A semi-rotary mechanism with grooves on the convex surface

A convex profile and profile technology, applied in the field of bionic machinery, can solve the problems of poor movement stability and bearing capacity of the mechanism, poor movement stability and bearing capacity, and many parts of the transmission system, so as to improve the bearing capacity and work efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

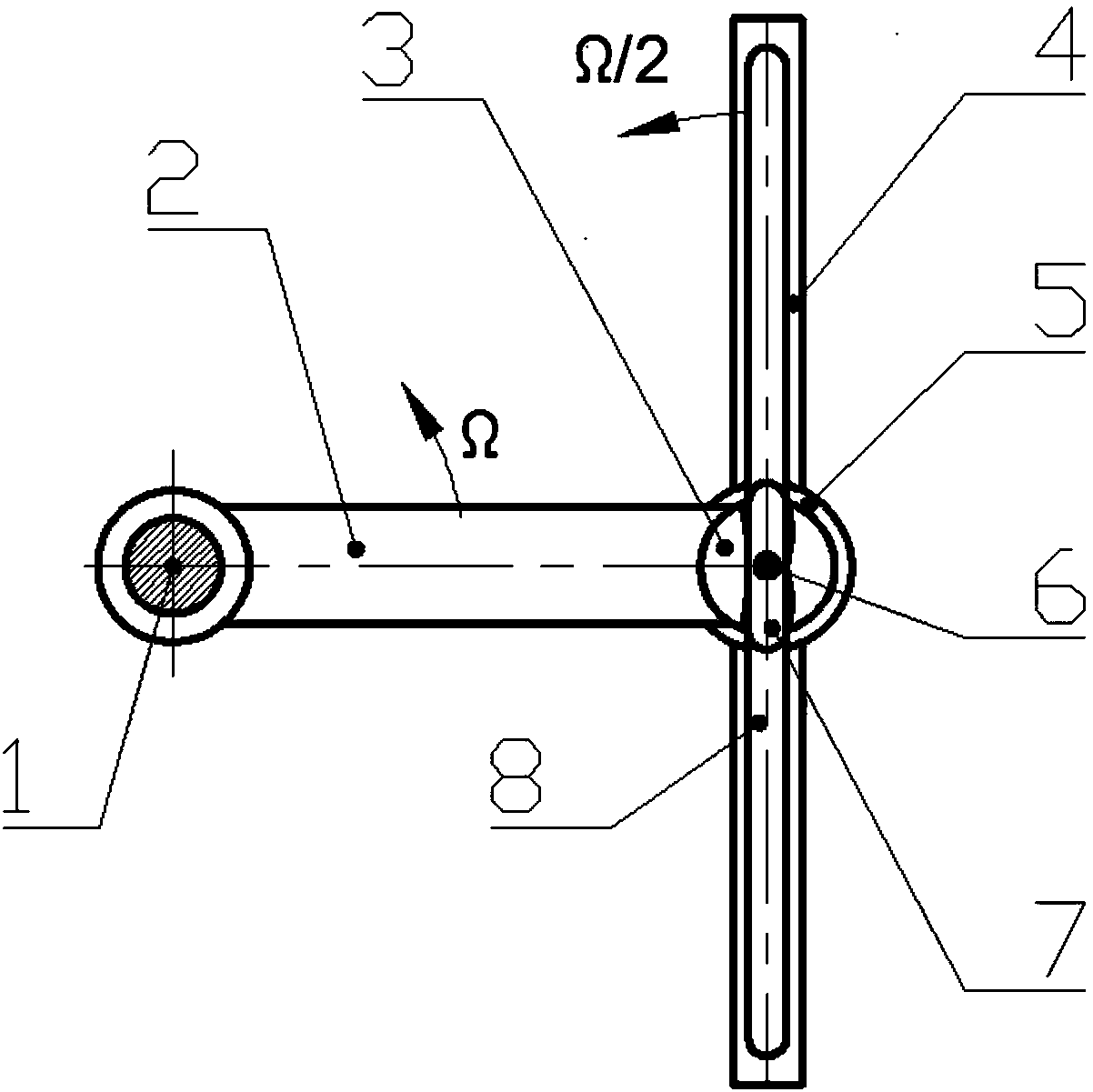

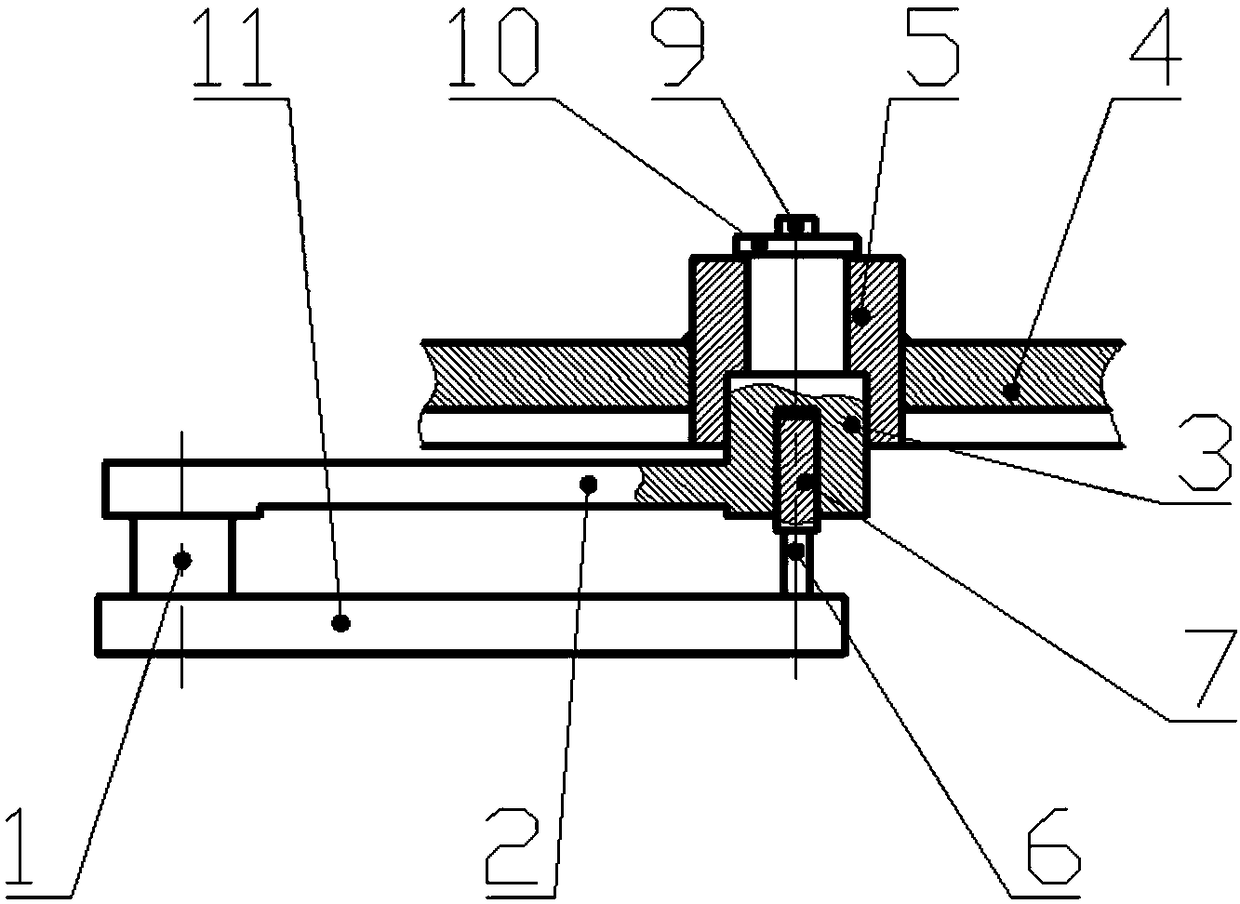

