Automatic copper wire oil scraping and recovering device

An oil recovery and copper wire technology, applied in the field of copper wire manufacturing, can solve problems such as wire drawing oil waste, and achieve the effects of good oil scraping effect, cleanliness and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

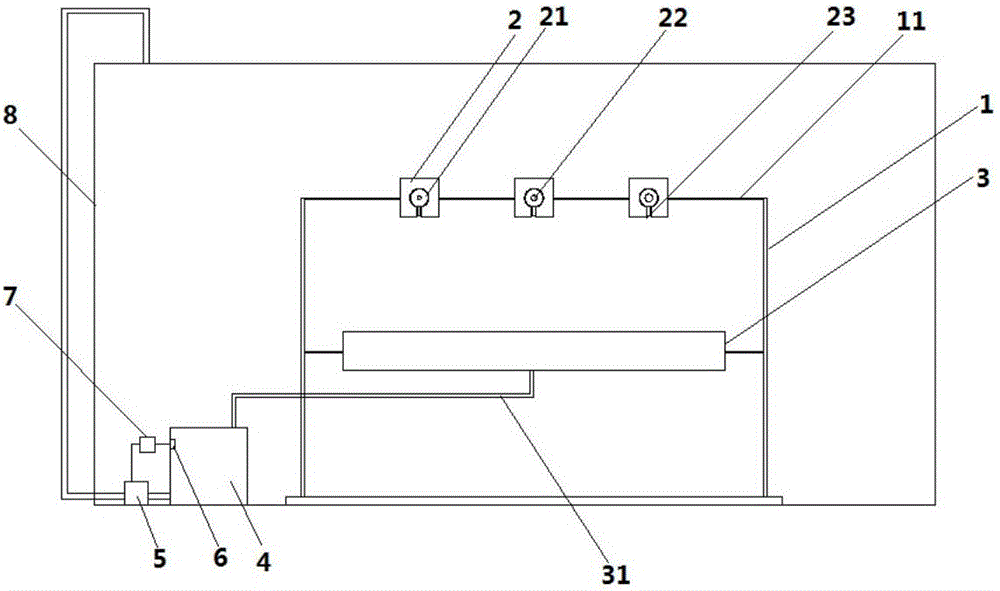

[0013] An automatic copper wire scraping oil recovery device, such as figure 1 As shown, it includes a frame 1, an oil scraper block 2, an oil guide groove 3, and an oil sump 4. The frame 1 is provided with a beam 11, a mounting seat is provided on the beam 11, and the back of the oil scraper block 2 is close to the mounting seat The oil scraper block 2 is a square rubber block. The front side of the oil scraper block 2 is provided with a circular groove 21, and the bottom of the groove 21 is provided with a through oil scraper block 2 There are threading holes 22 on the front and back. The copper wire passes through the threading holes 22 from the front of the oil scraper block 2 to pass through the oil scraper block 2. The front of the oil scraper block 2 is also provided with a strip connected to the circular groove 21 Groove 23, the other end of the strip groove 23 passes through the edge of the oil scraper block 2, the groove of the strip groove 23 is vertically downward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com