Oil scraper ring for pistons of internal combustion engines

A technology for oil scraping rings and internal combustion engines, applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as wear, increase fuel consumption, and reduce the efficiency of internal combustion engines, so as to achieve improved efficiency, improved oil scraping performance, and reduced axial height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

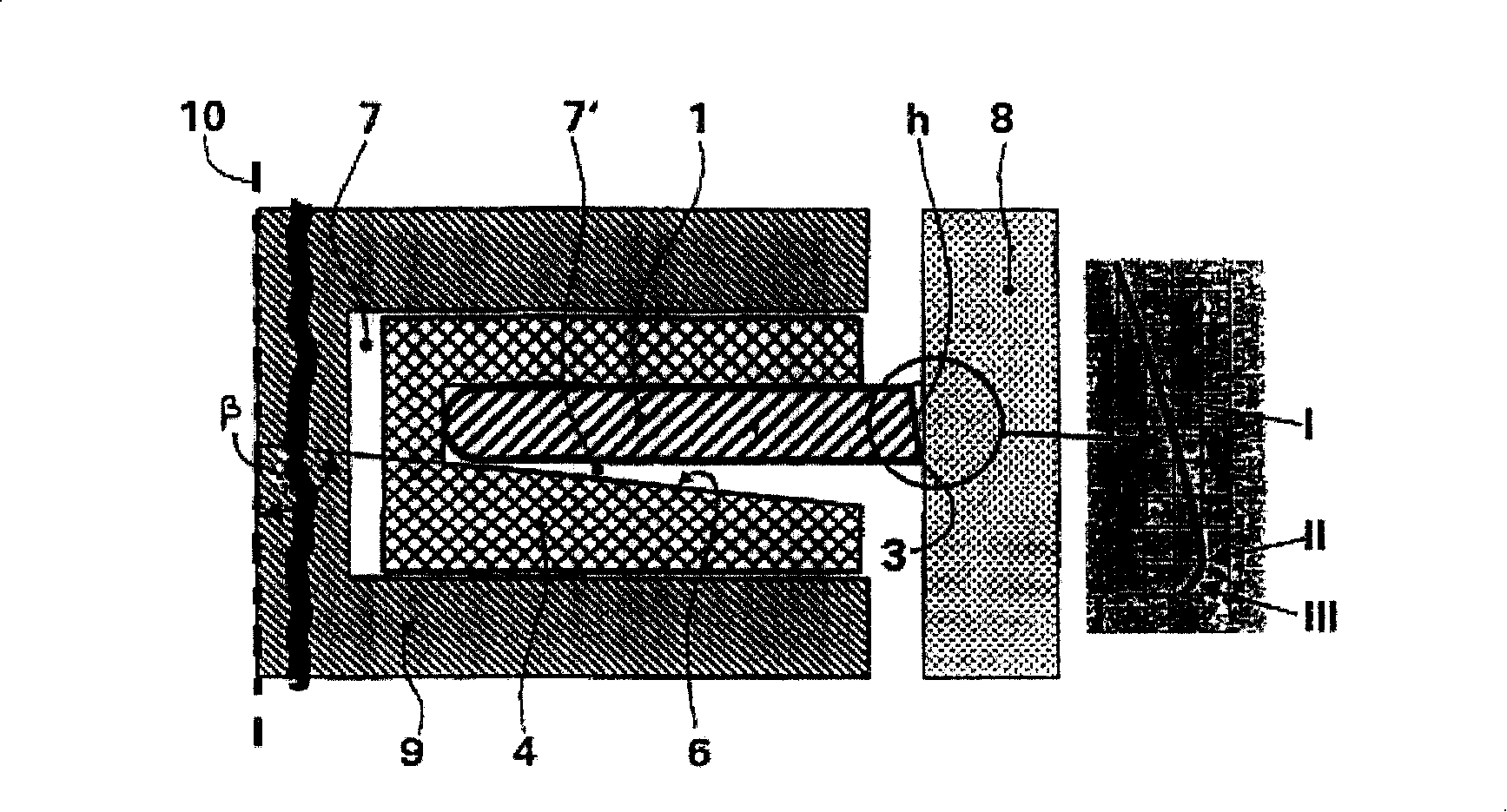

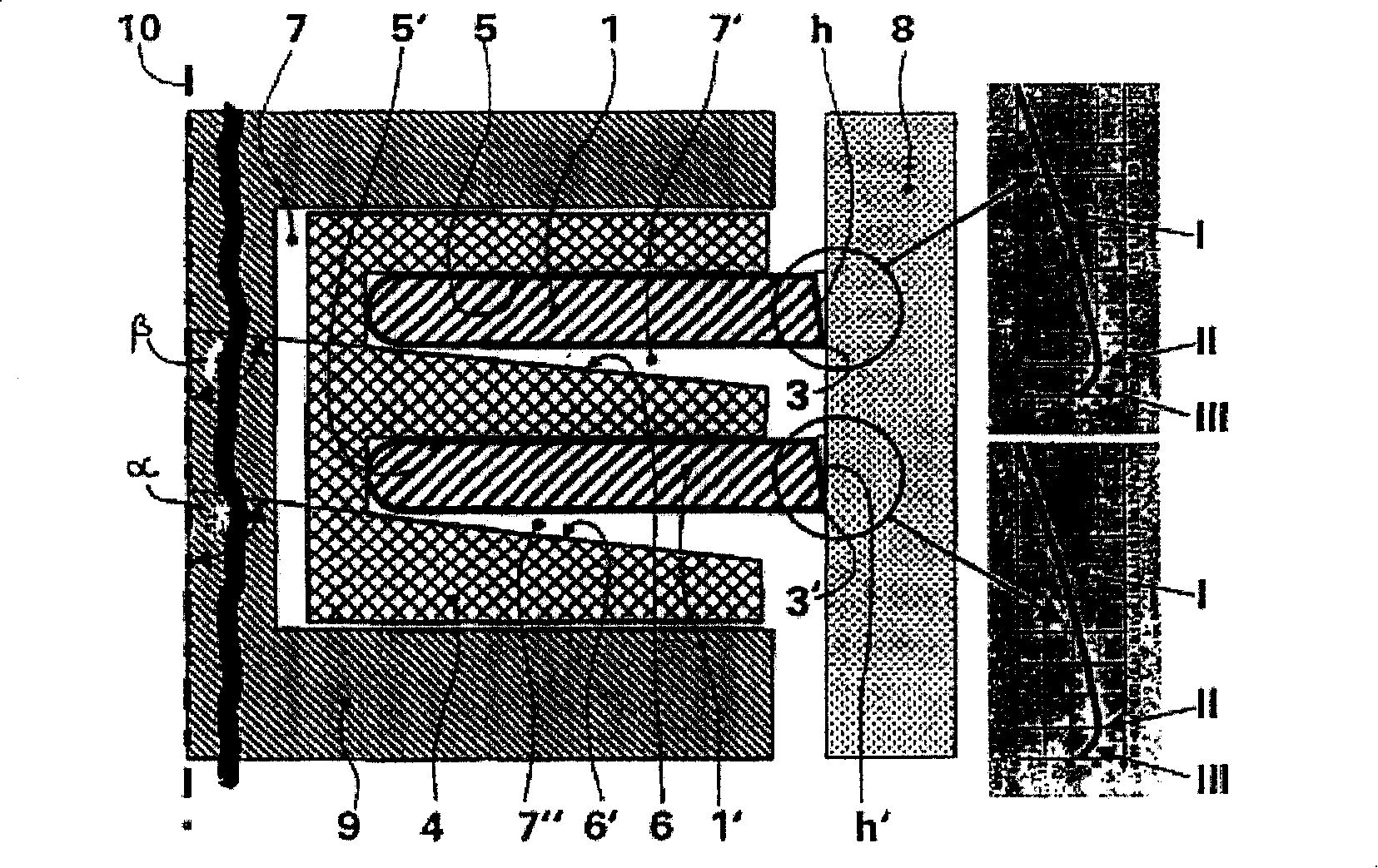

[0026] Such as figure 1 It can be seen that an oil wiper ring consists of a disk 1 and an expansion spring 4 which presses the disk radially against a cylinder wall 8 . Expansion spring 4 is installed in an annular groove 7, and this annular groove has two sides that become 90 degrees with piston shaft 10, and this expansion spring has the shape and size corresponding to annular groove. The expansion spring has a first reed groove 7' which has a reed groove side 5 representing the side facing the top side of the piston and a reed groove side 6 representing the side facing away from the top side of the piston. According to the invention, the spring groove side 5 facing the piston crown is arranged at 90° to the piston shaft 10, wherein the spring groove flank 6 facing away from the piston crown extends obliquely at an angle β away from the piston crown to the spring outer circumference. Preferably, the angle β is 85° to 87°.

[0027] According to the invention, the disk 1 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com