Oil separator

A technology of oil separator and oil plate, which is applied in the direction of chemical instruments and methods, grease/oily substance/floating matter removal device, flotation water/sewage treatment, etc., can solve the problem of destroying the state of liquid stratification, and reduce the Residue, effect-enhancing, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

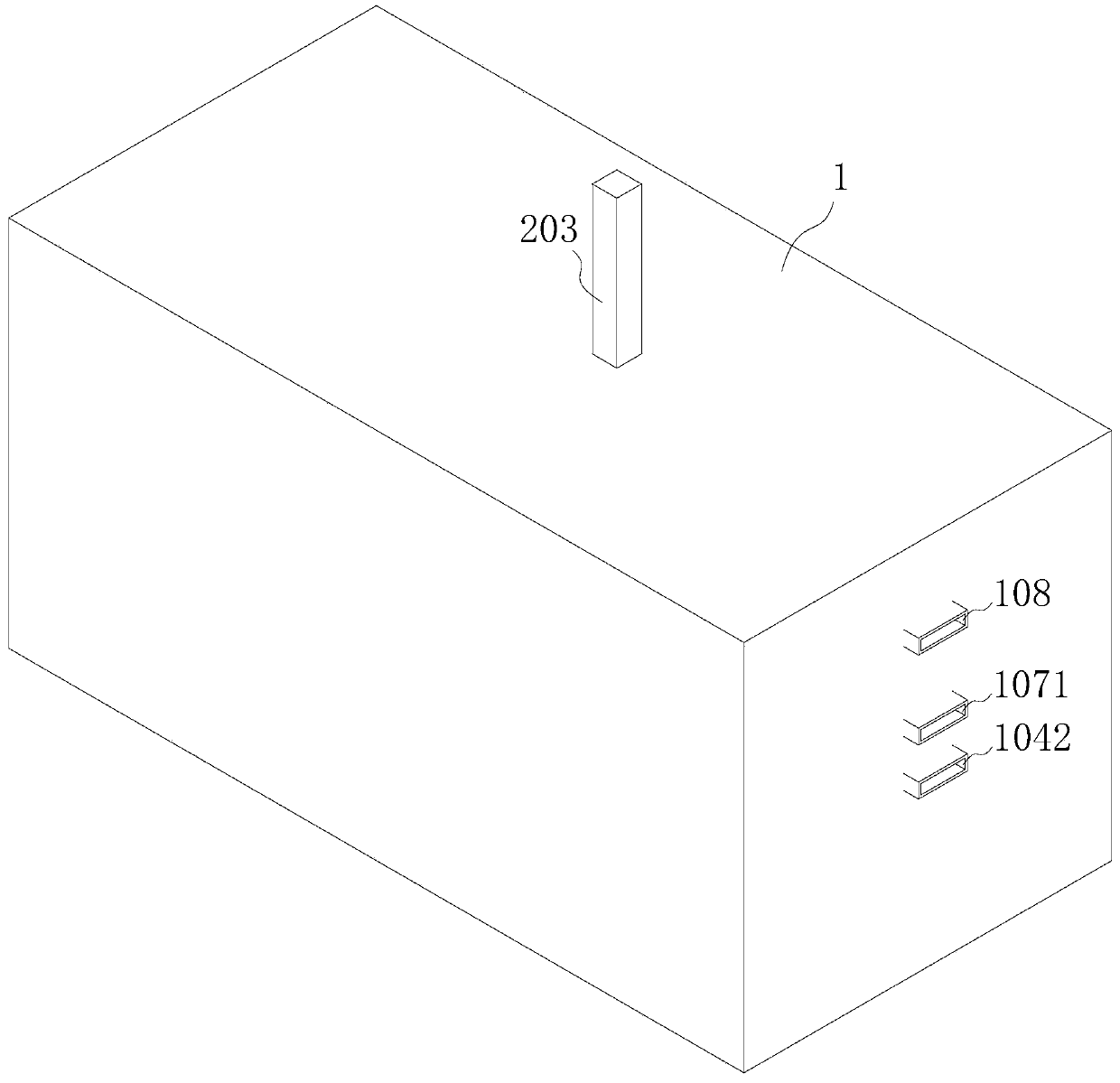

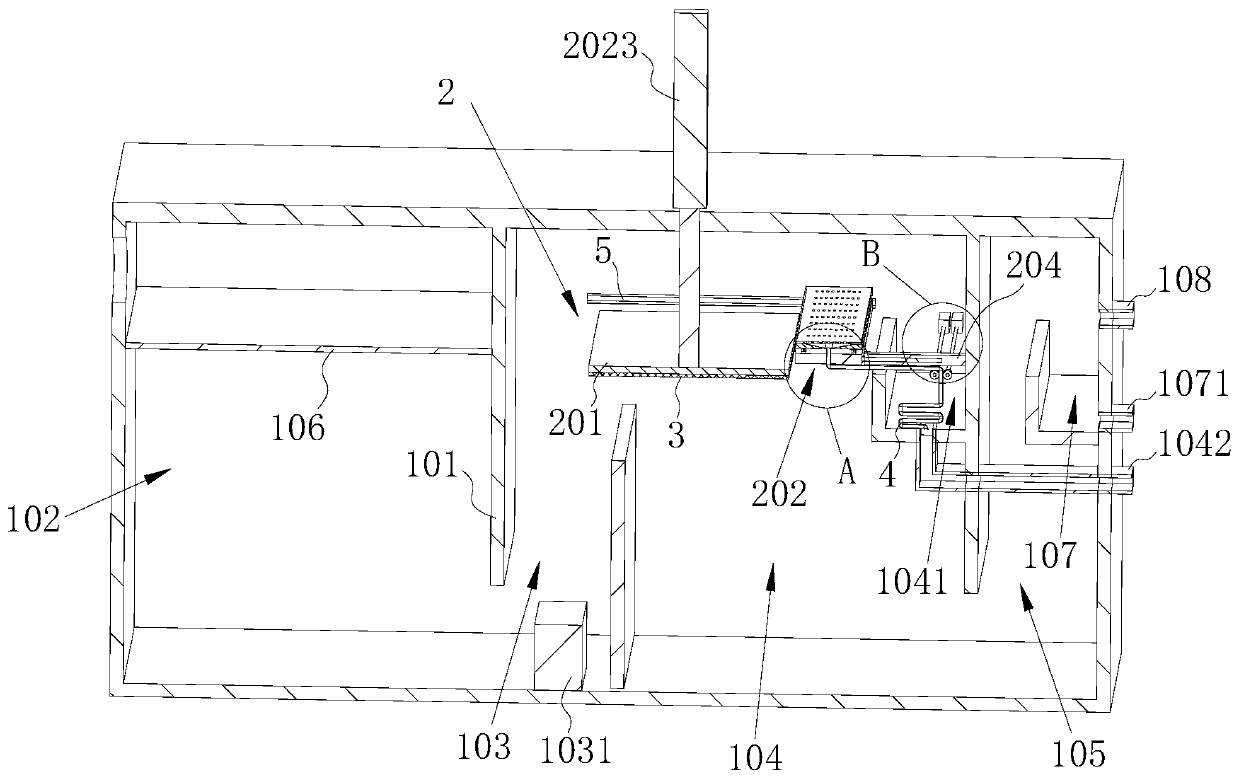

[0054] refer to figure 1 as well as figure 2 , this embodiment discloses an oil separator, comprising a box body 1, a partition 101 is arranged inside the box body 1, and the partition plate 101 divides the space inside the box body 1 into a solid-liquid separation chamber 102, a bubble generation chamber 103, The oil-water separation chamber 104 and the drainage chamber 105, and the solid-liquid separation chamber 102 are provided with a filter screen 106 for filtering solid impurities and realizing solid-liquid separation;

[0055] The bubble generating chamber 103 is provided with a bubble generator 1031, and the oil-water separation chamber 104 is provided with an oil collection tank 1041 and an oil-water separation device 2. In this embodiment, the bubble generator 1031 is a commonly used microbubble generator 1031 on the market. The device 1031 generates air bubbles, and the floating air bubbles carry the oil in the sewage to float up.

[0056] refer to figure 1 with...

