Cylinder body of diesel engine

A cylinder block and diesel engine technology, applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of ineffective reduction of diesel engine combustion noise radiation, high scrap rate, and high noise of diesel engines, so as to improve stiffness and oil scraping Effect, the effect of reducing engine oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

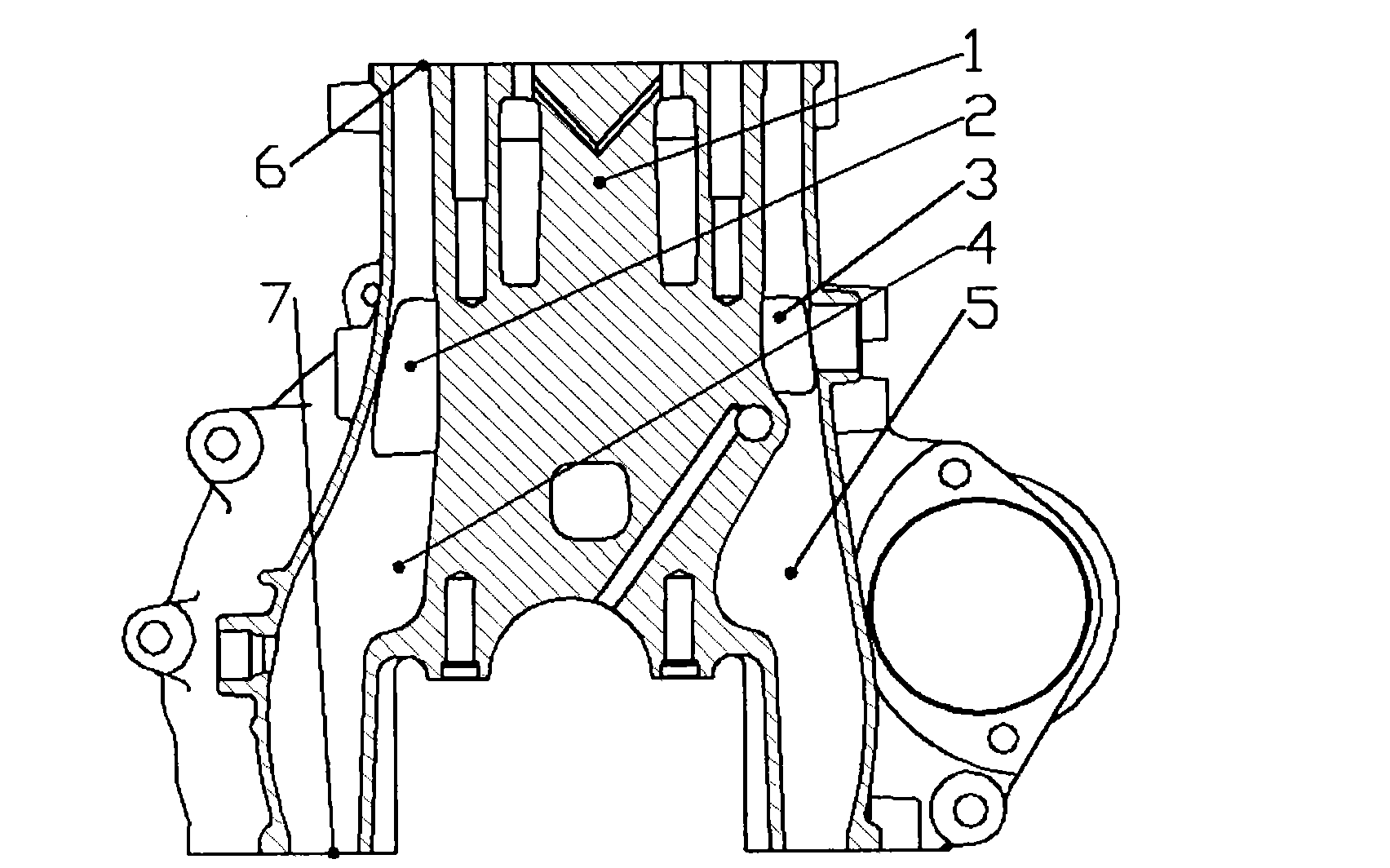

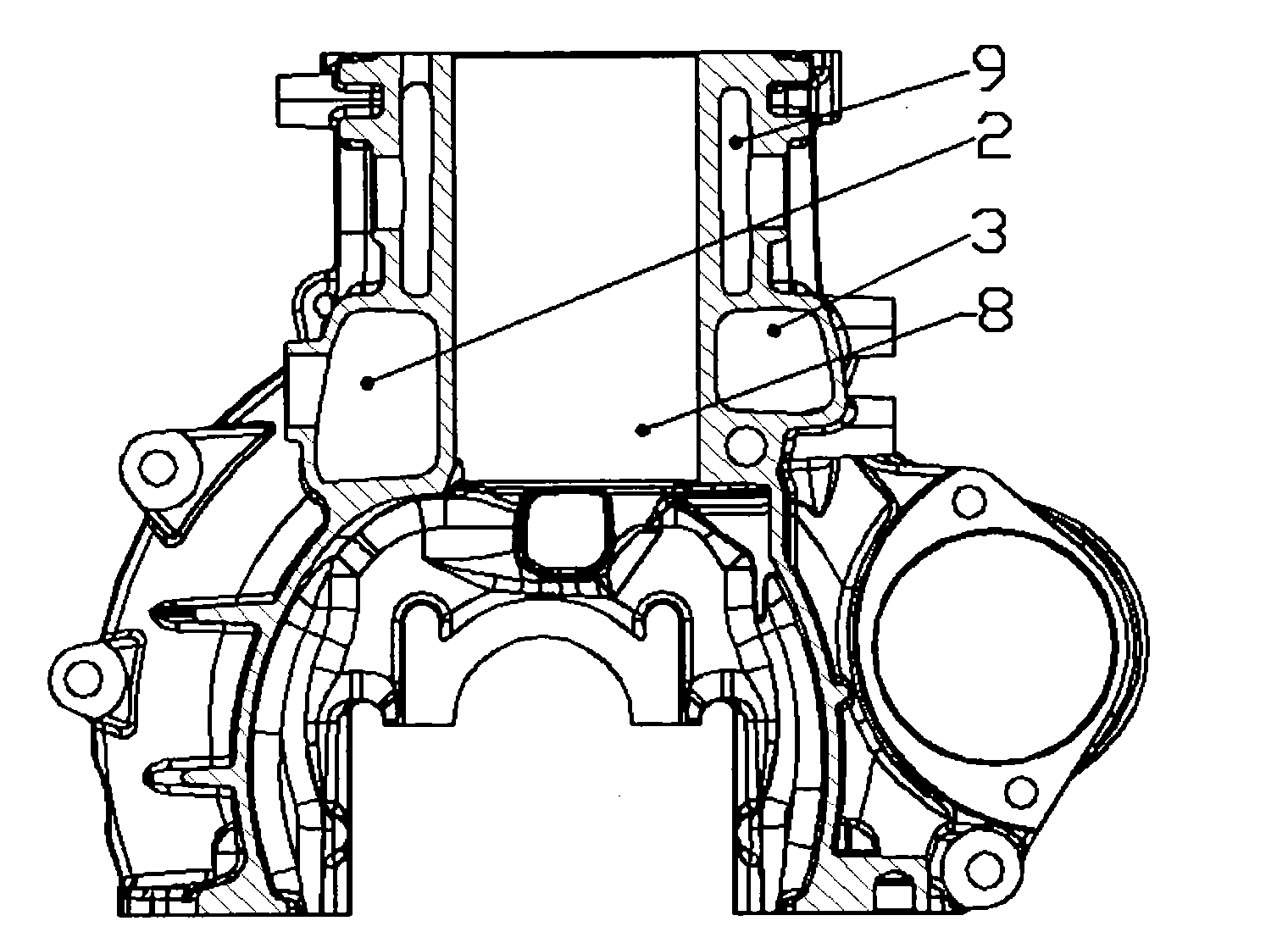

[0020] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be noted that the directional qualifiers such as up, down, left and right appearing in the present invention refer to the positions shown in the drawings for a clearer understanding of its structure, and do not limit the protection scope of the technical solution of the present invention.

