High-tap-density high-nickel ternary precursor as well as preparation method and application thereof

A technology of tap density and precursors, which is applied in the field of high-nickel ternary precursors, can solve the problems of low tap density of ternary precursors, ineffective utilization of three wastes, and high energy consumption, etc., to improve the particle size of precursors, Good uniformity and the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

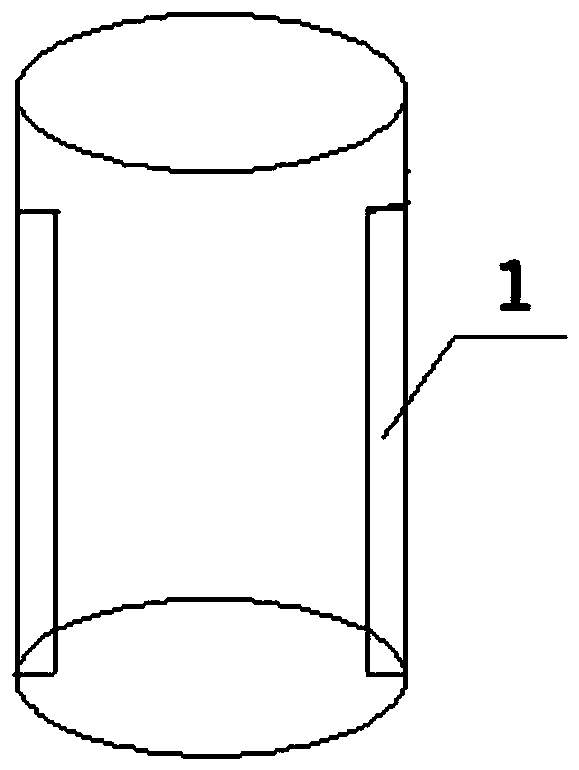

[0045] This embodiment discloses a method for preparing a high-tap density and high-nickel ternary precursor. The method adopts such as figure 2 As shown in the container, the reactor is a cylindrical reactor, and two baffles 1 are longitudinally symmetrically arranged on the inner wall of the cylindrical reactor, and the baffles 1 extend radially, and the baffles 1 The ratio of the radial length to the inner diameter of the cylindrical reactor is 1.5:10; the center of the inner bottom of the cylindrical reactor is provided with a stirring device.

