Patents

Literature

45results about How to "Increase tangential force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

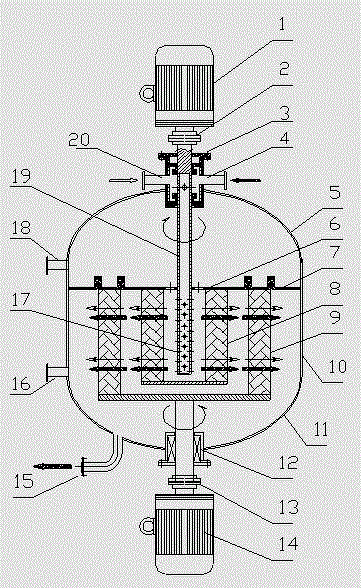

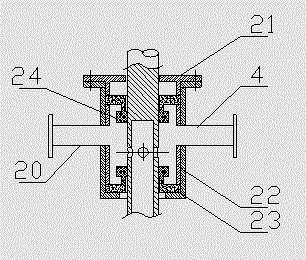

Novel alkylation reactor and alkylation reaction method

ActiveCN104549114AFully dispersedBoost octaneLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystAlkene

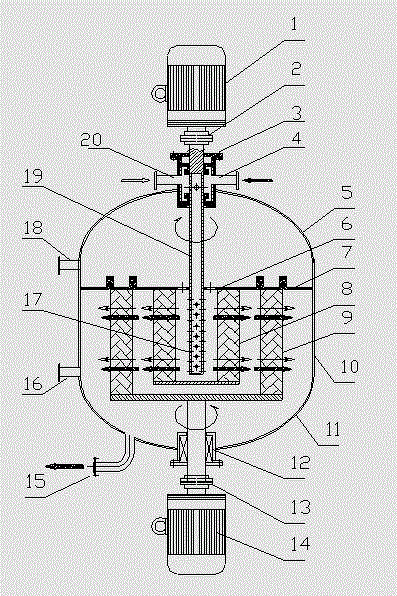

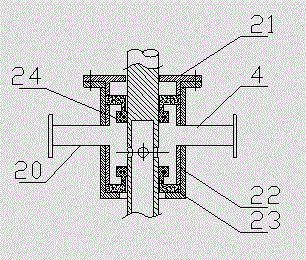

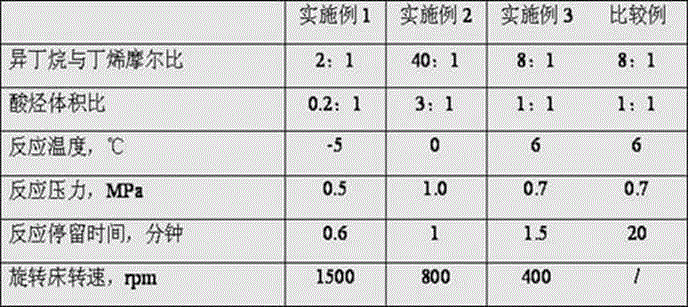

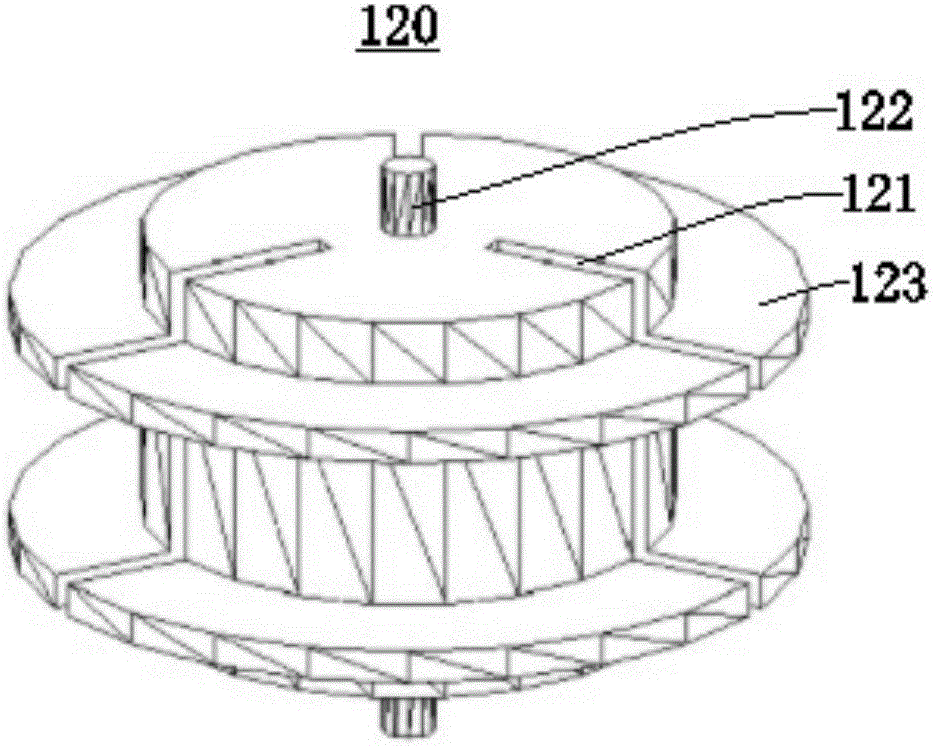

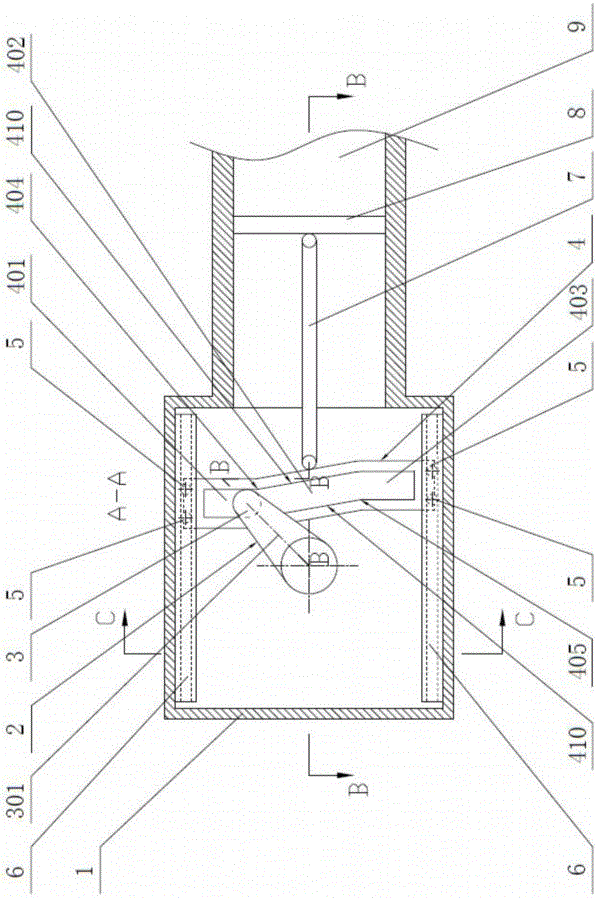

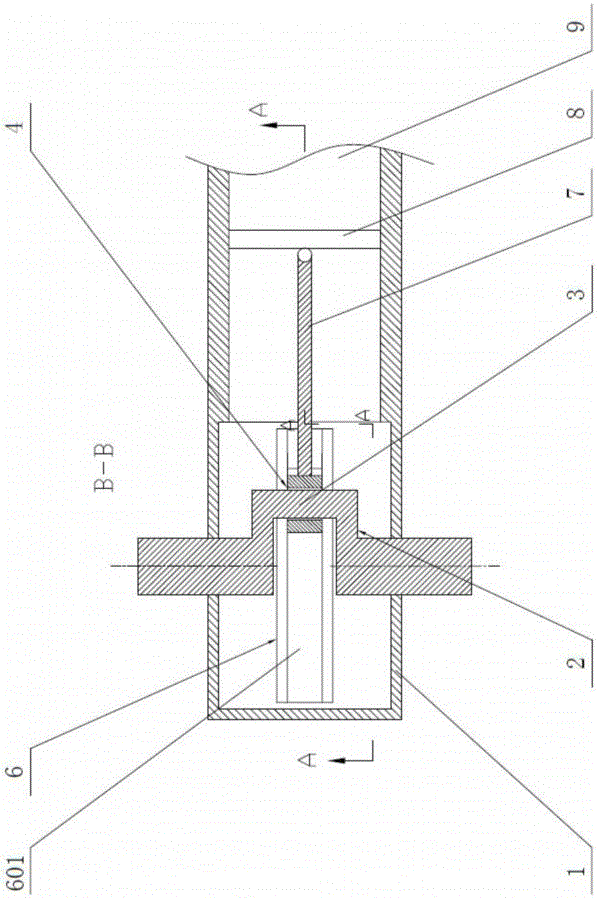

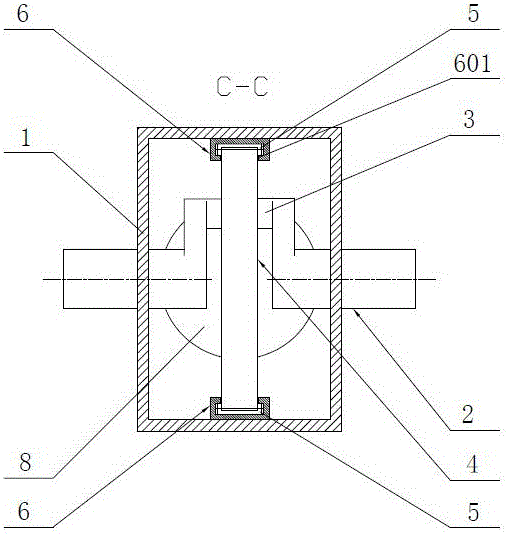

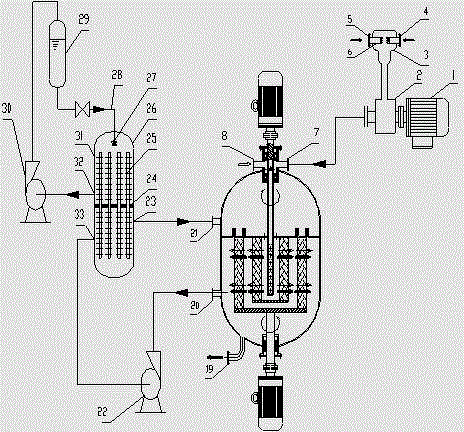

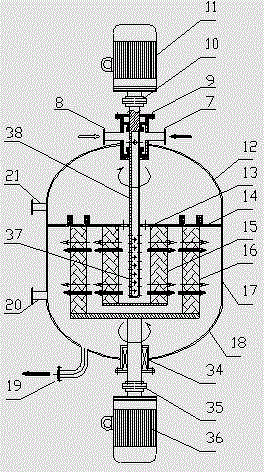

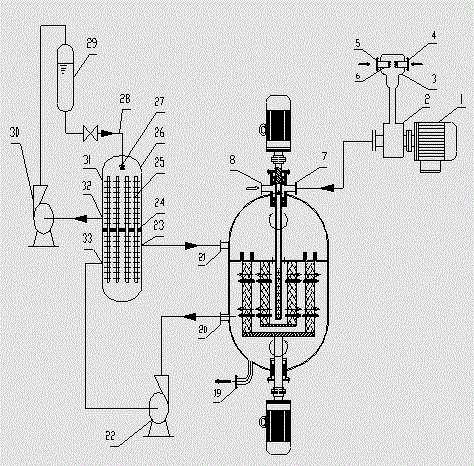

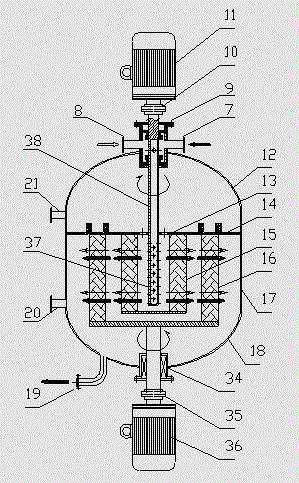

The invention discloses an alkylation reactor and an alkylation reaction method. The alkylation reactor comprises a reactor drum body, a sealing head, an inner rotating bed, an outer rotating bed, a feeding pipe, a fed material distributing pipe, a discharging opening, a circular cooling gas inlet and a circular cooling gas outlet, wherein the reactor drum body and the sealing head form a closed shell; the inner rotating bed is arranged in the middle in the shell; the fed material distributing pipe is arranged in a central hollow drum structure of the inner rotating bed and is communicated with the feeding pipe; a feeding mixer is arranged at the connecting position of the feeding pipe and the sealing head; the discharging opening is formed in the lower part of the shell; the inner rotating bed is connected with a driving device by the feeding pipe; the outer rotating bed is arranged at the outer side of the inner rotating bed; the upper end of the inner rotating bed and the fed material distributing pipe are connected into an integrated structure by a sealing member; the outer rotating bed and the shell are fixedly connected; and the outer rotating bed is connected with the driving device at the lower part by a rotating shaft. The alkylation reactor and the alkylation reaction method disclosed by the invention have the advantages that concentrated sulfuric acid is adopted as a catalyst, iso-butane and olefin are adopted as materials to carry out alkylation reaction, the reaction can be carried out under low temperature, the acid consumption is low and the quality of a product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gear-tooth block meshing switching device for linear reciprocating motion and rotational motion

The invention provides a gear-tooth block meshing switching device for linear reciprocating motion and rotational motion. Four pairs of track plates are mounted in a casing, one ends of the track plates are hinged to the inner walls of the two sides of the casing, the other ends of the track plates are provided with track grooves respectively, and a track shifting mechanism lifter is arranged among the four pairs of track plates. Tooth block lines including a plurality of tooth blocks are mounted on a driving frame mechanism, sliding pins extending from two sides of each tooth block are respective disposed in each track groove, a gear fixedly mounted with a transmission shaft is arranged between the two tooth block lines, and the lifter driving device drives the lifter to lift or descend the track plates. Besides, a frame of the driving frame mechanism is connected with one end of a connecting rod, and the other end of the connecting rod is connected with a piston. The switching device is capable of realizing equivalent switching between linear reciprocating motion and rotational motion.

Owner:安里千

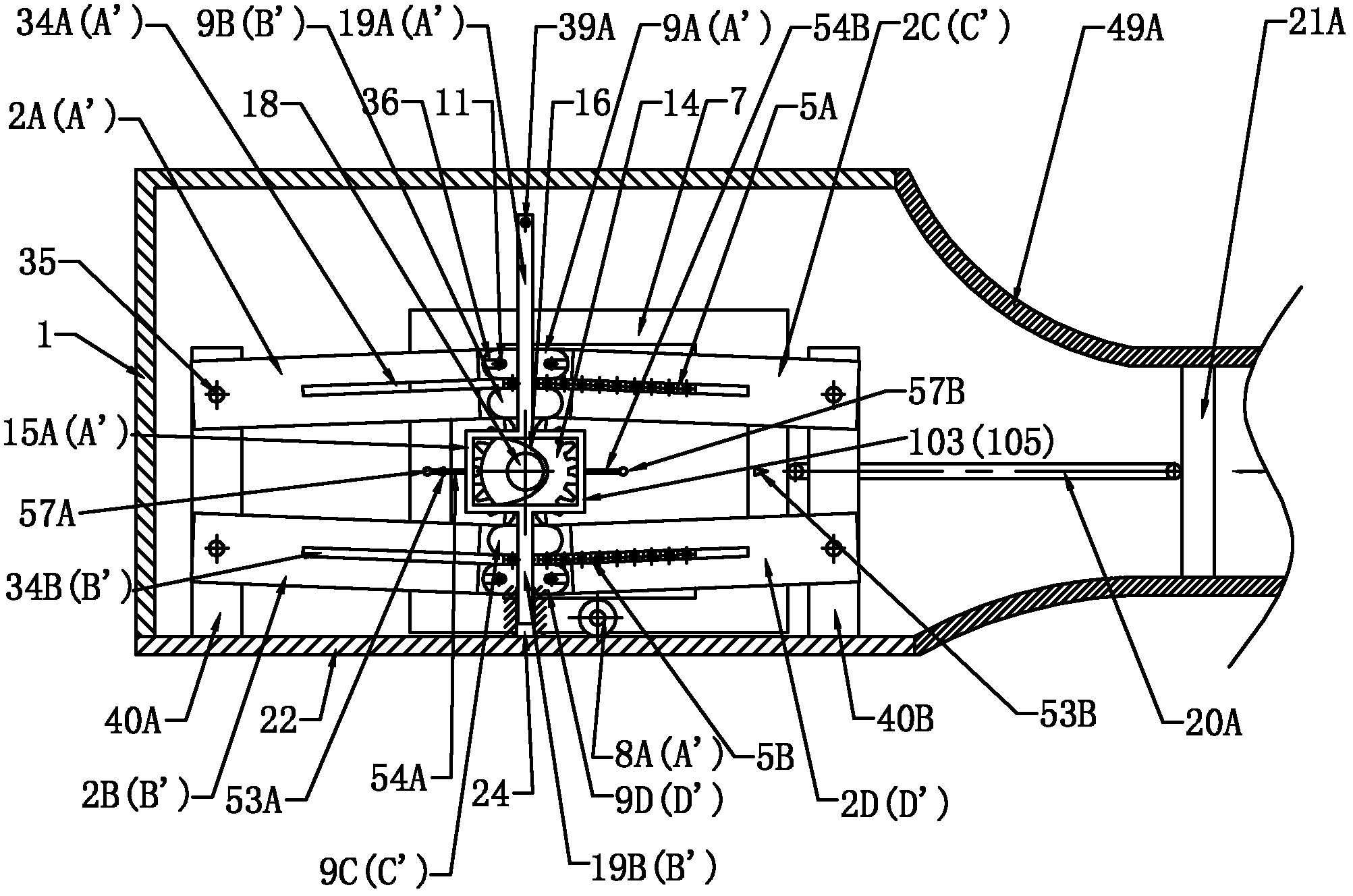

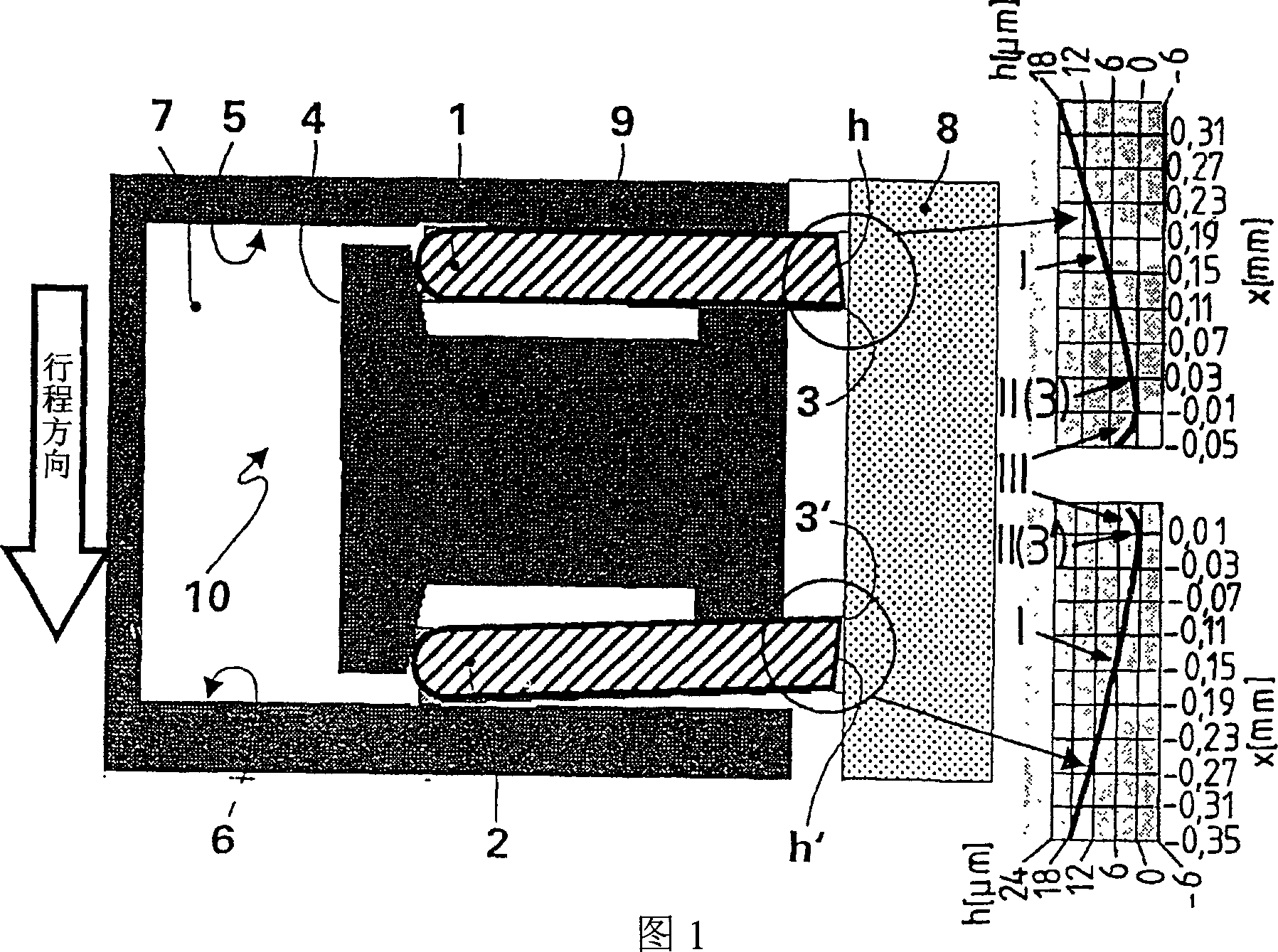

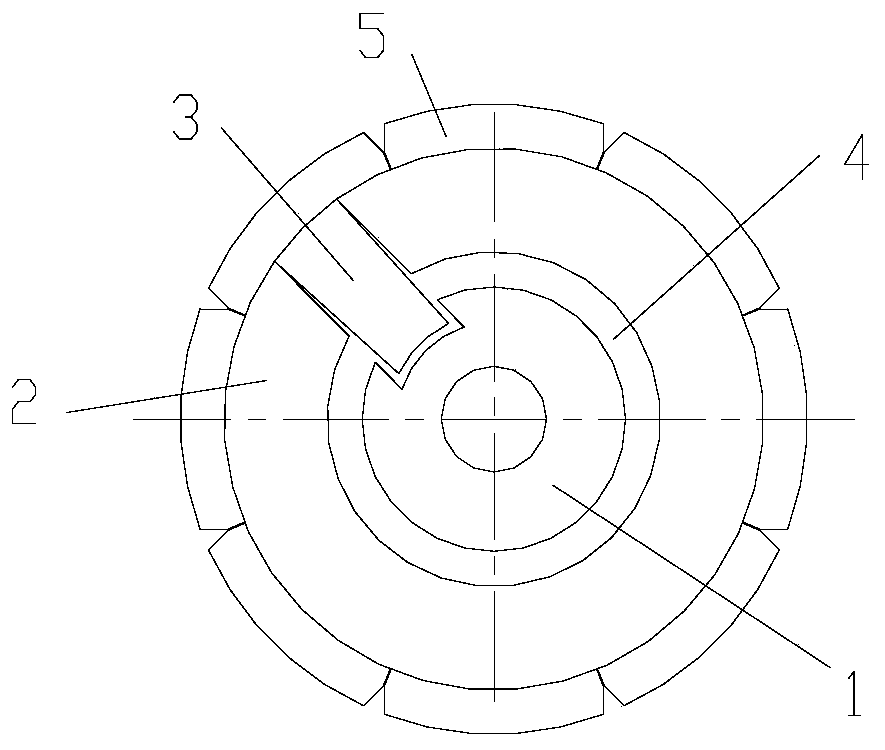

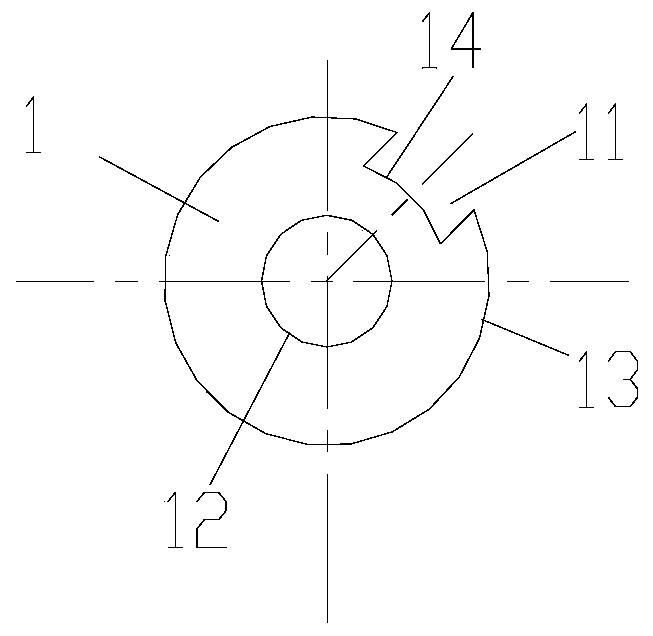

Rotary motion and reciprocating motion converting device

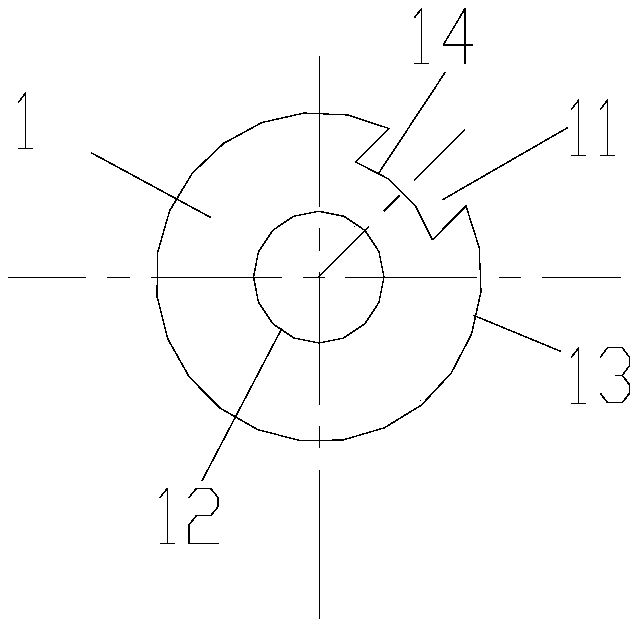

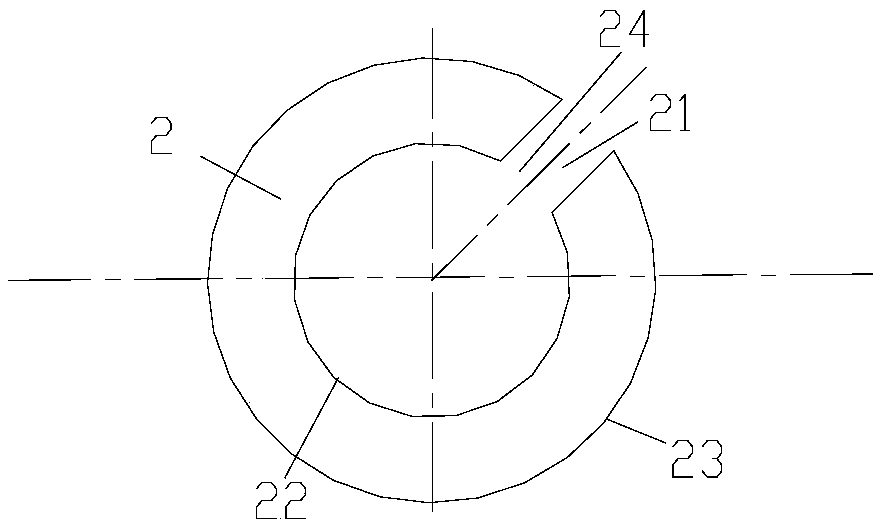

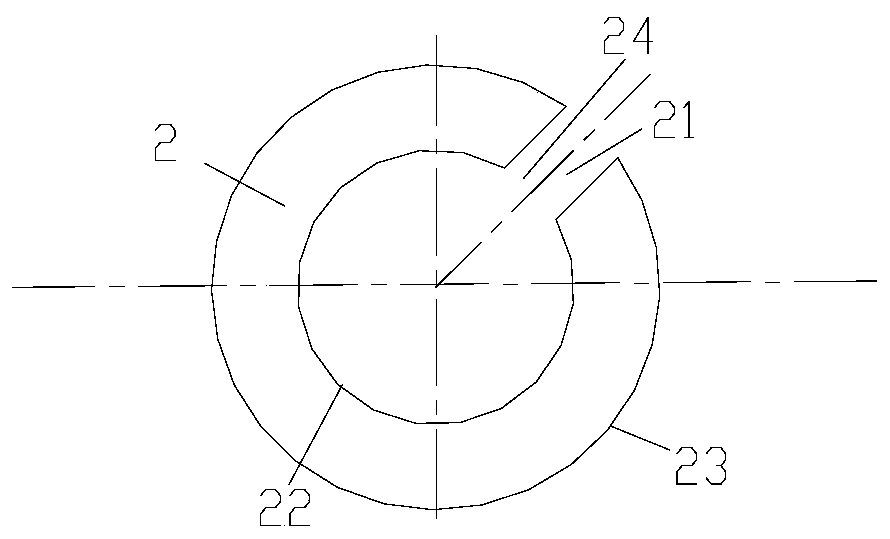

InactiveCN102207179AReasonable power transmission and movement mode conversionIncrease tangential forceFriction gearingsPistonReciprocating motion

