Oil scraping device

An oil scraping device and oil scraping roller technology, applied in the workpiece cleaning device, workpiece surface treatment equipment, metal rolling and other directions, can solve the problem that the water on the strip surface is not removed, the oil scraping roller is difficult to scrape clean, and the strip surface is rusted. and other problems, to achieve the effect of shortening the time of roll change, compact structure and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

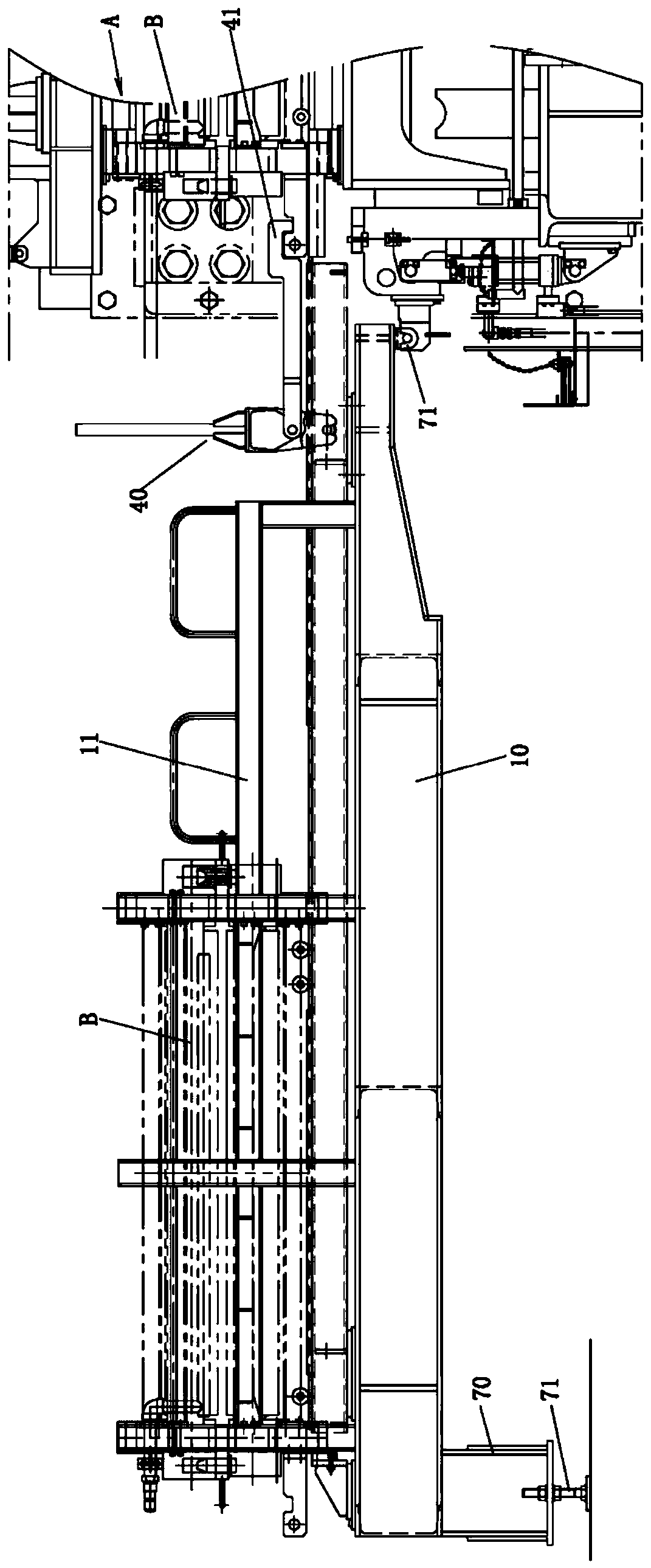

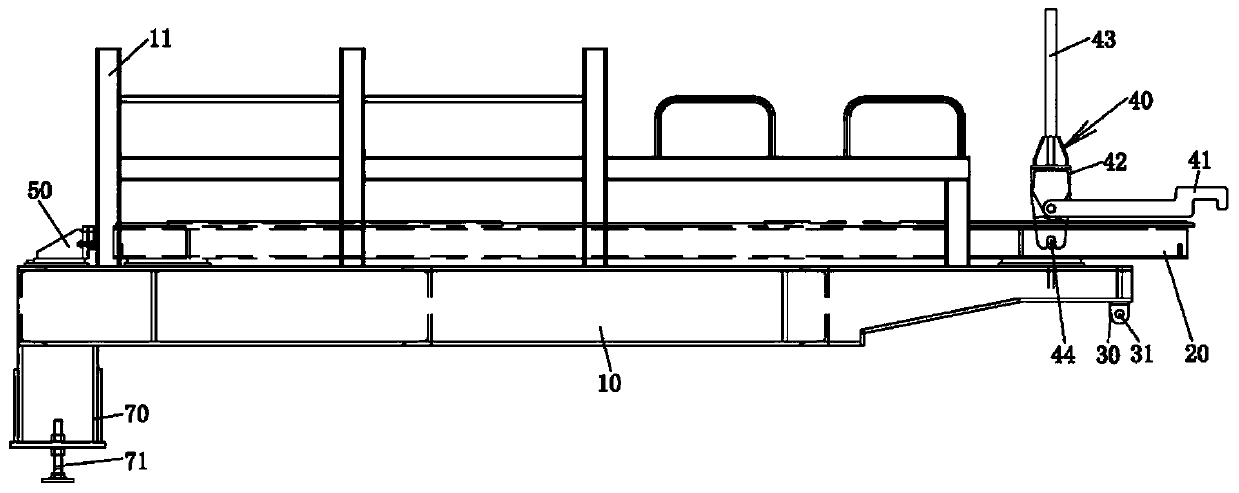

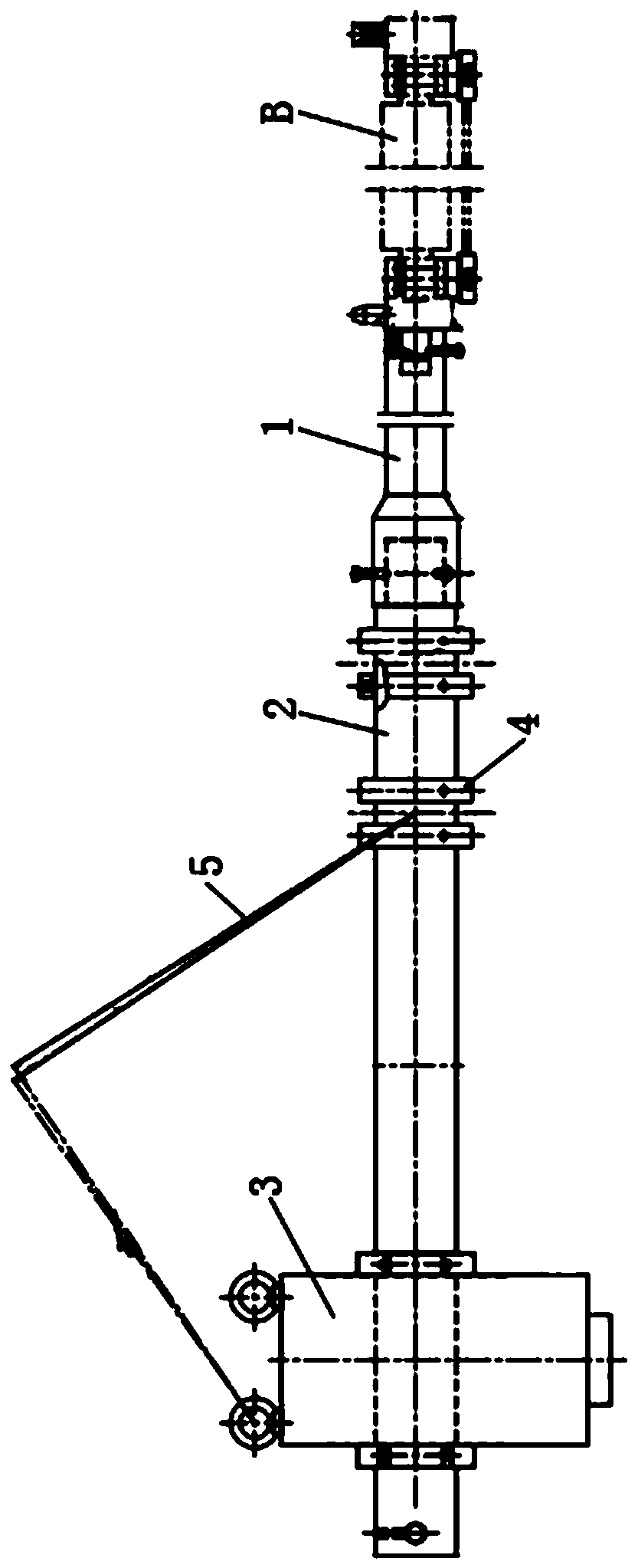

[0030] Such as figure 1 , the oil scraping and roller changing system of the present invention is made up of oil scraping device A and the roller changing device of quick replacement oil scraping roller B, and the following two major parts are described respectively below:

[0031] Such as figure 1 and figure 2 , the roll changing device for quickly changing the oil scraping roller B, including a roll changing frame 10, one or more roll changing tracks, a positioning part 30, and a roll changing driving mechanism 40, which will be described in detail below:

[0032] Such as figure 1 and figure 2 , since the oil scraping roller B is composed of an upper roller assembly and a lower roller assembly, and the upper roller assembly and the lower roller assembly move at the same time, therefore, the overall height of the oil scraping roller B is relatively high, thus, on the roller stand 10 The guardrail 11 is set, and the oil scraping roller B is blocked by the guardrail 11, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com