Scraper ring, three-combination piston oil ring and scraper ring preparation method

A scraper ring and annular technology, applied in the field of piston rings, can solve the problems of excessive wear of the lining ear, reduced combined tension, small oil storage space, etc., so as to reduce residual lubricating oil, reduce contact surface pressure, and improve lubrication conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

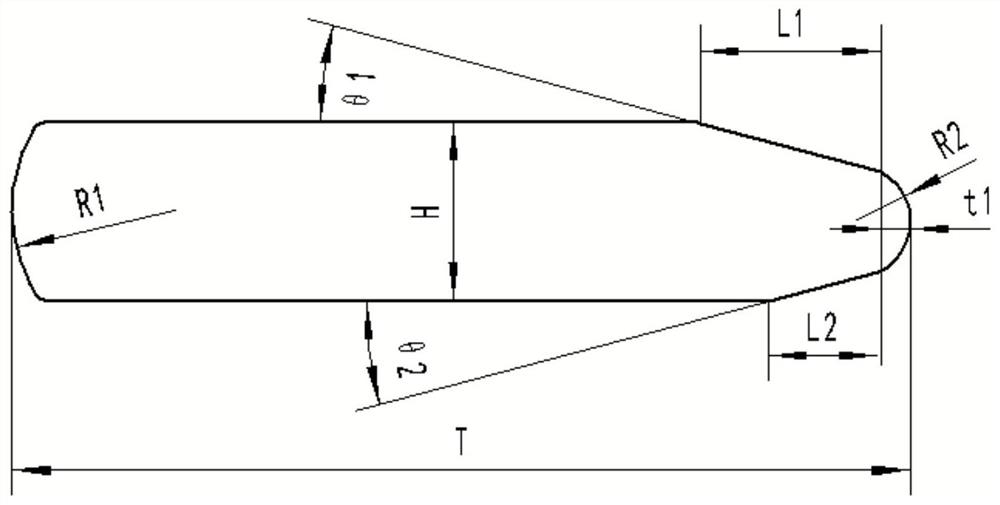

[0043] The dimensions of the scraper ring used in Embodiment 1 are as follows: scraper ring height H=0.3mm, scraper ring width T=1.4mm, inner circular arc radius R1=0.7H=0.21mm, outer circular arc radius R2 = 0.25H = 0.075mm, the length of the upper transition slope L1 = 0.45H = 0.135mm, the length of the lower transition slope L2 = 0.3H = 0.09mm, the angle between the upper and lower transition slopes and the upper and lower surfaces θ1 = θ2 = 30°, outside the scraper Arc surface height t1=0.6R2=0.045mm.

Embodiment 2

[0045] The dimensions of the scraper ring used in Embodiment 2 are as follows: scraper ring height H=0.4mm, scraper ring width T=2.65mm, inner circular arc radius R1=0.875H=0.21mm, outer circular arc radius R2 = 0.375H = 0.15mm, the length of the upper transition slope L1 = 0.55H = 0.22mm, the length of the lower transition slope L2 = 0.35H = 0.14mm, the angle between the upper and lower transition slopes and the upper and lower surfaces θ1 = θ2 = 37°, outside the scraper Arc surface height t1=0.67R2=0.10mm.

Embodiment 3

[0047]The dimensions of the scraper ring used in Embodiment 3 are as follows: scraper ring height H=0.5mm, scraper ring width T=3.8mm, inner circular arc radius R1=0.9H=0.45mm, outer circular arc radius R2 =0.4H=0.2mm, the length of the upper transition bevel L1=0.65H=0.0.325mm, the length of the lower transition bevel L2=0.4H=0.2mm, the angle between the upper and lower transition bevel and the upper and lower surfaces θ1=θ2=45°, scraper The height of the outer arc surface t1=0.8R2=0.16mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com