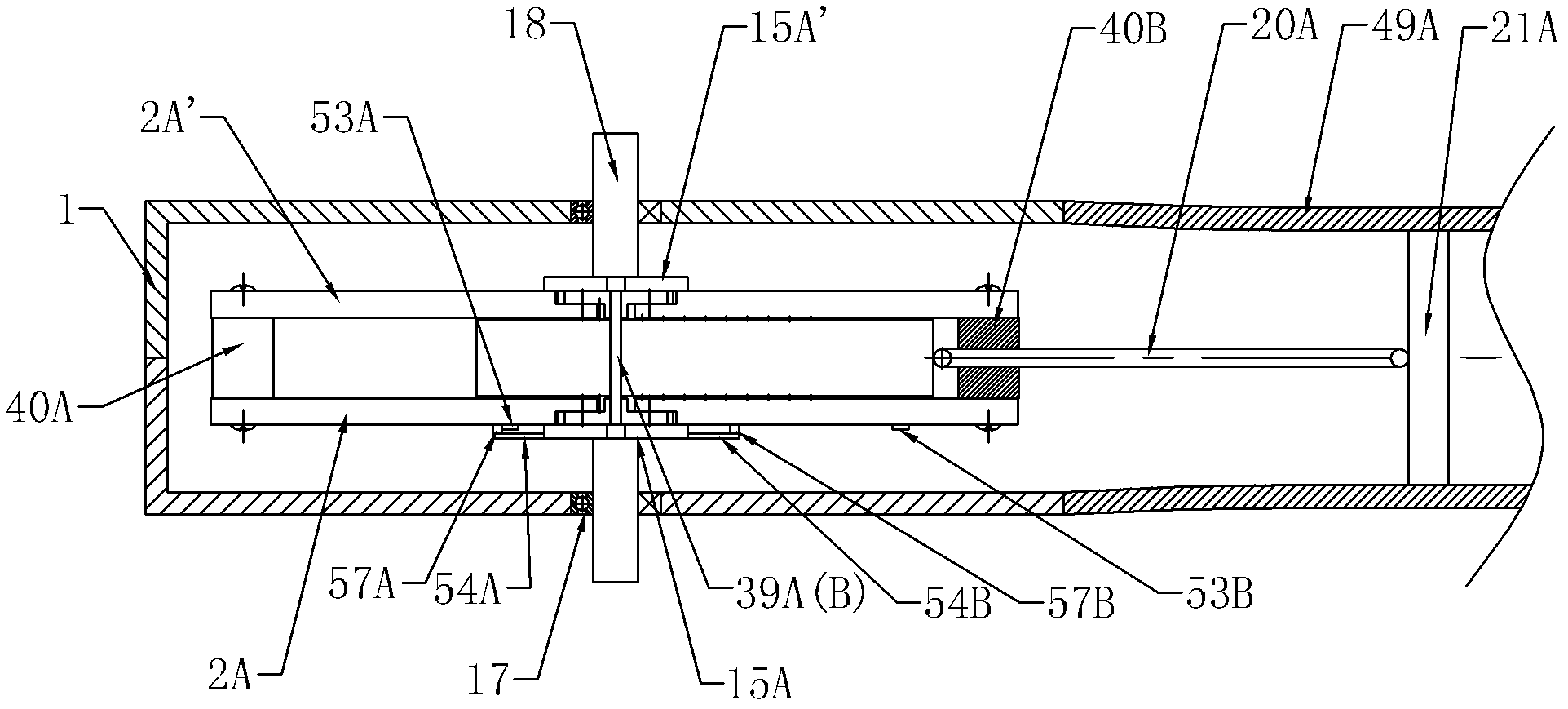

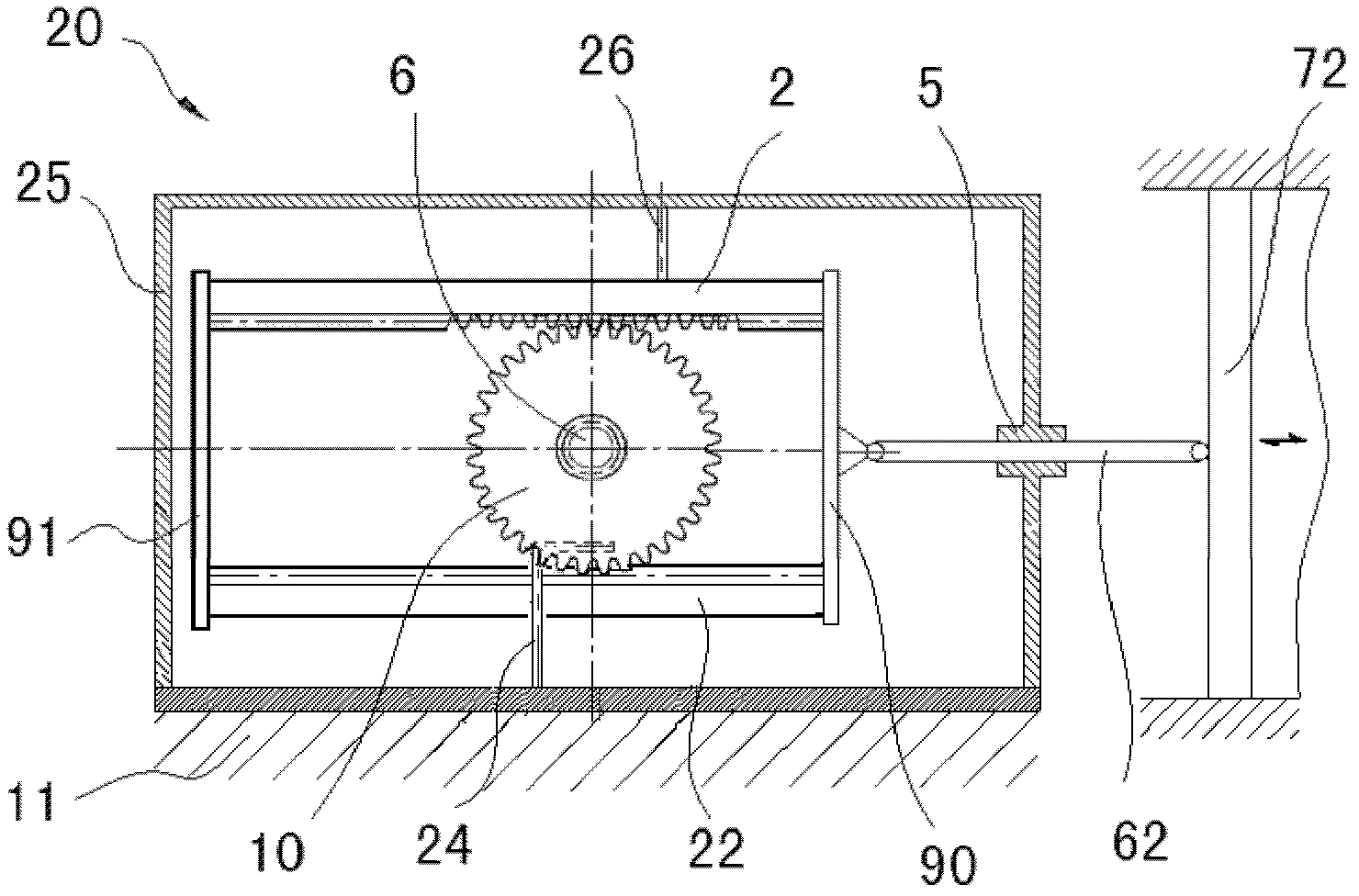

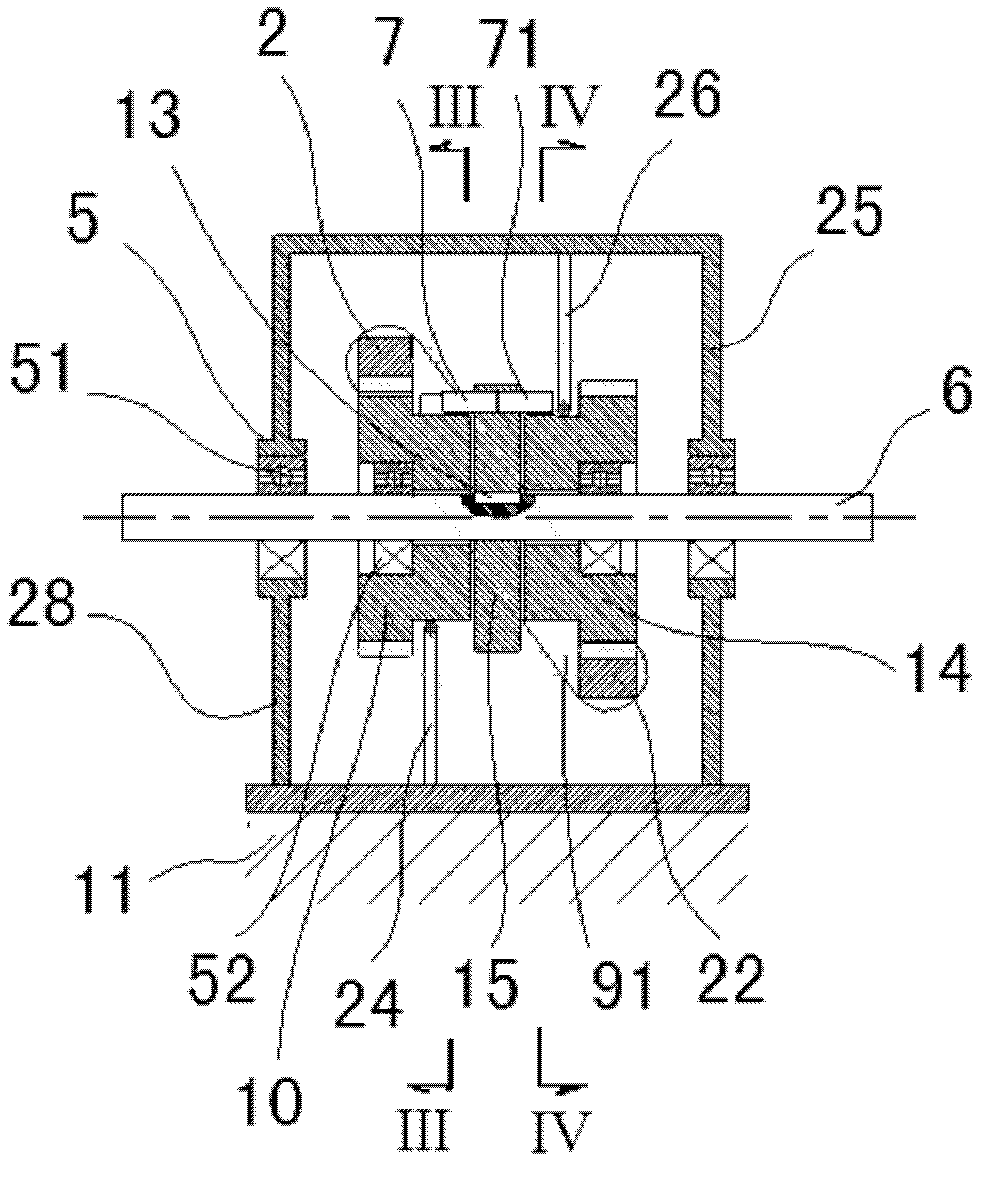

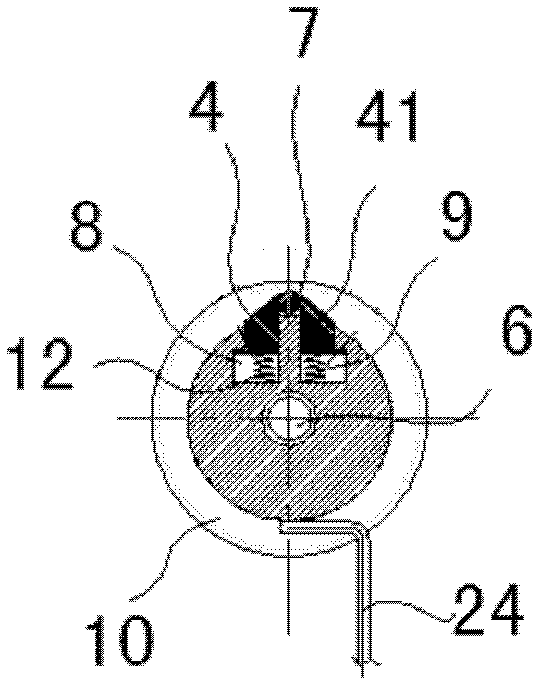

The invention relates to a rotary motion and reciprocating motion converting device (20) which comprises pistons (72, 74, 76, 78), wherein one end of each piston rods (62, 64) is connected with the pistons (72, 74, 76, 78); a shell (25) is installed on a base seat (11); a side wall (28) of the shell (25) is provided with a bearing seat (5); a transmission shaft (6) is installed in the bearing seat (5); the transmission shaft (6) is provided with transmission wheels (15, 17); the edge parts of the transmission wheels (15, 17) are provided with column pins (7, 71) extending out axially; a first gear (10) and a second gear (14) which can rotate relative to the transmission shaft (6) are installed close to the transmission wheels (15, 17); the first gear (10) and a first rack (2) are meshed mutually; the second gear (14) and a second rack (22) are meshed mutually; the first rack (2) and the second rack (22) are respectively positioned at two sides of the transmission shaft (6); connecting plates (90, 91) are connected with the end parts of the first rack (2) and the second rack (22); the connecting plates (90,91) are connected with other ends of the piston rods (62, 64); tooth-free parts of the first gear (10) and the second gear (14) are respectively provided with pin grooves (9, 21); the pin grooves (9, 21) are internally provided with sliding blocks (32, 42) which are matched with the column pins (7, 71); and the restoration springs (12, 121) are arranged below the sliding blocks (32, 42). Thus the conversion between the rotary motion and the reciprocating motion is realized.

Owner:安里千

Rolling apparatus

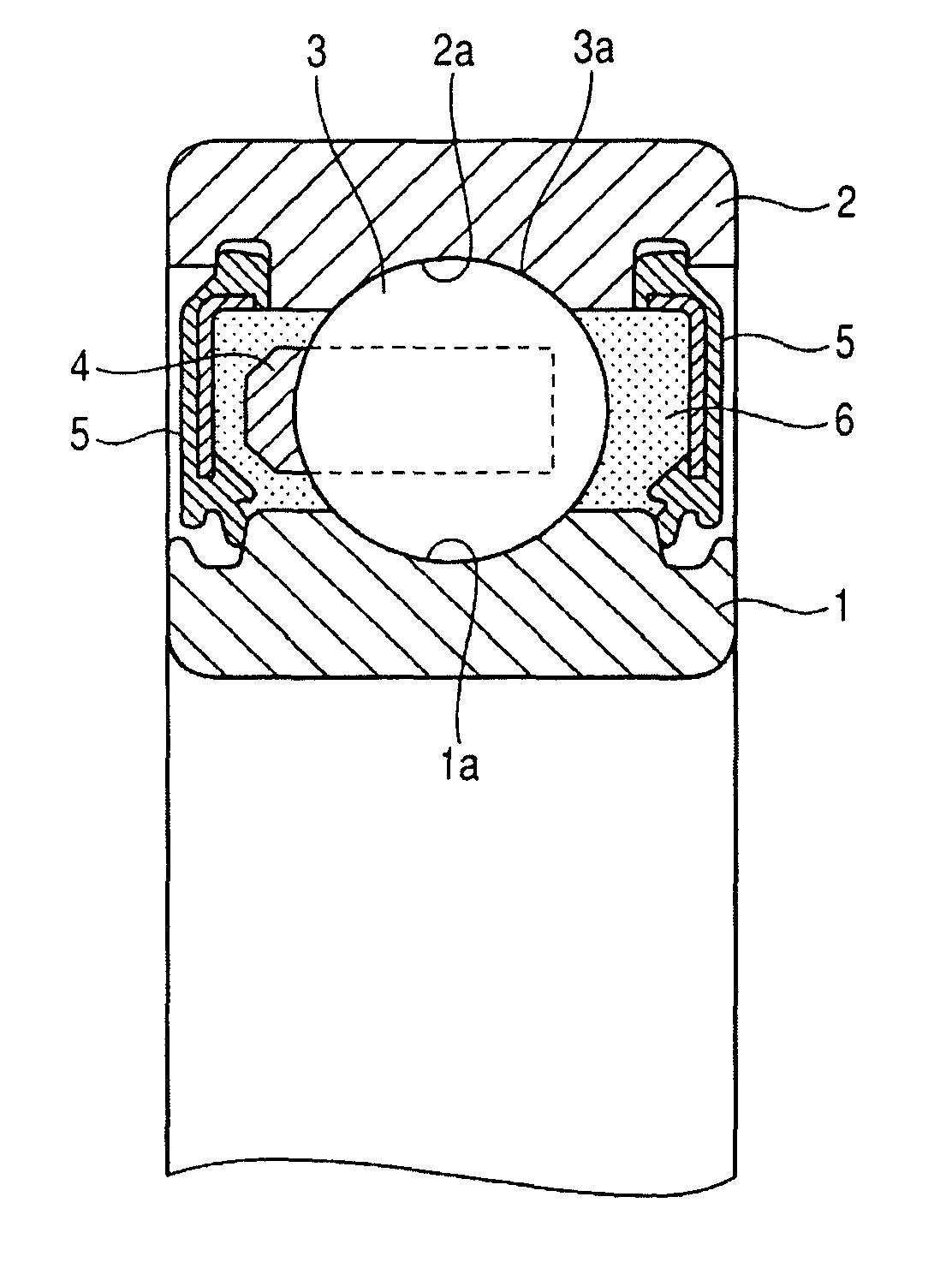

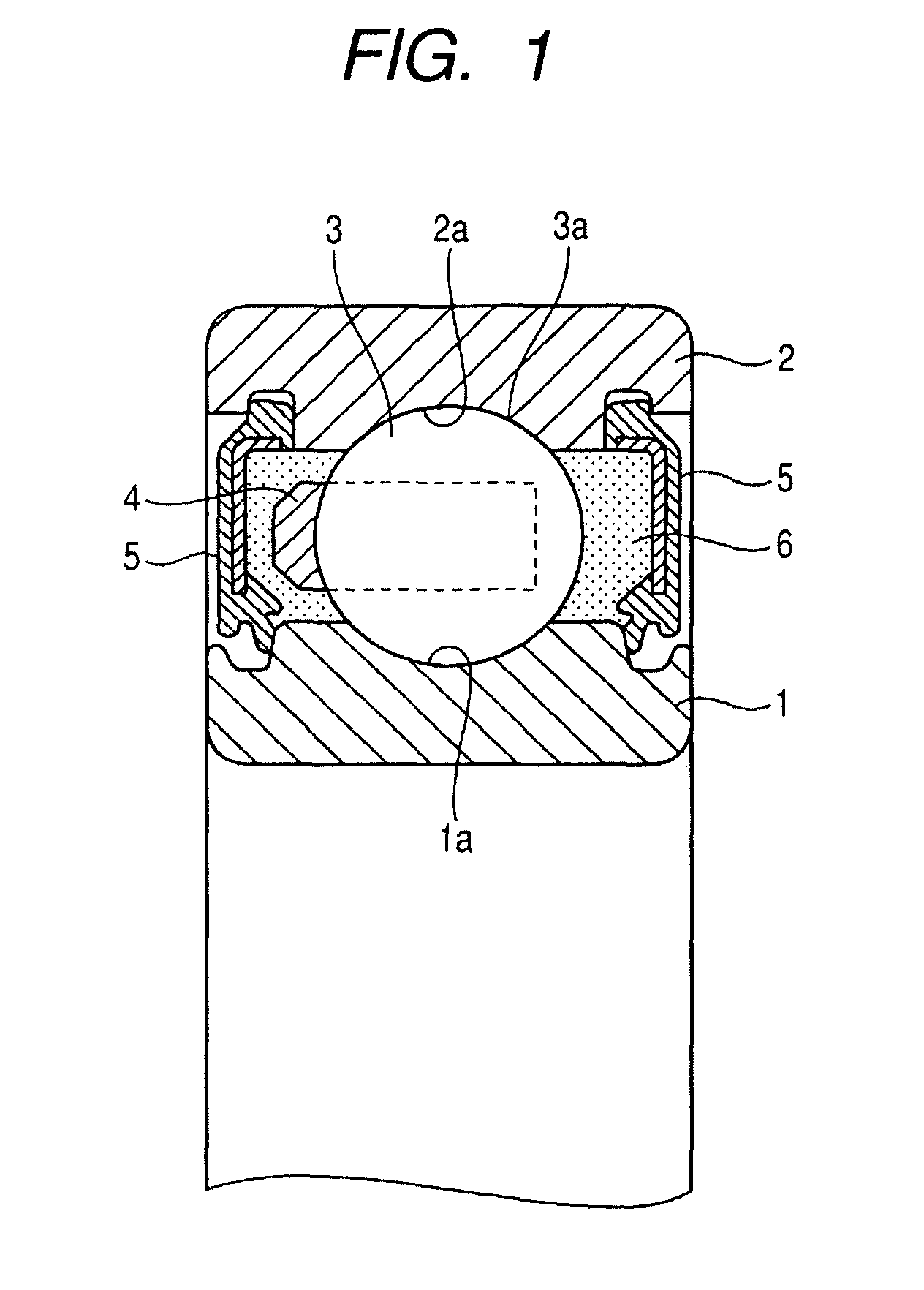

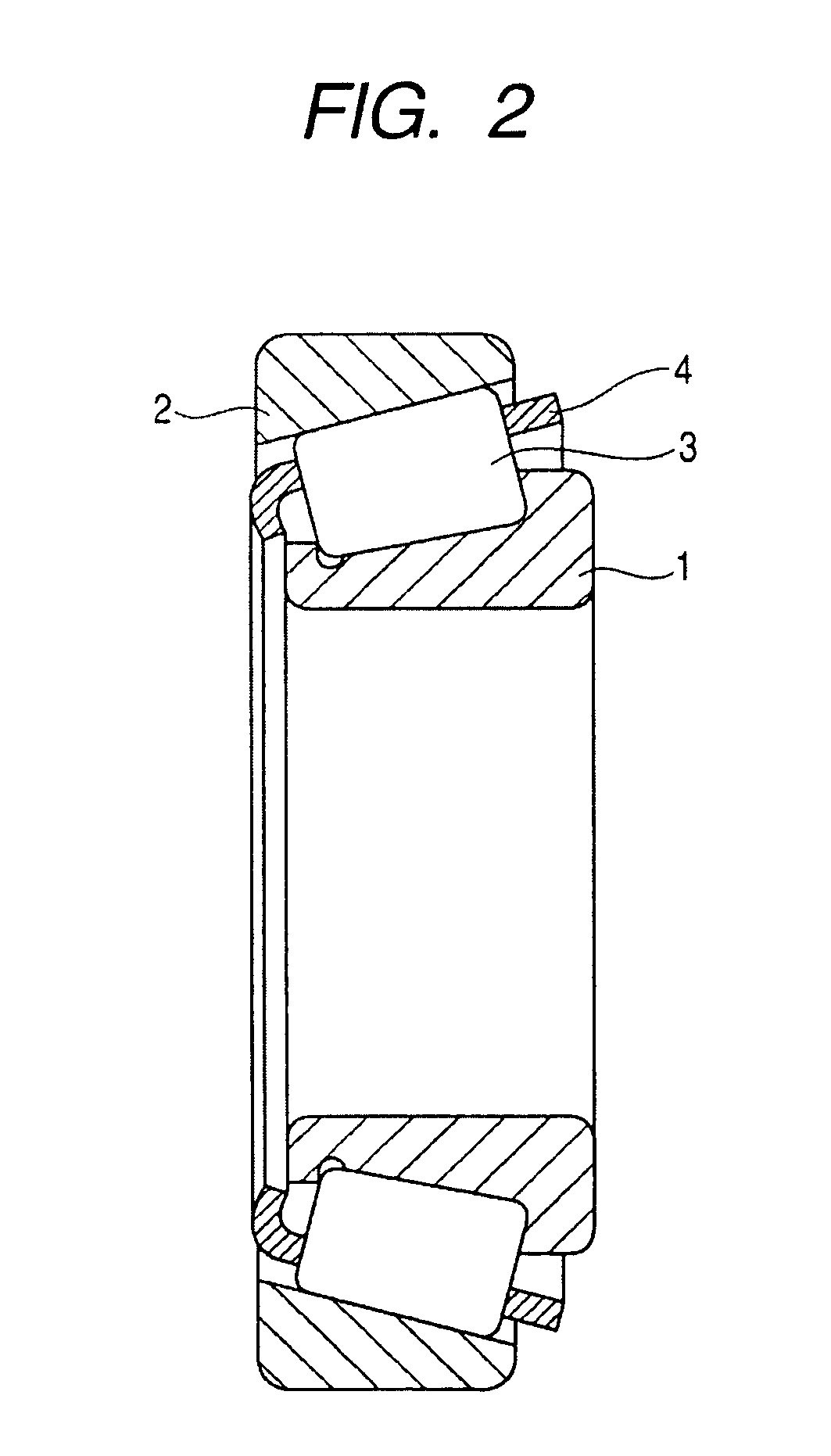

A rolling apparatus including an external member having a raceway surface on an inner peripheral surface thereof, an internal member having a raceway surface on an outer peripheral surface thereof, and a plurality of rolling elements which are rotatably provided between the raceway surface of the external member and the raceway surface of the internal member. A surface of at least one of the internal member, the external member, and the rolling elements is subjected to carbonitriding or nitriding; an area percentage of a nitride containing Si and Mn is 1% or more and 20% or less; surface hardness is HV750 or more. When depth from the raceway surface or depth from a rolling surface of the rolling element is defined as Z and diameter of the rolling element is defined as d, hardness at Z=0.045 d is HV650 to 850, and hardness at Z=0.18 d is HV400 to 800.