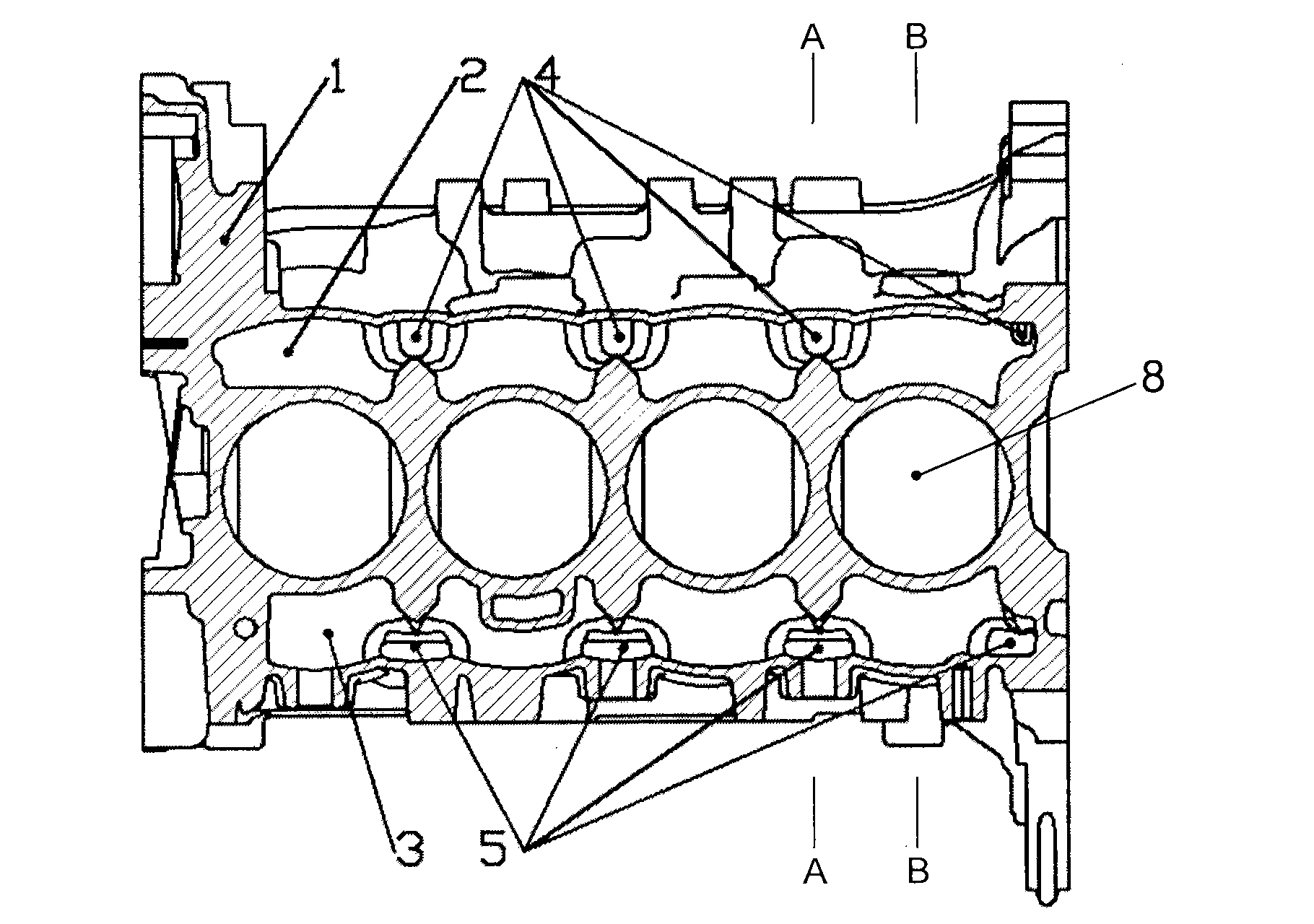

[0021] Such as Figures 1 to 4 The diesel engine cylinder structure shown, wherein the cylinder block 1 extends laterally along the direction of the crankshaft (known structure, so not shown in the figure) at the bottom of the cylinder block, four cylinder holes 8 are arranged side by side on the upper part of the cylinder block 1, and each cylinder hole 8. Four crankcase blow-by passages 4 and four engine oil return passages 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com