Sliding chute and crankshaft linked engine transmission mechanism

A technology of transmission mechanism and engine, applied in the direction of machine/engine, transmission device, mechanical equipment, etc., can solve the problems of reducing piston work efficiency, increasing uneven friction and impact, accelerating cylinder wall, etc., to achieve power transmission and movement mode. Reasonable conversion, reduce vibration and noise, avoid the effect of lateral friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

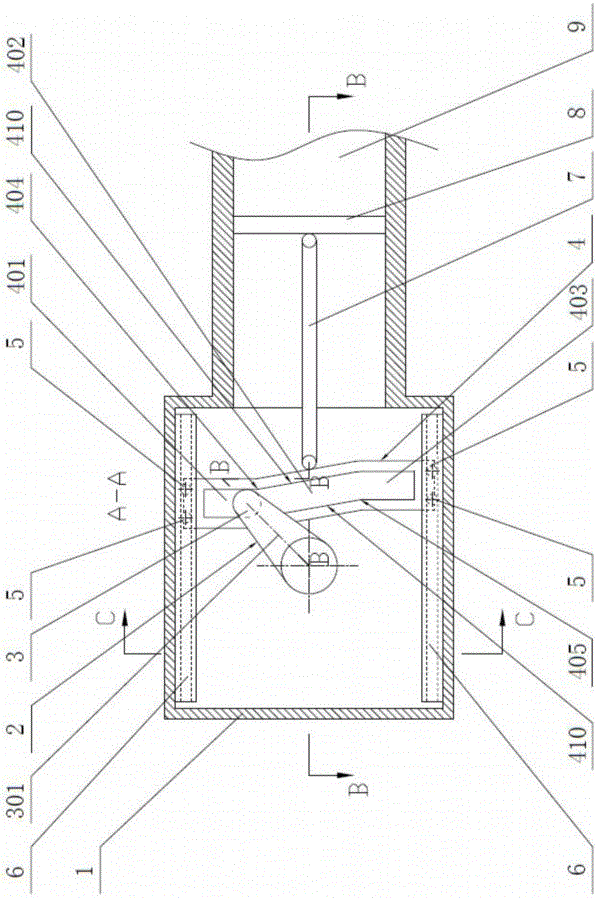

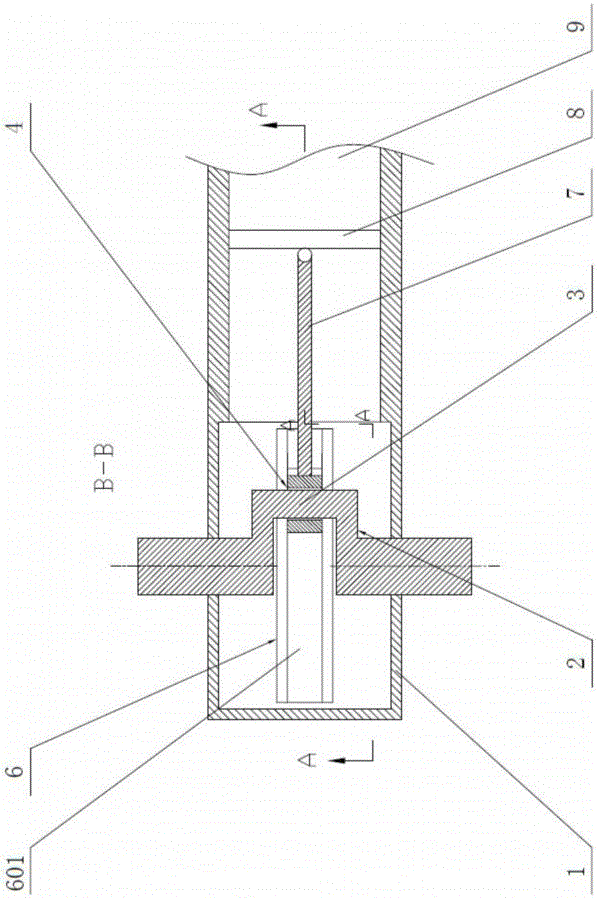

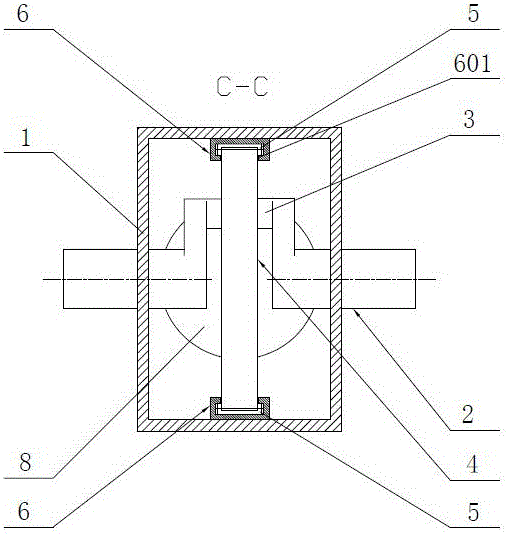

[0040] The specific implementation of the engine transmission mechanism in which the chute is linked with the crankshaft provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0041] The structure of the first embodiment of the present invention is as follows:

[0042] like figure 1 , 2 , 3, the crankshaft 2 is installed on the front and rear side walls of the housing 1, the distance from the axis of the crankshaft 2 to the axis of the journal 3 of the crankshaft 2 is the radius of rotation 301 of the journal 3, and the connecting rod chute closed at both ends 4 is set on the journal 3, the width of the connecting rod chute 4 is equal to the diameter of the journal 3, the two ends of the connecting rod chute 4 are provided with drag-reducing rollers 5, and the upper and lower inner walls of the housing 1 are respectively provided with shape In the same guide chute 6, the drag r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com