Owner:NSK LTD

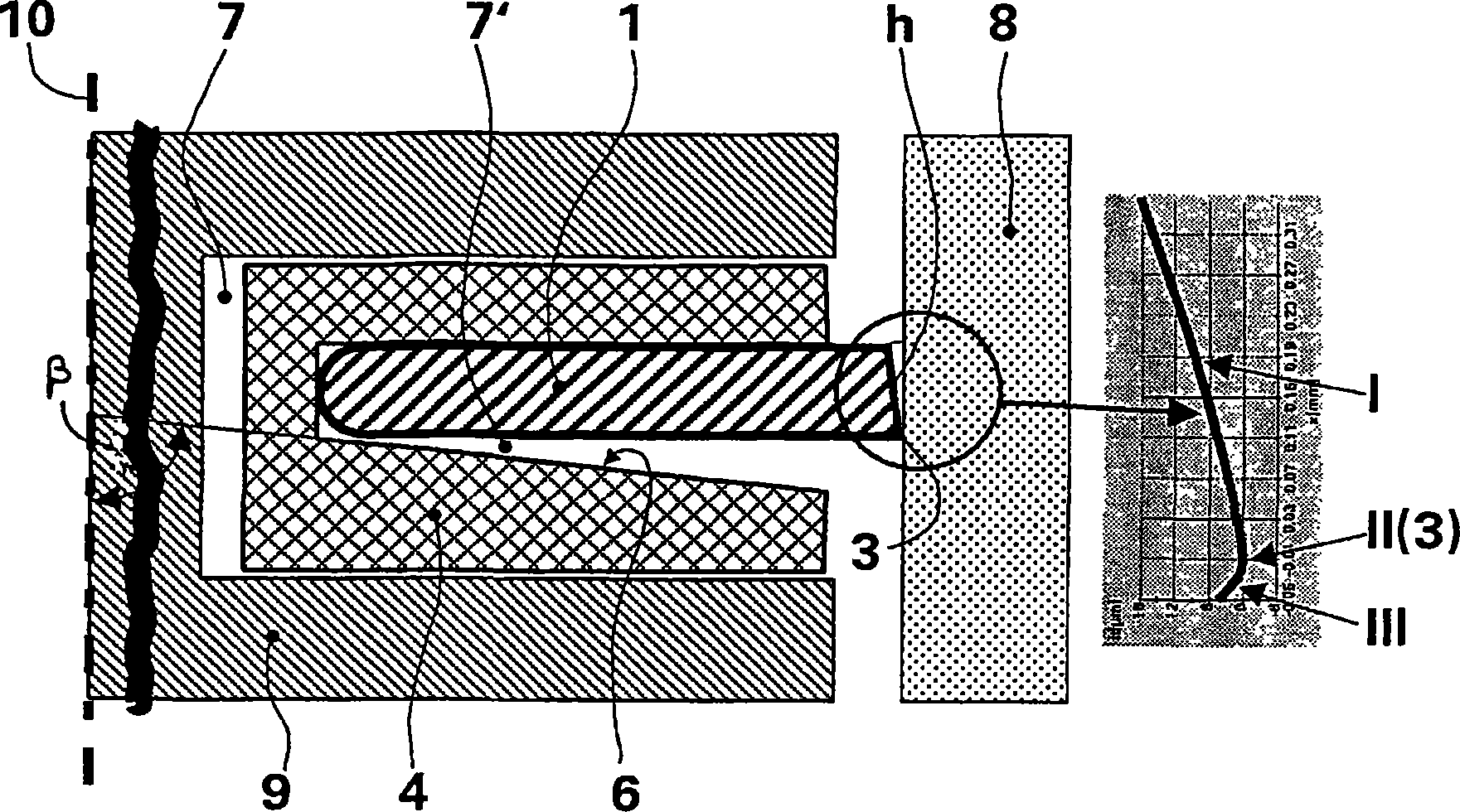

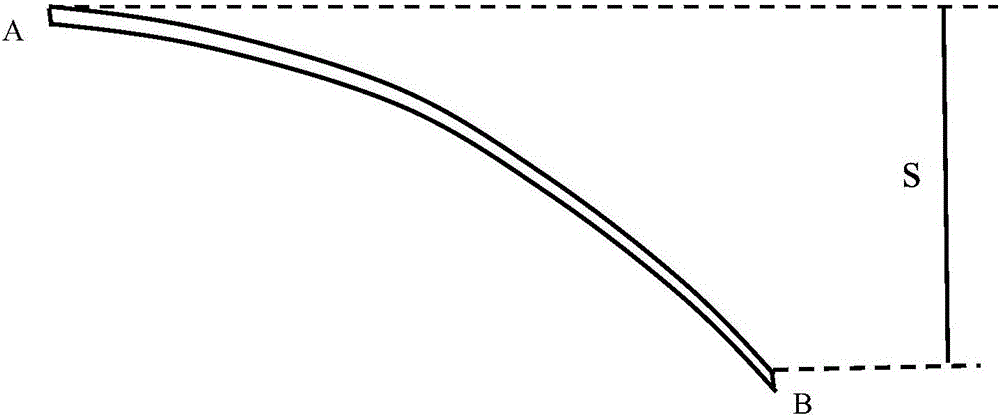

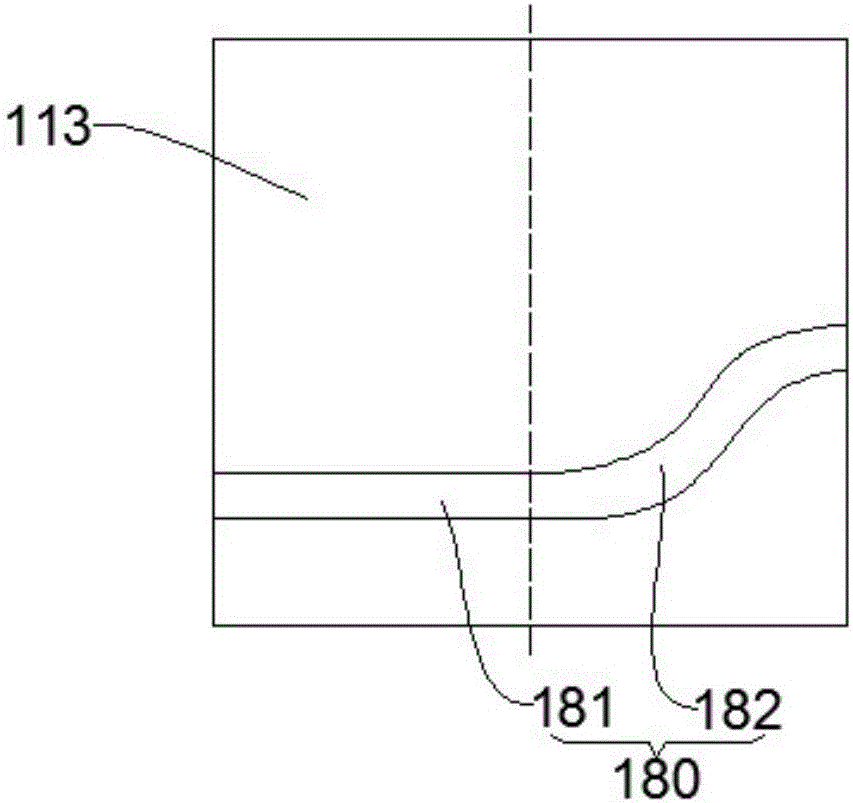

Oil scraper ring for pistons of internal combustion engines

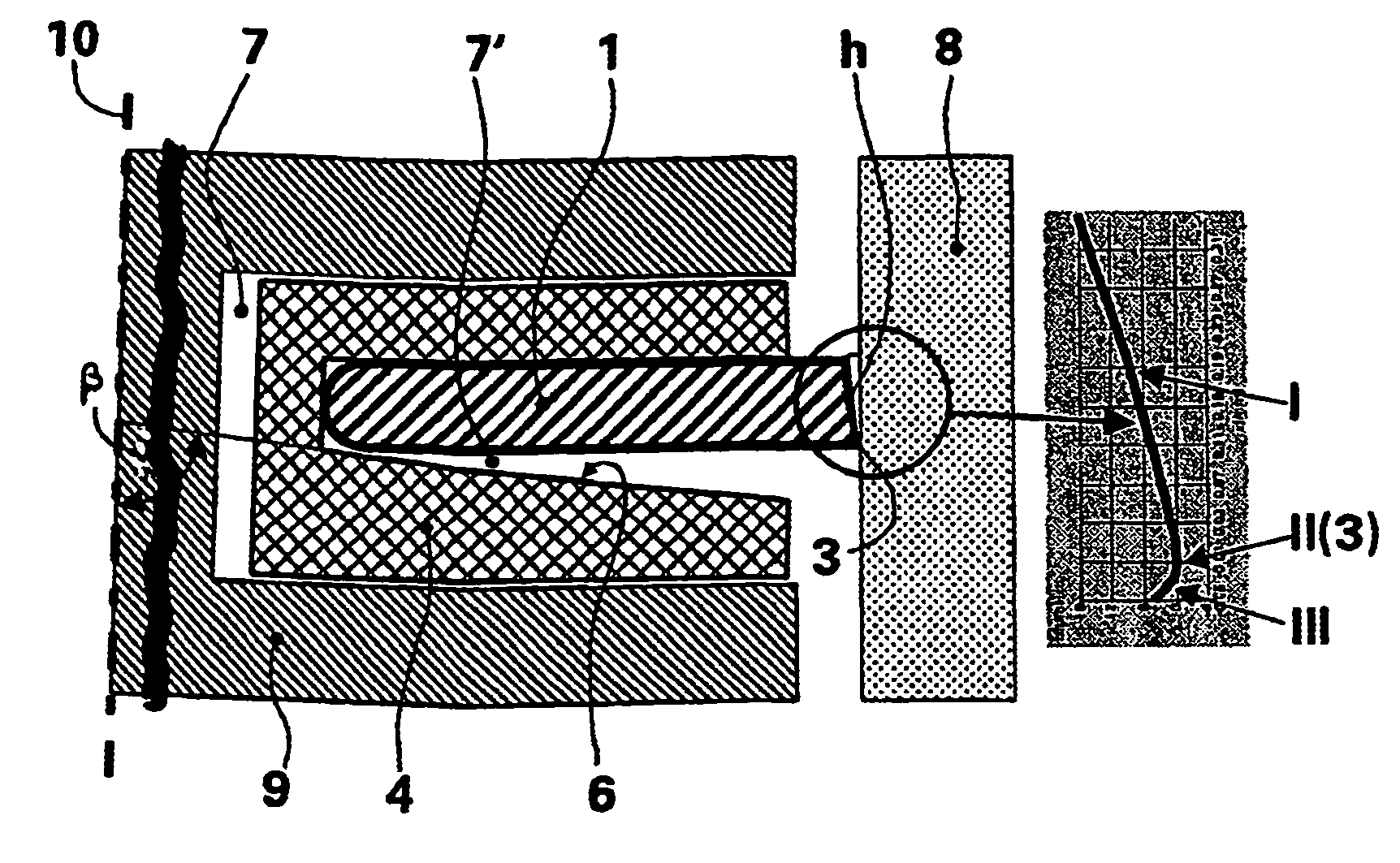

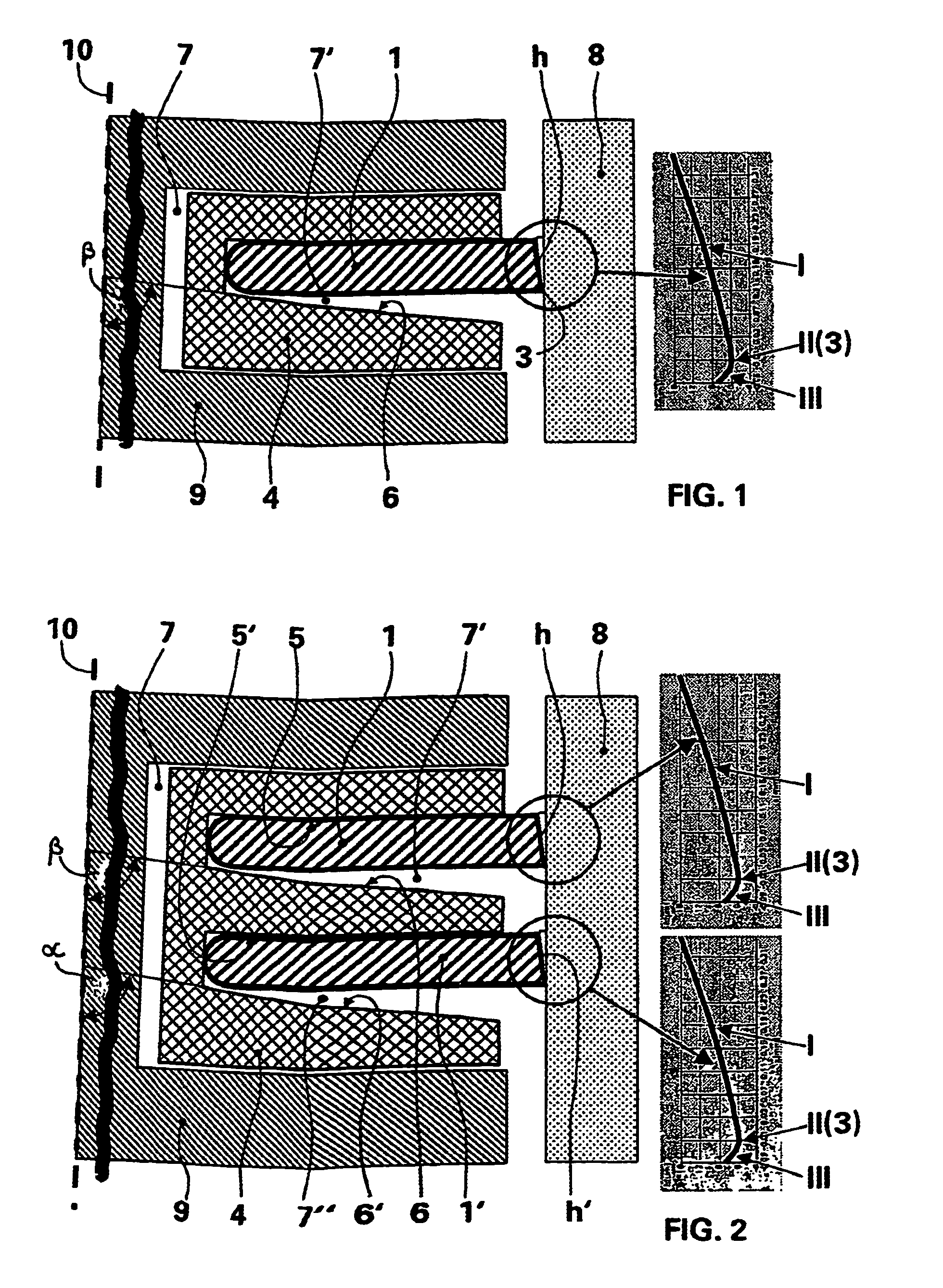

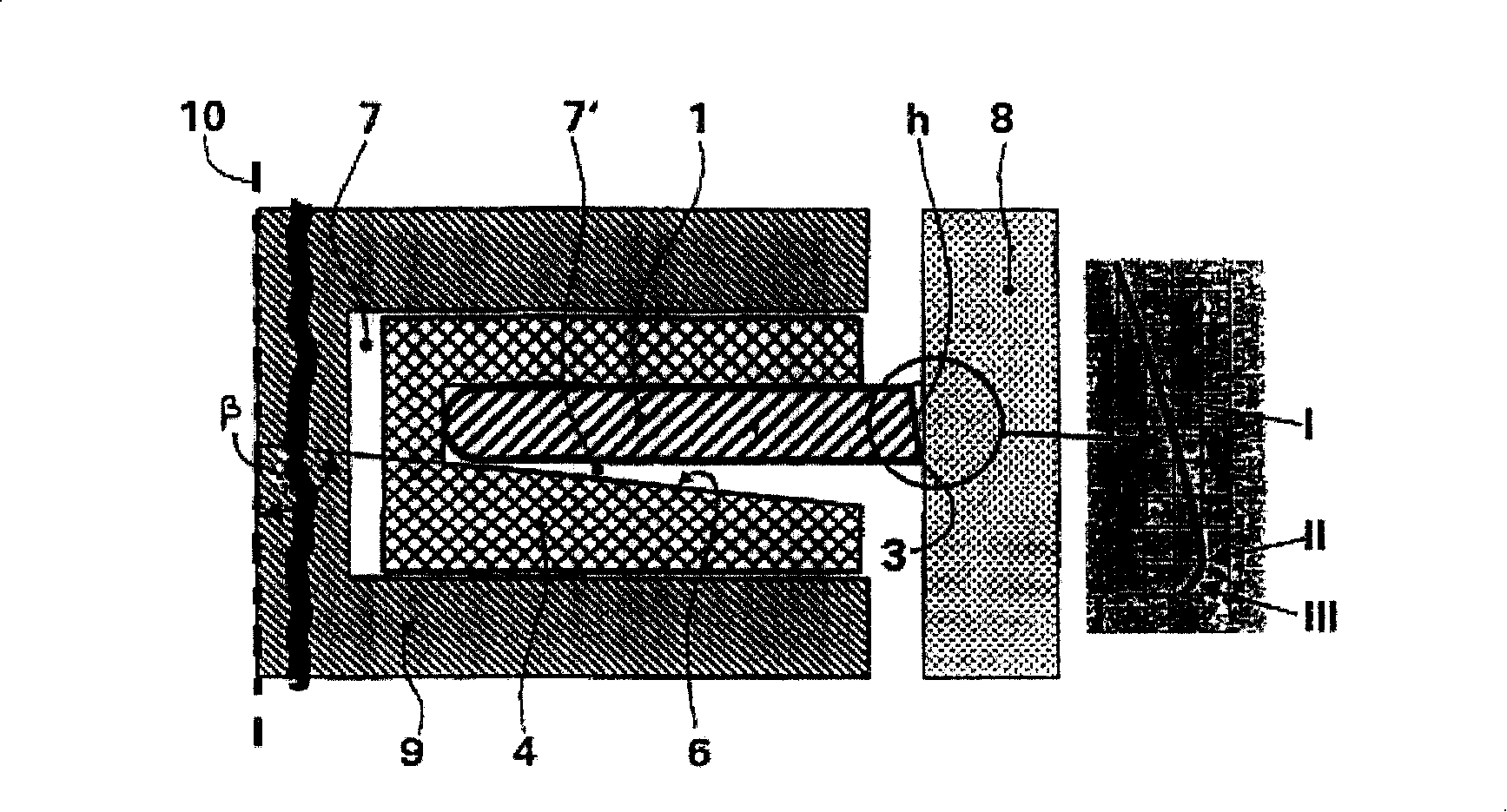

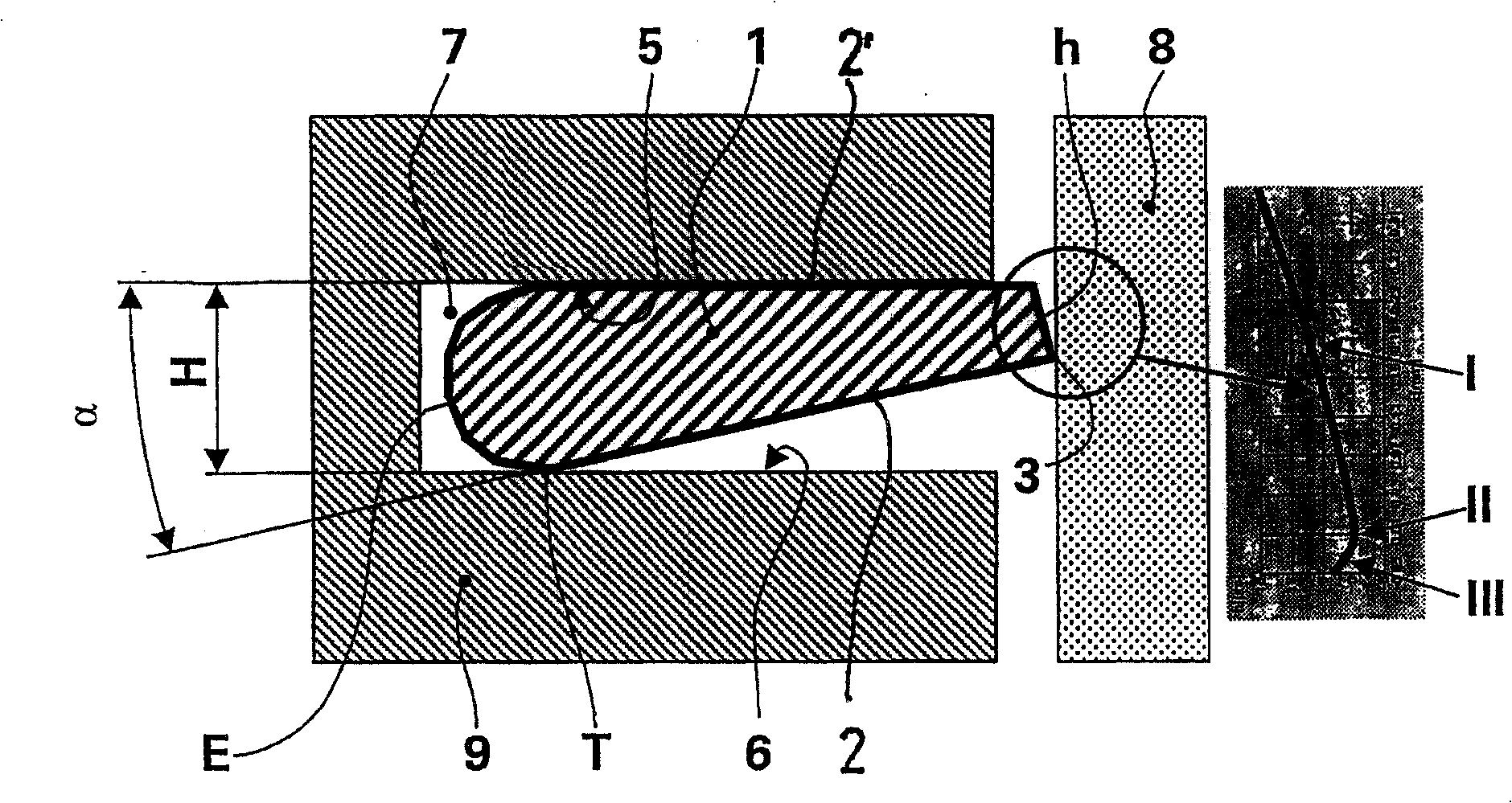

The invention relates to an oil scraper ring for pistons of internal combustion engines, said oil scraper ring comprising a disc (1) that is provided with parallel flanks and a bearing surface (h) having an asymmetrical crowned form with a vertex line (3) extending over the periphery of the disc. A bracing spring (4) arranged in a ring groove (7) of the piston and comprising a spring groove side (6) opposing the piston head and a spring groove side (5) facing the piston head presses the disc (1) radially against the cylinder wall (8). The aim of the invention is to achieve an improved oil scraping action compared to that of prior art, while reducing the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides (5, 6) extends at an angle (ss) in relation to the piston axis (10) in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface (h) of the disc (1) being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring (1) is mounted in the piston, the vertex line (3) of the bearing surface (h) is oriented in the direction of the ring groove side (6) opposing the piston head.

Owner:MAHLE GMBH

Hydrodynamic force conversion device

ActiveCN106368737ASimple structureEasy to manufactureRotary piston enginesMutual transformationMechanical energy

The invention relates to a hydrodynamic force conversion device and relates to the field of hydrodynamic force conversion. The hydrodynamic force conversion device comprises a stator, a rotor, a barrier plate and slide blocks. The rotor is rotatably connected to the stator, an annular cavity is formed between the relative side walls of the rotor and the stator, an inlet and an outlet are formed in the stator, the barrier plate is fixedly connected to the stator and is slidably connected to the rotor, and the barrier plate which is located in the annular cavity is arranged between the inlet and the outlet; chutes are formed on the surface, corresponding to the annular cavity, of the rotor; the slide block is arranged in each of the chutes; the slide blocks extend out from the chutes and divide the annular cavity together with the barrier plate into two sub-cavities which are different in pressure; and the slide block retracts back into the chutes so as to cross the barrier plate. The hydrodynamic force conversion device is simple in structure, and the mutual transformation efficiency of kinetic energy and mechanical energy of a fluid is high.

