Reciprocating compressor oil scraping structure

A compressor and reciprocating technology, which is applied in the field of compressor manufacturing, can solve the problems of incomplete oil scraping, low oil scraping efficiency, and unsmooth oil return, so as to prevent clogging, reduce economic losses, and improve safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

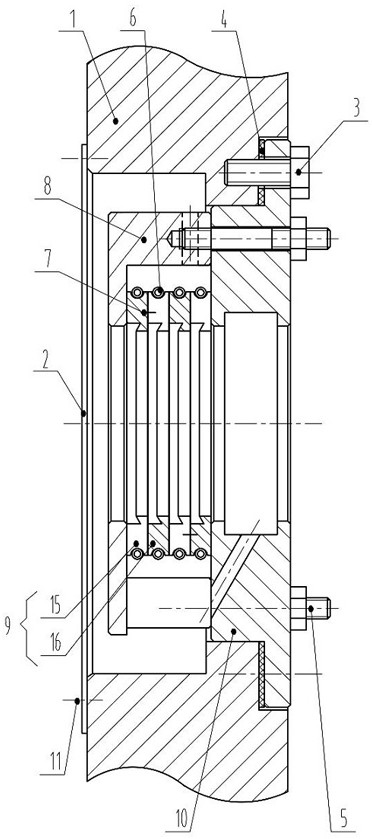

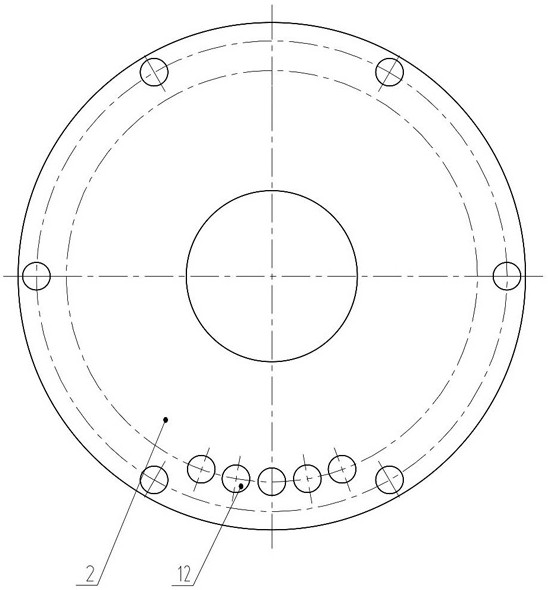

[0035] like Figure 1-Figure 3 As shown together, the present invention provides an oil scraping structure for a reciprocating compressor, which includes a socket 1, on which an oil wiper ring assembly is mounted, and the oil scraper ring assembly is fixedly connected to the socket 1 through a first bolt 3; An annular sealing gasket 4 is arranged between the socket 1 and the scraper ring assembly, and the material of the sealing gasket 4 is preferably rubber asbestos board.

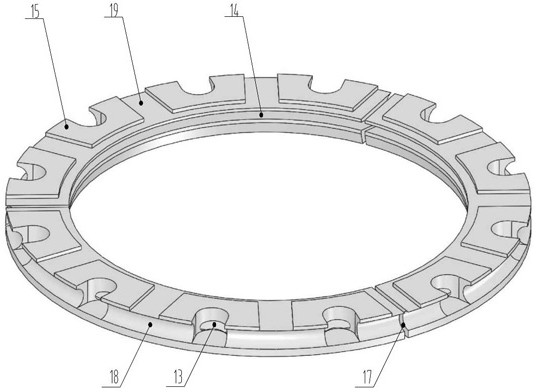

[0036] The oil scraping ring assembly includes an oil scraping flange 10 , an oil scraping box 8 , an oil scraping ring pair 9 and a spring 6 , and the oil scraping flange 10 is fixedly connected to the coaxially arranged oil scraping box 8 through a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com