Integral dustproof structure for linear sliding rail

A technology of linear slide rail and dust-proof structure, which is applied in the direction of linear motion bearings, engine seals, bearings, etc., can solve the problems affecting the performance and life, and the limitation of dust-proof effects, etc., and achieve compact structure and improved scraping. Oil effect, effect of improving usability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

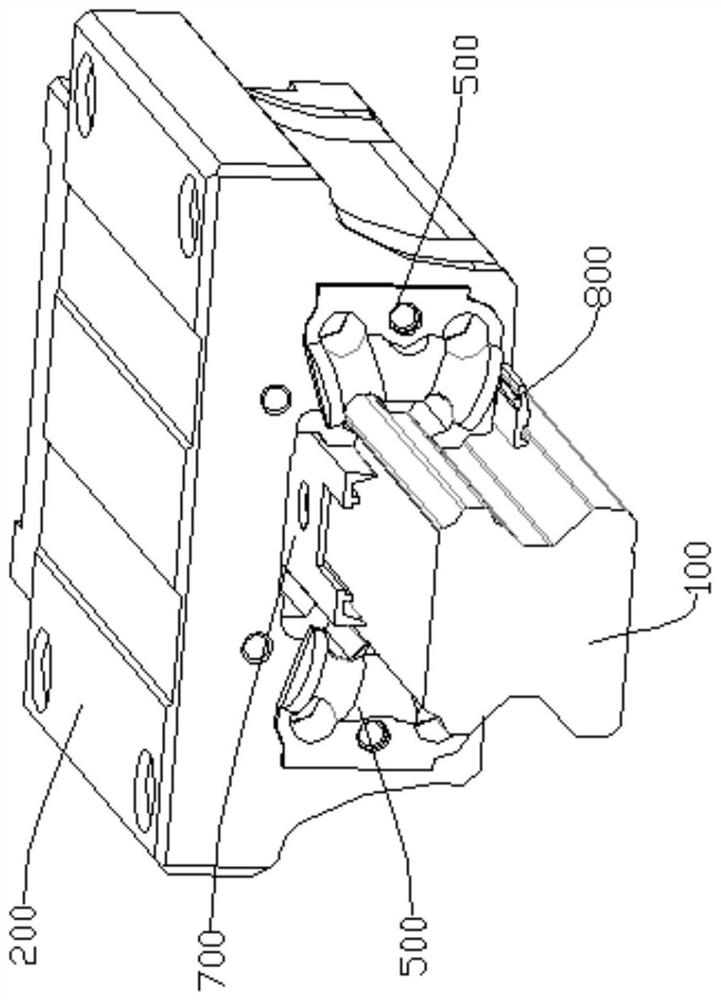

[0030] like figure 2 In the shown embodiment, it mainly includes a slide block 200, a first slide rail groove is arranged in the middle of the lower end surface of the slide block 200, and a slide rail 100 capable of sliding relative to the slide block 200 is arranged in the first slide rail groove 210, and the first slide rail groove Ball modules 500 are arranged on the left and right sides of 210 respectively, and the ball modules 500 and the slide rails 100 are rollingly connected. The ball module 500 is integrally formed by an injection molding process.