Owner:唐翊翃

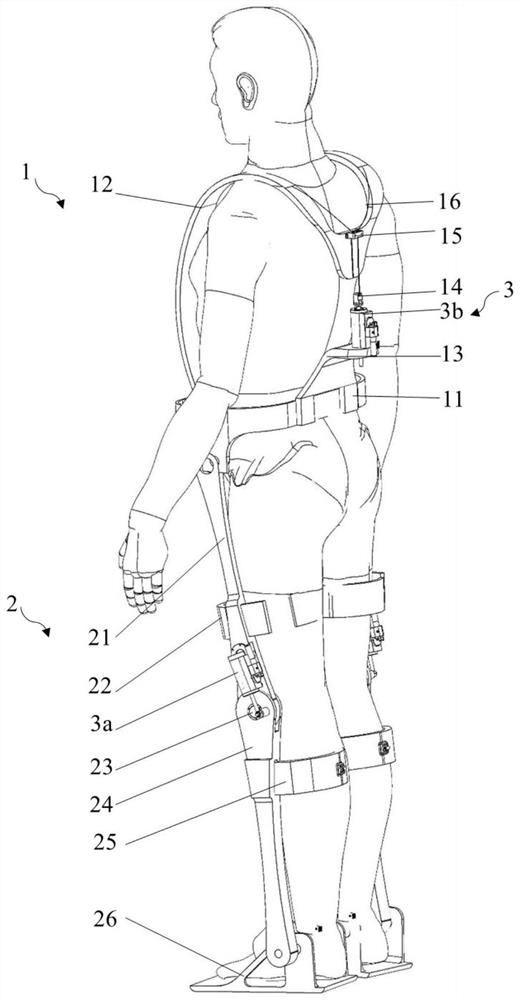

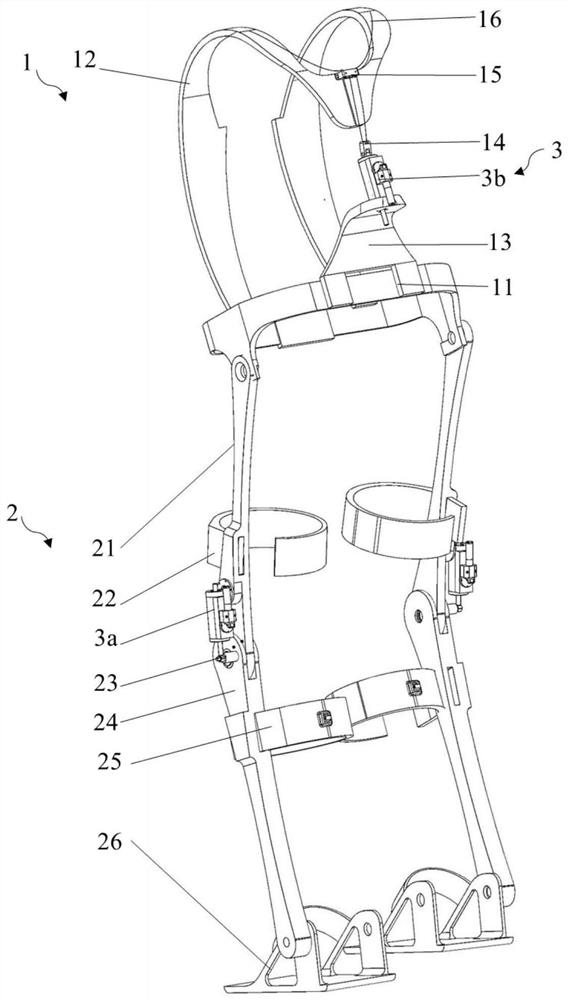

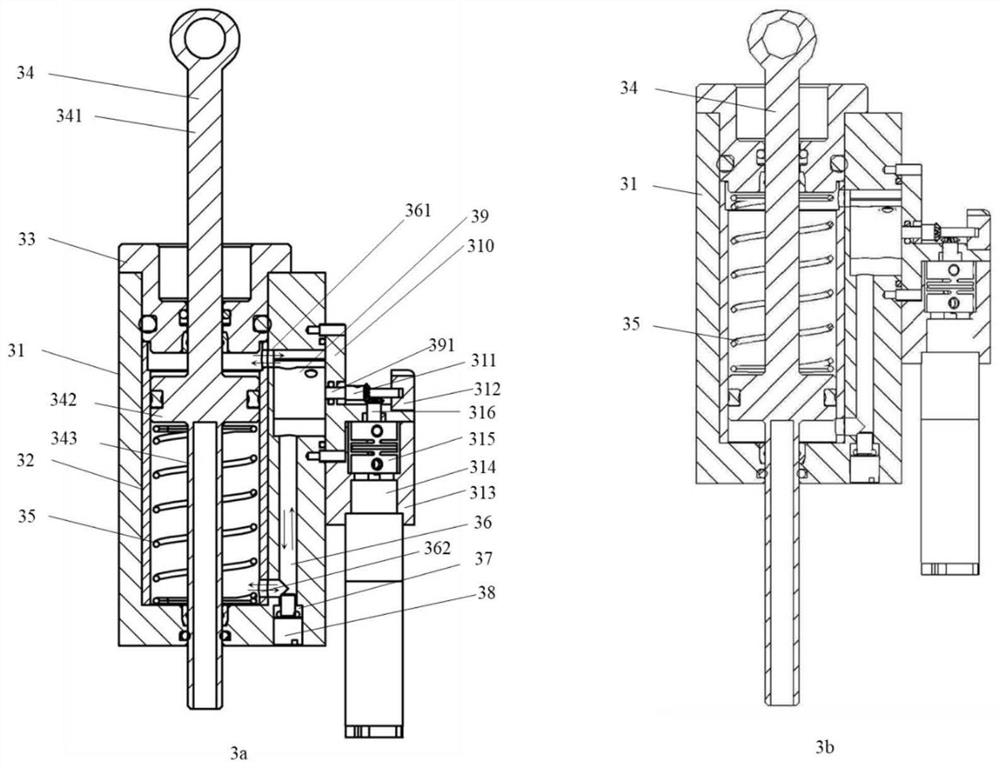

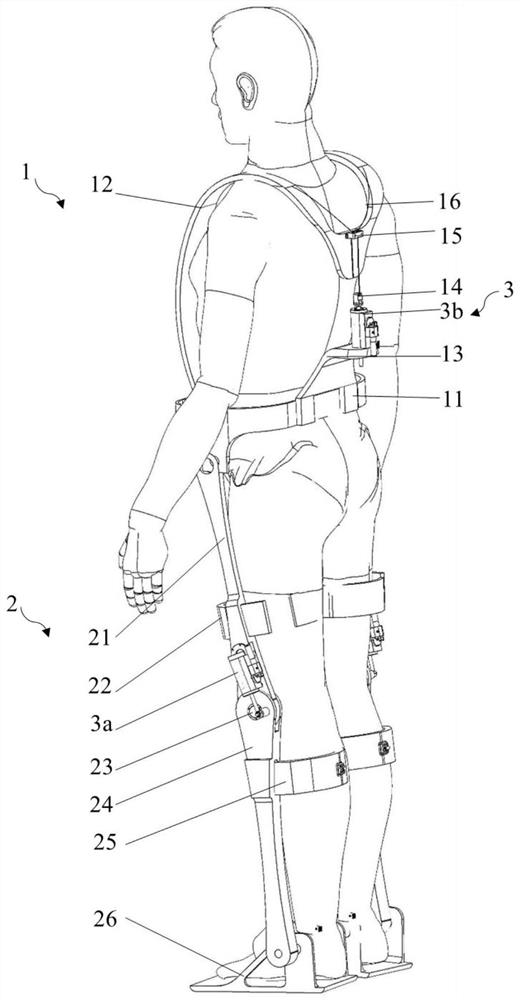

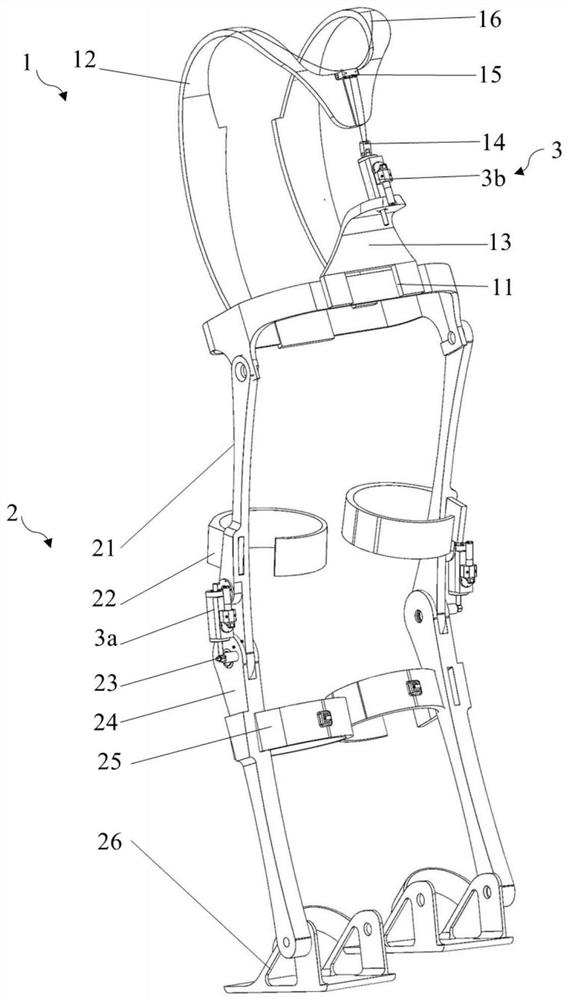

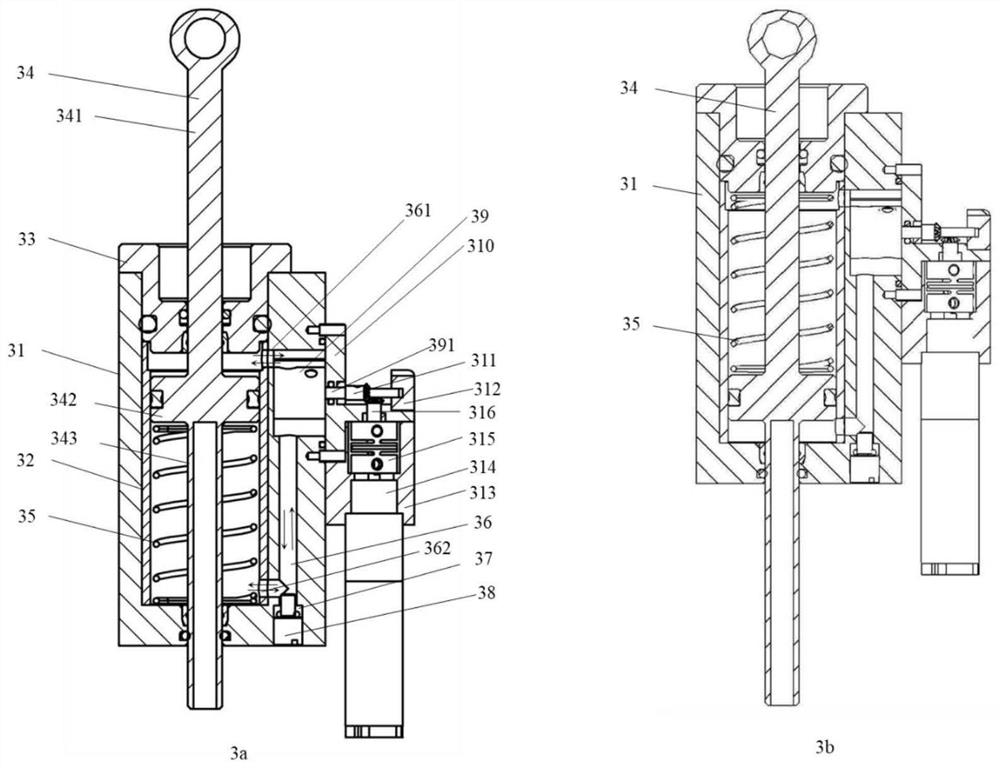

Semi-automatic rigid-flexible coupling type hydraulic exoskeleton

ActiveCN111805513ARealize regulationImprove applicabilityProgramme-controlled manipulatorEngineeringMachine

The invention discloses a semi-automatic rigid-flexible coupling type hydraulic exoskeleton, and relates to an assistant force mechanism in the field of robots. The exoskeleton comprises a waist unit,leg units and a hydraulic damper regulator. The hydraulic damper regulator comprises a cylinder body, a titanium alloy sleeve, a cylinder head, a piston, an extension assistant force spring, an oil inlet plug, an intersection channel type valve body, a valve body sealing seat, a valve body end bevel gear, an angle sensor, a motor fixing base, a direct-current servo motor, a coupling and a motor end bevel gear. The semi-automatic rigid-flexible coupling type hydraulic exoskeleton can achieve assistant force or damping adjustment in a weight carrying mode or on-load walking mode; in the weightcarrying mode, both a from-high-to-low carrying mode and a from-low-to-high carrying mode are supported, and the high applicability is achieved; assistant force can be provided to knee joints when theknee joints bend naturally when a user bends down; a semi-automatic torque adjustment system is formed by hydraulic dampers and springs, the assistant force and damping force can be adjusted in magnitude, the weight is light, and high coupling is achieved between human and machines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

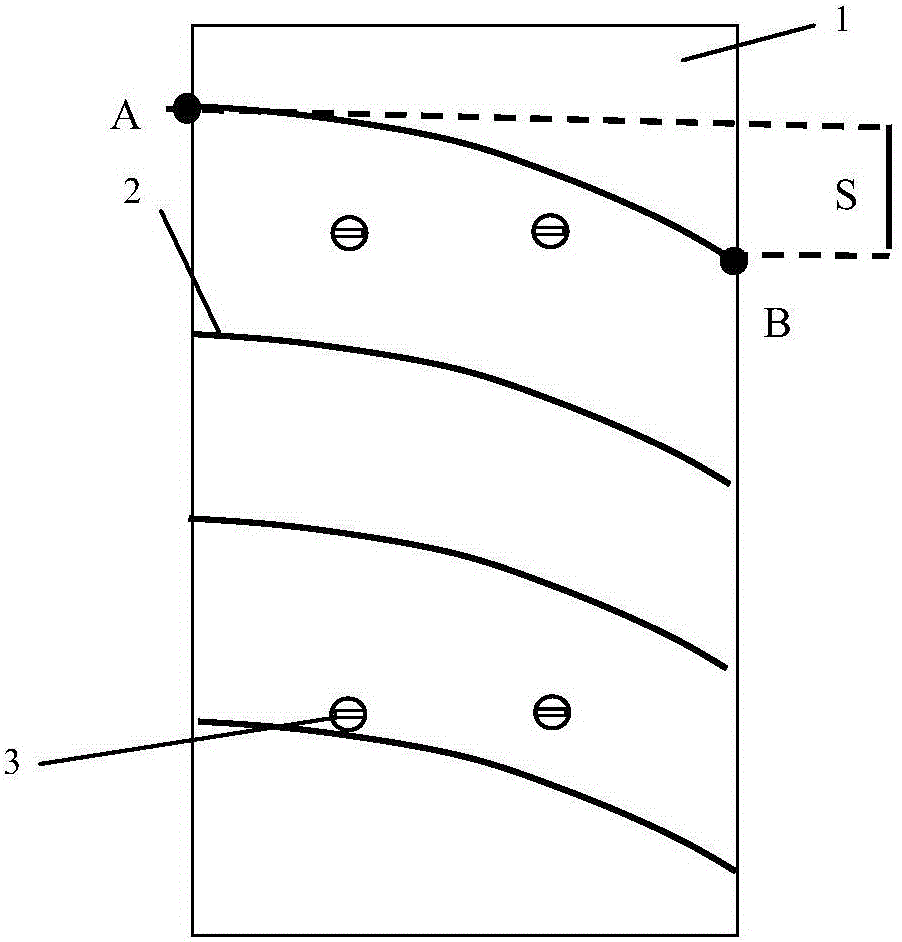

Sliding chute and crankshaft linked engine transmission mechanism

InactiveCN105840308AIncrease tangential forceImprove conversion efficiencyGearingMachines/enginesMechanical engineeringCrankshaft

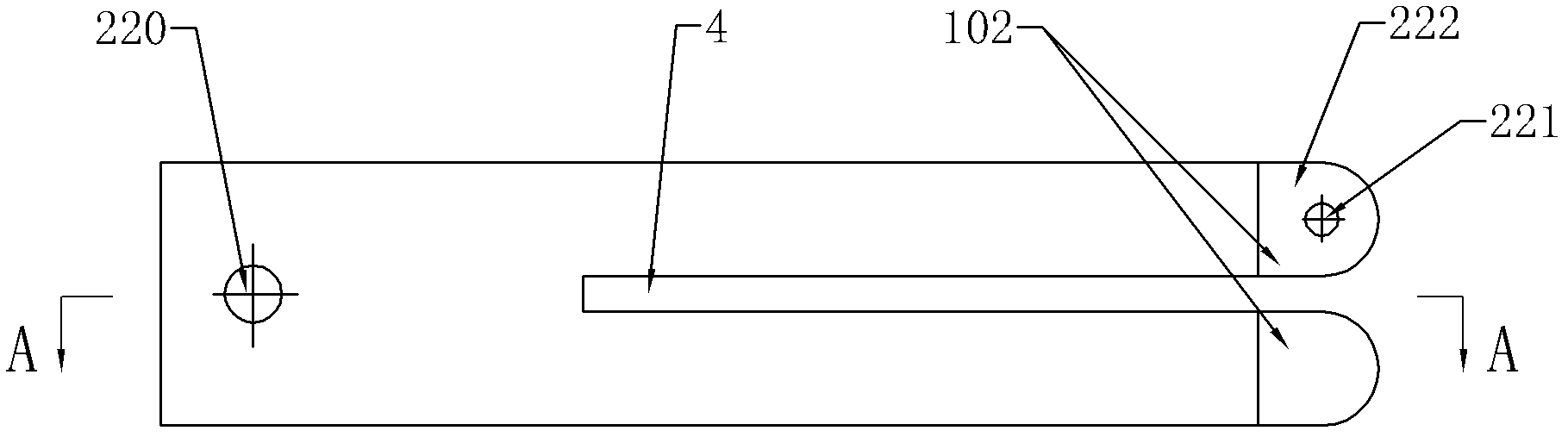

The invention provides a sliding chute and crankshaft linked engine transmission mechanism. The sliding chute and crankshaft linked engine transmission mechanism comprises a crankshaft 2, a connecting rod sliding chute 4 with the two ends closed, drag reduction rollers 5 and guide sliding grooves 6, wherein the crankshaft 2 is mounted on the front sidewall and the rear sidewall of a shell 1; a journal 3 of the crankshaft 2 is sleeved with the connecting rod sliding chute 4; the drag reduction rollers 5 are arranged at the two ends of the connecting rod sliding chute 4; the upper inner wall and the lower inner wall of the shell 1 are provided with the guide sliding grooves 6 of the same shape correspondingly; the drag reduction rollers 5 are arranged in the two parallel guide sliding grooves 6 correspondingly; and the chute wall of one side or the chute walls of the two sides of the connecting rod sliding chute 4 are connected with one or more connecting rods 7 and a piston or more pistons 8 of one or more air cylinders 9 to form a single-cylinder or multi-cylinder engine unit. By adopting the transmission mechanism, the output torque of an engine is increased, the lateral pressure of the pistons 8 to the air cylinders 9 is eliminated, and the conversion efficiency of the engine is improved.

Owner:安里千

Oil scraper ring for pistons of internal combustion engines

InactiveUS7396018B1Reduce frictionImprove wiping effectPiston ringsBraking action transmissionCombustionHead pressing

The invention relates to an oil scraper ring for pistons of internal combustion engines. The oil scraper ring comprises a disc that is provided with parallel flanks and a bearing surface having an asymmetrical crowned form with a vertex line extending over the periphery of the disc. A bracing spring arranged in a ring groove of the piston and comprising a spring groove side opposing the piston head and a spring groove side facing the piston head presses the disc radially against the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides extends at an angle in relation to the piston axis in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface of the disc being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring is mounted in the piston, the vertex line of the bearing surface is oriented in the direction of the ring groove side opposing the piston head.

