Vibration damping rotor iron core, vibration damping rotor and electric machine

A technology of rotor iron core and iron core, applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of motor vibration reduction performance, vibration reduction material falling off, motor quality abnormality, etc., to achieve enhanced reliability , Strengthen the tangential force and ensure the reliability of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

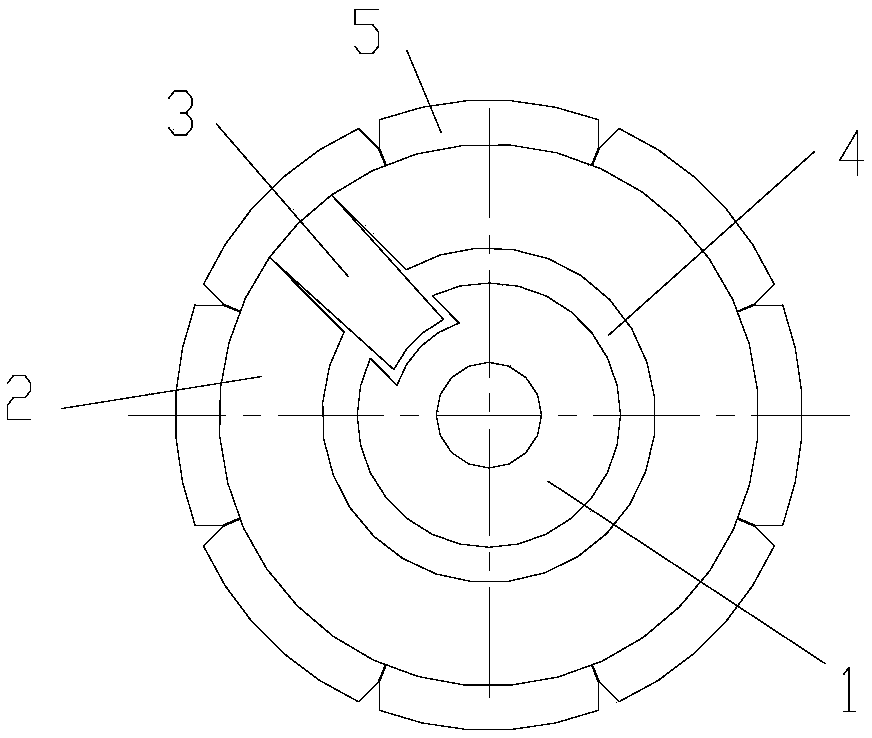

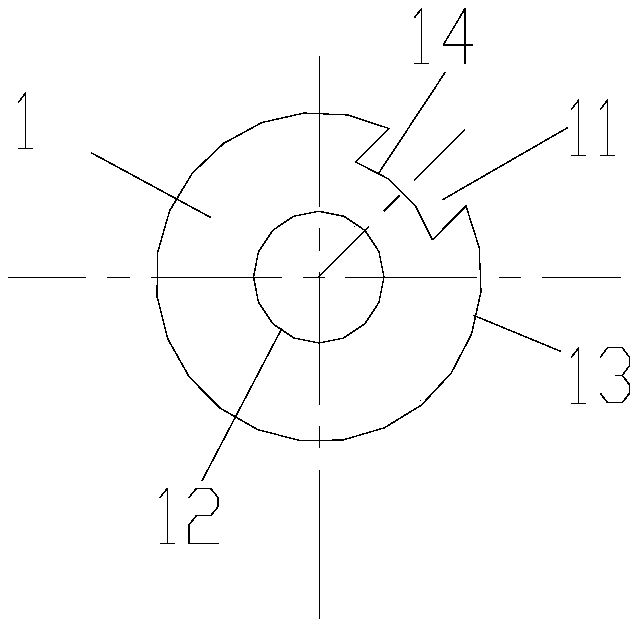

[0045] like Figure 1-8 As shown, the present invention provides a vibration-damping rotor core, which includes:

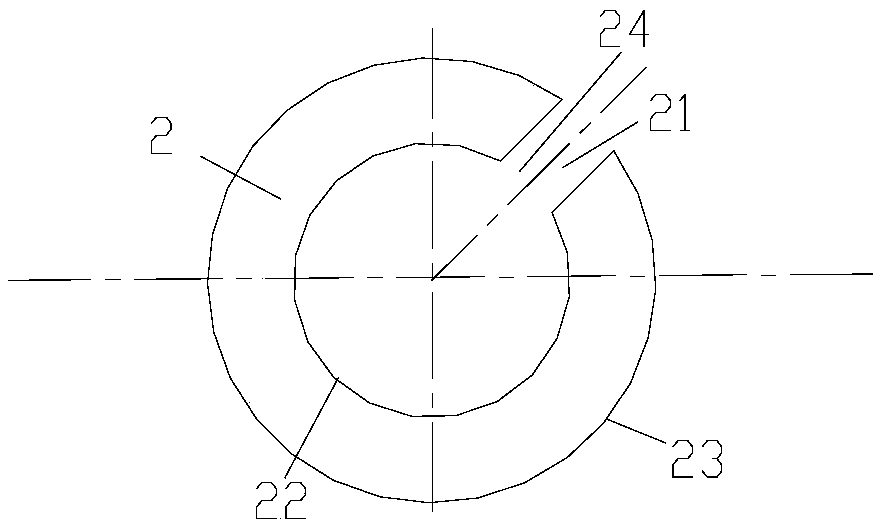

[0046] The inner rotor core 1 and the outer rotor core 2, the outer rotor core 2 can be sleeved on the outer periphery of the inner rotor core 2, and the inner rotor core 1 and the outer rotor core 2 A damping space for accommodating the damping material 4 can be formed between them;

[0047] The inner rotor core 1 is provided with a first groove 11 along the radial direction, and the outer rotor core 2 is also provided with a second groove 21 along the radial direction, and the first groove 11 can be connected with The second groove 21 is oppositely arranged;

[0048] It also includes a bridge iron core 3, which can be penetrated into the first groove 11 and the second groove 21 at the same time to form a circumferential gap between the inner rotor core 1 and the outer rotor core 2. relative positioning.

[0049]The present invention adopts the first groove p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com