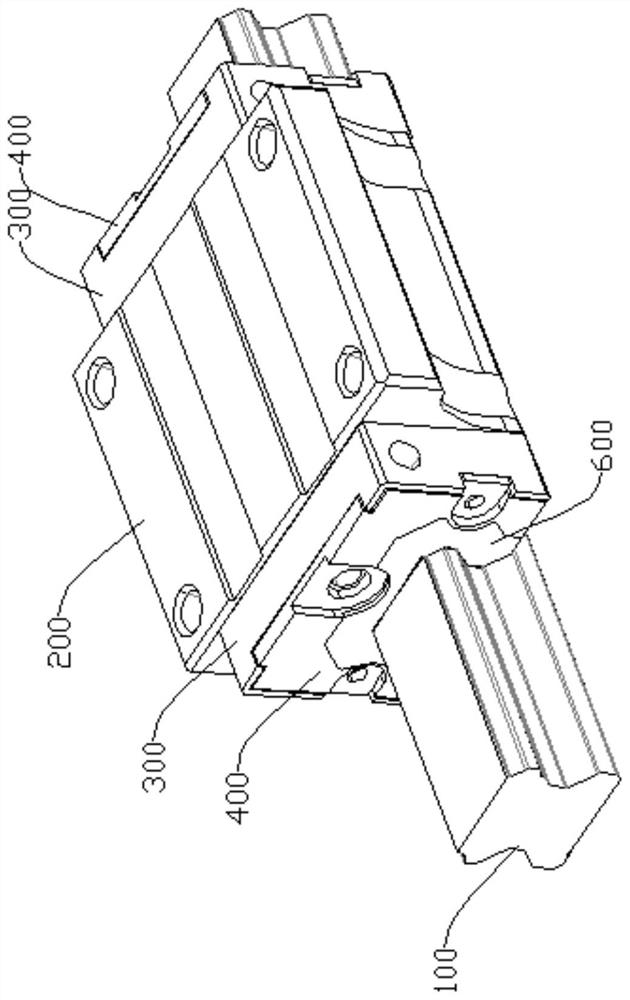

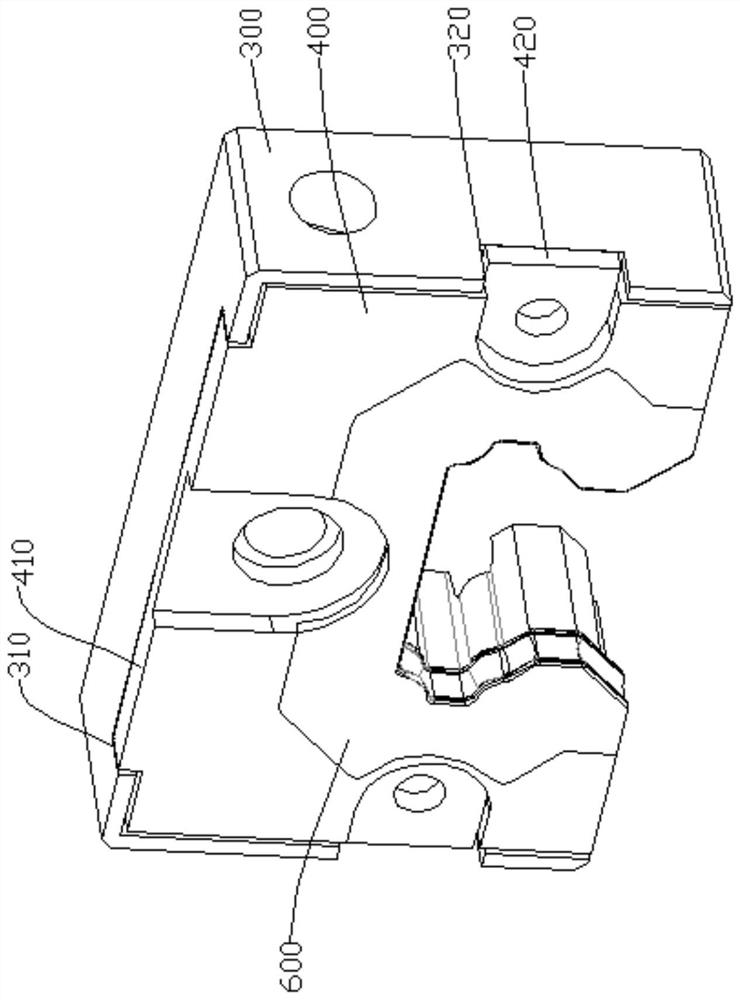

[0031] like figure 1 In the shown embodiment, the front and rear ends of the slider 200 are respectively detachably connected to the end cover 300 through the connecting piece, and the second slide rail groove 350 is arranged in the middle of the lower end surface of the end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com