Owner:MAHLE GMBH

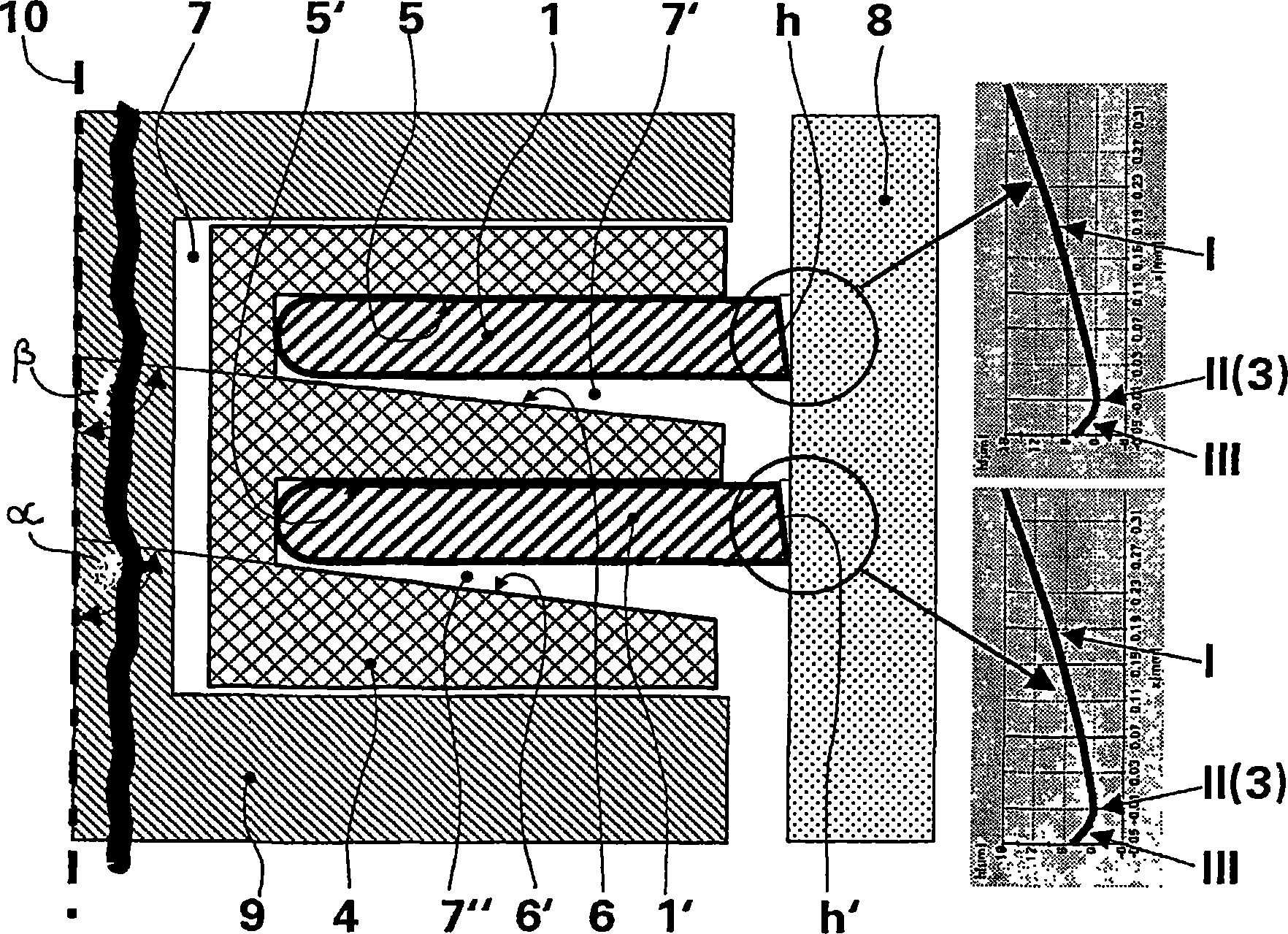

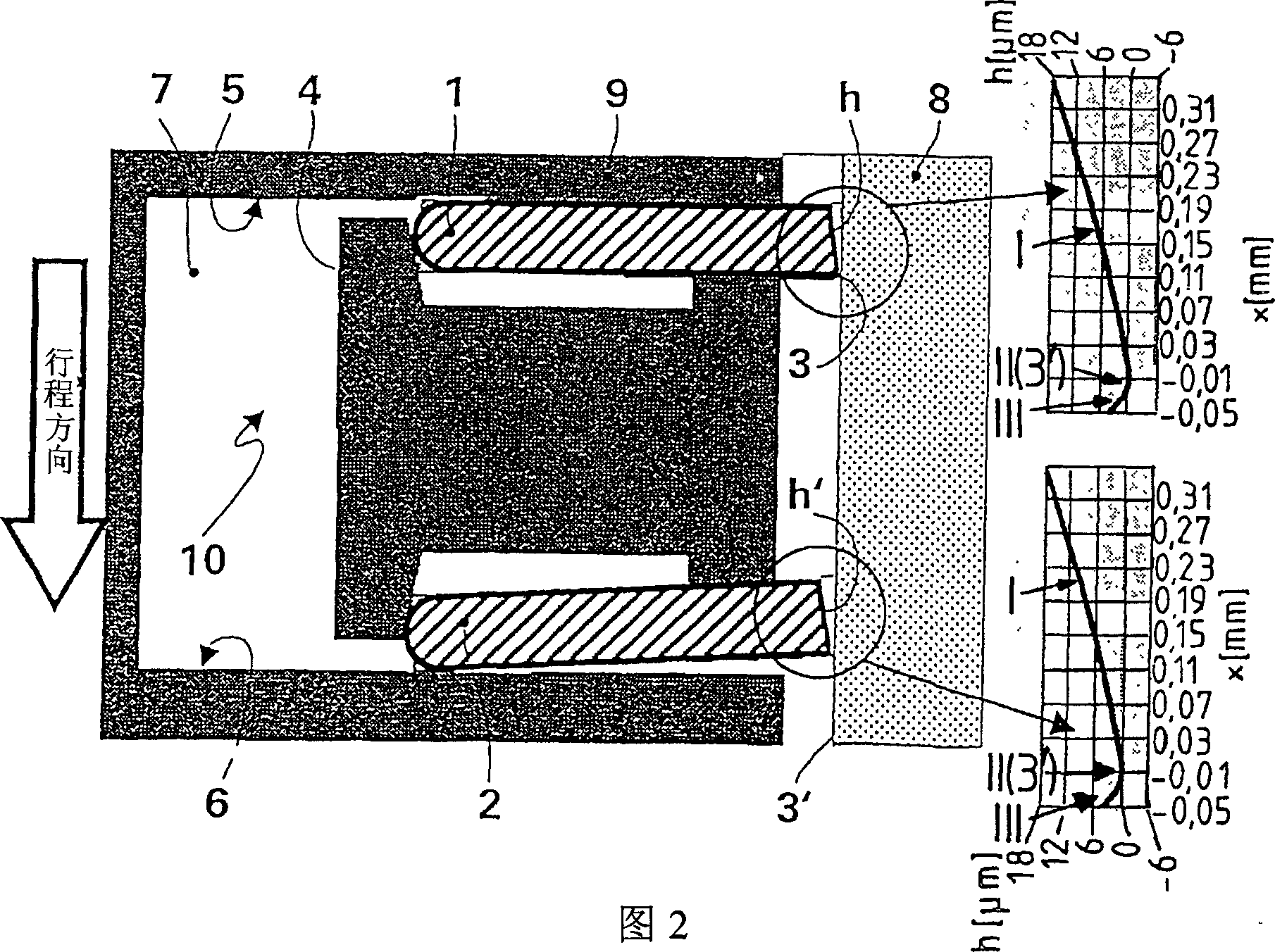

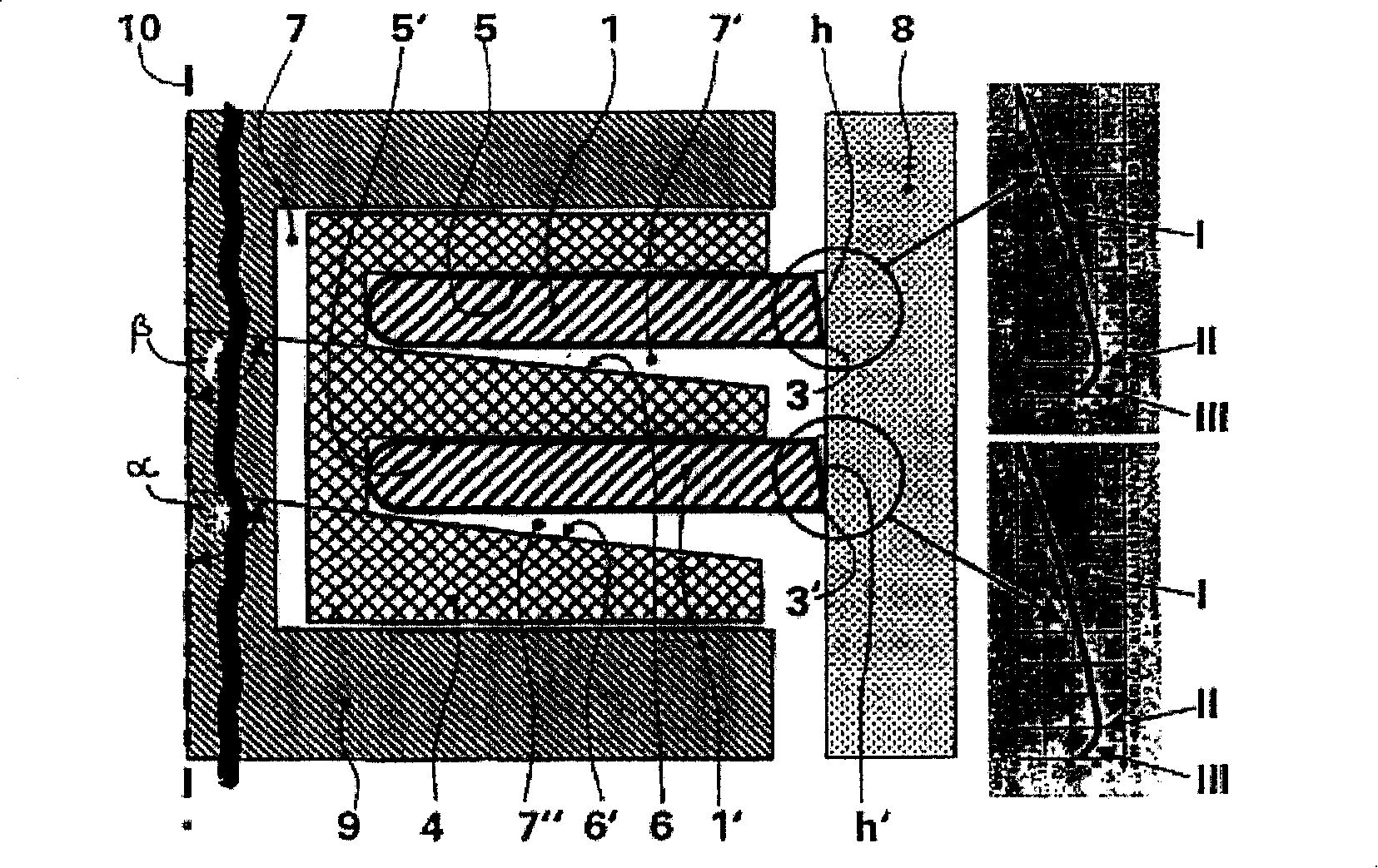

Multipart oil wiping ring for pistons of internal combustion engines

The invention relates to a multipart oil wiping ring for pistons of internal combustion engines, comprising two steel strip-type lamellae with parallel sides, the running surfaces of which are provided with a convexly asymmetric shape having a vertex line that extends across the circumference of the lamellae, and a bracing spring located between the lamellae, said bracing spring pressing the lamellae in an axial direction against one respective side of an annular groove in the piston and in a radial direction against the cylinder wall. The aim of the invention is to obtain an oil-wiping effect that is improved compared to prior art while reducing wear of the running surface. Said aim is achieved by configuring the running surfaces (h, h') of both lamellae so as to make the same correspond to a final contour approaching a condition of wear in the run-in state of the engine, the vertex lines (3, 3') of the running surfaces (h, h') being oriented counter to the direction of the center of the annular groove (3) in the mounted states of the oil ring (10) in the piston.

