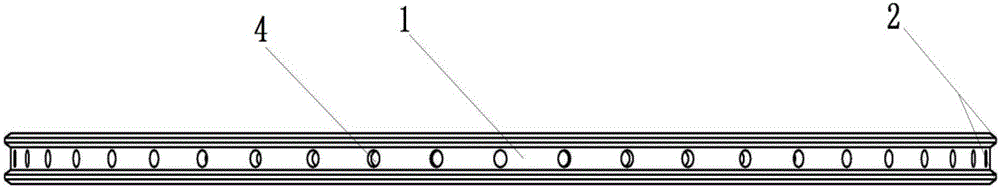

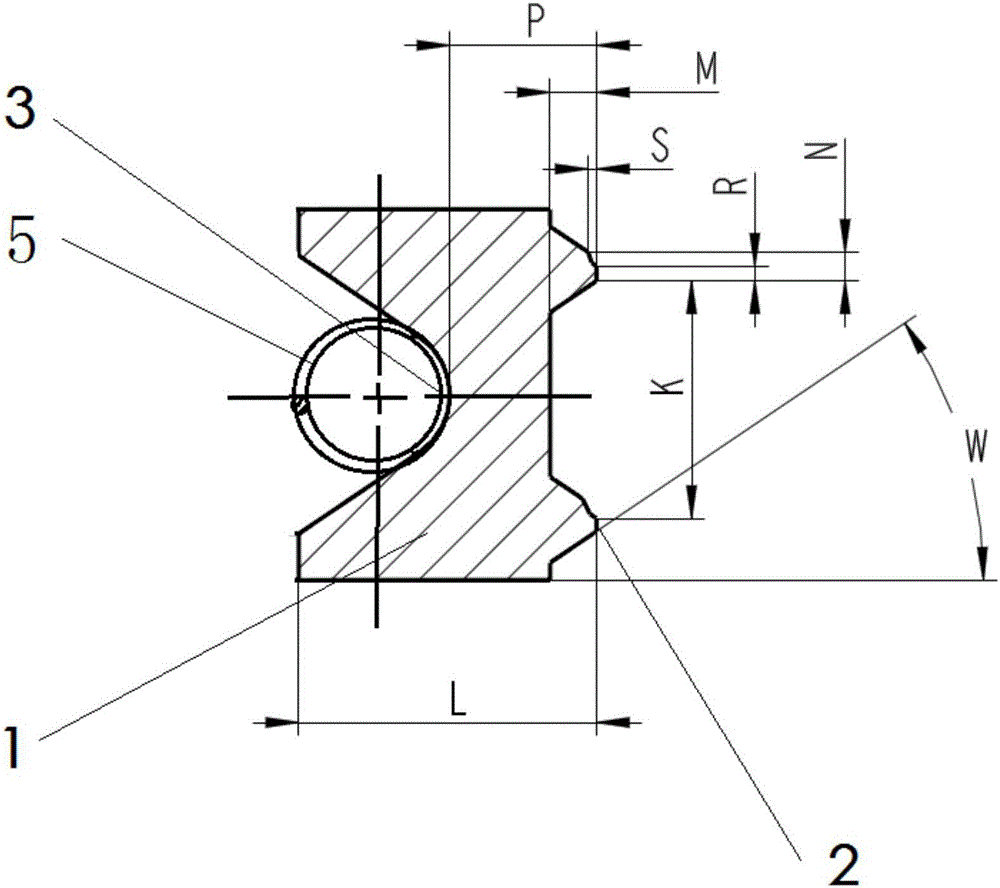

[0010] The structure of the piston ring with good oil scraping function is: there are two symmetrical oil scraping blades 2 on the outer surface of the piston ring 1, the top of the oil scraping blade is designed as a ladder, and the distance between the smallest steps is R=0.14 mm, the height of the step S=0.01mm. The inner surface of the piston ring is provided with a groove 3, which is used to fix the helical lining spring, and the outer surface of the piston ring is provided with N small oil return holes 4 evenly distributed.

[0011] The section width of the piston ring is 3.21±0.5mm; the distance between the top of the groove and the outer end of the trapezoidal oil scraper is 1.58mm±0.5; the distance between the top centers of the two oil scrapers is 2.45±0.5mm; is 35°±5°; the overall width of the top of the trapezoidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com