Large reciprocating type oil scraping ring assembly of process compressor

A technology for oil scraping rings and compressors, which is used in variable capacity pump components, liquid variable capacity machinery, pump components, etc. and other problems, to achieve the effect of less leakage, enhanced oil scraping effect, and reduced resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

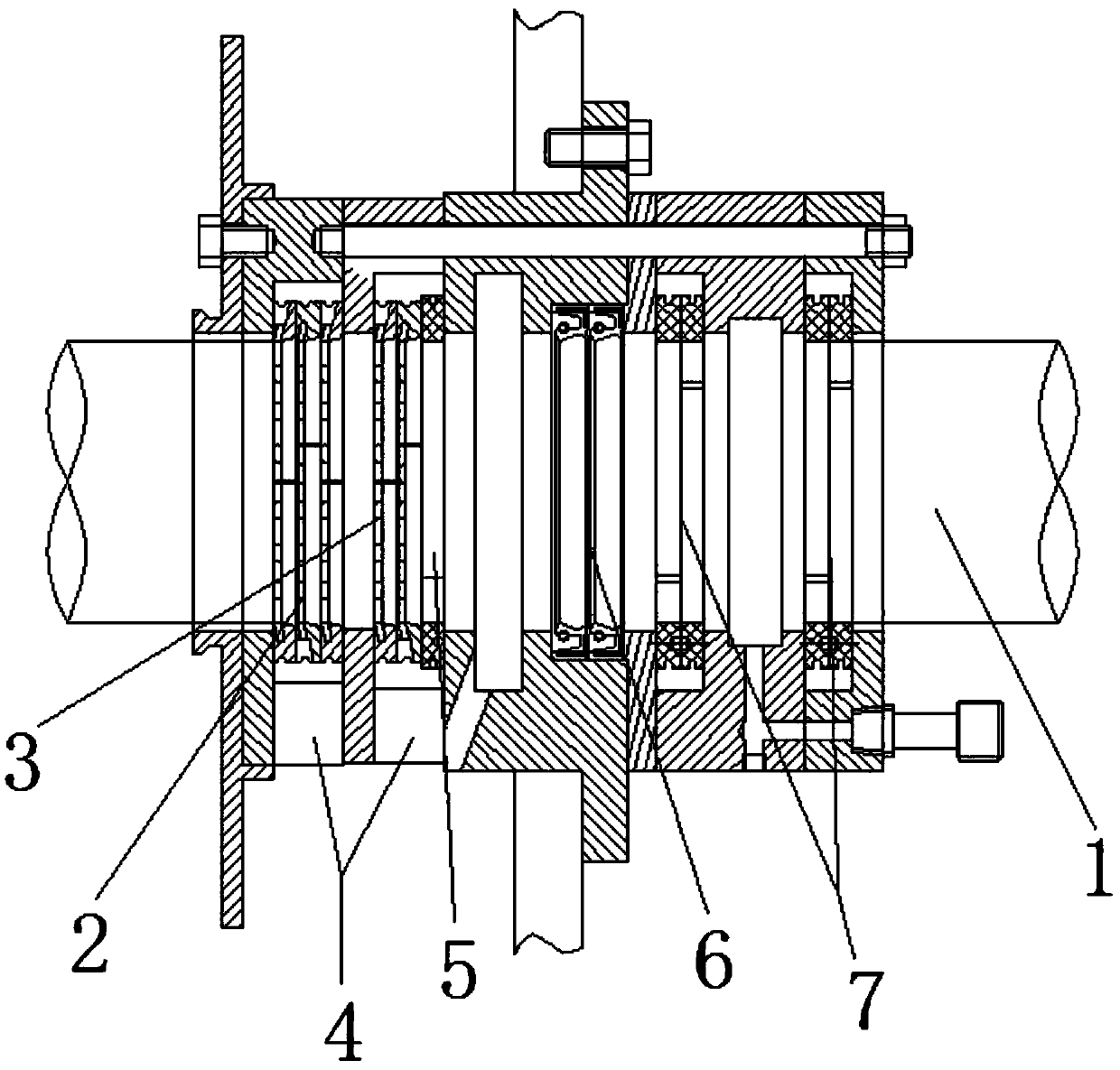

[0011] Such as Figure 1 ~ Figure 2 As shown, a large-scale reciprocating process compressor oil wiper ring assembly includes a compressor body, a piston rod 1 is arranged in the compressor body, and a first oil scraper ring 2 and a second scraper ring 2 are arranged on the piston rod 1 Oil ring 3, oil scraper boxes 4 are provided on the periphery of the oil scraper ring, and a pulsation seal ring 5 is provided on one side of the second oil scraper ring 3, and the second oil scraper ring 3 is far away from the first scraper ring. One side of the oil ring 2 is provided with an oil seal 6, and the piston rod 1 is provided with a dynamic sealing ring 7 on the side of the oil seal 6 away from the scraper ring.