Owner:MAHLE GMBH

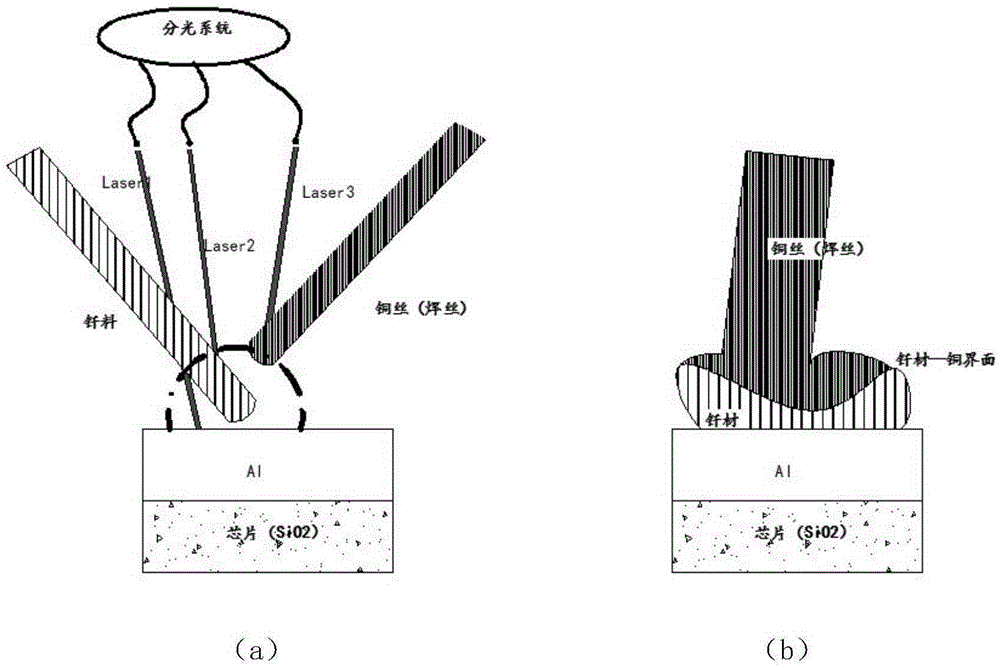

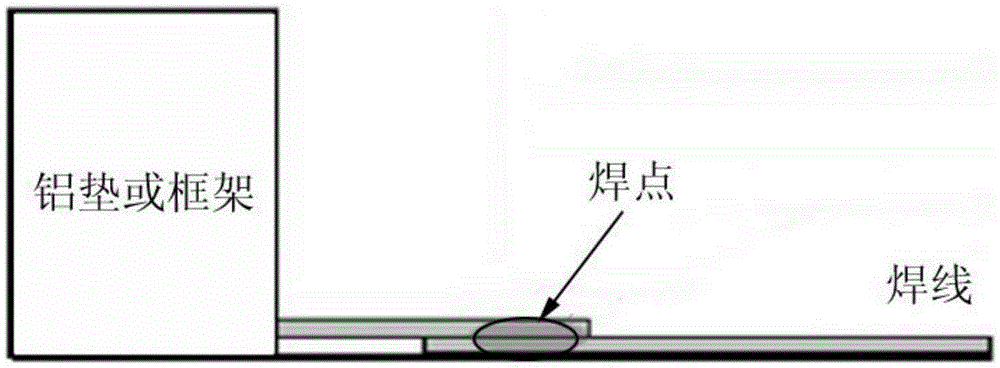

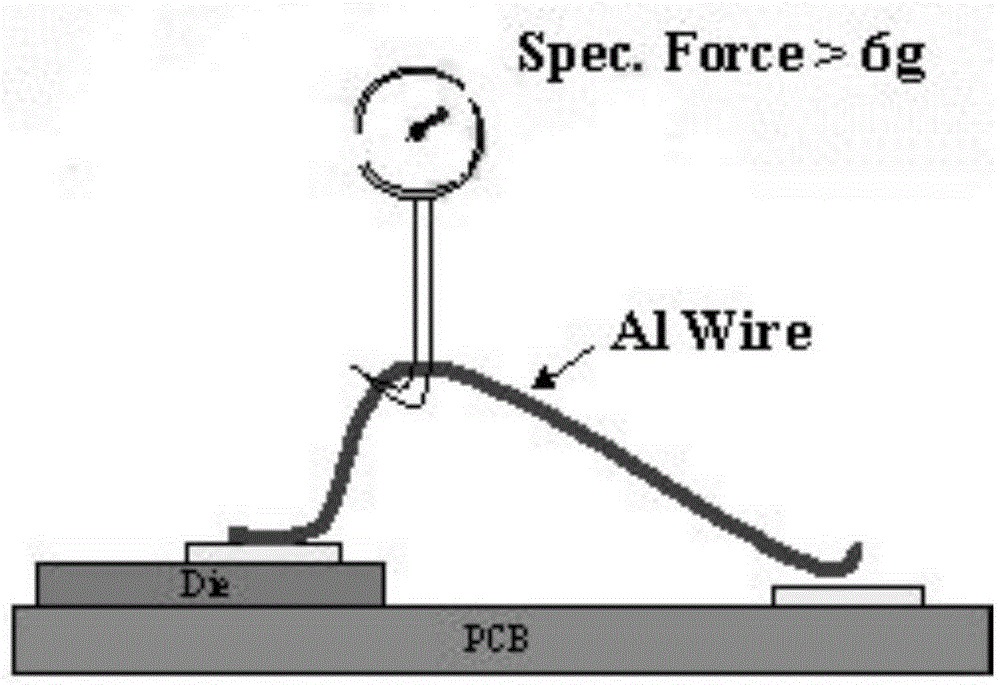

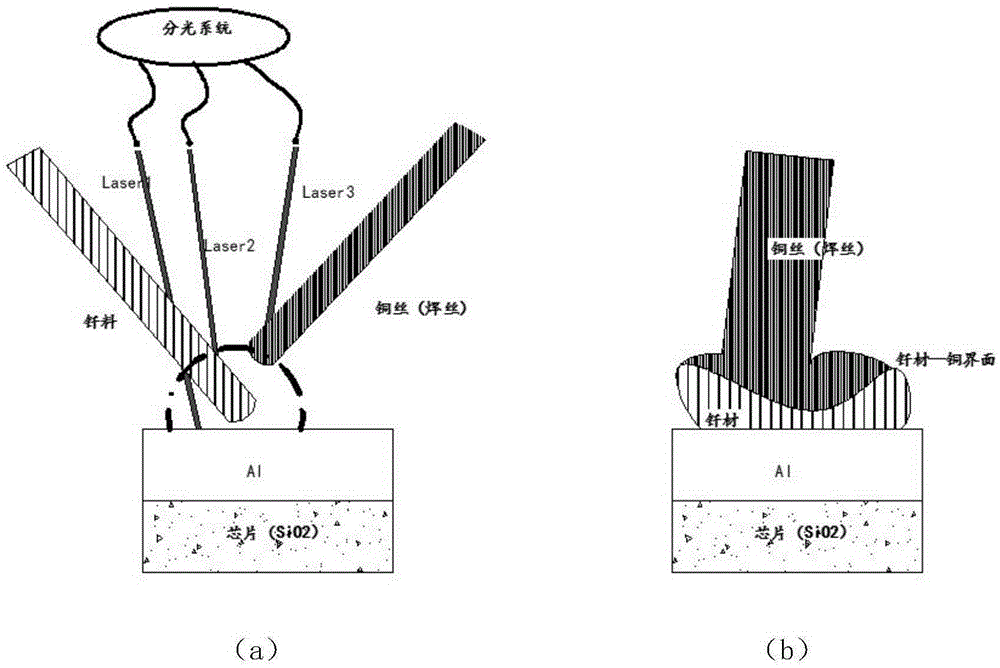

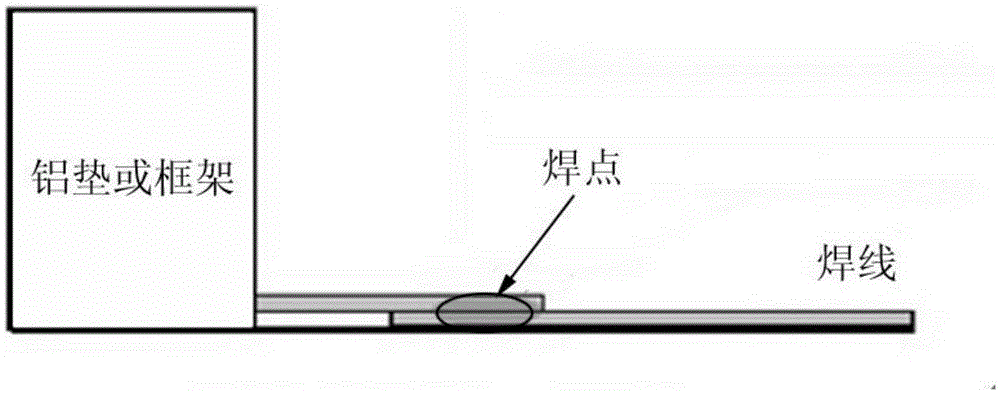

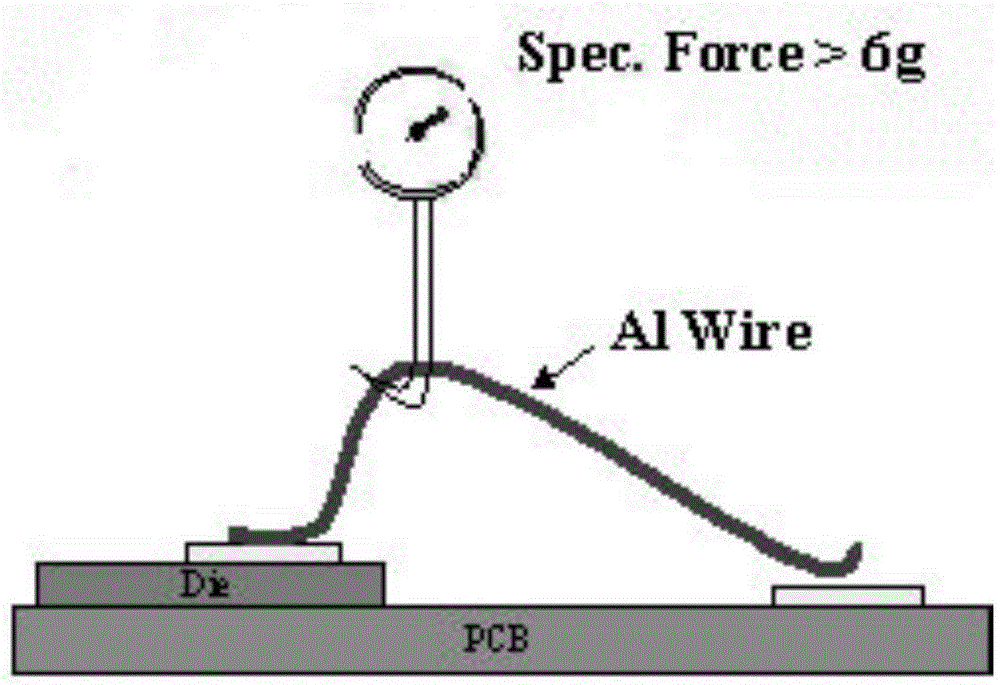

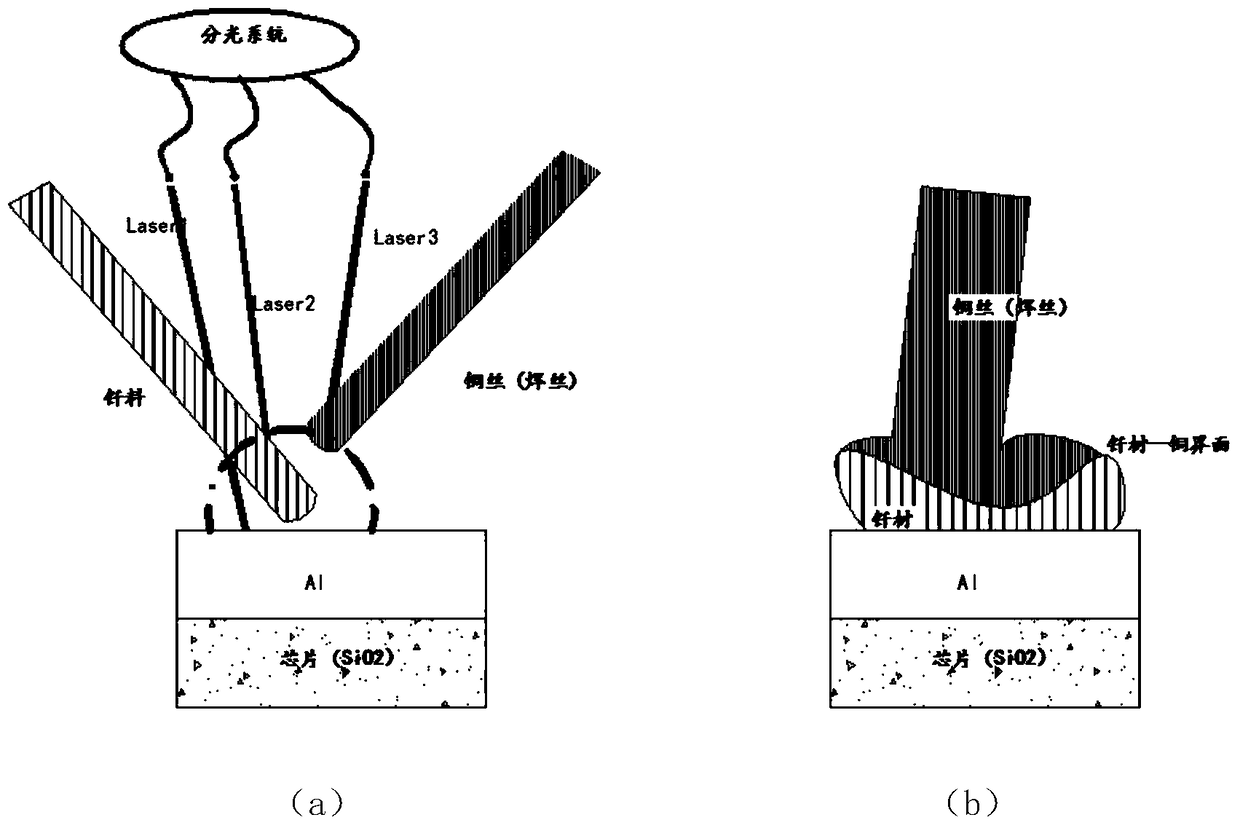

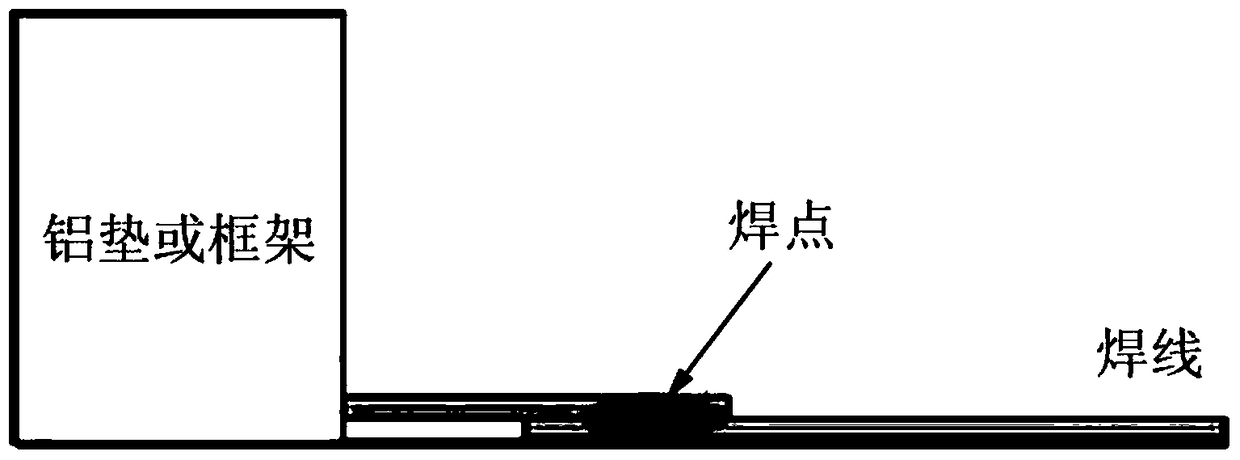

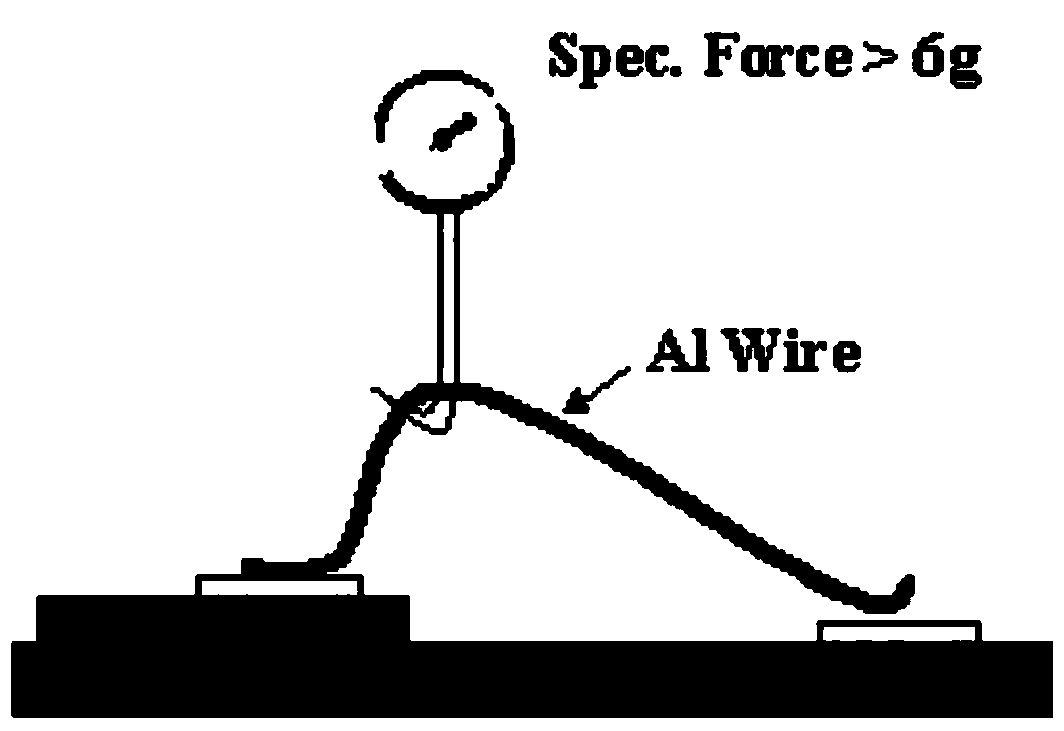

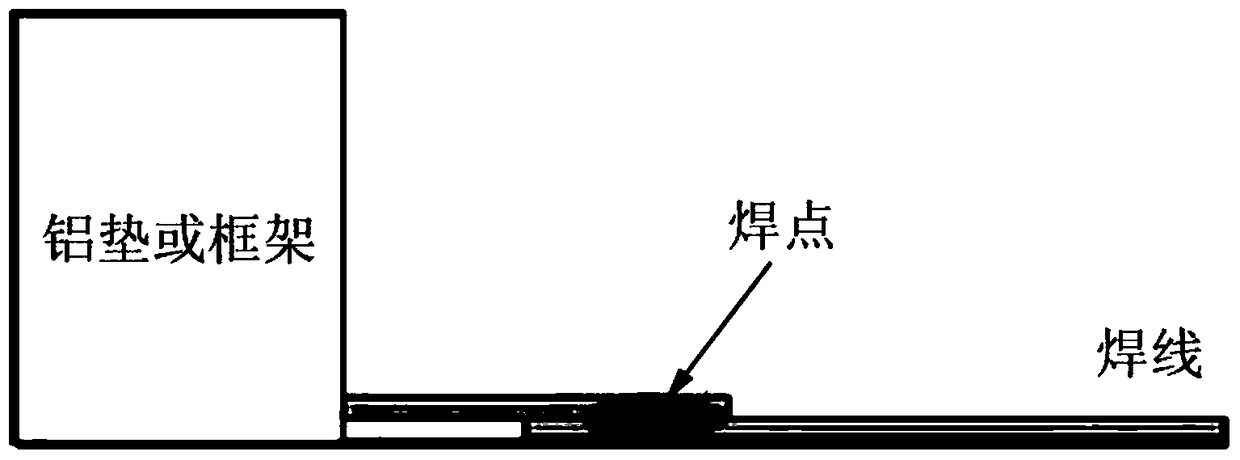

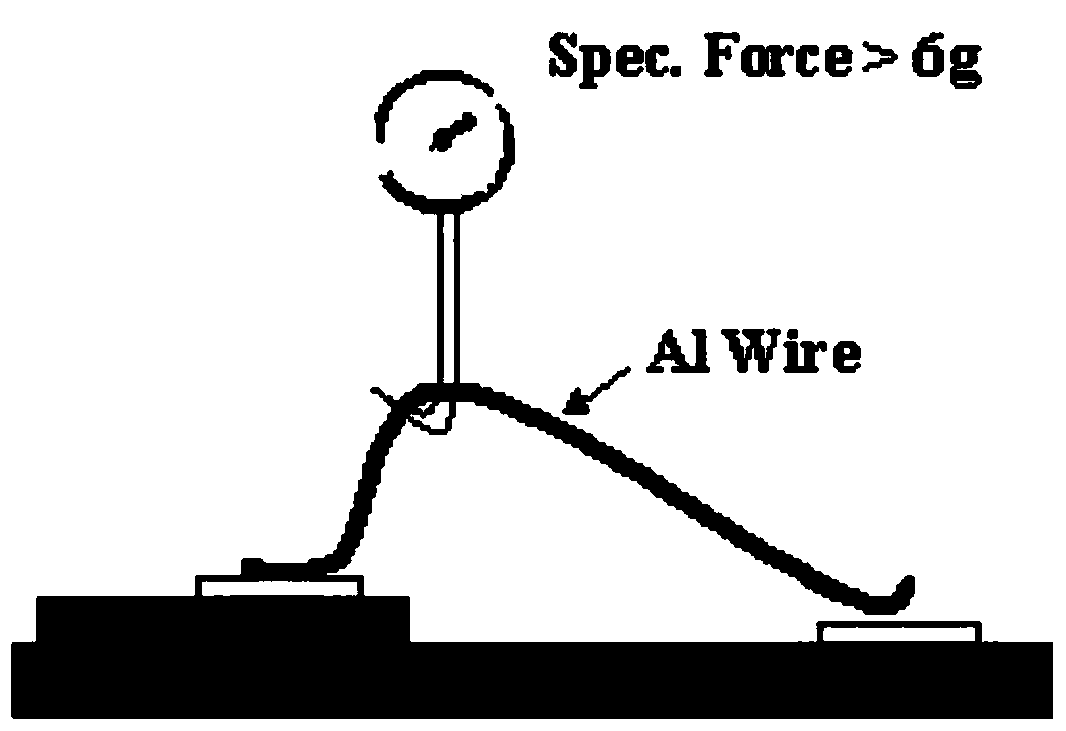

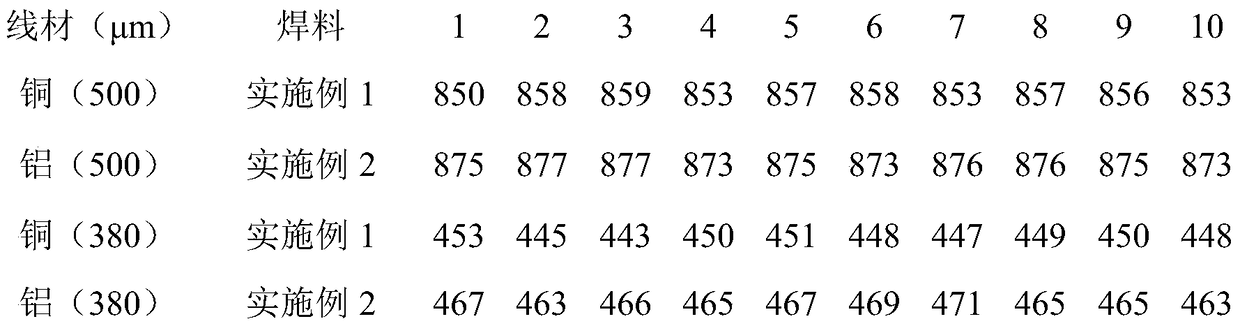

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

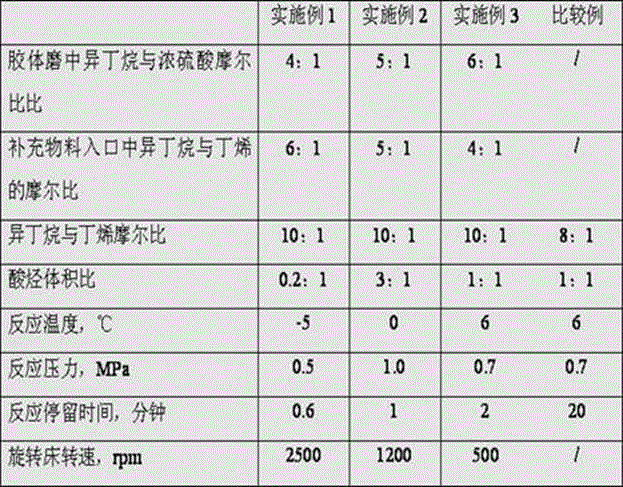

Two-segment-charged alkylation reaction method

ActiveCN104560143AImprove mass transfer efficiencyEnhanced mass transferLiquid hydrocarbon mixtures productionHydrocarbonsHydrocarbon mixturesEmulsion

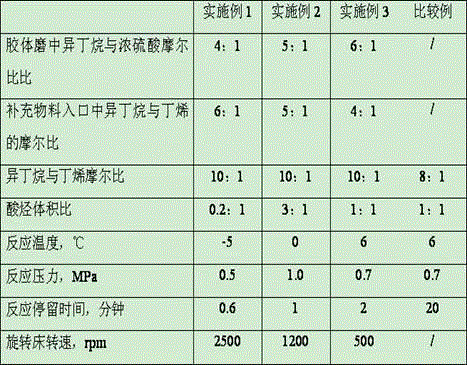

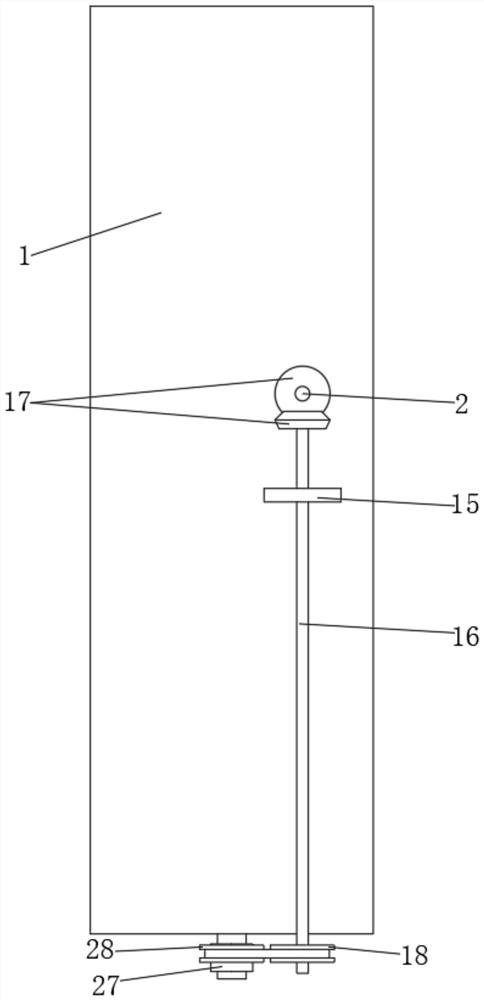

The invention discloses a two-segment-charged alkylation reaction method. The alkylation reaction method comprises the steps: enabling concentrated sulfuric acid and isobutane to enter a colloid mill, and thoroughly mixing, so as to form an emulsion; enabling the emulsion and a hydrocarbon mixture containing C3-C5 alkene and isobutane to enter an alkylation reactor for reaction, wherein the reactor comprises a tube body, closure heads, an inner revolving bed, an outer revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet and a circulating cooling gas outlet; the inner revolving bed is connected with an upper driving device through the charging pipe, the upper end of the inner revolving bed and the charge distribution pipe are fixedly connected into an integrated structure through a sealing member, the upper part of the outer revolving bed and a reactor shell body are fixedly connected through a sealing member, and the outer revolving bed is connected with a lower driving device through a revolving shaft. The alkylation reaction method disclosed by the invention has the advantages that the degree of mixing of isobutane and concentrated sulfuric acid can be greatly increased, the reaction can be carried out at relatively low temperature, the acid consumption of the reaction is low, the quality of products is high, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lead welding device and technique for packaging semiconductor power device

ActiveCN105458435AImprove efficiencySmall heat affected zoneWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding device and technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. The device is a laser wire welding machine and comprises a computer main board, a laser generator, a chip and frame image identification system, a feeding system and an XY workbench. The computer main board is used for controlling all the actions of the laser wire welding machine to achieve the whole automatic and accurate wire welding technique process; the laser generator is used for outputting laser spots of the required power and the required diameter; and the feeding system is used for accurately conveying a frame, a lead and a brazing wire to the work position before welding actions are executed. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers. By the adoption of the device and technique, a wet aluminum pad and a frame are directly melted to achieve the stable and reliable connection of the lead, a chip and the frame, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

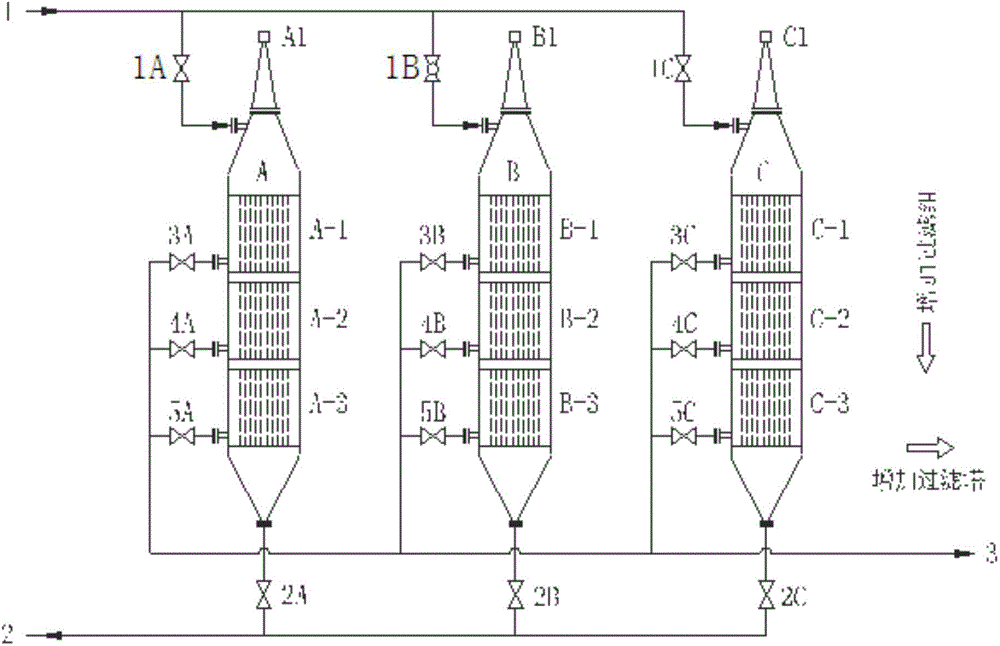

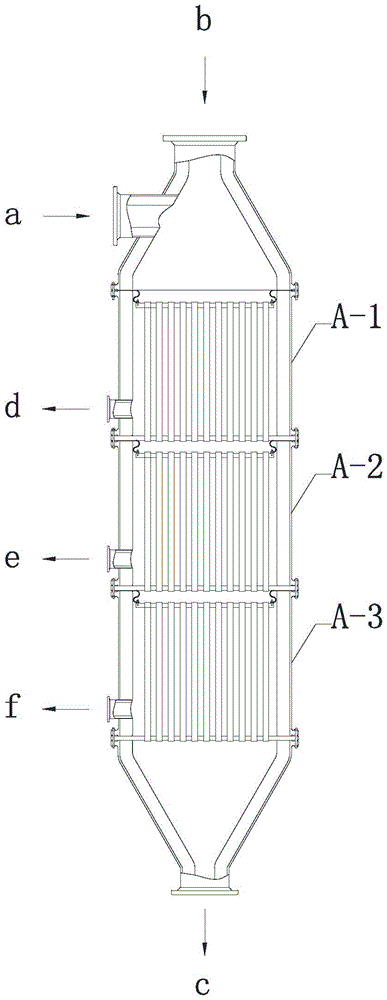

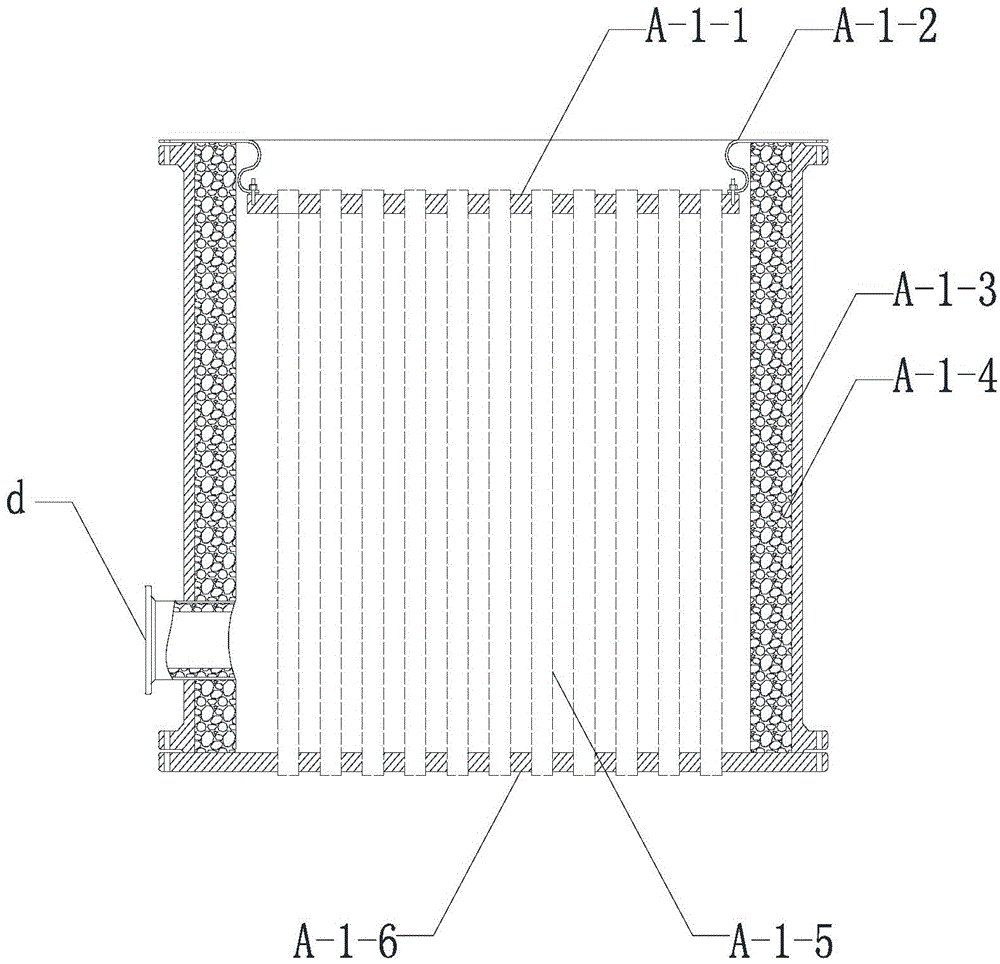

Self-cleaning high-temperature oil gas filter dust-removal process device and method

InactiveCN104785023AThe overall structure is simpleEasy maintenance and repairDispersed particle filtrationExhaust gasDiameter ratio

The invention discloses a self-cleaning high-temperature oil gas filter dust-removal process device and method. The device comprises a plurality of filter towers connected in parallel, wherein each filter tower comprises an upper seal head, a lower seal head and a plurality of tower filter groups which are perpendicularly stacked and the same; upper seal heads of which the side surfaces are provided with high-temperature oil gas connectors are arranged at the upper ends of the perpendicularly stacked tower filter groups; the lower seal heads provided with dust-containing exhaust connectors are arranged at the lower ends of the perpendicularly stacked tower filter groups; the upper ends of the filter towers are connected in parallel through the high-temperature oil gas connectors; the lower ends of the filter towers are connected in parallel through the dust-containing exhaust connectors; a filter group purified-gas connector is formed in each tower filter group; the filter tower groups are connected in parallel through the filter group purified-gas connectors. According to the invention, after the device adopts a tower structure, the process device with a reasonable height-diameter ratio can be designed; after the high-temperature pyrolysis oil gas treated by the self-cleaning high-temperature oil gas filter dust-removal process device and method is recovered, the solid content of coal tar is less than 0.5 mg / L, so that the technical requirements of coal tar deep-processing process are completely met.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

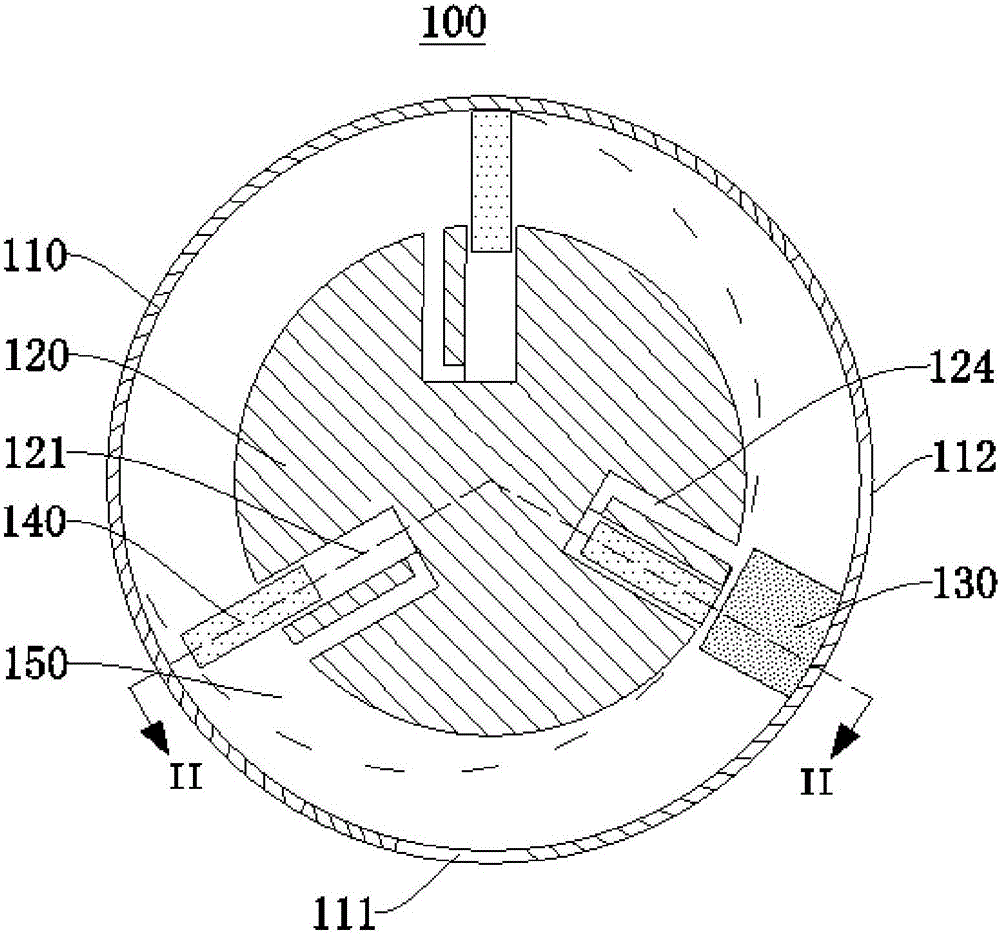

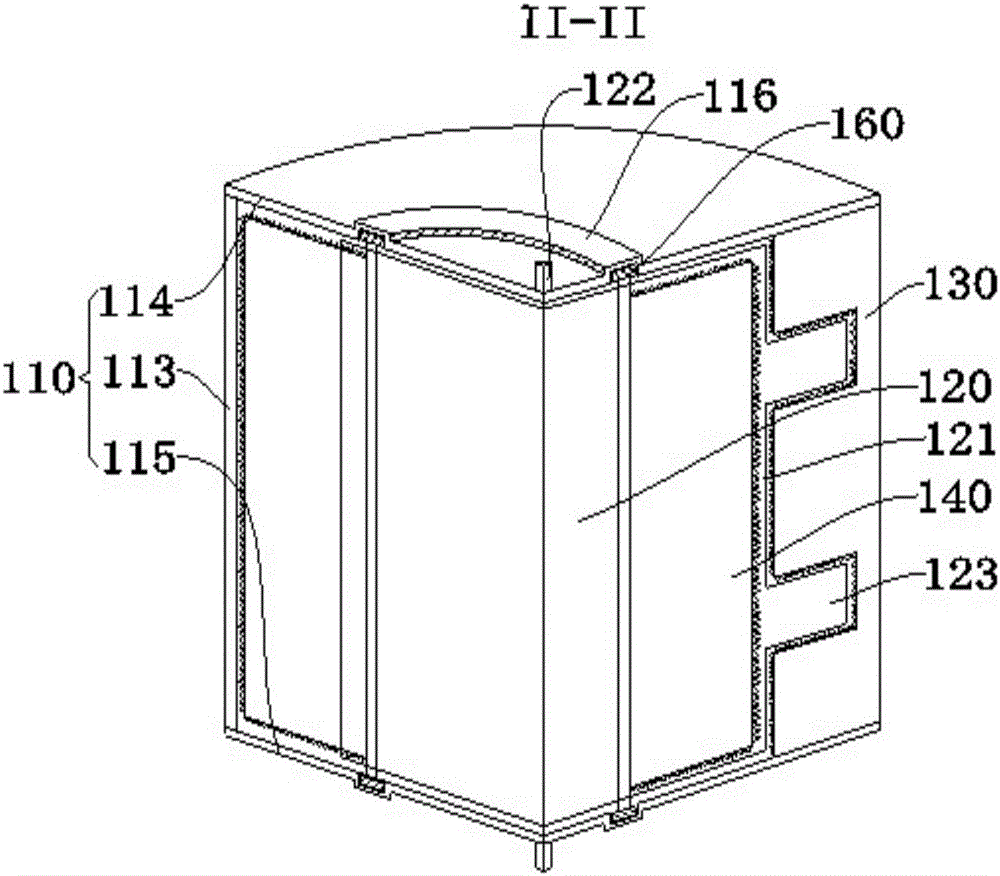

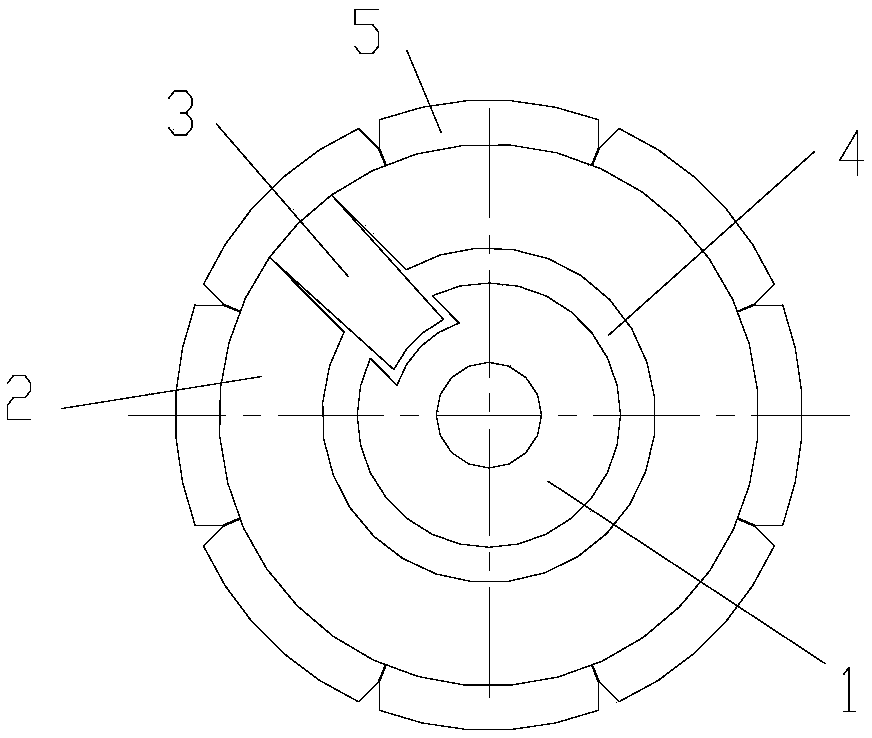

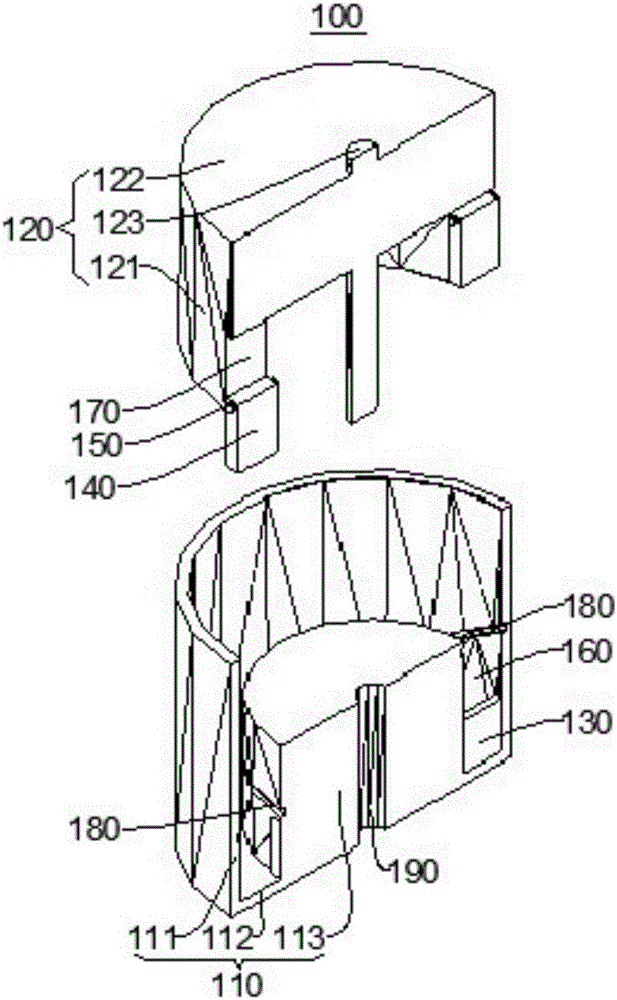

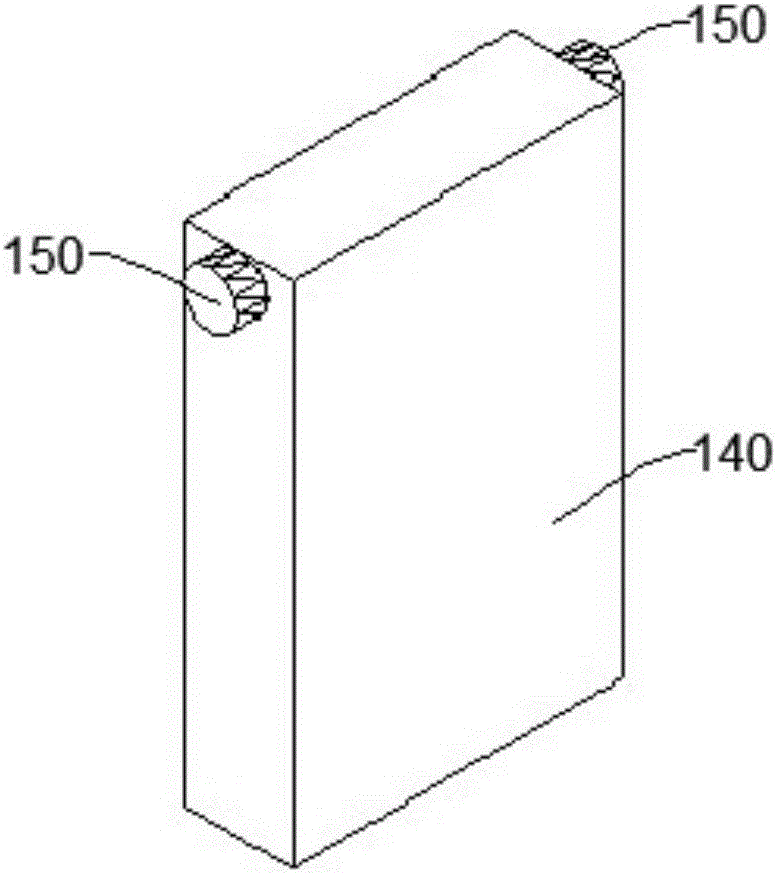

Vibration damping rotor iron core, vibration damping rotor and electric machine

ActiveCN109067031AImprove reliabilityGuaranteed reliabilityMagnetic circuit rotating partsElectric machineEngineering

The invention provides a vibration damping rotor iron core, a vibration damping rotor and an electric machine. The vibration damping rotor iron core comprises an inner rotor iron core and an outer rotor iron core. The outer rotor iron core can be sleeved on the outer periphery of the inner rotor iron core, and a vibration damping space containing vibration damping material can be formed between the inner rotor iron core and the outer rotor iron core. The inner rotor iron core is provided with a first groove along the radial direction, and the outer rotor iron core is also provided with a second groove along the radial direction, and the first groove can be arranged opposite to the second groove. Also included is a bridge core capable of simultaneously penetrating into the first groove andthe second groove to form a circumferential relative positioning of the inner rotor iron core and the outer rotor iron core. The invention can realize the limit of the vibration damping material on the circumference, strengthen the tangential force of the vibration damping material on the circumference, prevent the vibration damping material from falling off due to the force, ensure the reliability of the rotor when the rotor rotates at high speed, and strengthen the reliability of the motor.