Embodiment 2

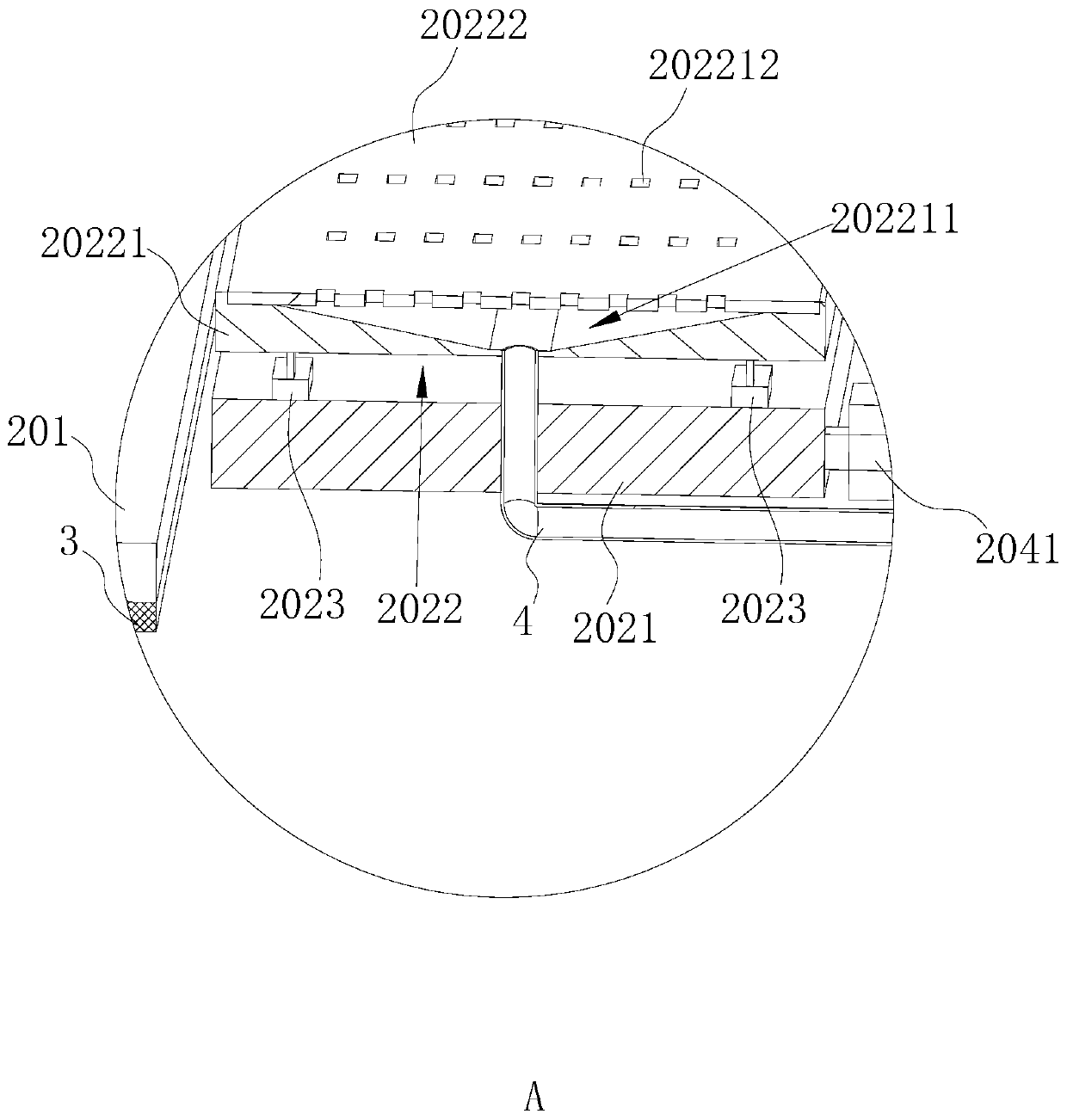

[0076] refer to Figure 5 as well as Image 6 , this embodiment discloses another oil trap, based on Embodiment 1, and the difference from Embodiment 1 is that the oil scraper 202 includes a base 2021 and an oil scraper 2022, and the base 2021 is provided with a receiving groove 20211, The oil scraper 202 is rotatably installed in the accommodation groove 20211, and the bottom of the accommodation groove 20211 is provided with an oil receiving groove 20212, and one side of the oil scraper 202 is provided with an oil scraper protrusion 20223 that abuts against the lower surface of the oil absorber 201, and the accommodation groove 20211 A rotary drive assembly 20213 is provided inside to drive the oil scraper 202 to turn over. The rotary drive assembly 20213 is set in the receiving groove 20211 and located at one end where the oil scraper 2022 of the oil scraper 202 is located. In this embodiment, the rotary drive assembly 20213 includes Rotate and drive the telescopic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com