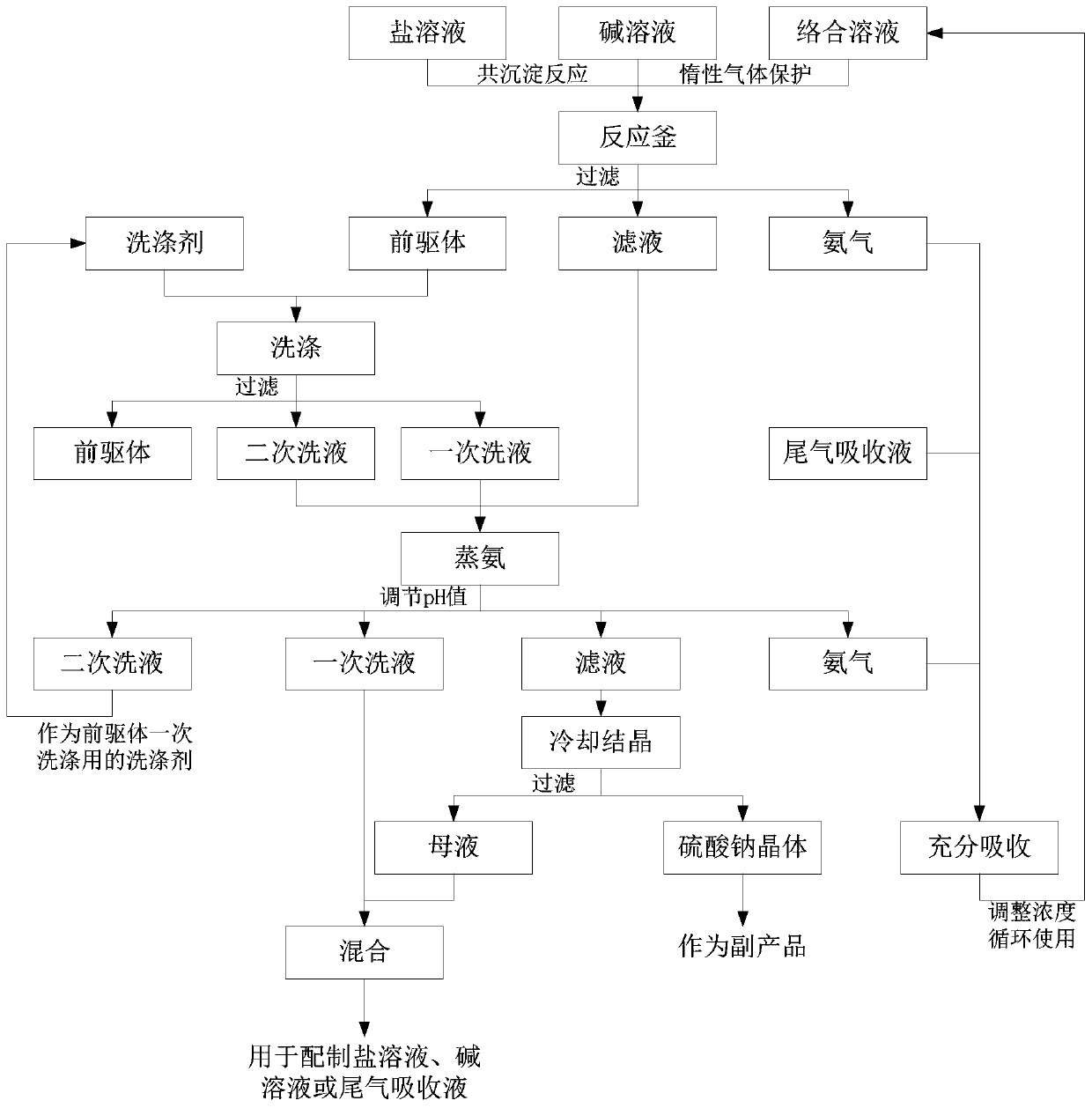

[0046] High tap density and high nickel ternary precursor preparation method, such as figure 1 shown, including the following steps:

[0047] Dissolve nickel sulfate hexahydrate, cobalt sulfate heptahydrate, and manganese sulfate monohydrate in pure water according to the molar ratio Ni:Co:Mn=6:2:2, and prepare a salt solution with a total concentration of three metal ions of 2mol / L .

Embodiment 2

[0054] This example discloses a method for preparing a high-tap density and high-nickel ternary precursor, using the same reactor as in Example 1, including the following steps:

[0055] Dissolve nickel sulfate hexahydrate, cobalt sulfate heptahydrate, and manganese sulfate monohydrate in pure water according to the molar ratio Ni:Co:Mn=6:2:2, and prepare a salt with a total concentration of three metal ions of 1.5mol / L solution.

[0056] Dissolve sodium hydroxide in pure water to prepare an alkaline solution with a concentration of 4 mol / L.

[0057] Dissolve ammonium sulfate in pure water to prepare a concentration of 5mol / L (as NH 4 + meter) complexing agent solution.

[0058] Nitrogen is used as the protective gas for the reaction, and its flow rate is controlled to be 50L / h. The salt solution, complex solution and alkali solution are respectively added to the bottom of the reaction kettle through a peristaltic pump for coprecipitation reaction, and the feeding speed of ...

Embodiment 3

[0062] This embodiment discloses a method for preparing a high-tap density high-nickel ternary precursor, including the following steps:

[0063] Dissolve nickel sulfate hexahydrate, cobalt sulfate heptahydrate, and manganese sulfate monohydrate in pure water according to the molar ratio Ni:Co:Mn=6:2:2, and prepare a salt solution with a total concentration of three metal ions of 3mol / L .

[0064] Dissolve sodium hydroxide in pure water to prepare an alkaline solution with a concentration of 6 mol / L.

[0065] Dissolve ammonium sulfate in pure water to prepare a concentration of 6mol / L (as NH 4 + meter) complexing agent solution.

[0066] Nitrogen is used as the protective gas for the reaction, and its flow rate is controlled to be 150L / h. The salt solution, complex solution and alkali solution are respectively added to the reaction kettle through a peristaltic pump for coprecipitation reaction, and the feeding speed of the salt solution is controlled to match the ammonium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com