Owner:GREE ELECTRIC APPLIANCES INC +1

Method for improving wind power utilization of vertical axis wind turbine blade by using guide strip technology

InactiveCN105041563AEasy to liftIncrease tangential forceRenewable energy generationMachines/enginesOffset distanceTurbine blade

The invention discloses a method for improving wind power utilization of vertical axis wind turbine blade by using a guide strip technology. One guide strip is mounted on each of positions, which are located at 20%, 40%, 60% and 80% of the vertical axis wind turbine blade in a blade stretching direction. Height of the guide strips is 3% of blade chord length and thickness of the guide strips is 1% of the blade chord length. The guide strips extend to the blade tail edge from the blade front edge; and an offset distance front the front point positions of the front edges of the guide strips to final points of the tail edges of the guide strips is 6% of the blade chord length. The method has the effects and beneficial effects that: a flow-through path of airflow of the wind turbine blade is controlled by adopting the blade guide strip technology, so that angles that the airflow enters and leaves the blade are changed, thereby increasing lifting force of the blade and increasing tangential force of the blade simultaneously. The method has the advantages of reducing starting wind velocity of a fan, improving a wind energy utilization coefficient, and the like.

Owner:SHENYANG AEROSPACE UNIVERSITY

A wire bonding process for semiconductor power device packaging

ActiveCN105458434BNo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

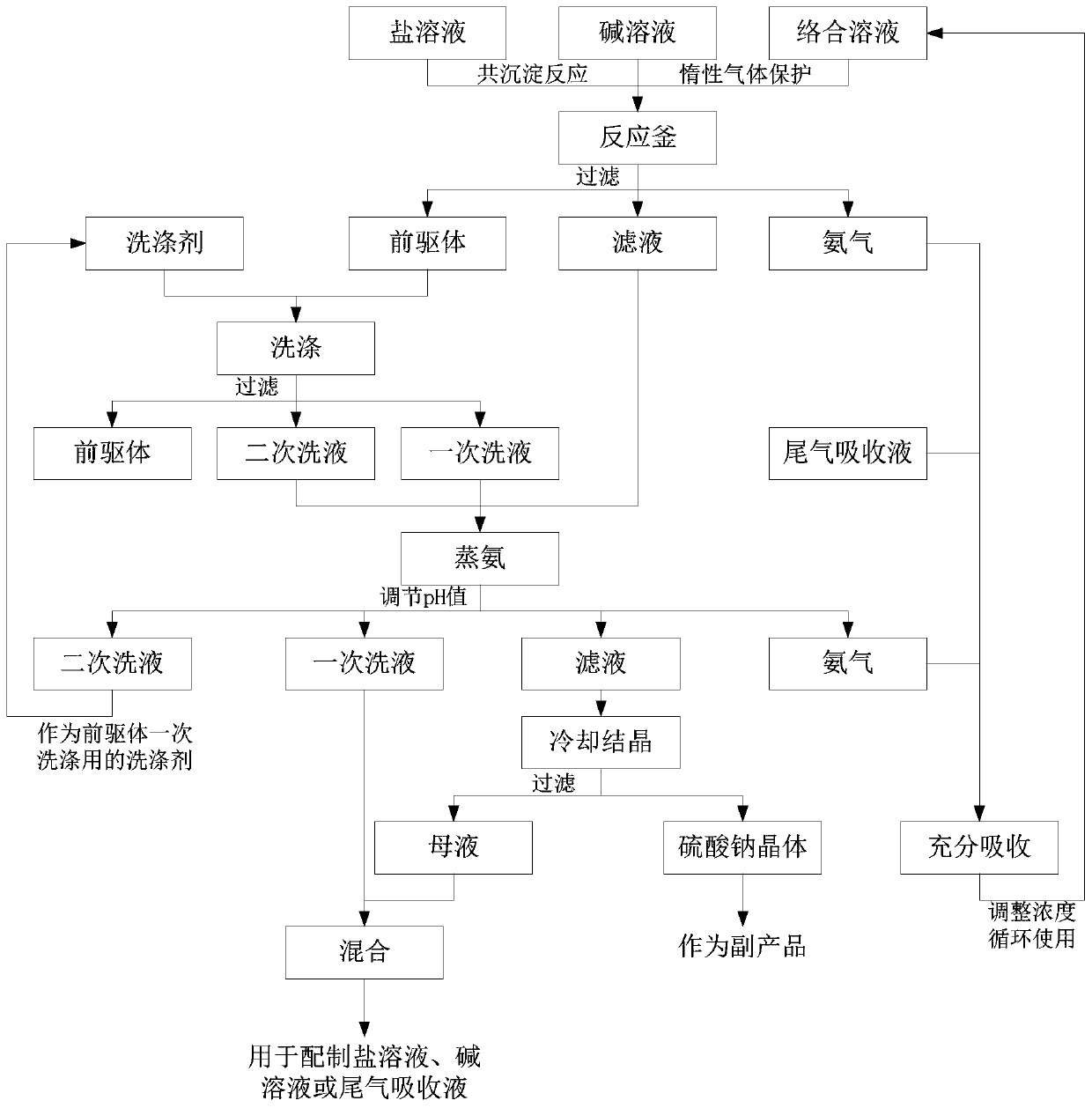

High-tap-density high-nickel ternary precursor as well as preparation method and application thereof

ActiveCN111018007AIncrease energy densityIncrease added valueCell electrodesNickel compoundsNickelSalt solution

The invention provides a high-tap-density high-nickel ternary precursor and a preparation method and an application thereof. The preparation method of the ternary precursor comprises the steps that a,a salt solution and a complexing solution are continuously added to the bottom of a reactor, and when the particle size D50 of a current precursor reaches 10-12 [mu]m, controlling the pH value of a reaction system to be 11.10-11.50; b, controlling the pH value of the reaction system to be 10.50-10.90 when the particle size D50 of the current precursor reaches 8-10 [mu]m; and repeating the step aand the step b for multiple times to obtain the high-tap-density high-nickel ternary precursor with the particle size D50 of 8-12 [mu]m and the tap density of 2.4-2.5 g / mL, thereby solving the problems of difficulty in controlling the size of the precursor, low tap density and the like in the prior art. According to the preparation method of the ternary material precursor, ammonia gas and waste liquid in a system are recycled, sodium sulfate in the system is separated out through cooling crystallization to be used as a by-product, and resource comprehensive utilization of three wastes is achieved.

Owner:大连融科储能集团股份有限公司

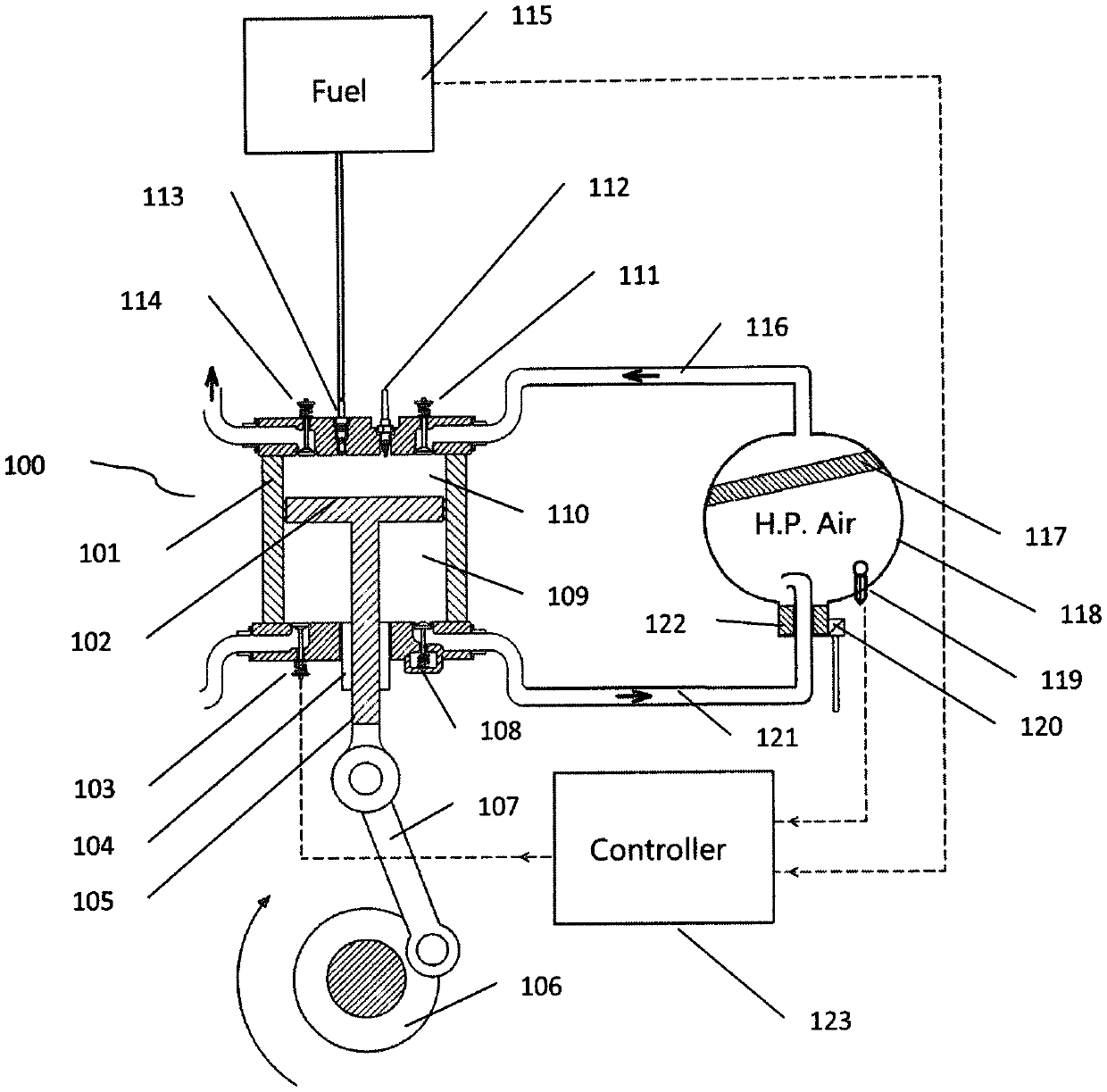

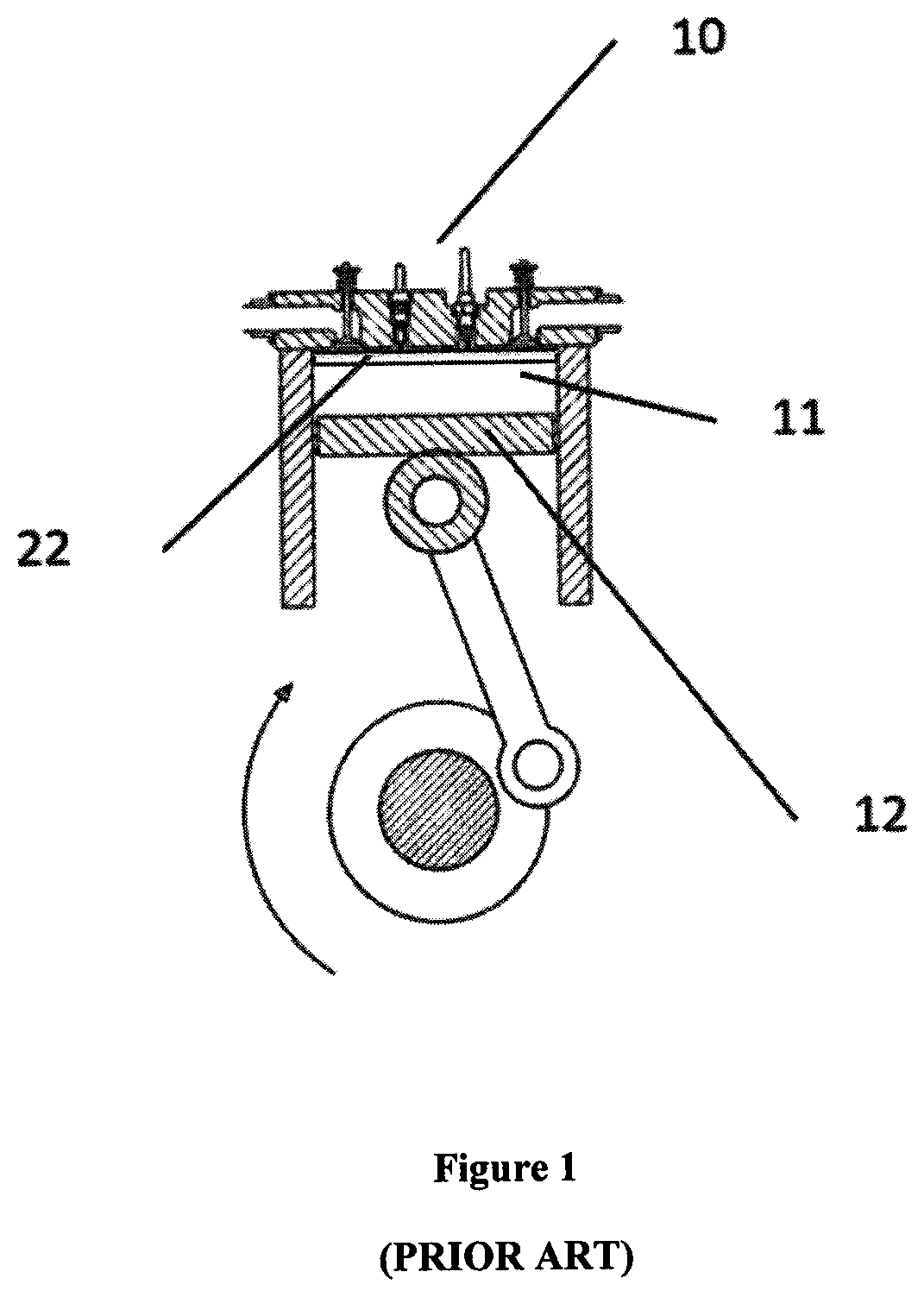

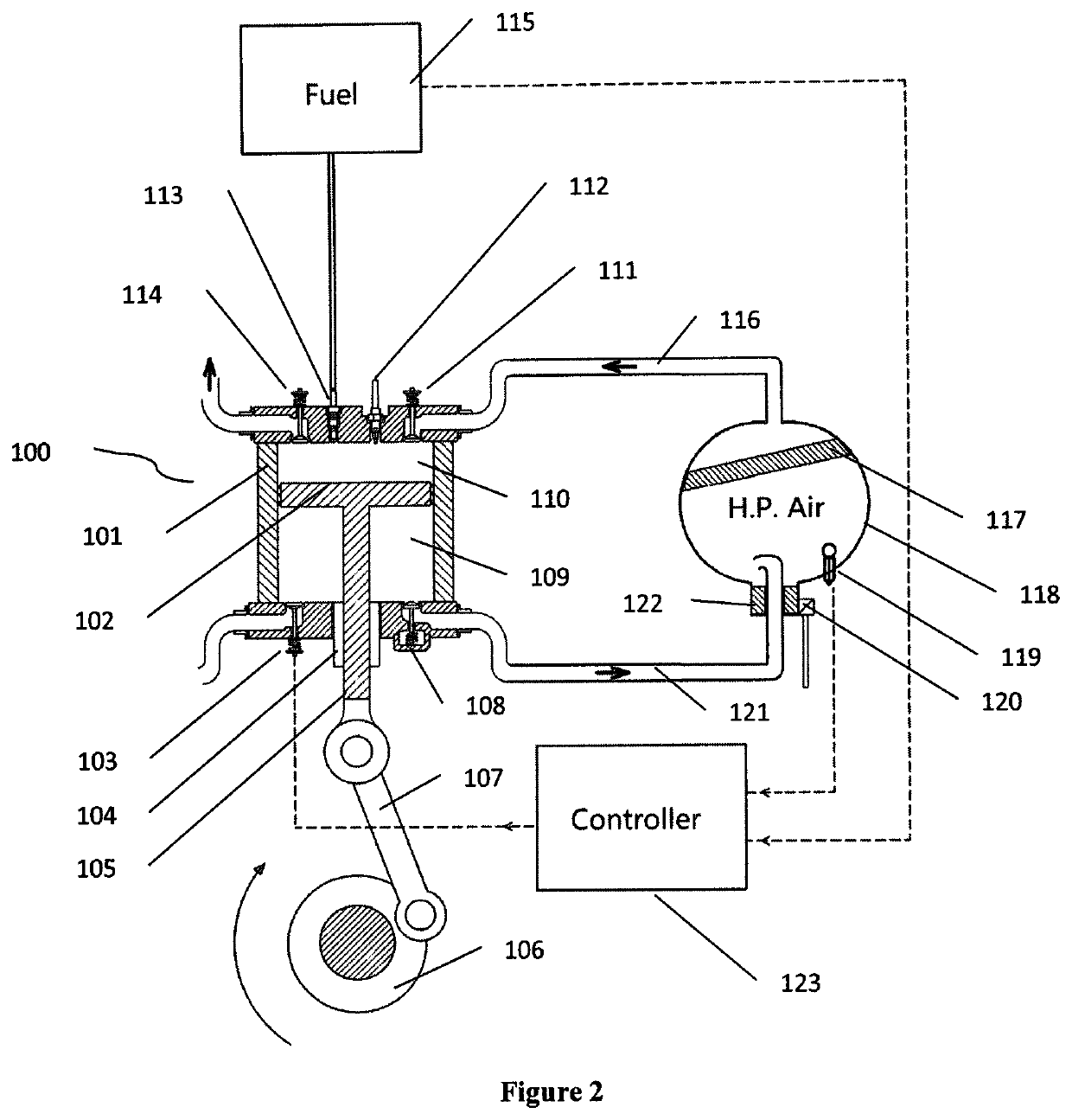

System and method of reciprocating piston engine, multi-fuel piston engine

ActiveUS11078836B1Increase tangential forceReduced clearance volumeInternal combustion piston enginesOutput powerGasolineControl theory

The present disclosure relates to piston engine systems which are no longer restricted by their compression ratios. Rather, a mixture of fuel and pre-compressed air is used to complete the combustion. The pressure of the compressed air is independently controlled. As a result, the clearance volume can be reduced to less than 1 / 50 or to zero, and the piston engine systems can be used with different types of fuels, for example, gasoline, diesel, ethanol, or vegetable oils.