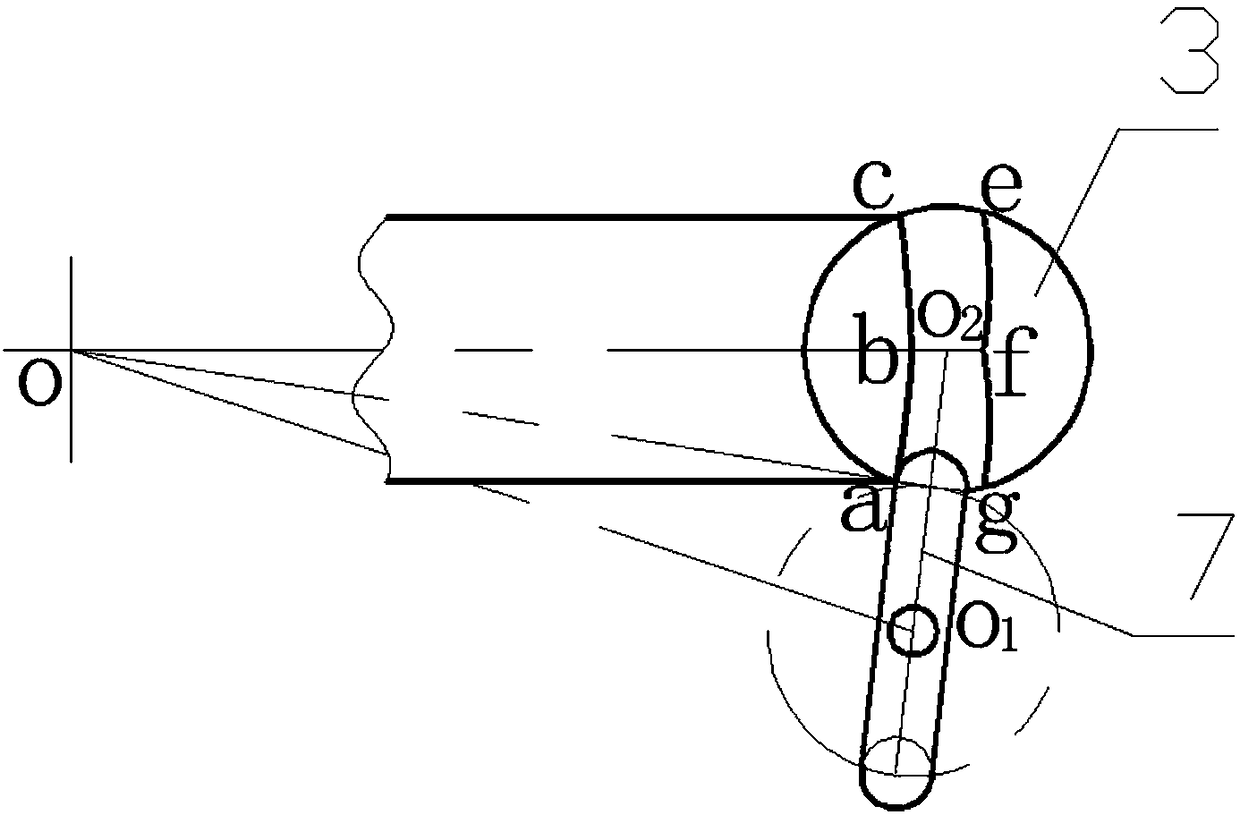

[0015] Depend on figure 1 It can be seen that one end of the crank 2 is fixedly connected to the main shaft 1 , and the other end is fixedly connected to the moving shaft 3 , and the convex surface groove on the moving shaft 3 is symmetrical to the axis of the crank 2 . The slide block 7 is fixedly connected with the auxiliary shaft 6, the distance from the auxiliary shaft 6 to the main shaft 1 is equal to the length of the crank 2, and the length of the slide block 7 is equal to the length of the cam profile groove+the thickness of the slide block 7. The middle part of the half-rotating rod 4 is fixedly connected with the axle sleeve 5, and the half-rotating rod 4 has a longitudinal chute 8 along the rod axis direction. The length of the longitudinal chute 8 must be greater than 4 times the length of the crank 2. The longitudinal chute 8 A corresponding notch is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com