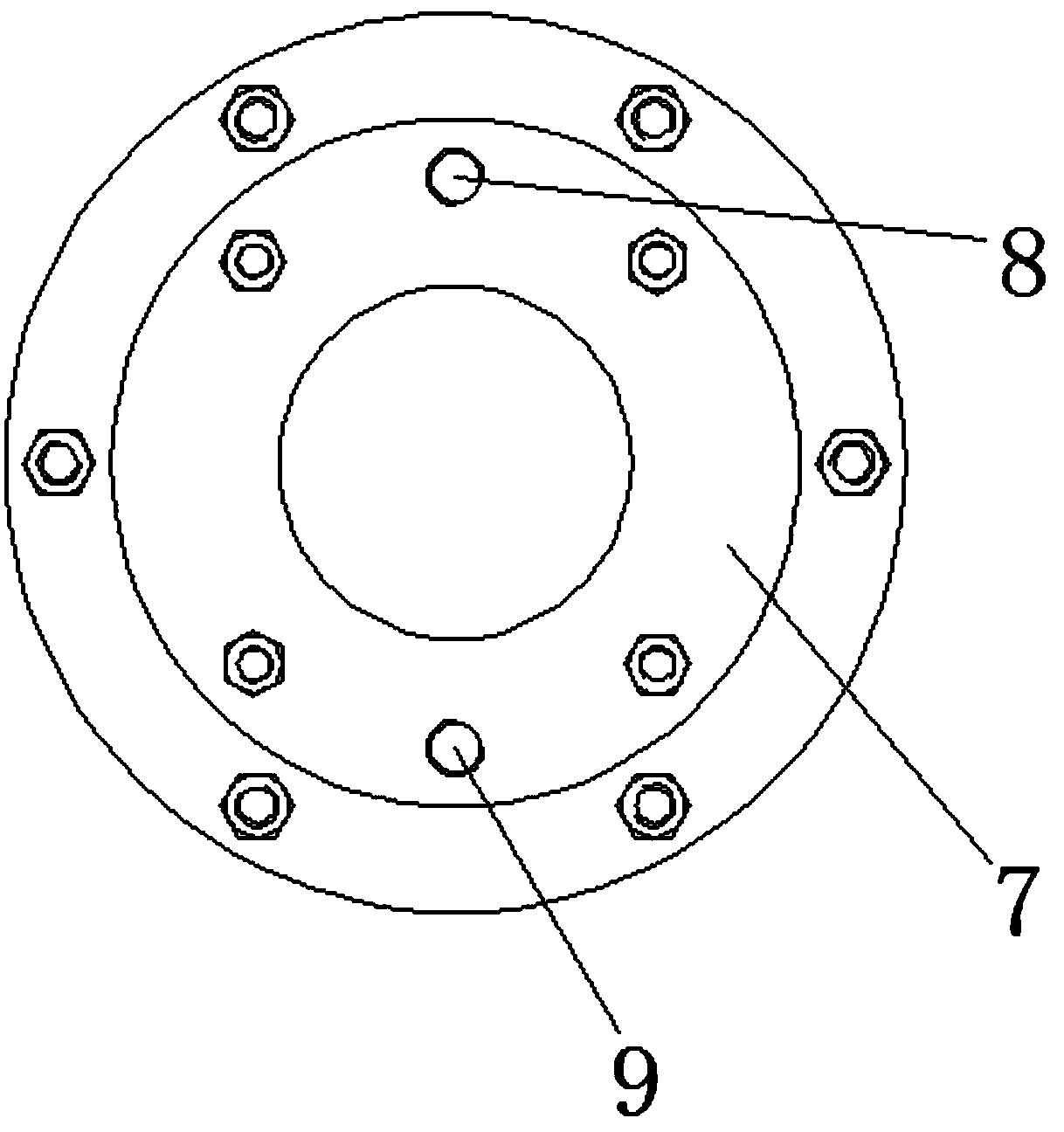

[0012] The nitrogen gas inlet hole 8 and the nitrogen gas outlet hole 9 on the surface of the dynamic sealing ring 7, the nitrogen gas inlet hole 8 is corresponding to the nitrogen gas outlet hole 9 positions, and the nitrogen gas inlet hole 8 and the nitrogen gas outlet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com