Owner:CANADAVFD CORP LTD

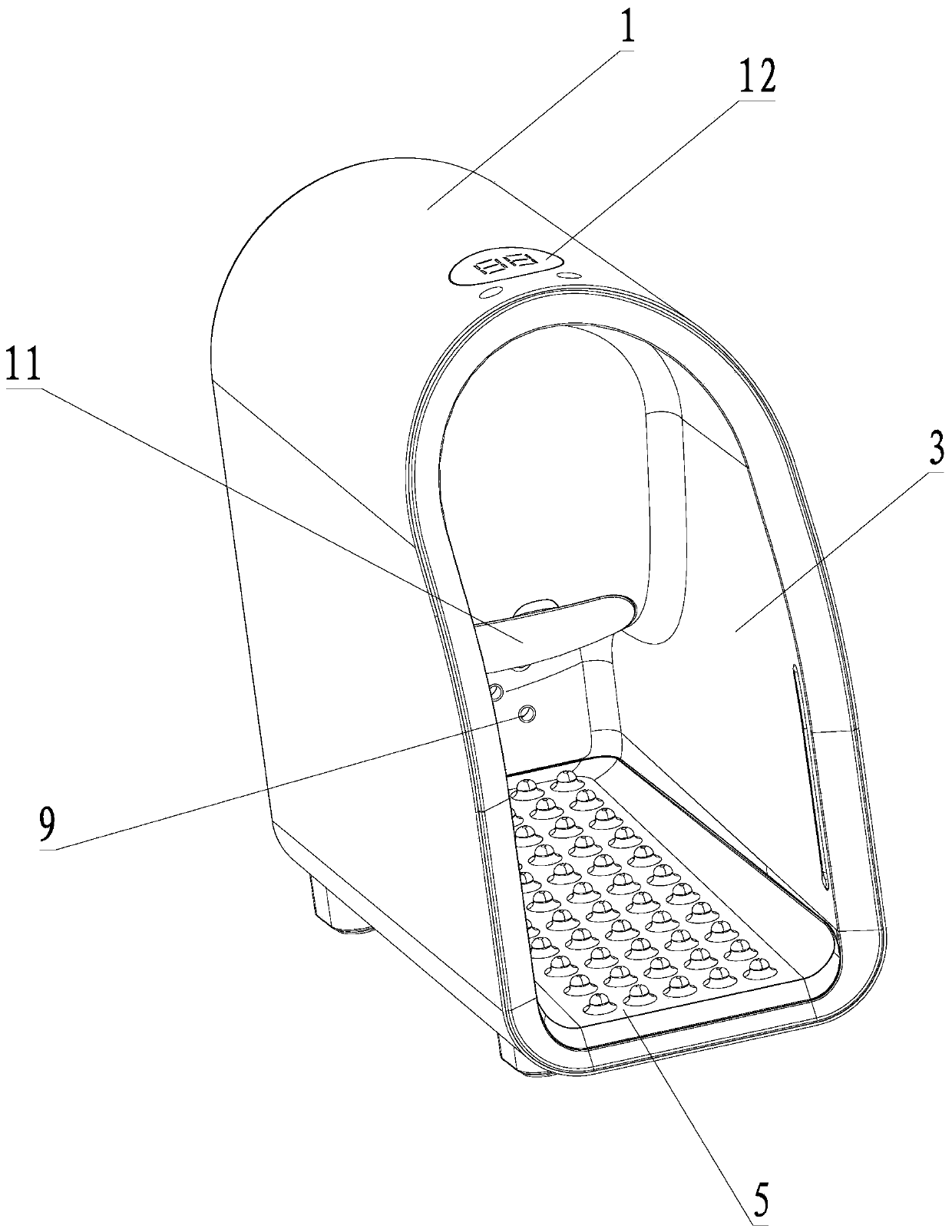

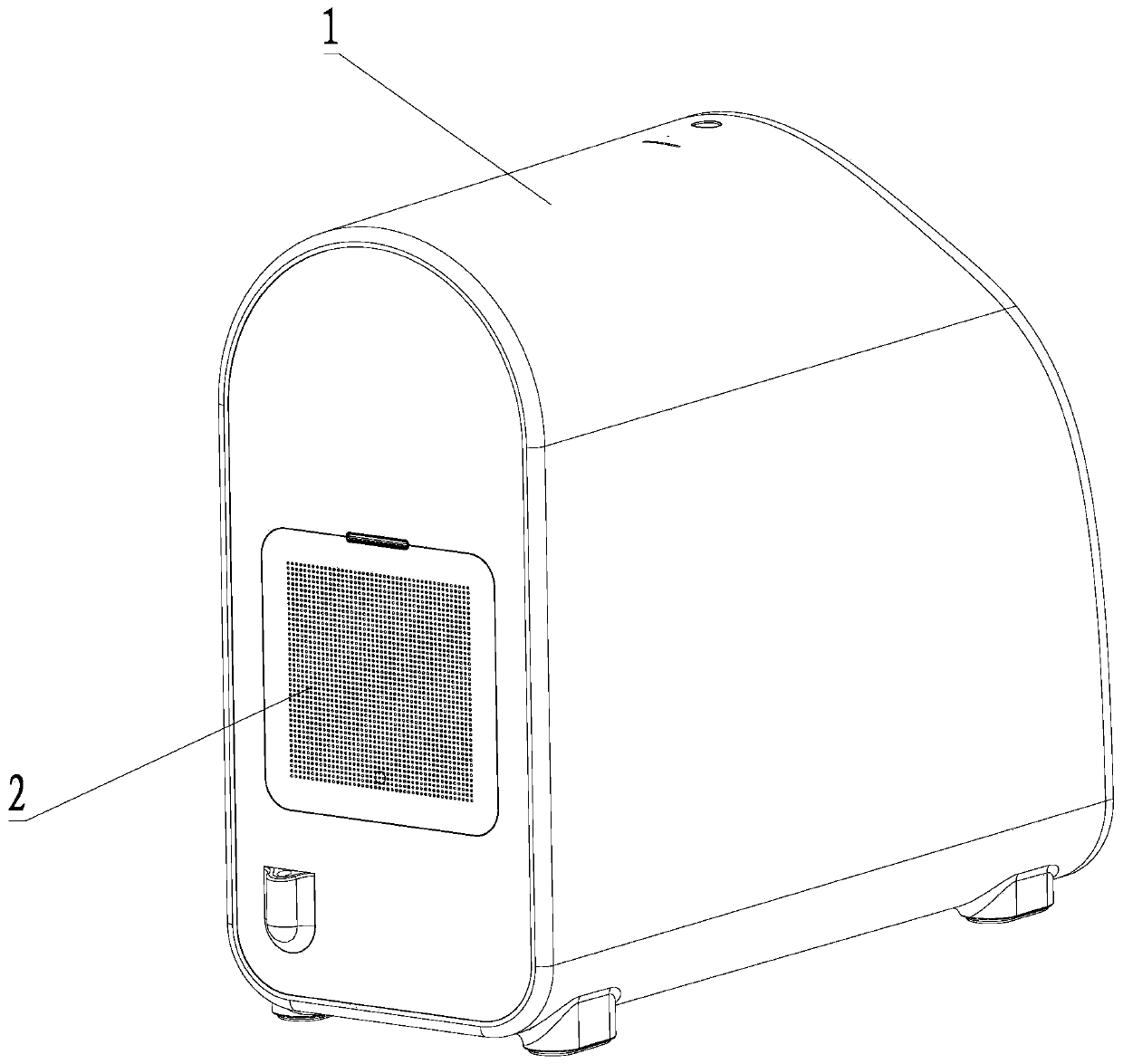

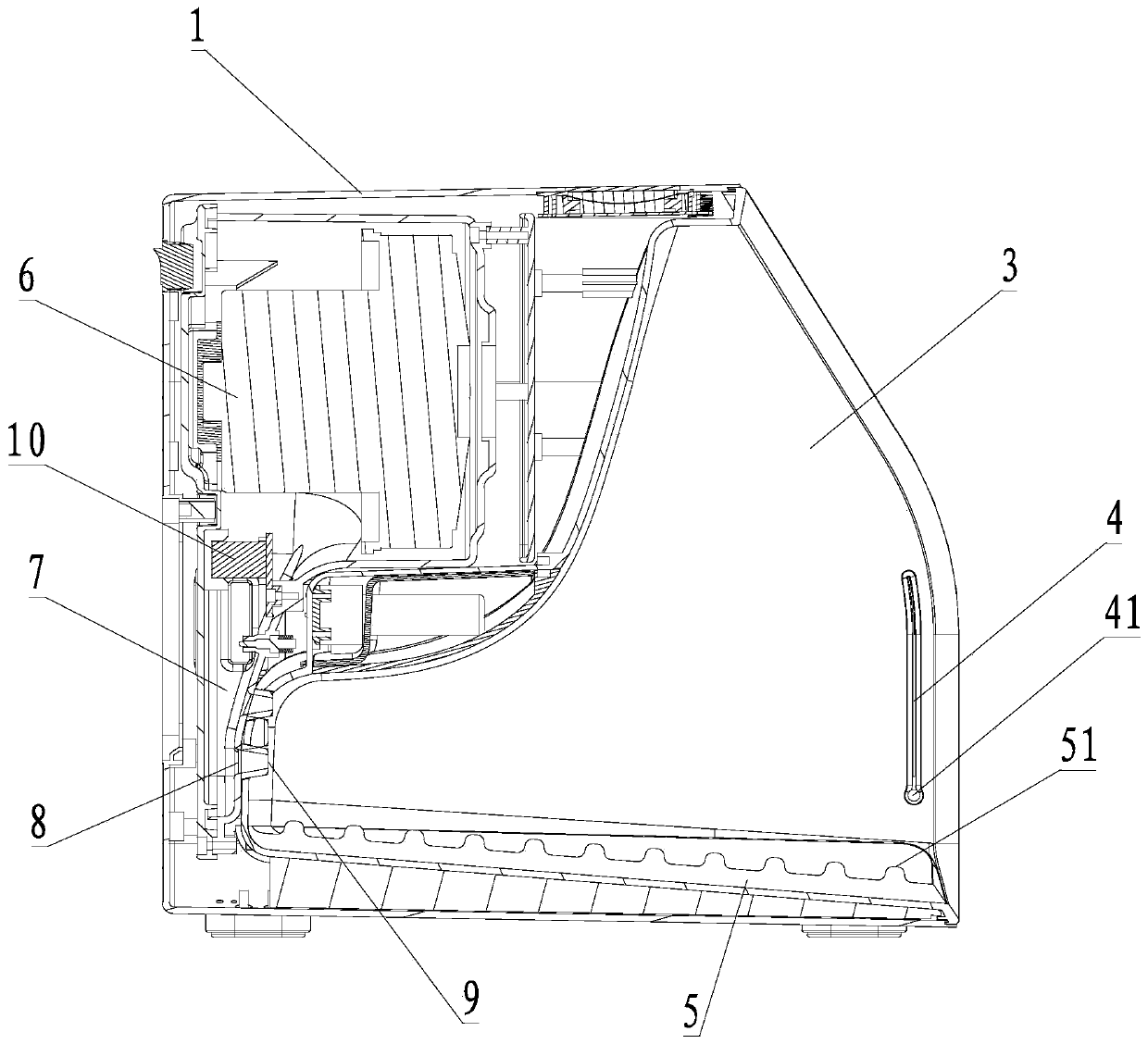

Foot dryer

PendingCN111202459ASimple structureEasy to useLight therapyDomestic applicationsFoot cushionEngineering

The invention provides a foot dryer comprising a shell and a fan. The fan is arranged in the shell, the shell is provided with a containing cavity, the shell is provided with a containing cavity opening corresponding to the containing cavity, the inner wall of the containing cavity is provided with an air outlet, the air outlet is communicated with an air outlet of the fan through an air outlet duct, the outer side of the shell is provided with an air inlet opening, the air inlet opening is communicated with an air inlet of the fan through an air inlet duct, and soft foot pads are arranged atthe bottom of the containing cavity. The foot dryer has the following beneficial effects: the foot dryer is simple in structure and convenient to use; the air outlet in the cavity is used for impacting the foot surface and the tangential force, generated by the airflow impact, of the feet is increased, so that water spots on the foot faces are blown off, the foot drying time is effectively shortened, the foot drying effect is improved; the pneumatic noise at the air outlet is effectively lowered through the design of the air outlet, so that the working noise of the foot dryer is lowered; the comfort degree is improved in cooperation with a soft foot pad at the bottom, so that the user experience is greatly improved.

Owner:DONGGUAN QMS LIGHTING TECH CO LTD

Hydrodynamic force conversion device

ActiveCN106703891ASimple structureEasy to manufactureRotary piston enginesMechanical energyEngineering

The invention provides a hydrodynamic force conversion device, and relates to the field of hydrodynamic force conversion. The hydrodynamic force conversion device comprises a stator, a rotor, an obstruction plate and sliding blocks; the rotor is rotatably connected with the stator, and a ring cavity is formed between the opposite bottom walls of the stator and the rotor; an inlet and an outlet are formed in the stator, the obstruction plate is fixedly connected to the stator and is in sliding connection with the rotor, the obstruction plate is located in the ring cavity and located between the inlet and the outlet, and sliding grooves are formed in the end face, corresponding to the ring cavity, of the rotor; each sliding groove is internally provided with one sliding block; the sliding blocks stretch out of the sliding grooves, the ring cavity is divided into two sub cavities with unequal pressures through the sliding blocks and the obstruction plate, the inlet and the outlet are located in the two sub cavities correspondingly, and the sliding blocks retract into the sliding grooves to cross the obstruction plate. The hydrodynamic force conversion device is simple in structure, and high in conversion efficiency of kinetic energy and mechanical energy.

Owner:唐翊翃

A vibration-damping rotor core, a vibration-damping rotor and a motor

ActiveCN109067031BImprove reliabilityGuaranteed reliabilityMagnetic circuit rotating partsElectric machineTangential force

Owner:GREE ELECTRIC APPLIANCES INC +1

A semi-active rigid-flexible coupling hydraulic exoskeleton

ActiveCN111805513BRealize regulationImprove applicabilityProgramme-controlled manipulatorCylinder headCoupling

The invention discloses a semi-active rigid-flexible coupling hydraulic exoskeleton, which relates to a power assist mechanism in the field of robots, comprising: a waist assembly and a leg assembly; Alloy sleeve, cylinder head, piston, extension spring, oil filler plug, staggered channel valve body, valve body seal seat, valve body end bevel gear, angle sensor, motor mount, DC servo motor, coupling and motor Bevel gear. The present invention can realize the power assist or damping adjustment of two modes of carrying heavy objects and walking with load; in the mode of carrying heavy objects, it can support two carrying modes from high to low and from low to high, and the applicability At the same time, it can provide assistance to the knee joint when the knee joint is naturally flexed in a bent state; a semi-active torque adjustment system is formed by a hydraulic damper and a spring, and the assistance and damping force can be adjusted; light weight, strong man-machine coupling .

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A kind of two-stage feed alkylation reaction process method

ActiveCN104560143BImprove mass transfer efficiencyEnhanced mass transferLiquid hydrocarbon mixtures productionHydrocarbonsThermodynamicsEmulsion

The invention discloses a two-stage feeding alkylation reaction method. Concentrated sulfuric acid and isobutane enter a colloid mill and are fully mixed to form an emulsion; the emulsion enters with mixed hydrocarbons containing C3-C5 olefins and isobutane The reaction is carried out in the alkylation reactor; the reactor includes a cylinder, a head, an inner rotating bed, an outer rotating bed, a feed pipe, a feed distribution pipe, a material outlet, a circulating cooling gas inlet, and a circulating cooling gas outlet; the inner rotating The bed is connected to the upper driving device through the feed pipe, the upper part of the inner rotating bed and the feed distribution pipe are fixedly connected by a sealing member, and the upper part of the outer rotating bed is fixedly connected to the reactor shell through a sealing member. The bed is connected to the lower drive unit through a rotating shaft. The alkylation reaction method of the invention can greatly increase the mixing degree of isobutane and concentrated sulfuric acid, can ensure that the reaction is carried out at a lower temperature, has low reaction acid consumption, high product quality, and small equipment scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of lead solder solder for semiconductor power device packaging and its preparation method and application

ActiveCN105499829BFirmly connectedAvoid heat damageSolid-state devicesWelding/cutting media/materialsManufacturing technologyCopper

The invention discloses lead welding brazing filler metal for packaging of a semiconductor power device and a preparation method and application thereof, and belongs to the technical field of packaging and manufacturing of semiconductor power devices. The brazing filler metal is brazing filler metal for a copper or aluminum lead; the brazing filler metal for the copper lead (wt.%) comprises 20-29% of Cu, 10.0-20.0% of Al, 2.0-11.0% of Ag, 2.0-5.0% of Bi, 3.0-9.0% of Sb, 3.0-9.0% of In and the balance of Sn; and the brazing filler metal for the aluminum lead (wt.%) comprises 21.0-29.0% of Cu, 18.0-27% of Al, 2.0-9.0% of Ag, 2.0-3.5% of Bi, 6.0-8.0% of Sb, 6.0-8.0% of In and the balance of Sn. In a lead welding process of the brazing filler metal for packaging of the semiconductor power device, the welding temperature is 280-320 DEG C to directly melt and moisten an aluminum pad and a frame to realize stable and reliable connection among the three.

Owner:王伟

A kind of alkylation reactor and the method of alkylation reaction

ActiveCN104549114BFully dispersedBoost octaneLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferEngineering

The invention discloses an alkylation reactor and an alkylation reaction method. The alkylation reactor comprises a reactor drum body, a sealing head, an inner rotating bed, an outer rotating bed, a feeding pipe, a fed material distributing pipe, a discharging opening, a circular cooling gas inlet and a circular cooling gas outlet, wherein the reactor drum body and the sealing head form a closed shell; the inner rotating bed is arranged in the middle in the shell; the fed material distributing pipe is arranged in a central hollow drum structure of the inner rotating bed and is communicated with the feeding pipe; a feeding mixer is arranged at the connecting position of the feeding pipe and the sealing head; the discharging opening is formed in the lower part of the shell; the inner rotating bed is connected with a driving device by the feeding pipe; the outer rotating bed is arranged at the outer side of the inner rotating bed; the upper end of the inner rotating bed and the fed material distributing pipe are connected into an integrated structure by a sealing member; the outer rotating bed and the shell are fixedly connected; and the outer rotating bed is connected with the driving device at the lower part by a rotating shaft. The alkylation reactor and the alkylation reaction method disclosed by the invention have the advantages that concentrated sulfuric acid is adopted as a catalyst, iso-butane and olefin are adopted as materials to carry out alkylation reaction, the reaction can be carried out under low temperature, the acid consumption is low and the quality of a product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil scraper ring for pistons of internal combustion engines

The invention relates to an oil scraper ring for pistons of internal combustion engines, said oil scraper ring comprising a disc (1) that is provided with parallel flanks and a bearing surface (h) having an asymmetrical crowned form with a vertex line (3) extending over the periphery of the disc. A bracing spring (4) arranged in a ring groove (7) of the piston and comprising a spring groove side (6) opposing the piston head and a spring groove side (5) facing the piston head presses the disc (1) radially against the cylinder wall (8). The aim of the invention is to achieve an improved oil scraping action compared to that of prior art, while reducing the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides (5, 6) extends at an angle (ss) in relation to the piston axis (10) in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface (h) of the disc (1) being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring (1) is mounted in the piston, the vertex line (3) of the bearing surface (h) is oriented in the direction of the ring groove side (6) opposing the piston head.

Owner:MAHLE GMBH

Oil scraper ring for pistons of internal combustion engines

InactiveCN100427815CReduce wearImprove efficiencyPiston ringsMachines/enginesScraping - actionCombustion

Owner:MAHLE GMBH

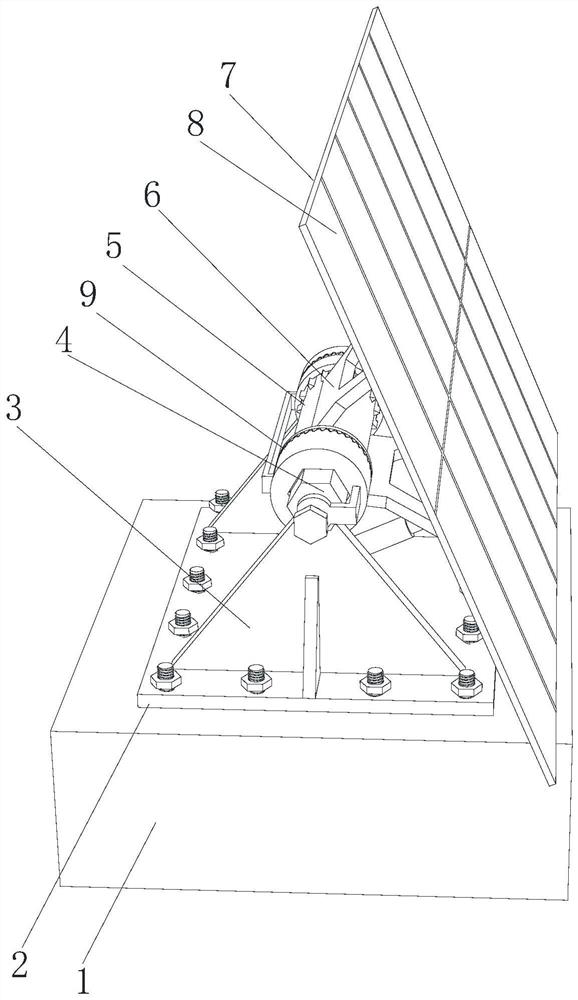

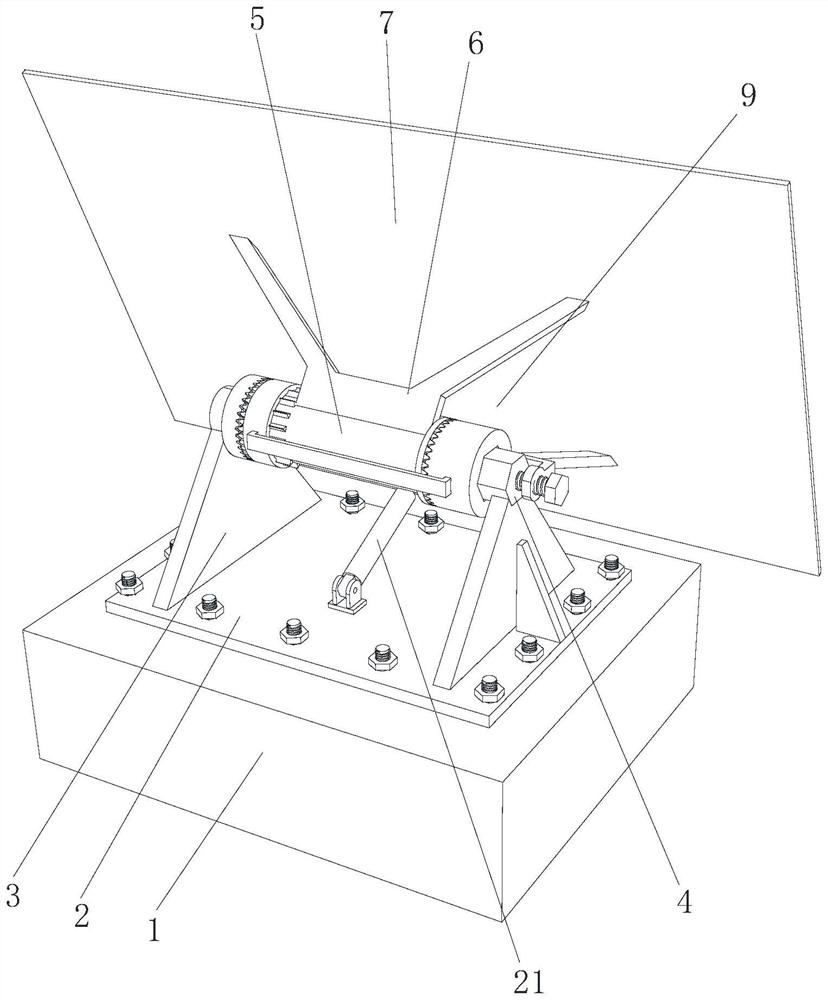

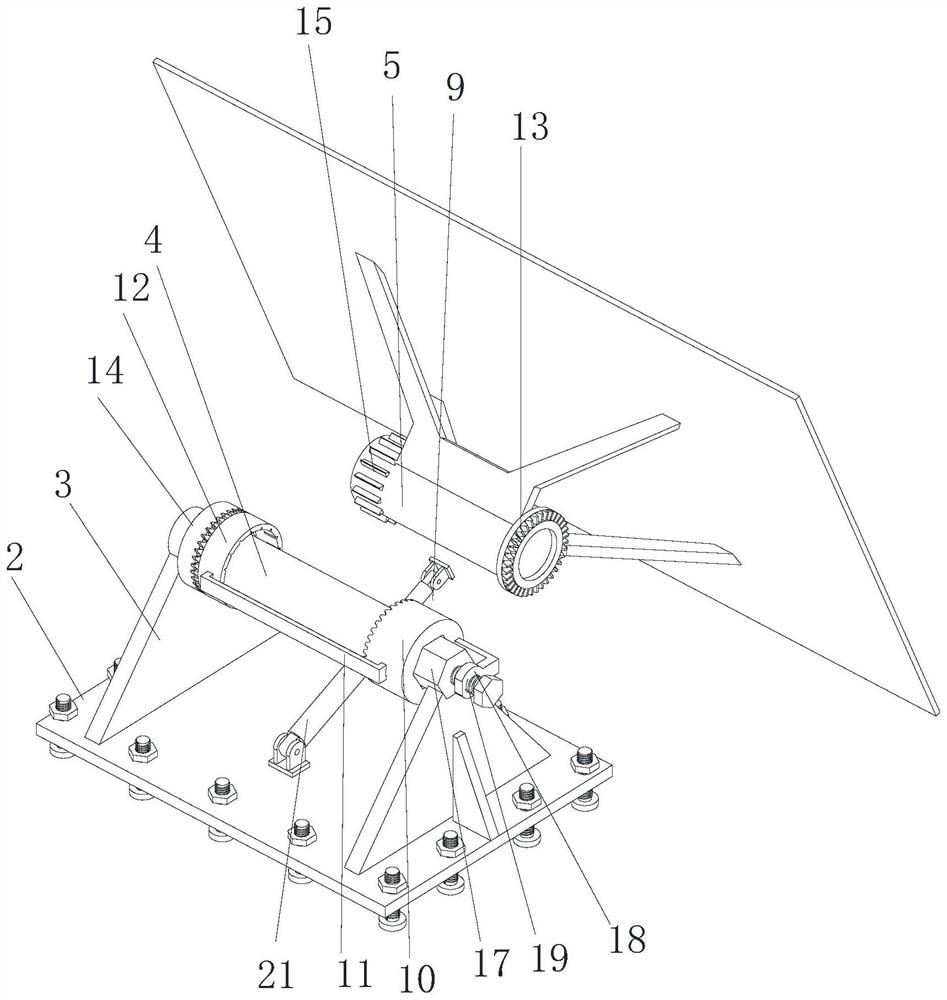

Mounting and fixing device for photovoltaic panel

PendingCN114665804AIncrease the areaIncrease connection areaPhotovoltaic supportsPhotovoltaic energy generationSolar energy conversion efficiencyStructural engineering

The invention discloses a photovoltaic panel mounting and fixing device which comprises a base, a base is fixedly connected to the base through bolts, a pair of supporting plates are arranged on the base, a fixing shaft is fixedly connected between the supporting plates on the two sides, a rotating shaft sleeve is rotationally connected to the outer side of the fixing shaft, and a bottom plate is fixedly connected to the rotating shaft sleeve through a connecting support. A group of photovoltaic panels are fixedly connected to the surface of the side, back on to the base, of the bottom plate, locking sleeves are transversely and slidably connected to the fixing shaft and comprise the left locking sleeve and the right locking sleeve, the left locking sleeve and the right locking sleeve are fixedly connected through a fixing rod, the left end of the fixing shaft is fixedly connected with a left locking seat, and the right end of the rotating shaft sleeve is fixedly connected with a right locking seat; and the left locking sleeve and the left locking seat as well as the right locking sleeve and the right locking seat are clamped and matched through an annular fluted disc. The problem that an existing photovoltaic panel is low in solar energy conversion efficiency can be solved, and the photovoltaic panel is convenient to adjust, high in structural stability, large in photovoltaic panel bearing area and worthy of popularization.

Owner:华能青海发电有限公司

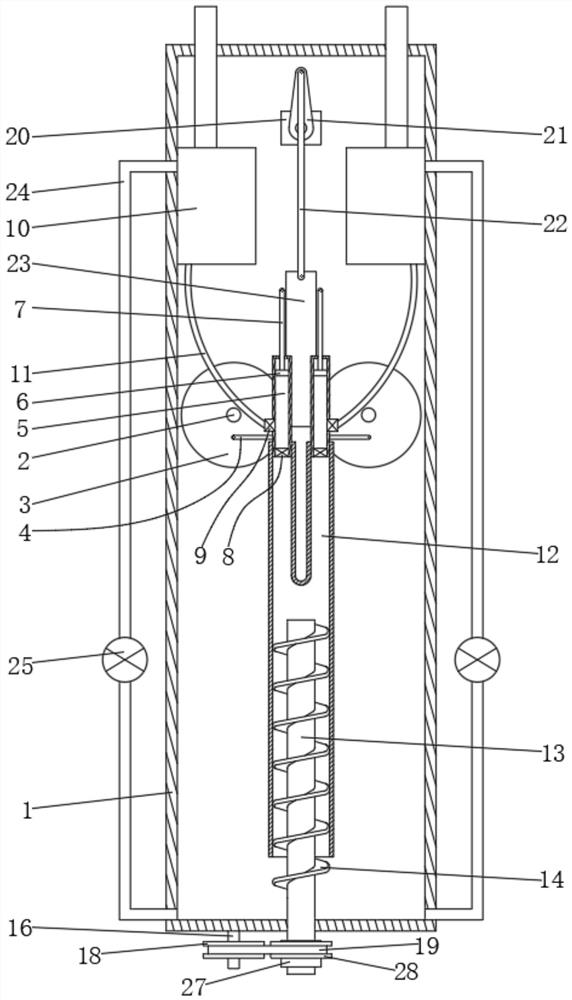

A kind of hemodialysis ab liquid tube multi-functional placement disinfection equipment and its use method

ActiveCN111906099BTo achieve the effect of disinfection and cleaningBig impactHollow article cleaningLavatory sanitoryGear wheelEngineering

The invention discloses a hemodialysis AB liquid tube multi-functional placement and disinfection equipment, which includes a placement box, the surfaces of two pendulum shafts are fixedly connected with gears, and a driving mechanism for driving the two gears to swing back and forth is arranged in the placement box. The surfaces of the two gears are all hinged with transmission arms, the opposite sides of the two transmission arms are fixedly connected with piston cylinders, the inner walls of the two piston cylinders are all slidingly connected with pistons, the upper surfaces of the two pistons are all fixedly connected with piston rods, and the pistons The top of the barrel is provided with a through hole for the piston rod to pass through and slide. The upper ends of the two piston rods are hinged with the inner wall of the storage box. Cleaning parts are arranged in the storage box. The three ports of the AB liquid pipe are respectively socketed in the At the barrel mouths of the two piston barrels and on the cleaning component, any swing shaft protrudes from the back side of the placement box, and is connected with the cleaning component through the transmission component. The invention has the effect of disinfecting and cleaning the inner wall of the AB liquid pipe through mechanical operation.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com